Carbide end mills make cutting steel surprisingly easy and efficient. With the right technique, you can achieve smooth, accurate cuts without frustration. This guide shows you how to use a carbide end mill effectively for effortless steel cutting, even if you’re new to machining. Let’s get started!

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Have you ever looked at a piece of steel and felt a bit intimidated, especially when thinking about cutting it precisely? Many beginners find steel a tough nut to crack, leading to rough cuts, tool breakage, or just plain frustration. But what if I told you there’s a tool that can make cutting steel feel almost effortless? That’s where the carbide end mill shines. These aren’t your typical cutting tools; they’re designed for much tougher jobs.

I remember my early days, struggling with softer metals and dreading the moment I’d have to face steel. It felt like a huge leap. But once I understood the power and proper use of a carbide end mill, my world changed. Suddenly, steel became manageable, even enjoyable, to machine. We’re going to walk through everything you need to know, from picking the right end mill to setting up your machine. Get ready to tackle steel with confidence!

What is a Carbide End Mill and Why It’s Your Steel-Cutting Superpower

At its heart, an end mill is a type of milling cutter. Think of it like a drill bit that can also move sideways. It spins and cuts material away, shaping it precisely. But not all end mills are created equal, especially when it comes to steel.

A carbide end mill is made from tungsten carbide, which is an incredibly hard and wear-resistant material. This hardness is crucial because steel is much harder than materials like aluminum or wood. When you use a standard high-speed steel (HSS) end mill on hard materials like steel, it can dull quickly, overheat, and even snap. Carbide end mills, however, can withstand higher temperatures and pressures, allowing them to cut through steel efficiently and cleanly.

The Magic of Carbide

Why is carbide so special for cutting steel? Let’s break it down:

- Extreme Hardness: Tungsten carbide is second only to diamond in hardness. This means it stays sharp for much longer, even when cutting tough materials.

- Heat Resistance: Machining generates heat. Carbide can handle much higher temperatures than HSS without losing its cutting edge. This is vital for steel, which requires robust tooling to manage the heat created during cutting.

- Rigidity: Carbide is also a very rigid material. This means less flex and chatter during cutting, leading to smoother surfaces and more accurate dimensions on your workpiece.

- Wear Resistance: Because it’s so hard, a carbide end mill will last significantly longer than an HSS one when used for the same tasks, especially on steel. This means fewer tool changes and a more consistent cutting process.

When we talk about specific types, like a “carbide end mill 3/16 inch 8mm shank standard length for carbon steel MQL friendly,” we’re getting into the specifics that make it ideal for your job. The 3/16 inch size refers to the cutting diameter, 8mm shank fits many common collets, standard length provides good reach, and MQL (Minimum Quantity Lubrication) friendly coatings help manage heat and chip evacuation, which is essential for carbon steel.

Choosing the Right Carbide End Mill for Steel

Not all carbide end mills are designed for the same job. For cutting steel, especially common carbon steels, you’ll want to consider a few key features. This ensures you’re not just using a carbide end mill, but the right one.

Key Features to Look For:

- Material: As we discussed, solid carbide is the way to go for steel.

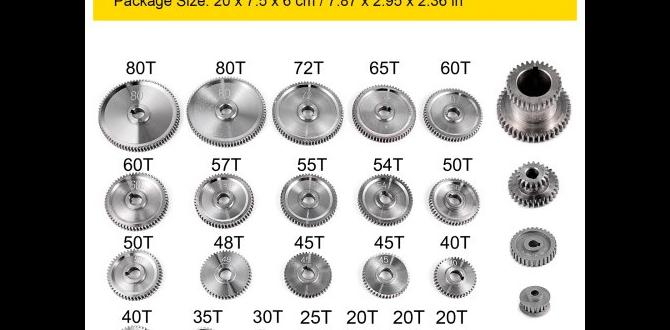

- Number of Flutes: Flutes are the spiral grooves along the cutting edge.

- 2 Flutes: Generally preferred for softer materials and for plunging or slotting. They offer more chip clearance, which is important when cutting steel.

- 3-4 Flutes: Good all-around choices for general milling operations. More flutes mean a smoother finish but less chip clearance. For steel, 2 or 4 flutes are often recommended.

- High Flute Count (5+): Usually for softer materials or high-speed finishing on aluminum. Not ideal for general steel cutting.

