Quick Summary: For machining Inconel 718 without coolant, a high-quality carbide end mill is crucial. Using the right geometry, heat-resistant coatings, and robust construction ensures efficient, chatter-free dry cutting and extends tool life, even with this challenging superalloy. Opt for specialized INCO cutters for best results.

Hey there, aspiring machinists and workshop enthusiasts! Daniel Bates here from Lathe Hub. If you’ve ever tried to machine Inconel 718 dry, you know it can be a real head-scratcher. This super strong metal loves to fight back, generating a ton of heat and dulling tools faster than you can blink. But don’t sweat it! With the right approach, you can conquer Inconel 718. Today, we’re diving deep into how to use the perfect carbide end mill for dry cutting this tough material. We’ll break it all down simply, step-by-step, so you can machine with confidence.

The Challenge of Inconel 718

Inconel 718 is an absolute superstar in demanding environments. Think jet engines, rocket motors, and high-stress industrial applications. Its exceptional strength, high-temperature performance, and corrosion resistance make it a fantastic material. However, these same qualities make it incredibly difficult to machine.

Why is it so tough? Inconel 718 has:

- High tensile strength

- Excellent fatigue strength

- Good creep-rupture strength

- High hardness, especially at elevated temperatures

These properties mean Inconel 718 tends to work harden rapidly. As a cutting tool removes material, the surrounding metal becomes even harder, making subsequent cuts tougher. This leads to high cutting forces, excessive heat, and rapid tool wear. Trying to machine it dry, without the cooling and lubricating benefits of cutting fluid, amplifies these issues significantly.

Why Carbide for Inconel 718 Dry Cutting?

When machining Inconel 718 dry, your choice of cutting tool material is paramount. While other materials might struggle, carbide shines for a few key reasons:

- Heat Resistance: Carbide is naturally more heat-resistant than High-Speed Steel (HSS). Dry machining Inconel 718 generates immense heat, and carbide can withstand these temperatures without losing its hardness as quickly.

- Hardness: Carbide’s inherent hardness allows it to cut through the tough, work-hardening nature of Inconel 718.

- Rigidity: Carbide tools are generally more rigid than HSS, which helps minimize chatter and vibration, crucial for achieving a good surface finish on tough materials.

However, not all carbide end mills are created equal when it comes to this specific application. You need a specialized tool.

Choosing the Right Carbide End Mill

For Inconel 718 dry cutting, you’re not just grabbing any old carbide end mill off the shelf. You need a tool specifically engineered for this task. Let’s look at the features that make a carbide end mill suitable:

Geometry is King

The shape and design of the end mill’s cutting edges play a massive role.

- High Helix Angle: Many specialized end mills for Inconel 718 feature a high helix angle (often 45 degrees or more). This geometry provides a slicing or shearing action, helping to break up chips effectively and reduce cutting forces. It also helps to evacuate chips more easily.

- Corner Radius/Chamfer: A small corner radius or a chamfer on the cutting edge helps to strengthen the edge and reduce chipping. This is vital for managing the high forces involved.

- Fewer Flutes: For Inconel 718, especially in dry cutting, tools with fewer flutes (like 2 or 3 flutes for slotting and 4 flutes for general milling) are often preferred. This provides more chip clearance, preventing chips from recutting and causing tool breakage or surface damage. More flutes can sometimes lead to chip packing in tough materials.

- Center Cut: Ensure the end mill is center-cutting, meaning it can plunge vertically into the material if needed.

Material and Coatings

Even within carbide, there are variations:

- Sub-micrograin Carbide: This grade of carbide offers a superior balance of toughness and wear resistance, making it ideal for abrasive and heat-generating applications like Inconel 718.

- Advanced Coatings: Standard coatings like TiN or AlTiN might not be enough. Look for specialized coatings designed for high-temperature alloys. Common choices include:

- ZrN (Zirconium Nitride): Good for reducing friction and built-up edge.

- TiB2 (Titanium Diboride): Excellent for dry machining and heat resistance.

- TiCN (Titanium Carbonitride): Offers a good balance of hardness and lubricity.

- DLC (Diamond-Like Carbon): While less common for Inconel, it can offer superior lubricity and wear resistance in specific scenarios, though it can be brittle.

- “INCO” or “Nickel Alloy” Specific Cutters: Many tool manufacturers offer end mills explicitly designed for Inconel and other nickel-based alloys. These often combine optimized geometry, sub-micrograin carbide, and specialized coatings for maximum performance.

Tool Specifications: A Specific Example

When you’re searching for the right tool, you might encounter descriptions like “carbide end mill 3/16 inch 8mm shank reduced neck for Inconel 718 dry cutting.” Let’s break that down:

- Carbide End Mill: This is your tool material and type.

- 3/16 inch: This is the diameter of the cutting edge, crucial for fitting your machining operation.

