Quick Summary:

For precision work on D2 tool steel, a quality carbide end mill with an 8mm shank and reduced neck is your best bet. It offers superior hardness and heat resistance needed for this tough material, minimizing chatter and improving finish.

Working with D2 tool steel can feel like a challenge, especially when you want a clean, precise cut. Many beginners find their tools struggling, leading to frustration and less-than-perfect results. It’s common to worry about damaging your workpiece or your cutting tool. But don’t worry! With the right technique and the correct carbide end mill, machining D2 becomes manageable and even rewarding. This guide will walk you through everything you need to know, from understanding why certain end mills excel with D2 to how to use them safely and effectively. Get ready to unlock precision on this tough material!

Why D2 Tool Steel Needs Special Attention

D2 tool steel is a popular choice in many industries because it’s incredibly hard and holds its edge well. If you’ve ever handled tools made from D2, you know they’re built to last. This toughness comes from its high carbon and chromium content, which also makes it very wear-resistant.

However, this hardness also means D2 is difficult to machine. It has a tendency to work-harden, meaning it gets even tougher as you cut into it. This can lead to rapid tool wear, chatter (unwanted vibrations), and poor surface finishes if you’re not using the right tools and techniques. For us hobbyists and makers, this is where a specialized tool like a carbide end mill becomes essential.

The Power of Carbide End Mills for D2 Steel

When it comes to cutting tough materials like D2 tool steel, carbide end mills are often the go-to choice, and for good reason. Let’s break down why they are so effective:

Carbide, also known as tungsten carbide, is a composite material that is exceptionally hard and dense. This extreme hardness is what gives carbide end mills their advantage. They can maintain their cutting edge at much higher temperatures than high-speed steel (HSS) tools. Since machining D2 can generate significant heat, carbide’s heat resistance is a major benefit.

Beyond heat resistance, carbide end mills offer:

- Superior Hardness: They are significantly harder than HSS, allowing them to cut through hardened materials like D2 with less difficulty.

- Increased Rigidity: Carbide is a stiffer material, which helps reduce unwanted vibrations or chatter during machining. This leads to smoother cuts and better surface finish.

- Longer Tool Life: Due to their hardness and heat resistance, carbide end mills generally last much longer when cutting difficult materials compared to HSS alternatives.

- Higher Machining Speeds: Their ability to withstand heat and maintain sharpness allows for faster cutting speeds, improving productivity.

For D2 steel, especially if you’re aiming for precision, a standard end mill might not cut it. You need something that won’t break down quickly and can handle the material’s resistance. This is where specific carbide end mill designs come into play to maximize performance.

Choosing the Right Carbide End Mill: Key Features

Not all carbide end mills are created equal, and for D2 tool steel, a few specific features can make a world of difference. When you’re looking for an end mill to tackle D2, keep these important characteristics in mind:

Material and Coating

As we’ve discussed, carbide is the base material. But the right coating can further enhance performance. Gold-colored coatings like TiN (Titanium Nitride) or darker coatings like TiCN (Titanium Carbonitride) or AlTiN (Aluminum Titanium Nitride) are common. These coatings add an extra layer of hardness, lubrication, and heat resistance, all of which are crucial for cutting D2.

Number of Flutes

Flutes are the helical grooves that run along the cutting edge of the end mill. The number of flutes affects chip evacuation and cutting rigidity.

- 2-Flute End Mills: These are generally better for slotting and roughing operations. They provide more space for chips to escape, which is important in tough materials where chips can be large and gummy.

- 3-Flute End Mills: A good all-around choice, offering a balance between chip evacuation and cutting edge engagement.

- 4-Flute End Mills: Offer the most rigidity and a better surface finish, but they can have trouble clearing chips in softer or gummy materials. For D2, which isn’t typically thought of as “gummy” but can be prone to chip packing, a 4-flute might require careful chip management.

For D2 tool steel, especially in finishing passes, a 4-flute end mill can provide excellent results. However, for materials where you might be removing a lot of material or experiencing chip buildup, a 2-flute or 3-flute might be a better starting point. Many sources, like Modern Machine Shop, recommend using fewer flutes for slotting and roughing tough materials to improve chip evacuation.

Geometry and Design: The Edge of Precision

Beyond the basic flutes, the specific geometry of the end mill is vital. For D2 tool steel, you’ll often encounter specialized designs that help overcome its inherent challenges.

