A 3/16-inch 8mm shank carbide end mill is your ticket to long-lasting, precise cuts in metal and other tough materials. Choosing the right one and using it correctly means fewer tool changes, better finishes, and less frustration for your projects. Get ready to unlock superior performance and durability!

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Ever grabbed a tool, only to have it wear out way too fast, leaving you with a rough cut and a sigh? It’s a common frustration, especially when you’re working with tougher materials like steel or needing to make precise shapes. You want your tools to last, to perform reliably, and to make your job easier, not harder. That’s where a good quality carbide end mill, like a 3/16-inch with an 8mm shank, truly shines. Today, we’re diving deep into what makes these specific mills so great for endurance and how you can get the absolute best out of them. Stick around, and you’ll be cutting with confidence and getting those long-lasting results you’re after!

Understanding the Carbide Advantage

Carbide, specifically Tungsten Carbide, is a game-changer in cutting tools. It’s incredibly hard, far harder than high-speed steel (HSS) that many older tools are made from. This hardness translates directly into several benefits for your machining.

Extreme Hardness: Carbide’s ability to resist wear means it stays sharp for much longer than HSS. This is crucial for consistent cuts and reduces the need for frequent tool sharpening or replacement.

High-Temperature Resistance: Carbide cutting edges can withstand higher temperatures generated during machining without softening. This allows for faster cutting speeds, which can significantly speed up your work.

Rigidity: Carbide is denser and more rigid than steel. This means less flex and vibration during a cut, leading to more accurate machining and better surface finishes.

When you combine these properties with the specific dimensions of a 3/16-inch cutting diameter and an 8mm shank, you get a versatile tool suitable for a wide range of tasks.

Why 3/16 Inch and 8mm Shank?

Choosing the right size for your end mill is as important as choosing the right material. The 3/16-inch diameter is a fantastic “sweet spot” for many common milling operations. It’s small enough for detailed work, like cutting out intricate shapes or creating small pockets, but robust enough for general material removal.

The 8mm shank is also a popular size, especially for smaller milling machines and CNC routers. It offers a good balance of rigidity and compatibility with many common collet systems. A sturdy shank prevents vibration and provides the stability needed for precise cutting.

Key Benefits of this Combination:

Versatility: Suitable for chamfering, slotting, profiling, and general pocketing in various materials.

Precision: The rigidity of the carbide and the standard shank size contribute to accurate and repeatable results.

Efficiency: Longer tool life means less downtime and fewer tool changes, saving you time and money.

Material Compatibility: Excellent for machining metals like aluminum, brass, mild steel, and even some harder steels, as well as plastics and dense woods.

Essential Features for Long Life

Not all carbide end mills are created equal. When aiming for “essential long life,” certain features become especially important. These aren’t just fancy buzzwords; they directly impact how well and how long your tool will perform.

1. Carbide Grade and Coating

The grade of carbide (its purity and grain size) affects its toughness and wear resistance. For general machining of metals, a medium-to-fine grain carbide is often ideal. Beyond the base material, coatings add another layer of protection and performance.

Uncoated: Good for softer materials or when you need to see the material being cut directly. Generally less wear-resistant than coated options.

TiN (Titanium Nitride): A gold-colored coating. It adds hardness and reduces friction, improving tool life on steels and aluminum.

TiCN (Titanium Carbonitride): A greyish coating. Harder than TiN, it offers even better wear resistance for harder materials.

TiAlN (Titanium Aluminum Nitride): A dark, iridescent coating. Excellent for high-temperature applications and machining tougher steels and exotic alloys. It forms a protective oxide layer at high heat.

AlTiN (Aluminum Titanium Nitride): Similar to TiAlN, offering high-temperature resistance and excellent performance on hardened steels.

For a 3/16-inch 8mm shank carbide end mill targeting long life in carbon steel, an uncoated or TiN coated mill is a good starting point for general use, offering a balance of performance and cost. For continuous or more demanding carbon steel work, TiAlN or AlTiN coatings are superior choices for extended tool life and faster cutting.

2. Flute Design

The number of flutes (the spiraled cutting edges) and their geometry play a critical role in chip evacuation and cutting efficiency.

2-Flute End Mills: Generally preferred for slotting and plunging operations. They provide good chip clearance, which is essential for preventing chip recutting and tool breakage, especially in softer materials like aluminum.

4-Flute End Mills: These are more versatile and are excellent for side milling, profiling, and general machining. The extra flutes allow for higher feed rates when chip evacuation is not a bottleneck, and they offer a smoother finish on harder materials due to better support. For long-life operations in materials like carbon steel, 4-flute end mills are often favored. For a 3/16-inch size, 2 or 4 flutes are most common, with 4 flutes often offering better performance for metals when chip management is handled well.

3. End Geometry (Flat, Ball, Corner Radius)

The shape of the end of the mill determines the kind of features you can create.

