3/16 Inch 8mm Shank Carbide End Mill for PEEK: Achieve Precise Cuts with Confidence. This guide explains how to select and use this specific tool for PEEK machining, ensuring accuracy and excellent finishes.

Working with advanced materials like PEEK can be tricky. You need the right tools to get clean, accurate cuts without damaging your workpiece or your machine. A common challenge for beginners is choosing the correct end mill, especially when dealing with plastics that can melt or chip. This is where a specific carbide end mill comes into play. We’ll walk you through exactly why a 3/16 inch diameter, 8mm shank carbide end mill is your go-to for PEEK and how to use it like a pro, even if you’re just starting out.

What is PEEK, and Why Does it Need Special Machining?

Polyetheretherketone (PEEK) is a high-performance thermoplastic known for its incredible strength, stiffness, and resistance to heat and chemicals. Because of these properties, it’s used in demanding applications like aerospace components, medical implants, and automotive parts. However, PEEK isn’t like brass or aluminum. It has a relatively low melting point for a plastic, meaning it can soften and deform if you use the wrong cutting speeds or tools. This can lead to:

- Melting and gummy chips

- Poor surface finish

- Tool breakage

- Inaccurate dimensions

To machine PEEK successfully, you need tools that can remove material efficiently without generating excessive heat. This is precisely where specific types of carbide end mills shine.

Why a 3/16 Inch Carbide End Mill with an 8mm Shank is Perfect for PEEK

Let’s break down why this particular combination is so good for machining PEEK. It’s all about controlled material removal and tool stability.

Carbide: The Material Choice

Carbide, or tungsten carbide, is much harder and stiffer than high-speed steel (HSS). This means it can:

- Hold a sharper edge for longer.

- Cut materials like PEEK more effectively without deforming.

- Handle higher cutting speeds and feeds, though we’ll dial these back for PEEK.

- Generate less heat at the cutting edge because it cuts cleaner.

For PEEK, the hardness of carbide prevents the material from gumming up the flutes and ensures a clean cut.

The 3/16 Inch Diameter

A 3/16 inch (approximately 4.76mm) diameter is a versatile size. It’s:

- Small enough for detailed work and intricate shapes, which are common with PEEK parts.

- Large enough to remove material efficiently without being too delicate.

- Often a good starting point for hobbyist and smaller-scale machining needs.

This size allows for precise control over the material removal process, reducing the risk of chipping or melting.

The 8mm Shank

The shank is the part of the end mill that goes into your machine’s collet or tool holder. An 8mm shank (which is very close to 3/16 inch, or 0.1875 inches) provides a good balance of:

- Rigidity: A solid connection means less chance of vibration or chatter, leading to a smoother finish.

- Compatibility: Most common collet sets and tool holders for hobby and light industrial machines will accommodate 8mm.

- Tool Support: It offers enough surface area for the collet to grip securely, preventing the tool from slipping under load.

A stable tool holder is crucial for predictable results, especially with materials like PEEK that can be unforgiving.

“Long Reach” Consideration for PEEK

When we talk about a “carbide end mill 3/16 inch 8mm shank long reach for PEEK,” the “long reach” aspect is important for certain PEEK applications. A longer flute length (the cutting part of the tool) allows you to:

- Machine deeper pockets.

- Reach into cavities.

- Avoid collisions with the workpiece or fixture if your setup requires it.

However, it’s very important to note that longer reach tools are inherently less rigid. For PEEK, especially if you don’t absolutely need the reach, a shorter, more robust end mill is often preferable for maximum stability and heat dissipation. If your job requires depth, ensure you use appropriate speeds and feeds to compensate for the increased tool overhang.

Choosing the Right Carbide End Mill for PEEK: Key Features

Not all carbide end mills are created equal. When selecting one for PEEK, keep these features in mind:

Number of Flutes

Flutes are the helical grooves in the end mill that carry away chips. For plastics like PEEK, fewer flutes are generally better:

- 2-Flute: Ideal for plastics like PEEK. The larger chip evacuation space between the two flutes prevents the soft PEEK from clogging the tool and building up heat.

- 3-Flute: Can work, but might require careful speed and feed selection to avoid melting.

- 4-Flute: Generally too many flutes for PEEK; they can lead to poor chip evacuation and overheating.

So, for PEEK, aim for a 2-flute carbide end mill with a 3/16-inch diameter and an 8mm shank.

Coating

While PEEK doesn’t typically require exotic coatings, a ‘bright’ or ‘uncoated’ finish is often preferred. Some specialized coatings may work, but avoid anything that tends to stick to plastics or create extra friction.

