Quick Summary:

For a reliable PMMA (acrylic) machining solution, a 3/16-inch carbide end mill with an 8mm shank is an excellent choice. Its precision cutting edges and appropriate shank diameter offer superior chip evacuation and clean finishes in acrylic, making it ideal for hobbyists and professionals alike.

Mastering PMMA Machining: Your Guide to the 3/16 Inch Carbide End Mill with 8mm Shank

Working with PMMA, often called acrylic, can be a bit tricky for beginners. It’s a fantastic material for many projects, from custom signage to intricate prototypes, but it has a tendency to melt and chip if not cut correctly. This can lead to frustrating results. But don’t worry! With the right tool, you can achieve smooth, clean cuts every time. Today, we’re focusing on a specific tool that’s become a go-to for many of us in the workshop: the 3/16-inch carbide end mill with an 8mm shank. It’s a workhorse for acrylic, and I’m going to show you exactly why and how to use it effectively. Let’s get those projects looking sharp!

Why the 3/16 Inch Carbide End Mill is Your PMMA Best Friend

When you first start milling PMMA, you’ll quickly realize that not all cutting tools are created equal for this material. Many standard end mills can cause the acrylic to gum up, melt, or chip, leading to a messy finish and wasted material. That’s where specialized tooling comes in. The combination of a 3/16-inch cutting diameter and an 8mm shank on a carbide end mill offers a winning formula for PMMA.

Carbide, or tungsten carbide, is a super-hard material that holds its edge exceptionally well, even at the higher spindle speeds often used for plastics. This hardness prevents the tool from dulling quickly, which is crucial for maintaining clean cuts.

The 3/16-inch diameter is a versatile size, perfect for detailed work like engraving text or cutting out small parts, while still being substantial enough for larger profiles.

Now, the 8mm shank might seem like a minor detail, but it’s quite important. It provides a good balance of rigidity for a tool of this cutting diameter. A shank that’s too small can lead to chatter and vibration, degrading the surface finish. An 8mm shank offers enough mass to keep the cut stable, especially when paired with modern CNC machines or even a well-secured manual mill.

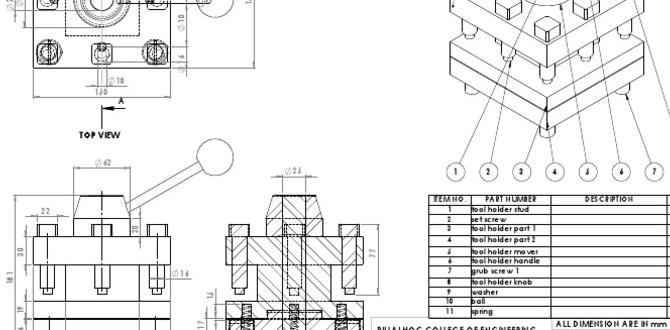

Understanding the Anatomy of Our PMMA End Mill

Before we dive into using it, let’s get familiar with the parts of our 3/16-inch carbide end mill with an 8mm shank that are relevant to cutting PMMA. Understanding these features will help you appreciate why this tool is so effective.

Flutes: These are the helical grooves that run along the cutting head of the end mill. For PMMA, you generally want a low flute count, typically 2 or sometimes 3.

2 Flutes: These are fantastic for plastics like PMMA. They provide more chip clearance, which is essential because melted acrylic can stick to the tool. Better clearance means less melting and cleaner cuts.

3 Flutes: Can offer a smoother finish on some materials, but for PMMA, the increased chip evacuation of 2-flute tools is usually preferred.

Cutting Edges: These are the sharp edges at the bottom and sides of the flutes that actually do the cutting. High-quality carbide offers sharp, durable edges.

Helix Angle: This is the angle of the flutes. For plastics, a steeper helix angle (often 30-45 degrees) is common. This angle helps to shear the material cleanly and push the chips away from the cutting zone.