Square End Mill (Flat End): The most common type. Used for creating flat-bottomed slots, pockets, and square corners. Requires a slight milling lead angle or shallow passes to avoid rubbing at the bottom.

Ball Nose End Mill: Has a hemispherical tip. Ideal for 3D contouring, creating radiused features, and generating a smooth, continuous surface finish.

Corner Radius End Mill: Features a small radius at the corners of a square end. This strengthens the cutting edge, making it more resistant to chipping and wear, especially when taking heavier cuts. It also leaves a small radius in the internal corners of a pocket, which can be beneficial for stress distribution. For long life, especially in tougher materials, a corner radius end mill is often an excellent choice as it protects the cutting edge from chipping.

For a general-purpose, long-life 3/16-inch 8mm shank end mill, a square end mill with a small corner radius is an outstanding choice for durability.

4. Shank Type (Plain, Weldon, Form Fit)

While the 8mm shank is standard, how it’s manufactured can matter.

Plain Shank: A simple cylindrical shank. Held by the collet or tool holder.

Weldon Shank: Features a flat, machined relief (a “dog” or “drive flat”) that is clamped by the screw in the tool holder. This provides superior holding force and prevents rotation, significantly reducing the risk of the tool slipping, especially under heavy loads. For demanding applications aiming for long tool life and reliability, a Weldon shank is highly recommended.

Selecting Your 3/16 Inch 8mm Shank Carbide End Mill

When you’re ready to purchase, consider these factors to ensure you get a tool that will last.

Key Specifications to Look For:

Material: Always look for Tungsten Carbide.

Diameter: 3/16 inch (0.1875 inches).

Shank Diameter: 8mm (approximately 0.315 inches).

Flute Count: 2 or 4 flutes. 4 flutes are often better for most steel cutting.

Coating: Consider TiN, TiCN, TiAlN, or AlTiN for improved wear resistance and performance in steel.

End Style: Square with a small corner radius for durability.

Length: Standard or extended lengths are available. For general use, a standard length that doesn’t put excessive overhang on your spindle is best for rigidity.

Here’s a quick look at how different features impact performance and life:

| Feature | Benefit for Long Life | Best For |

|---|---|---|

| Carbide Grade | Higher hardness and wear resistance prevent premature dulling. | All materials, especially harder ones. |

| TiAlN/AlTiN Coating | Reduces friction and resists heat built-up, prolonging edge life in steel. | Carbon steel, hardened steels. |

| 4 Flutes | Better chip management and surface finish in solids, leading to less heat buildup. | Steels, cast iron. |

| Corner Radius | Strengthens the cutting edge, preventing chipping. | Heavier cuts, harder materials. |

| Weldon Shank | Secure grip prevents slipping and tool damage. | High-feed rates, demanding operations. |

Where to Buy: Reputable Sources

Purchasing from reputable tool suppliers is essential for ensuring you get genuine carbide tools with accurate specifications. Look for well-known manufacturers or authorized distributors. Websites like MSC Industrial Supply, Grainger, or dedicated machining supply stores are excellent resources. For a deeper understanding of cutting tool materials and their applications, resources such as the Machinery Lubricants website offer detailed insights into manufacturing technologies.

Setting Up for Success: Your 3/16 Inch 8mm Shank End Mill

Getting the most life out of your end mill starts before you even make the first cut. Proper setup is crucial.

1. Tool Holder and Collet Selection

Collet Chuck: The most common method for holding end mills on milling machines. Ensure your collet is the correct size for the 8mm shank. A slightly worn collet can lead to runout (the tool wobbling), which causes chatter, poor finish, and accelerated tool wear. Use high-quality, matched collets. For an imperial machine with a metric shank, proper adapter sleeves might be needed, or a dedicated 8mm collet if available.

Tool Holder: A Weldon shank is best secured in a tool holder with a set screw. Make sure the set screw engages the Weldon flat securely. This prevents axial slippage and rotation.

Runout: Aim for minimal runout. Even a few thousandths of an inch can drastically reduce tool life. A runout as low as 0.0005″ is desirable.

2. Spindle Speed and Feed Rate (SFM and IPM)

This is where many beginners struggle, leading to premature tool failure. The goal is to find a balance that cuts efficiently without overheating or stressing the tool.

Surface Feet per Minute (SFM): The speed at which the cutting edge moves across the material. Carbide tools can run much faster than HSS. A good starting point for 3/16″ carbide end mills in mild steel might be around 300-500 SFM.

Revolutions Per Minute (RPM): Calculated using SFM and the tool diameter:

`RPM = (SFM 3.82) / Diameter (inches)`

For a 3/16″ (0.1875″) tool at 400 SFM: `RPM = (400 3.82) / 0.1875 = 8192 RPM.`

Inches Per Minute (IPM): The rate at which the tool advances into the material. This is influenced by the number of flutes and the desired chip load.