- 8mm Shank: This is the diameter of the non-cutting shaft that goes into your tool holder. Compatibility is key here.

- Reduced Neck: This feature, often called a “neck relief” or “undercut,” is a slight diademeter reduction behind the cutting flutes. It’s vital for reaching into deeper pockets or slots without the non-cutting shank rubbing against the workpiece. This is a common requirement when machining complex geometries in tough materials.

- For Inconel 718 Dry Cutting: This explicitly states the intended application, meaning the tool has been designed with the necessary features.

Setting Up Your Machine for Dry Cutting

Even with the perfect tool, proper machine setup is critical for successful Inconel 718 dry machining. Safety and precision are your top priorities.

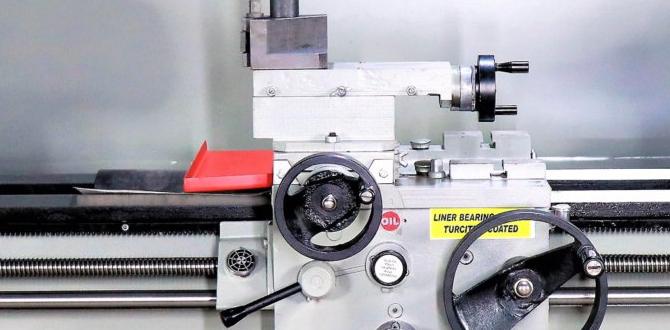

Machine Rigidity and Tool Holding

- Ensure your milling machine is robust and in good condition. A rigid machine minimizes vibration, which is essential to prevent chatter marks and tool breakage.

- Use a high-quality tool holder. A hydraulic or shrink-fit holder provides the best runout accuracy and holding power, which is far superior to a basic collet chuck for demanding jobs. Minimize the tool projection (how far the end mill sticks out of the holder) to increase rigidity.

Spindle Speed (RPM) and Feed Rate

This is where things get tricky, and manufacturer recommendations are your best friend. However, here are general guidelines:

- Speed (RPM): Inconel 718 typically requires lower spindle speeds compared to softer metals like aluminum or mild steel. This is to manage heat and prevent the cutting edge from overheating. Think of speeds often in the range of 100-500 SFM (Surface Feet per Minute), which translates to RPM depending on your tool diameter. A good starting point formula is:RPM = (SFM 3.82) / Diameter (inches)For example, for a 1/4 inch end mill at 200 SFM: RPM = (200 3.82) / 0.25 = 3056 RPM. Always check your tool manufacturer’s data!

- Feed Rate (IPM): Feed rate (Inches Per Minute) is equally important for chip load and heat management. A high feed rate can lead to excessive heat and cutting forces, while too low a feed rate can cause rubbing and work hardening. Aim for a chip load that’s appropriate for the tool’s diameter and flute count. A common starting point might be 0.001 to 0.005 inches per tooth for smaller diameter tools.IPM = Chip Load per Tooth Number of Flutes RPMFor instance, with a 4-flute end mill at 3000 RPM and a chip load of 0.002 inches/tooth: IPM = 0.002 4 3000 = 24 inches per minute.

Machining Inconel 718 dry is an art that comes with practice. Always start with conservative speeds and feeds Recommended by the tool manufacturer (often found on their website or data sheets for specific “INCO” end mills). Listen to the machine and watch the chips. If chips are fine and Powdery, you might be too hot or feeding too slow. If chips are large and gummy, you might be feeding too fast.

Chip Evacuation: A Major Concern

Without coolant to blast chips away, you become responsible for their removal. This is a huge challenge in dry machining, especially Inconel 718, which produces large, stringy chips.

- Air Blast: A powerful, directed stream of compressed air can help blow chips away from the cutting zone. Position it strategically.

- Vacuum System: A shop vac with a nozzle near the cutter can assist in chip evacuation.

- Pecking/Retraction: For plunging or slotting, use a “pecking” cycle. This involves plunging a short distance, retracting to clear chips, and repeating. It significantly reduces the risk of chip buildup.

- Tool Path Strategy: Employ machining strategies that minimize chip re-cutting. Climb milling is often preferred over conventional milling for Inconel 718 as it can reduce cutting forces and improve surface finish.

Machining Strategies and Best Practices

Let’s outline a general approach to machining Inconel 718 using the right carbide end mill dry.

Preparation is Key

- Inspect the Tool: Before every operation, check your carbide end mill for any signs of wear, chipping, or damage. A compromised tool is an invitation for disaster.

- Secure Workpiece: Ensure your Inconel 718 workpiece is firmly clamped. Any movement will negatively impact the cut. Use a rigid setup, ideally with a vise that has hardened jaws.

- Machine Condition: Verify your milling machine is clean, lubricated, and has no play in its axes.