Coatings: Some end mills come with special coatings (like TiN, TiCN, or specialized plastic coatings). While not always necessary for PMMA, certain coatings can further reduce friction and prevent material buildup, leading to even better results. For PMMA, a simple uncoated or polished flute is often perfectly adequate.

Shank: This is the part of the end mill that is held by the tool holder. Our focus is on the 8mm shank. Its diameter provides rigidity and ensures good clamping force in the collet.

Key Benefits of Using This Specific End Mill for PMMA

Let’s break down the specific advantages you gain by choosing a 3/16-inch carbide end mill with an 8mm shank for your PMMA projects:

Superior Chip Evacuation: As mentioned, PMMA tends to melt. The design features of a good PMMA end mill, especially those with fewer flutes and a polished finish, are optimized to get those chips out of the cut zone quickly. This prevents heat buildup, which is the number one enemy of a clean acrylic cut.

Reduced Melting and Gumming: Because the chips are cleared efficiently, less heat is generated. This means the acrylic is less likely to melt and gum up on the cutting edges, ensuring the tool stays sharp and continues to cut cleanly.

Excellent Surface Finish: When you’ve got good chip clearance and minimal melting, you get a smooth, glossy surface finish on your PMMA. This often means less sanding and polishing work later on, saving you time and effort.

Durability and Longevity: Carbide is much harder than High-Speed Steel (HSS). This means your end mill will last longer, maintain its sharpness through many projects, and maintain consistent cutting performance, which is vital for repeatable results.

Precision Control: The 3/16-inch size allows for fine detail work. Coupled with the stable 8mm shank, you get predictable and precise movements from your milling machine, translating to accurate parts.

Versatility: While ideal for PMMA, this type of end mill can also be surprisingly effective on other plastics and softer materials where chip buildup is a concern.

When to Choose a 3/16 Inch Carbide End Mill with 8mm Shank

This tool is your go-to for a variety of PMMA machining tasks. Here are some common scenarios where it shines:

Engraving Text and Logos: The smaller diameter is perfect for cutting fine details into acrylic surfaces.

Cutting Out Complex Shapes: For intricate profiles and shapes that require precise cuts.

Pocketing and Slotting: Creating recesses or channels in PMMA parts.

Prototyping: Rapidly creating test pieces or functional prototypes from acrylic.

Sign Making: Machining custom acrylic signs, letters, or decorative elements.

Hobbyist Projects: From model making to enclosures for electronics, this is a strong performer.

You might need to consider other tools if you are:

Milling very thick sections of acrylic where a larger diameter might be more efficient to remove material faster.

Working with materials other than plastics where different flute geometries or materials (like HSS for some soft metals) are more appropriate.

Essential Settings for Machining PMMA with Your 8mm Shank End Mill

Getting the settings right is just as crucial as having the right tool. Incorrect speeds and feeds can still lead to melting and a poor finish, even with the best end mill. These are general guidelines, and you may need to fine-tune them based on your specific machine, the exact type of acrylic, and the end mill’s manufacturer recommendations.

Spindle Speed (RPM)

For PMMA, you generally want to run at a relatively high spindle speed to achieve a good surface finish and to help chip evacuation. A good starting point is often between 10,000 and 20,000 RPM.

Why High RPM? Higher speeds mean the cutting edge moves faster, shearing the plastic more cleanly. It’s like using a sharp knife quickly instead of dragging a dull one slowly.

Considerations:

Cooling: At these speeds, heat can build up quickly. Good airflow or a coolant mist can help considerably.

Machine Capability: Ensure your machine can achieve and maintain these speeds reliably.

Feed Rate (IPM or mm/min)

The feed rate is how fast the end mill moves through the material. This needs to be balanced with the spindle speed. You want to feed fast enough to evacuate the chips but not so fast that you overload the cutting edges or cause excessive heat.

General Guideline: A common starting point for a 3/16-inch end mill in PMMA might be around 20-40 inches per minute (IPM) or roughly 500-1000 mm/min.

