Have you ever wondered how small metal parts are made with great precision? One tool that makes this possible is the compact metal lathe. This amazing machine can shape metal into all sorts of designs. But did you know that you can also create a compact metal lathe design using CAD software?

CAD, or computer-aided design, helps engineers and hobbyists plan their projects on a computer. Imagine drawing your ideas before making them real! It’s like a digital blueprint. With compact metal lathe CAD design, building your own lathe becomes easier and more fun.

Many people enjoy creating their own tools. It gives them a sense of satisfaction. Plus, custom designs can help fit your specific needs. Want to make a special part for your project? Designing your own lathe might be the answer!

Let’s dive into how compact metal lathe CAD design can change the way you think about metalworking. You might just find your next favorite hobby!

Compact Metal Lathe Cad Design: A Comprehensive Guide

Compact Metal Lathe CAD Design

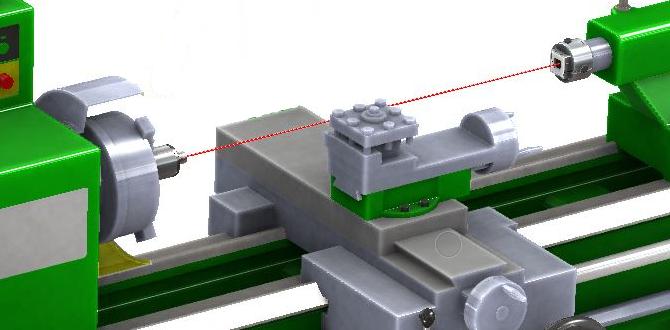

A compact metal lathe is a machine that can shape metal into various parts. CAD design helps create detailed drawings for building these lathes. With 3D modeling, engineers can visualize every angle. Did you know that using CAD can save time and reduce mistakes? By simulating parts before production, designers avoid costly errors. Learning how to use CAD for compact metal lathes opens doors to innovation and precision in metalworking. Isn’t that cool?Understanding Compact Metal Lathes

Definition and purpose of compact metal lathes. Benefits of using compact models in various applications.Compact metal lathes are like the talented smaller siblings of traditional lathes. They spin metal to create different shapes and sizes, making them perfect for both hobbyists and professionals. These nifty machines fit snugly in small workshops, making them a favorite for tight spaces. Plus, they’re great for projects like model making and crafting unique parts!

| Benefit | Details |

|---|---|

| Space-saving | Perfect for small workspaces. |

| Versatile | Ideal for many projects like repairs or creative crafts. |

| Easy to use | Simple controls make them user-friendly. |

These lathes are not only fun to use but also make your projects shine! Imagine creating something awesome from a chunk of metal. It’s like magic but with tools!

Key Features of Compact Metal Lathes

Essential components and their functions. Differences between compact lathes and traditional lathes.Compact metal lathes have unique parts that help them work well. Key components include the spindle, tailstock, and tool rest. The spindle spins the material. The tailstock helps with support, and the tool rest holds the cutting tool in place. Compact lathes are smaller and lighter than traditional lathes, making them easier to move. They are perfect for small projects or spaces. Here are a few differences:

- Size: Compact lathes are more portable.

- Cost: They often cost less than traditional lathes.

- Ease of use: Compact lathes are easier for beginners.

These features make compact lathes a smart choice for many hobbyists!

What makes compact metal lathes different?

Compact metal lathes are smaller and lighter, making them easier to handle. They also cost less and are often easier to learn. Their design suits hobbyists and small workshops well.

Benefits of CAD Design in Metal Lathe Manufacturing

How CAD enhances precision and efficiency. Advantages of using CAD over traditional drafting methods.Using CAD for metal lathe design is like having a magic wand for precision! It helps manufacturers create parts that fit perfectly without the guesswork. With CAD, each detail is clear and easy to see. Compared to old-school drawing methods, CAD is faster too! Imagine finishing a task in half the time—all while sipping your coffee!

| Benefits | CAD Design | Traditional Drafting |

|---|---|---|

| Precision | High precision with digital tools | Manual errors possible |

| Efficiency | Quick modifications | Time-consuming revisions |

| Visualization | 3D modeling available | 2D drawings only |

With these advantages, CAD is clearly the superhero in the world of metal lathes! Who knew design could be this fun and efficient?

Software Options for CAD Design in Metal Lathes

Popular CAD software for metalworking. Comparison of features and pricing of top CAD tools.Many people use CAD software for designing metal lathes. Popular options include:

- AutoCAD: Great for 2D and 3D designs. Prices start around $1,700/year.

- Fusion 360: Cloud-based and user-friendly. It’s about $495/year.