Helix Angle

The helix angle is the angle of the flutes. Common angles are 30°, 45°, and 60°.

- Moderate Helix Angle (e.g., 30°-45°): Often a good balance for PEEK. It provides decent cutting action and helps with chip evacuation without being so aggressive that it grabs the material.

- High Helix Angle (steeper): Can sometimes cause chatter or pull the workpiece.

- Low Helix Angle (shallower): May not cut as cleanly.

A standard, moderate helix is usually your best bet.

End Type

- Square End: Most common. Creates sharp internal corners.

- Ball Nose End: Creates a rounded tip, good for 3D contouring and creating fillets.

- Corner Radius End: Has a small radius on the cutting tips to strengthen them and create a slight radius in corners, preventing stress points.

For general milling and pocketing, a square end is fine. If you need rounded internal corners or specific 3D profiles, a ball nose or corner radius end mill would be appropriate. Always research the specific shape needed for your project.

Essential Setup and Safety Practices

Before you even think about cutting, safety and proper setup are paramount. This applies to any machining, but PEEK has its own quirks.

Machine Setup

Ensure your milling machine is in good working order. This includes:

- Cleanliness: Make sure your spindle and collets are free of debris.

- Spindle Runout: Low runout (how much the tool wobbles) is crucial for precise cuts and tool longevity. A 3/16″ carbide end mill is small, and high runout will make it chatter and fail quickly. A precision ER collet or collet chuck is essential to minimize runout.

- Workholding: Secure your PEEK workpiece firmly. Use clamps, vises, or custom fixtures that won’t deform the plastic.

Personal Protective Equipment (PPE)

Always wear appropriate PPE:

- Safety Glasses: Non-negotiable. PEEK chips are hard and can fly.

- Face Shield: Recommended for added protection, especially when starting.

- Gloves: Protect your hands from sharp edges.

- Hearing Protection: Milling machines can be loud.

Coolant/Lubrication

For PEEK, heat management is key. While some advanced applications might use high-pressure air, for beginners, a spray mist lubricant or a specialized plastic cutting fluid can be very beneficial. These:

- Reduce friction and heat

- Improve chip evacuation

- Ensure a better surface finish

Look for lubricants designed for plastics or general-purpose cutting fluids. Avoid heavy oils that can contaminate PEEK, which is often used in clean environments.

Step-by-Step Guide: Machining PEEK with Your 3/16 Inch End Mill

Here’s how to get started. Imagine you’re pocketing a simple square into a block of PEEK.

Step 1: Secure the Workpiece

Place your PEEK block securely in your milling vise or on your machine bed. Ensure it’s flat and won’t move during machining. Use parallels if needed to get it level.

Step 2: Install the End Mill

In your milling machine’s spindle, insert the 3/16 inch carbide end mill into an appropriate collet (an 8mm collet is typically used for an 8mm shank). Tighten the collet securely using a wrench. Ensure it’s seated properly in the spindle or tool holder.

Step 3: Set Your Zero Point (Origin)

Using your machine’s control or a digital read-out (DRO), set your X, Y, and Z zero points. For Z zero, this is usually the top surface of your workpiece. Carefully touch off the side of the workpiece for your X and Y zeros.

Step 4: Determine Cutting Speeds and Feeds

This is CRITICAL for PEEK. Because it can melt, you need to balance removing material quickly enough to be efficient but slowly enough to prevent heat buildup. These are starting points and will vary based on your machine rigidity, coolant, and specific PEEK grade:

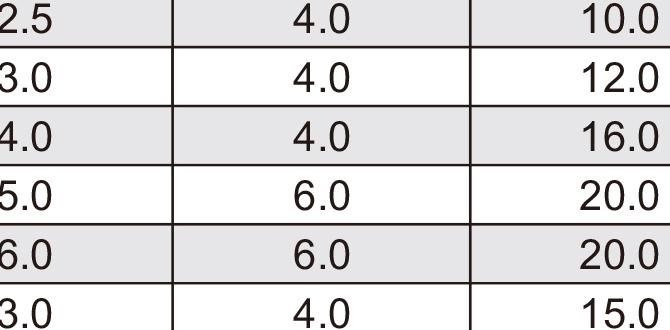

| Operation | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (Max) | Stepover (Width of Cut) |

|---|---|---|---|---|

| Roughing Pocket/Contour | 8,000 – 15,000 RPM | 10 – 25 IPM | 0.050″ – 0.075″ (1.27mm – 1.90mm) | 30% – 50% of tool diameter (approx. 0.057″ – 0.094″) |

| Finishing Pocket/Contour | 10,000 – 18,000 RPM | 20 – 40 IPM | 0.010″ – 0.020″ (0.25mm – 0.50mm) | 15% – 25% of tool diameter (approx. 0.028″ – 0.047″) |

Important Notes:

- Always start at the lower end of these suggestions and increase gradually if your machine and material can handle it.