Reduced Neck Design (or Neck Relief)

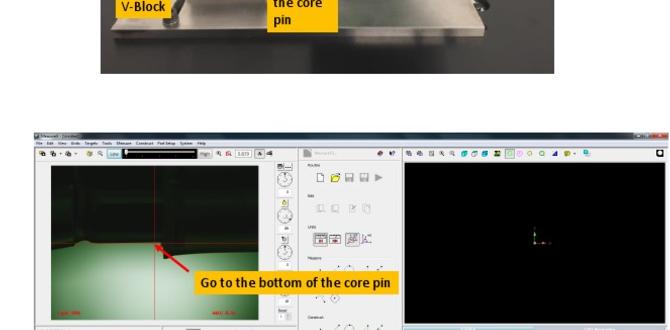

This is a critical feature for anyone machining D2. A reduced neck end mill has a portion behind the cutting flutes that is ground smaller in diameter. This is known as neck relief. Why is this so important?

- Minimizes Deflection: When a standard end mill cuts into tough material, the cutting forces can cause the end mill shank to flex or deflect. A reduced neck means less material is in contact with the workpiece after the cut, reducing friction and the forces that cause deflection. This is especially crucial when using smaller diameter end mills, like a 1/4″ or 3/16″ carbide end mill, to achieve precise contours and pocket depths.

- Improved Accessibility: The smaller diameter in the neck allows the end mill to reach into tighter areas or deeper pockets without the non-cutting shank rubbing against the workpiece walls. This is vital for creating intricate geometries.

- Reduced Chatter: By lessening deflection and rubbing, the reduced neck helps to create a more stable cutting process, leading to less chatter and a better surface finish.

When you see a description like “carbide end mill 3/16 inch 8mm shank reduced neck,” it’s a strong indicator that this end mill is designed for challenging materials and precise work. The 8mm shank offers a good balance of rigidity and common tooling size, fitting many collet systems.

Corner Radii and Chamfers

End mills can have sharp corners, or they can be designed with a small radius (a rounded corner) or a chamfer (a beveled edge). For D2, a small corner radius can help to:

- Strengthen the Cutting Edge: A slight radius on the end mill’s corner puts less stress on that point, making it less likely to chip or break.

- Improve Surface Finish: Rounded edges can help to produce a smoother surface finish by reducing the tendency for the tool to dig in or create sharp corners that might snag.

Very sharp, square corners can be prone to chipping in very hard materials. A tiny radius, often referred to as a “corner radius” or “corner round,” is usually preferred for milling tool steels.

Technical Specifications: What to Look For

When you’re browsing for end mills, you’ll see a lot of numbers and acronyms. Here’s a quick guide to the most important ones to understand when selecting one for D2 steel:

End Mill Diameter

This is the diameter of the cutting portion of the end mill. Common sizes include 1/8″, 3/16″, 1/4″, 6mm, 8mm, etc. For precision work on D2, you might use a smaller diameter, like 3/16″ or 8mm shank carbide end mills, to get into tight details.

Shank Diameter

This is the diameter of the part that goes into your tool holder or collet. An 8mm shank is a common metric size, offering good rigidity for its diameter. You’ll also see imperial sizes like 1/4″ (which is very close to 6.35mm) or 1/2″. Make sure the shank diameter matches your collet or tool holder.

Overall Length (OAL)

This is the total length of the end mill, from the tip of the cutting edge to the end of the shank. Longer end mills give you more reach but can be less rigid and more prone to deflection. For D2, you generally want the shortest OAL that will reach your workpiece.

Length of Cut (LOC)

This is the length of the cutting portion of the end mill (how far down the flutes go). Ensure the LOC is sufficient for the depth of cut you intend to make. For deep pockets, you might need a longer LOC, but remember that longer LOCs can increase deflection.

Coating

As discussed, coatings like TiN, TiCN, or AlTiN significantly improve performance on D2. Look for these.

Number of Flutes

Typically 2, 3, or 4 for solid carbide end mills. For D2, you’ll often find 3 or 4 flutes are good, with 2 flutes useful for slotting.

Material

Ensure it’s solid carbide. Many end mills are made from various grades of carbide powder pressed and sintered, often with cobalt binder for toughness.

Here’s a quick look at how these might appear on a product:

| Feature | Example Specification | Importance for D2 Steel |

|---|---|---|

| Diameter | 3/16″ (or 4.76mm) | For detailed work and control. |

| Shank Diameter | 8mm | Common, rigid shank size for stability. |

| Number of Flutes | 4 | Good for finishing and rigidity; requires good chip evacuation. |

| Coating | AlTiN | Excellent heat resistance and hardness for D2. |

| Corner Radius | 0.010″ (e.g., 0.25mm) | Strengthens corners, improves finish. |

| Neck Relief | Yes | Crucial for minimizing deflection and chatter. |

Machining D2 Tool Steel: Practical Steps for Beginners

Now that you’ve selected the right tool, let’s get to the actual machining. Working with D2 requires a slightly different approach to ensure success and tool longevity. Safety is always paramount, so ensure you have your safety glasses on!