- Coating: Coatings add a layer of protection to the carbide, enhancing performance.

- Uncoated: Okay for some lighter tasks but generally not the best for steel.

- TiN (Titanium Nitride): A basic, general-purpose coating that adds some hardness and lubricity.

- TiCN (Titanium Carbonitride): Harder than TiN, offers better wear resistance, great for steel.

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications and hard materials like steel and stainless steel. It forms a protective aluminum oxide layer at high heat. This is often your best bet for steel.

- ZrN (Zirconium Nitride): Another good option for steel and stainless steel, known for good lubricity.

- Geometry: Some end mills have specific flute shapes or corner radii designed for steel. A small corner radius can add strength and improve the surface finish.

- Shank Size: Ensure the shank (the part that goes into your tool holder or collet) matches your machine’s spindle. Common sizes are 1/4″, 1/2″, 6mm, 8mm, etc. A “carbide end mill 3/16 inch 8mm shank” means it has a 3/16″ cutting diameter and an 8mm shank. Your collet needs to be able to hold an 8mm shank.

- Length: Standard length offers a good balance. Extended lengths are for reaching deeper into workpieces, but they can lead to more vibration and deflection.

Why MQL Friendly is a Big Deal for Steel

MQL stands for Minimum Quantity Lubrication. It’s a system that delivers a fine mist of coolant and lubricant directly to the cutting zone. For steel, this is incredibly beneficial:

- Cools the Cutting Edge: Reduces heat buildup, preventing the carbide from overheating.

- Lubricates: Reduces friction between the tool and workpiece, leading to a smoother cut and longer tool life.

- Chips Away Freely: Helps to evacuate chips, preventing them from welding to the cutting edge.

- Environmentally Friendly: Uses far less coolant than traditional flood cooling.

An “MQL friendly” end mill typically has features or coatings that work well with this type of lubrication, whether it has internal coolant channels or a specific coating that performs better under MQL conditions.

Essential Tools and Setup for Effortless Steel Cutting

Before you even think about hitting “start” on your machine, having the right setup is crucial for success and safety. It’s not just about the end mill; it’s about the whole system working together.

Your Workshop Checklist:

- CNC Mill or Manual Milling Machine: A rigid milling machine is essential. A shaky or worn-out machine will give you trouble, no matter how good your end mill is.

- Collet Chuck or Tool Holder: To hold the end mill securely in the spindle. Make sure you have the correct size collet or holder for your end mill’s shank (e.g., an 8mm collet for an 8mm shank). A good quality collet chuck provides the best runout.

- Workholding: This is how you secure your steel workpiece to the machine table. Options include:

- Vises: A sturdy milling vise is common and effective.

- Clamps: Specialized clamps for holding workpieces directly to the table or a fixture.

- Fixtures: Custom-made setups for specific parts.

Ensure your workholding is robust and won’t move during the cut.

- Safety Glasses and Face Shield: Non-negotiable. Steel chips can fly with surprising force.

- Hearing Protection: Milling can be loud.

- Gloves: For handling sharp metal and for general workshop safety (though avoid loose gloves near rotating machinery).

- Coolant System (MQL or Flood): MQL systems are excellent for steel, as mentioned. If you don’t have MQL, a flood coolant system or even a good cutting fluid applied manually can help. A link to resources on machining coolants can be found via the Machinetoolhelp.com guide to machining fluids.

- Measuring Tools: Calipers and a dial indicator or digital readout (DRO) for precise measurements.

- Chip Brush or Vacuum: For cleaning up chips safely.

Setting Up Your Machine:

A few key settings will make a big difference:

- Spindle Speed (RPM): This is how fast the end mill spins. For carbide end mills in steel, speeds tend to be lower than for softer materials.

- Feed Rate: This is how fast the end mill moves through the material. A proper feed rate ensures the carbide takes decent chips without overloading.

- Depth of Cut (DOC): How deep each pass of the end mill goes. It’s usually best to take lighter passes with carbide.

- Stepover: For contouring or pocketing, this is how much the end mill moves sideways on each pass.

- Workpiece Alignment: Ensure your steel is square and held firmly.

Finding the exact settings can depend on your specific machine, the type of steel, and the end mill. Many end mill manufacturers provide recommended speeds and feeds for their tools. Always start conservatively!