- SolidWorks: A strong choice for detailed projects, costing around $4,000/year.

- FreeCAD: A free option with strong features for beginners.

These programs offer different tools. Choose one based on your needs and budget.

What is the best CAD software for metalworking?

AutoCAD, Fusion 360, and SolidWorks are top choices. They vary in price and features to help with different projects.

Designing a Compact Metal Lathe: Step-by-Step Process

Initial considerations and planning stages. Detailed walkthrough of the CAD design process.Before diving into designing your compact metal lathe, think about the size and purpose. What will you create with it? There’s nothing worse than a lathe that can’t handle that big project! Next, sketch out your ideas on paper. Grab a pencil—remember, it’s not an art competition. Then, it’s time for CAD! This software helps you visualize your design in 3D. It’s like playing with digital Lego, but for grown-ups!

| Considerations | Actions |

|---|---|

| Purpose | Define what you will make |

| Size | Determine the space available |

| Sketching | Draw initial ideas |

| CAD Design | Use software to create a 3D model |

Remember, patience is key in this process. Design can be fiddly, but soon enough, you’ll have a neat little lathe ready to roll! And if it doesn’t turn out perfect, don’t worry; it’s all part of the fun—just like learning to ride a bike, but with less skinned knees!

Case Studies of Successful Compact Metal Lathe Designs

Examination of notable projects and their outcomes. Lessons learned from practical applications.Many projects have shown great success with compact metal lathe designs. For example, one team created a small lathe for hobbyists. They achieved smooth cuts and precise measurements. This project taught important lessons:

- Test designs multiple times for best results.

- Get feedback to improve the project.

- Think about safety features from the start.

Such lessons help future designs be even better.

What are some examples of successful projects?

Many teams built strong compact metal lathes with great results, showing what works best.

The Future of Compact Metal Lathes and CAD Technology

Trends shaping the development of metal lathes. Potential advancements in CAD tools and techniques.Metal lathes are changing fast. New trends are shaping their design and use. For example, more people are using compact metal lathes in smaller workshops. This makes working easier and more efficient. CAD tools are also getting better. They help users design parts faster and with more precision. Some upcoming changes include:

- Improved software for easy design.

- 3D printing integration.

- Better user interfaces for quicker learning.

With these advancements, the future of metal lathes looks bright!

What are the latest trends in CAD tools?

CAD tools are now becoming more user-friendly. Many focus on cloud technology, allowing collaboration from anywhere. This means teamwork can happen faster and easier!

Conclusion

In summary, a compact metal lathe with CAD design can boost your project efficiency. It helps you create precise parts quickly and easily. You can customize designs to fit your needs. To learn more, explore tutorials or guides on metal lathes and CAD software. Start your journey into metalworking with hands-on practice and discover the fun of creating!FAQs

What Are The Key Design Considerations For Creating A Compact Metal Lathe In Cad Software?When designing a compact metal lathe in CAD (Computer-Aided Design) software, we need to think about a few important things. First, we have to make sure the size is small enough to fit in tight spaces. Next, we should choose strong materials so it can work safely and last a long time. We also need to think about how easy it is to use and move around. Finally, we want to include clear instructions or labels for everyone to understand how to operate it.

How Can You Optimize A Cad Model Of A Compact Metal Lathe For Efficient Manufacturing And Assembly?To optimize a CAD model of a compact metal lathe, you can start by simplifying its design. Remove any extra parts that aren’t needed. Use shapes that are easier to make and fit together. You should also check for parts that can be combined to save space. Finally, make sure everything is easy to reach when assembling.

What Materials Should Be Considered In The Cad Design Of A Compact Metal Lathe To Ensure Durability And Precision?When designing a compact metal lathe, you should think about strong materials. Steel is a great choice because it’s tough and lasts a long time. You can also use aluminum for parts that need to be light but still strong. Remember to choose good bearings so the lathe turns smoothly and accurately. These materials will help your lathe be both durable and precise!

How Can Simulation Tools Within Cad Software Enhance The Design Process For A Compact Metal Lathe?Simulation tools in CAD (Computer-Aided Design) software help us test designs before building them. You can see how the compact metal lathe will work. This way, we can find problems early. We can change things easily without wasting materials. It makes our design better and faster!

What Are The Common Challenges Faced When Designing A Compact Metal Lathe In Cad, And How Can They Be Addressed?When we design a compact metal lathe using computer software (CAD), we face several challenges. First, we need to make sure all parts fit together in a small space. Sometimes, parts might be too tight or hard to reach. To fix this, we can test our design in the software and change it until it works well. Another challenge is keeping everything strong and safe, so we check materials and structure carefully.