1. Secure Your Workpiece

This is the foundation of good machining. D2 is tough, and the forces involved can be significant. Ensure your workpiece is rigidly clamped. If you’re using a vise, make sure it’s securely bolted to the machine table. Any movement here will lead to poor results and potential danger.

2. Set Up Your Machine

Spindle Speed (RPM): For carbide end mills cutting D2, you’ll typically use lower speeds than you might with softer metals. A good starting point might be between 300-800 RPM, depending on the diameter of your end mill and the specific grade of D2. Always consult any manufacturer recommendations for your end mill or D2 steel if available.

Feed Rate (IPM or mm/min): This is how fast the tool moves into the material. This is often more critical than RPM for tough materials. You want a feed rate that allows the tool to cut efficiently without overloading. For a 3/16″ or 8mm carbide end mill, a starting point might be between 5-20 inches per minute (IPM) or roughly 125-500 mm/min. The goal is to hear a consistent, light “shaving” sound, not a screaming or chattering noise.

Depth of Cut (DOC): For D2, especially with smaller end mills, it’s best to take lighter cuts. A radial depth of cut (how much of the tool’s diameter is engaged sideways) and axial depth of cut (how deep you’re cutting into the material) should be conservative. Start with a DOC of around 0.010″ – 0.050″ (0.25mm – 1.25mm) and adjust based on performance.

3. Coolant and Lubrication

Machining D2 generates heat. Using coolant or a suitable cutting fluid is highly recommended. It helps to:

- Cool the cutting edge, prolonging tool life.

- Lubricate the cut, reducing friction and making chip evacuation easier.

- Flush chips away from the cutting zone.

For end milling, a spray mist coolant system or a flood coolant system works well. If those aren’t available, a good quality cutting fluid applied directly to the cutting zone can help, though it’s less effective for heat management.

4. Machining Strategies

Climb Milling vs. Conventional Milling:

- Climb Milling: The cutting tool rotates in the same direction as its feed movement. This generally results in a better surface finish and less tool wear because the chips are thinner at the start of the cut and thicker at the end. However, it requires a machine with very little backlash (play in the lead screws) to prevent the tool from “grabbing.”

- Conventional Milling: The cutting tool rotates against its feed movement. This is generally safer in machines with some backlash but can lead to more tool wear and a rougher finish.

For D2, especially with a rigid setup and a good end mill, climb milling is often preferred for better results. Always start conventionally if you’re unsure about your machine’s rigidity or backlash.

Slotting vs. Pocketing:

- Slotting: Cutting a full slot. Use a 2-flute end mill if possible, and keep chip loads appropriate to avoid binding.

- Pocketing: Machining out an area. You can use different strategies like zig-zag or helical interpolation. For D2, consider taking shallow, wide passes rather than deep, narrow ones to manage heat and chip evacuation.

5. Chip Evacuation is Key

As mentioned, chips are your enemy when machining D2. If chips aren’t cleared properly, they can re-cut, generate excessive heat, and break your end mill. Ensure your coolant or air blast is effective. If you’re plunging or slotting, consider peck drilling (like a drill cycle, where the tool retracts periodically to clear chips).

6. Listen to Your Machine

Your ears are a great diagnostic tool. A smooth, light “shaving” sound is good. Grinding, squealing, or heavy clatter indicates a problem. This could be:

- Too high a speed (RPM)

- Too low a feed rate

- Too deep a cut

- Poor chip evacuation

- Workpiece or tool not properly secured

- End mill is dull or damaged

Stop the machine and investigate if you hear anything unusual.

Troubleshooting Common Issues

Even with the right tools, you might encounter problems. Here’s how to tackle them:

Excessive Chatter (Vibrations)

- Cause: Machine rigidity, workholding issues, dull tool, incorrect speeds/feeds, too deep a cut.

- Solution: Ensure your workpiece is clamped tightly. Shorten your tool projection (how far the end mill sticks out of the holder). Lighten your depth or width of cut. Try a slightly higher feed rate or a slower RPM (experiment!). Verify your end mill isn’t damaged.

Poor Surface Finish

- Cause: Chatter, chips re-cutting, incorrect feed rate, dull tool.

- Solution: Address chatter first. Use a clean cutting fluid. Ensure your feed rate is appropriate for the end mill and material (often a slightly higher feed can improve finish). Try a finishing pass with a lighter cut.

Tool Wear or Breakage

- Cause: Cutting too aggressively, insufficient coolant, wrong tool for the job, material inconsistencies (hard spots in D2).

- Solution: Reduce depth of cut and feed rate. Ensure adequate coolant flow. Double-check that you are using a carbide end mill suited for tool steel. Inspect your end mill for nicks or dullness before starting.

It’s a common