Woodworking is a popular hobby for many people. If you’re a woodworker, you may have heard about carbide tools and HSS tools. But which one is better for your wood lathe? That’s a question worth asking! Imagine you’re shaping a beautiful bowl on your lathe. You want the right tool to make your project smooth and easy.

Carbide tools last longer than HSS tools, which makes them very appealing. But do you know why? They can handle tough jobs without dulling quickly. This means less time sharpening and more time creating. On the other hand, HSS tools are often cheaper and can be sharpened easily at home. So, which tool will you choose?

In this article, we will dive into the exciting world of carbide tools versus HSS tools. You’ll learn the pros and cons of each type. By the end, you’ll feel confident in picking the right tool for your next project. Let’s explore together!

Carbide Tools Vs Hss Tools For Wood Lathe: Which Is Best?

Carbide Tools vs HSS Tools for Wood Lathe

Choosing between carbide tools and HSS tools for your wood lathe can be tricky. Carbide tools last longer and stay sharp, making them great for heavy use. In contrast, HSS tools are easier to sharpen, which is handy for beginners. Did you know that HSS tools were popular long before carbide? Each option has its strengths, so pick what fits your needs best for a smoother woodworking experience.Understanding Wood Lathe Tools

Definition and purpose of wood lathe tools. Brief history of tool evolution in woodworking.Wood lathe tools are special tools used to shape and smooth wood. They help create beautiful objects like bowls and furniture. Over time, these tools have changed to make woodworking easier and more fun. In the past, people used simple chisels made from stone or metal. Now, woodworkers can choose from advanced carbide tools and HSS tools to make their work even better.

What are wood lathe tools used for?

Wood lathe tools shape wood into round forms and smooth surfaces. They are essential for turning and crafting decorative items.

Quick History:

- Early tools were made of stone.

- Metal chisels became popular in the 1800s.

- Carbide and HSS tools emerged in the 20th century.

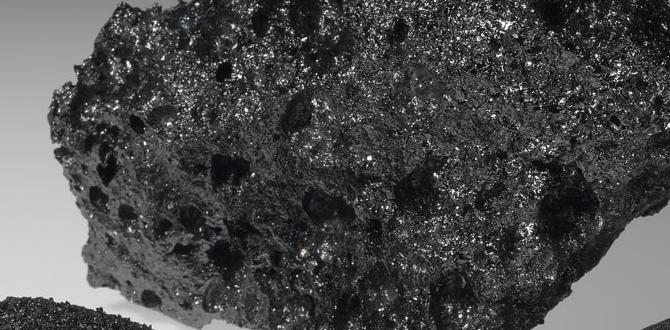

What are Carbide Tools?

Material composition and characteristics of carbide tools. Advantages of using carbide tools in woodworking.Carbide tools are made from a tough blend of tungsten and carbon. This combination creates a super-hard material that lasts longer than most others. They are great for spinning lathe work because they stay sharp longer and can handle tough wood. Plus, using carbide tools means less time sharpening and more time creating! Did you know they can last up to ten times longer than HSS tools? That’s like having a superhero in your toolbox!

| Characteristic | Carbide Tools | HSS Tools |

|---|---|---|

| Durability | Very High | Moderate |

| Sharpness Retention | Long-lasting | Needs Regular Sharpening |

| Cost | Higher | Lower |

What are HSS Tools?

Material composition and characteristics of highspeed steel (HSS) tools. Advantages of using HSS tools in woodworking.High-Speed Steel, or HSS, is a special material made of steel mixed with other elements like tungsten or molybdenum. This mix makes HSS strong and durable. HSS tools have some great features: they resist wear and stay sharp longer than regular steel. They also work well in high-speed cutting, which is perfect for woodworking. Here are some advantages:

- Good edge retention

- Heat resistance

- Smooth cuts

- Easy to sharpen

Using HSS tools helps woodworkers get the job done quickly and cleanly.

What are the benefits of HSS tools?

HSS tools offer excellent durability and resist heat. They are perfect for making clean cuts in wood, ensuring a nice finish on projects.

Comparison of Carbide Tools and HSS Tools

Durability and longevity of carbide vs HSS tools. Edge retention and sharpness comparison. Performance in various wood types.Carbide tools last longer than HSS tools. They resist wear and stay sharp for more time. HSS tools can dull quickly, especially with hard woods. It’s important to think about what wood you plan to use. Here’s a quick comparison:

- Durability: Carbide tools are tougher and last years.

- Edge Retention: Carbide keeps its edge longer.

- Performance: HSS works well on soft wood but struggles with hard wood.

Overall, choose carbide for durability and sharpness in different wood types.

Which is better for woodturning, carbide or HSS tools?

Carbide tools are better for woodturning because they stay sharp longer and handle various wood types well.

Cost Analysis

Initial investment costs for carbide and HSS tools. Longterm costs and value of each tool type.When you’re choosing tools for your wood lathe, the price counts! Carbide tools can be like the fancy coffee of the tool world—more expensive at first but lasting longer. They may cost about 50% more upfront than HSS tools. However, HSS tools may need to be replaced more often, leading to hidden costs. Here’s a simple breakdown to show how they compare:

| Tool Type | Initial Cost | Long-term Value |

|---|---|---|

| Carbide Tools | $30-$60 | High durability; saves money over time! |

| HSS Tools | $20-$40 | Weaker; may cost more in replacements! |

In the end, spending a little more on carbide tools may just save your wallet from crying later!