Chip Load (CL): The thickness of the material removed by each flute. A good chip load prevents the tool from rubbing and generating excessive heat. For a 3/16″ end mill in steel, a chip load might range from `0.002″ to 0.005″` per flute.

Feed Rate (IPM): Calculated using chip load, number of flutes, and RPM:

`Feed Rate (IPM) = Chip Load Number of Flutes RPM`

For a 4-flute mill with a 0.003″ chip load and 8192 RPM: `Feed Rate = 0.003 4 8192 = 196.6 IPM.`

Important Note: These are starting points! Always consult your material’s machining data or a reputable machining handbook. Adjust based on sound (listen for chatter), chip formation, and surface finish.

3. Depth of Cut (DOC) and Width of Cut (WOC)

For maximum tool life, avoid taking overly aggressive cuts.

Depth of Cut (DOC): How deep the end mill cuts into the material in a single pass. For a 3/16″ end mill, a DOC of 1/4 to 1/2 of the diameter is often recommended for steel, meaning 0.045″ to 0.090″.

Width of Cut (WOC): How much of the tool’s diameter is engaged with the material sideways. For slotting (full width), keep the DOC shallow. For pocketing or profiling, a WOC of 1/2 the diameter is common (0.0935″).

Taking lighter, more conservative cuts will always yield longer tool life, especially when you are learning or working with unoptimized settings.

Machining Techniques for Extended Tool Life

Beyond setup, how you operate the machine makes a huge difference. Think of it as gentle handling for your tools.

1. Climb Milling vs. Conventional Milling

Conventional Milling: The cutter rotates against the direction of feed. This tends to push the workpiece away from the cutter. Can be more prone to chatter and puts more impact stress on the cutting edge.

Climb Milling: The cutter rotates in the same direction as the feed. The cut starts at the top of the material. This results in a “climb” action, effectively lifting the material and pulling the cutter through. It generates less heat, produces a better surface finish, and significantly reduces stress on the cutting edge, leading to longer tool life. Always try to climb mill when possible. Ensure your machine has minimal backlash in the axis to prevent erratic cutting.

2. Chip Evacuation is Key

Clearance Angles: Ensure your machine and tool paths provide ample space for chips to escape. Clogged chips become re-cut chips, generating heat, dulling the tool, and potentially breaking it.

Lubrication/Coolant: For metals, using a cutting fluid or coolant is almost essential for long tool life. It cools the cutting edge, lubricates the interface, and helps wash away chips. For aluminum, a mist coolant or a specific aluminum cutting fluid works wonders. For steel, a flood coolant or a formulated cutting oil is beneficial.

3. Avoiding Dwell and Overheating

Don’t Dwell: Avoid stopping the feed motion while the tool is engaged in the cut. This concentrates heat on one spot.

Listen and Observe: Pay attention to the sound of the cut. A loud screech or high-pitched whine often indicates excessive heat or incorrect speeds/feeds. Look at the chips – are they a nice curly shape, or are they powdery and hot?

4. Break-In Cuts

For new tools, especially in harder materials, making a few “break-in” passes at shallow depths and widths can help seat the tool and remove any microscopic imperfections on the cutting edge without overloading it.

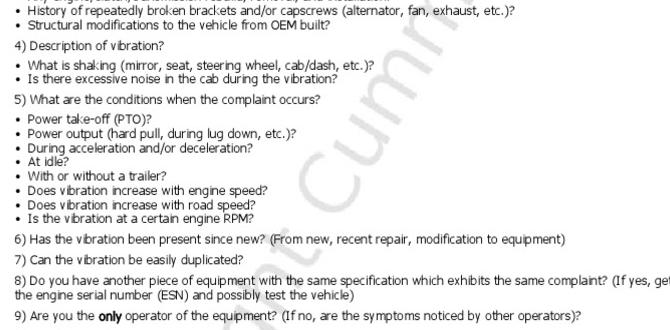

Common Problems and How to Solve Them

Even with the best practices, issues can arise. Here’s how to tackle them to preserve your tool.

1. Tool Wear (Dulling)

Symptoms: Increased cutting forces, poor surface finish, tool chatter, chips become small and powdery.

Solutions:

Check and adjust speeds and feeds. You might be running too fast or without enough chip load.

Ensure proper coolant is being used.

Verify tool holder and collet are not worn, causing runout.

Consider a different coating or carbide grade if working with very hard materials. Break-in as described above.

2. Chipping/Galling

Symptoms: Small pieces breaking off the cutting edge; material sticking to the cutting edge.

Solutions:

Chipping: Often caused by chatter, interrupted cuts, or taking too aggressive a depth/width of cut. Reduce DOC/WOC, ensure rigidity. Using a corner radius end mill helps.

Galling: Material adhering to the cutting edge. Common in ductile materials like aluminum or soft steels. Use more lubrication/coolant. Ensure adequate chip load. Consider a tool with a slicker coating (like TiN) or for softer materials, a ZrN (Zirconium Nitride) coating.

3. Tool Breakage

* **Symptoms