- A high spindle speed with a moderate feed rate is generally preferred for plastics to keep the tool from rubbing and generating heat.

- Effective chip evacuation is vital. If you see melting or gummy chips, you need to increase your feed rate, reduce your depth of cut, or improve your chip clearance.

- For the most accurate settings, consult with the end mill manufacturer’s recommendations or a reputable machining data handbook. You can find excellent resources online, such as those from the National Tooling & Manufacturing Association (NTMA) (Note: This is a PDF link).

Step 5: Perform Roughing Passes

Program or manually control your machine to make roughing cuts. Use the speeds and feeds from the table above. Take lighter depths of cut initially. The goal of roughing is to remove the bulk of the material. Ensure your machine is programmed to clear chips effectively, using a spiral or zig-zag pattern to avoid re-cutting chips.

Step 6: Make Finishing Passes

After roughing, perform one or two finishing passes. These should be with a much lighter depth of cut (e.g., 0.010″ to 0.020″) and potentially a slightly higher feed rate. This is what gives you that smooth, accurate surface finish. For finishing, a smaller stepover (width of cut) is recommended.

Step 7: Inspect Your Results

Once the machining is complete, carefully remove the part. Inspect it for:

- Accurate dimensions

- Smooth surface finish (no melting, melting, or chipping)

- Clean edges

If you encounter issues, review your speeds, feeds, and depth of cut. Small adjustments can make a big difference.

Troubleshooting Common PEEK Machining Issues

Even with the right tool, you might run into a few snags. Here’s how to fix them:

Issue: Melting or Gummy Chips

- Cause: Too much heat buildup.

- Solution:

- Reduce depth of cut.

- Increase spindle speed.

- Decrease feed rate slightly (counter-intuitive, but can sometimes help spread the heat over more time).

- Improve lubrication and coolant delivery.

- Ensure you are using a 2-flute end mill with large chip flutes.

Issue: Chipping or Poor Edge Finish

- Cause: Tool is too dull, incorrect speeds/feeds, or material inconsistency.

- Solution:

- Ensure your end mill is sharp.

- Reduce spindle speed.

- Increase feed rate.

- Use a lighter depth of cut.

- Check for excessive runout in your spindle/collet.

Issue: Tool Breakage

- Cause: Excessive force, long tool overhang, poor chip evacuation leading to tool binding.

- Solution:

- Reduce depth of cut and stepover significantly.

- Ensure the tool is firmly seated in the collet.

- Use a shorter end mill if possible.

- Verify speeds and feeds aren’t too aggressive.

- Check for any signs of vibration or chatter which indicate rigidity issues.

When to Consider Alternatives

While the 3/16 inch 8mm shank carbide end mill is excellent for PEEK, sometimes other tools might be better suited for specific tasks:

For Very Delicate Work or Thin Features:

Extremely small features might benefit from a ¼ inch (6mm) miniature end mill series if available in carbide with the right flute count. However, maintaining rigidity with such small tools is a much bigger challenge.

For Bulk Material Removal:

If you’re hogging out large amounts of material quickly and precision isn’t paramount, a slightly larger diameter end mill (e.g., 1/4 inch or 6mm) with more flutes (like a 2-flute) might be faster, but always monitor heat.

For Very High Volumes or Automated Machining:

- Specialized PEEK milling cutters might be designed for higher speeds and feeds.

- Some manufacturers offer end mills with specific geometries optimized for plastics.

However, for the beginner and intermediate user, the 3/16 inch, 2-flute carbide end mill with an 8mm shank is a reliable and accessible option.

FAQs About 3/16 Inch Carbide End Mills for PEEK

Q1: Can I use a 3/16 inch carbide end mill on my 3-axis CNC router for PEEK?

A1: Yes, absolutely! CNC routers are excellent for machining plastics like PEEK. Ensure your router has sufficient spindle RPM and rigidity. The principles of speed, feed, and chip evacuation remain the same. Use a solid mount for your router to minimize vibration.

Q2: Do I need a special type of PEEK?

A2: While there are different grades of PEEK (e