Maintenance and Care Requirements

Maintenance practices for carbide tools. Maintenance practices for HSS tools.Carbide tools and HSS tools each have their own maintenance styles. Carbide tools are tough cookies! They need minimal upkeep. A quick wipe after use keeps them happy and ready to go. In contrast, HSS tools crave a bit more love. Regular sharpening and cleaning help them shine. Remember, dull tools are like sad clowns! Keep them sharp and smiling for smooth wood turning. Below is a simple comparison of their upkeep:

| Tool Type | Maintenance Practices |

|---|---|

| Carbide Tools | Minimal cleaning, occasional inspection. |

| HSS Tools | Regular sharpening, cleaning, and oiling. |

User Experience and Feedback

Insights from woodworkers using carbide tools. Insights from woodworkers using HSS tools.Woodworkers have plenty to say about their favorite tools. Those using carbide tools often praise their long-lasting sharpness. “It cuts like butter,” one woodworker said, laughing. They also appreciate the smooth finish it gives to wood. On the other hand, fans of HSS tools enjoy their affordability and ease of sharpening. “It’s like having your cake and eating it too,” joked another user. Both tools have their quirks and charms, making the choice sometimes feel like choosing between pizza toppings!

| Tool Type | User Insights |

|---|---|

| Carbide Tools | Long-lasting, smooth cuts, need less frequent sharpening. |

| HSS Tools | Cost-effective, easy to sharpen, great for beginners. |

Conclusion

In conclusion, carbide tools last longer and stay sharp, making them great for serious woodworking. HSS tools are easier to sharpen but dull faster. If you’re a beginner, start with HSS for practice. As you gain experience, consider switching to carbide for convenience. Explore more resources to deepen your knowledge and enhance your wood lathe skills!FAQs

What Are The Main Differences In Cutting Performance Between Carbide Tools And Hss Tools When Used On A Wood Lathe?Carbide tools and HSS tools are both used on wood lathes, but they work differently. Carbide tools stay sharp longer, so you don’t have to sharpen them often. HSS tools are easier to sharpen but might wear out faster. This means you can use carbide tools for a longer time before needing a replacement. However, HSS tools can give nice finishes if you sharpen them well.

How Do The Costs Of Carbide Tools Compare To Hss Tools For Wood Lathe Applications, Considering Durability And Longevity?Carbide tools usually cost more than High-Speed Steel (HSS) tools. However, they last longer and stay sharp for a long time. This means you don’t have to replace them as often. In the end, you might save money because you don’t need to buy new tools as frequently. So, while carbide tools are pricier at first, they can be worth it for their durability.

In What Scenarios Would A Woodturner Prefer Carbide Tools Over Hss Tools And Vice Versa?A woodturner might choose carbide tools when making lots of pieces quickly. Carbide stays sharp longer, so you don’t have to sharpen it often. On the other hand, high-speed steel (HSS) tools are great for fine details. You can sharpen them easily to get a very smooth finish.

How Does The Sharpening Process Differ Between Carbide Tools And Hss Tools For Wood Lathe Use?When you sharpen carbide tools, you usually use a special grinder or diamond wheel to get a fine edge. This is because carbide is hard and needs special tools. For high-speed steel (HSS) tools, you can use a regular sharpening stone or a belt sander. HSS is easier to sharpen and can be done with common tools.

What Are The Best Practices For Maintaining And Storing Carbide Tools And Hss Tools To Ensure Optimal Performance In Woodturning?To keep your carbide and HSS (High-Speed Steel) tools sharp and ready, always clean them after use. Use a dry cloth to wipe them free of wood dust and resin. Store your tools in a dry place, like a toolbox or on a magnetic strip, to prevent rust. Avoid dropping or bumping your tools, as this can chip or break them. Lastly, check the sharpness regularly and sharpen them as needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Main Differences In Cutting Performance Between Carbide Tools And Hss Tools When Used On A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carbide tools and HSS tools are both used on wood lathes, but they work differently. Carbide tools stay sharp longer, so you don’t have to sharpen them often. HSS tools are easier to sharpen but might wear out faster. This means you can use carbide tools for a longer time before needing a replacement. However, HSS tools can give nice finishes if you sharpen them well.”}},{“@type”: “Question”,”name”: “How Do The Costs Of Carbide Tools Compare To Hss Tools For Wood Lathe Applications, Considering Durability And Longevity? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carbide tools usually cost more than High-Speed Steel (HSS) tools. However, they last longer and stay sharp for a long time. This means you don’t have to replace them as often. In the end, you might save money because you don’t need to buy new tools as frequently. So, while carbide tools are pricier at first, they can be worth it for their durability.”}},{“@type”: “Question”,”name”: “In What Scenarios Would A Woodturner Prefer Carbide Tools Over Hss Tools And Vice Versa? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A woodturner might choose carbide tools when making lots of pieces quickly. Carbide stays sharp longer, so you don’t have to sharpen it often. On the other hand, high-speed steel (HSS) tools are great for fine details. You can sharpen them easily to get a very smooth finish.”}},{“@type”: “Question”,”name”: “How Does The Sharpening Process Differ Between Carbide Tools And Hss Tools For Wood Lathe Use? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you sharpen carbide tools, you usually use a special grinder or diamond wheel to get a fine edge. This is because carbide is hard and needs special tools. For high-speed steel (HSS) tools, you can use a regular sharpening stone or a belt sander. HSS is easier to sharpen and can be done with common tools.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining And Storing Carbide Tools And Hss Tools To Ensure Optimal Performance In Woodturning? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your carbide and HSS (High-Speed Steel) tools sharp and ready, always clean them after use. Use a dry cloth to wipe them free of wood dust and resin. Store your tools in a dry place, like a toolbox or on a magnetic strip, to prevent rust. Avoid dropping or bumping your tools, as this can chip or break them. Lastly, check the sharpness regularly and sharpen them as needed.”}}]}