Chip Load: A more technical way to think about this is “chip load,” which is the thickness of the chip being removed by each cutting edge per revolution. For acrylic, a chip load of 0.002 – 0.005 inches per tooth is often recommended.

To calculate feed rate using chip load: `Feed Rate = Spindle Speed (RPM) × Number of Flutes × Chip Load per Tooth`

Example: With a spindle speed of 15,000 RPM, a 2-flute end mill, and a chip load of 0.003 inches per tooth:

`Feed Rate = 15,000 × 2 × 0.003 = 90 IPM`

Considerations:

Listen to your machine: If you hear screaming or chipping, your feed rate might be too slow, or your spindle speed too high. If the tool sounds like it’s rubbing or the acrylic is melting excessively, your feed rate might be too slow, or your spindle speed too low.

Depth of Cut: Shallower depths of cut are generally better for plastics.

Depth of Cut (DOC)

When milling PMMA, it’s usually best to take shallower cuts than you might with metal. This reduces the stress on the material and the tool, and it helps manage heat.

General Starting Point: For a 3/16-inch end mill, start with a depth of cut of around 0.06 to 0.12 inches (1.5 to 3 mm).

Multiple Passes: For deeper pockets or slots, it’s much better to make multiple shallow passes rather than one deep pass. This significantly improves chip evacuation and reduces heat buildup.

Engagement (Radial Depth of Cut)

This refers to how much of the end mill’s diameter is engaged in the cut sideways. For full-width slotting, the radial depth of cut is 100%. For contouring or pocketing, it’s usually much less.

For PMMA: Keeping the radial engagement relatively low (e.g., 20-50% of the tool diameter) can be beneficial, especially when contouring or profiling. This reduces the cutting forces and helps with chip clearing. Using techniques like “high-feed” milling, where the radial depth of cut is very small, can also be effective for plastics.

Recommended Settings Table for PMMA

Here’s a handy table summarizing our recommended settings. Always remember that these are starting points, and you should adjust based on your observations.

| Parameter | Typical Range for 3/16″ Carbide End Mill (8mm Shank) in PMMA | Notes |

|---|---|---|

| Spindle Speed (RPM) | 10,000 – 20,000 RPM | Higher speeds promote cleaner shearing and chip evacuation. |

| Feed Rate (IPM) | 20 – 40 IPM (approx. 500 – 1000 mm/min) | Adjust based on spindle speed and chip load. Listen to the cut. |

| Chip Load per Tooth | 0.002 – 0.005 inches | Crucial for setting appropriate feed rate. |

| Depth of Cut (Axial DOC) | 0.06 – 0.12 inches (1.5 – 3 mm) | Take shallower cuts; use multiple passes for deeper features. |

| Radial Depth of Cut (Engagement) | 20% – 50% of tool diameter (for contouring/pocketing) | Lower engagement helps with heat and chip evacuation. |

| Flute Count | 2 (preferred) | Maximizes chip clearance. |

Step-by-Step Guide: Milling PMMA with Your New End Mill

Now that we’ve covered the ‘why’ and the ‘what,’ let’s get practical. Here’s a step-by-step process for milling PMMA using your 3/16-inch carbide end mill with an 8mm shank.

Step 1: Secure Your Workpiece

Safety first! Ensure your PMMA sheet is firmly secured to your milling machine’s bed or vise. Use clamps or a vacuum table. Any movement during the cut can ruin your part or, worse, cause an accident.

Wipe down the surface to remove any dust or debris.

Use appropriate workholding – clamps should be placed to avoid interfering with the tool path and should apply pressure evenly.

Step 2: Install the End Mill

Proper installation of the end mill is critical for accuracy and safety.