Cutting Parameters: The Starting Point

As mentioned, always refer to the tool manufacturer’s specific recommendations for SFM and chip load. However, here’s a table to give you an idea of a starting point, using a specialized carbide end mill for Inconel 718, assuming a 3/16″ diameter tool:

| Operation | Tool Type | SFM (approx.) | Chip Load per Tooth (approx.) | Flutes | Notes |

|---|---|---|---|---|---|

| Face Milling / Contouring | 4-Flute ZrN Coated Carbide | 100-150 | 0.001″-0.003″ | 4 | Use a low axial depth of cut (DOC), high radial DOC (e.g., 50% of tool diameter for contouring). |

| Slotting / Pocketing | 2-Flute TiB2 Coated Carbide | 80-120 | 0.001″-0.002″ | 2 | Use pecking cycles. Keep axial DOC low. Ensure excellent chip evacuation. |

| Drilling (with plunge-capable end mill) | 2-Flute TiCN Coated Carbide | 50-100 | 0.001″-0.0015″ | 2 | Use a high feed rate during plunge, with rapid retraction for chip breaking (pecking). |

Important Note: These values are rough starting points. Your specific machine, tool holder, and the exact grade of Inconel 718 can influence optimal settings. A great resource for understanding material properties and machining data is the Sandvik Coromant website, which offers extensive machining guides.

Machining Techniques

- Depth of Cut (DOC): Keep the axial Depth of Cut small. For Inconel 718, it’s often suggested to limit axial DOC to 1-2 times the tool diameter, even less if encountering issues. Radial DOC (how much of the tool’s diameter engages the material sideways) can be higher for contouring, but significant for slotting.

- Climb Milling vs. Conventional Milling: For Inconel 718, climb milling (where the cutter rotates in the same direction as the feed) is generally preferred when possible. It can reduce cutting forces and improve surface finish by engaging the material with a diminishing chip thickness, which leads to less work hardening ahead of the cut. Conventional milling works the opposite way, engaging with a growing chip thickness, which can increase forces and vibration.

- Avoid Dwell: Never let the tool dwell in the cut. This is a recipe for work hardening and tool failure. If you need to stop the machine, do it at the end of a pass, not in the middle of a cut.

- Listen and Observe: Pay close attention to the sound of the cut. A smooth, consistent hum is good. Grinding, screaming, or excessive vibration indicates a problem that needs immediate attention.

Cooling and Lubrication (Even in Dry Cutting)

While we’re talking “dry” cutting, a minimal amount of lubrication or cooling can sometimes be beneficial to prevent chatter and reduce wear, even if it doesn’t involve a flood coolant system.

- Misting Systems: A fine mist of coolant or a specialized dry-machining lubricant can be applied directly to the cutting zone. This helps reduce friction and manage heat without creating large amounts of waste coolant. These systems use very little fluid.

- Air/Mist Combos: Some setups combine an air blast with a minimal mist lubricant for optimal chip evacuation and cooling.

For complete dry cutting, focus heavily on chip evacuation and selecting tools with good lubricity coatings like ZrN.

Troubleshooting Common Issues

Even with the best tools and setup, you might run into bumps. Here’s how to handle them:

Chatter/Vibration

- Cause: Tool overhang, machine rigidity, incorrect feeds/speeds, worn tooling, workpiece not clamped tightly.

- Solution: Reduce tool overhang, increase machine rigidity, check and adjust speeds/feeds (try increasing SFM slightly for a lighter cut, or adjust feed rate), inspect and replace the tool, clamp the workpiece more securely. Sometimes, a slight change in the axial DOC can help break the harmonic vibration.

Poor Surface Finish

- Cause: Tool wear, re-cutting chips, incorrect feeds/speeds, chatter.

- Solution: Use a sharp tool, ensure effective chip evacuation, adjust feeds and speeds, address chatter issues.

Rapid Tool Wear/Breakage

- Cause: Excessive heat, incorrect feeds/speeds (too slow or too fast), chip packing, aggressive cuts, tool material not suitable for Inconel.

- Solution: Use a tool specifically designed for Inconel 718 with appropriate coatings. Ensure speeds and feeds are within recommended ranges, focus on chip evacuation, reduce DOC, and consider a brief mist coolant if extreme.

Work Hardening

This is characteristic of Inconel 718. If you notice increased cutting forces and tool wear after a few passes, you are likely experiencing work hardening. The key is to cut aggressively enough to get past the hardened layer efficiently in a single pass, or to use a tool/strategy that minimizes the hardened zone. Using a sharp, specialized tool and appropriate speeds/feeds is your best defense.

FAQ: Your Burning Questions Answered

Q1: Do I absolutely need a special “INCO” end mill for Inconel 718, or can any carbide end mill work?

A1: While you might be able to make very shallow, light