Step-by-Step: Effortless Steel Cutting with Carbide

Now for the action! This process assumes you’re using a CNC mill, but the principles are the same for a manual machine, just with you controlling the movements. We’ll focus on a common operation: milling a pocket or slot.

Step 1: Secure Your Workpiece

Place your steel block firmly in the vise or on your fixture. Make sure it’s clean and that the vise jaws have good contact. Tighten it down securely. Use a dial indicator to ensure the workpiece is perfectly square with your machine axes (X and Y).

Step 2: Install the End Mill

Select the correct collet for your end mill’s shank diameter (e.g., 8mm). Insert the collet into the collet chuck, then insert the shank of your carbide end mill into the collet. Tighten the collet securely onto the end mill shank. Mount the collet chuck into your machine’s spindle.

Step 3: Set Your Work Offsets

This is crucial for telling your machine where the material is. Using your machine’s controls (or an edge finder on a manual machine), locate key points on your workpiece (like the corner or center). This establishes your X, Y, and Z zero points relative to the material.

Step 4: Program or Set Your Cutting Path

For CNC, you’ll program the toolpath using CAM software or by direct G-code entry. For a simple slot or pocket, this involves:

- Defining the Pocket/Slot Shape: The geometry you want to cut.

- Selecting the Tool: Your carbide end mill.

- Setting Speeds and Feeds: Use conservative starting points from the end mill manufacturer or a reliable machining calculator. For a 3/16″ carbide end mill in mild steel, you might start around 200-300 surface feet per minute (SFM) for speed, and a chip load of 0.001-0.002 inches per tooth (IPT). Convert SFM to RPM using the formula: RPM = (SFM 3.82) / Diameter_in_inches. For a 3/16″ (0.1875″) end mill at 250 SFM: RPM = (250 3.82) / 0.1875 = ~5093 RPM.

- Defining Depth of Cut (DOC): For steel, aim for a DOC that’s about 50-100% of the end mill’s diameter for slotting, or less for profiling. Start conservatively, perhaps 0.100″ to 0.125″ for a 3/16″ end mill in mild steel.

- Defining Stepover: For pockets, a stepover of 30-50% of the end mill’s diameter is common.

- Coolant: Ensure your MQL or flood coolant is set to activate.

On a manual mill, you’ll be moving the handwheels to control the feed and depth based on your programmed plan.

Step 5: The First Cut (The “Air Cut” or Light Pass)

Before cutting to full depth, it’s good practice to run the tool just above the surface of the material (an “air cut”) to verify the toolpath. Alternatively, make a very shallow first cut (e.g., 0.005″ to 0.010″ deep) to test your settings. Listen to the sound and watch for chips. A good cut sounds like a consistent “sugaring” or “shaving” noise. You shouldn’t hear screaming, chattering, or grinding.

Step 6: Execute the Main Cutting Operation

Once you’re confident in your setup and initial pass, proceed with the full cutting operation. Let the machine do the work. Monitor the process for any unusual sounds, vibrations, or excessive chip buildup. If anything seems wrong, stop the machine immediately.

Step 7: Chip Evacuation and Cleaning

As the end mill cuts, chips will be produced. For steel, good chip evacuation is key. If chips aren’t clearing properly, they can recut, overheat the tool, and lead to a broken end mill. MQL systems excel here. If using flood coolant, ensure it’s reaching the cutting zone effectively. Periodically, or if you notice chip packing, you might need to pause the operation and use a brush or compressed air (with caution!) to clear stubborn chips. Never use your hands!

Step 8: Finishing and Inspection

Once the cutting is complete, turn off the spindle and coolant. Carefully remove the workpiece. Inspect the cut surfaces for accuracy and finish. Use your calipers to check dimensions. If everything looks good, congratulations! You’ve successfully cut steel with your carbide end mill.

Troubleshooting Common Steel-Cutting Issues

Even with the best tools and setup, sometimes things don’t go perfectly. Here are a few common problems and how to fix them:

| Problem | Possible Cause(s) | Solution(s) |

|---|---|---|

| Tool Breakage |

|

|

| Poor Surface Finish (Roughness) |

|

|

| Excessive Heat/Melting |

|

|

| Workpiece Movement/Chatter |

|