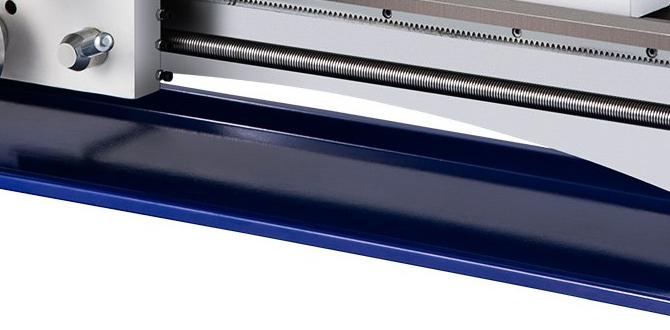

Insert the 8mm shank of the carbide end mill into a clean collet that matches the shank size (i.e., an 8mm collet).

Secure the collet in your machine’s spindle (or tool holder).

Ensure the end mill is seated correctly and tightened properly within the collet. Never run a tool with a shank not fully supported by the collet.

Step 3: Set Your Zero and Safety Height

Before starting any cutting operation, you need to tell your machine where your workpiece surface is and establish a safe height above it for tool movements.

Set Z-Zero: Carefully bring the tip of the end mill down to the surface of your PMMA. This is your Z-axis zero point. Most CNC machines have a way to set this electronically; for manual machines, you’ll use your DRO (Digital Readout) or dial indicator.

Set Safety Height: Establish a “safe Z height.” This is a height above your workpiece where the machine will retract the tool during non-cutting movements. This should be high enough to clear any clamps or fixtures. A common safe Z height might be 0.25 inches (6 mm) or more.

Step 4: Input Your Cutting Parameters

Enter the spindle speed, feed rate, and depth of cut into your CNC controller or set them manually on your machine. If you are using CAM software (Computer-Aided Manufacturing), these parameters will be part of your toolpath generation.

Initial Preview: If using CAM software, run a simulation to visually check your toolpaths and ensure there are no collisions and that the tool is clearing chips effectively in the simulation.

Step 5: Perform a Test Cut (Highly Recommended!)

It’s always wise to do a small test cut on a scrap piece of PMMA or an inconspicuous area of your main workpiece. This helps you verify your settings and listen to the sound of the cut without risking your primary part.

Cut a small square, a circle, or engrave a simple line.

Observe the chips: Are they small and fluffy, or are they melted and clumpy?

Feel the workpiece: Is it getting excessively hot?

Listen to the tool: Does it sound like it’s cutting cleanly, or is it chattering or struggling?

Step 6: Execute Your Main Cutting Program

Once you’re confident with your test cut, you can run your main program.

Start the Spindle: Bring the spindle up to the programmed speed.

Begin the Cut: Initiate the feed into the material at your set feed rate.

Monitor the Process: Stay with your machine while it’s running. Watch for any unusual sounds, vibrations, or excessive heat. Be ready to hit the E-stop (Emergency Stop) if anything seems wrong.

Step 7: Finishing and Inspection

After the machining is complete, allow the workpiece to cool slightly before handling.

Carefully remove the finished part from the machine.

Inspect the edges and surfaces for quality. You should see clean, sharp edges with minimal melting or chipping.

If there’s very light fuzz or small plastic debris, it can often be removed with a brush or compressed air.

Troubleshooting Common PMMA Machining Issues

Even with the right tool and settings, issues can arise. Here’s how to tackle the most common problems when machining PMMA.

Issue: Melting and Gumming on the End Mill

Cause: Insufficient chip clearance, wrong spindle speed/feed rate, too deep of a cut.

Solution:

Increase Spindle Speed: If your machine can handle it, try a higher RPM.

Increase Feed Rate: Ensure you’re feeding fast enough to get a proper chip load.

Take Lighter Cuts: Reduce the depth of cut (Axial DOC) and/or the stepover (Radial DOC).

Use Air Blast: Direct a stream of compressed air at the cutting zone to help cool and clear chips.

Consider an ‘O-Flute’ End Mill: These specialized end mills for plastics have a single, large flute designed specifically for maximum chip evacuation and minimal heat buildup. While our 2-flute is excellent,