Have you ever watched a metal lathe in action? It’s fascinating how these machines shape metal into precise parts. But did you know that the right coolant can make a big difference? Comparing different metal lathe coolants can help you find the best one for your projects.

Picture this: You’re in a workshop, working hard. Suddenly, your machine starts to overheat. Frustrating, right? That’s where metal lathe coolant comes in. Using the right coolant keeps everything running smoothly and prevents damage.

In this article, we will explore the different types of metal lathe coolants. You’ll learn about their benefits and how they affect your work. Let’s dive in and see which one is truly the best for your needs!

A Comprehensive Comparison Of Metal Lathe Coolant Options

Comparison Metal Lathe Coolant

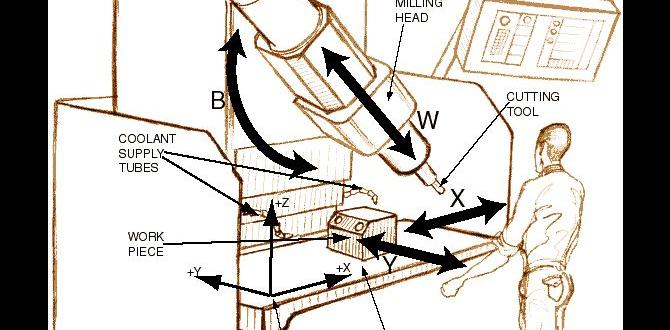

Choosing the right coolant for your metal lathe can greatly affect your projects. Coolants cool the metal and help to prevent damage during machining. You may find that water-based coolants are less expensive, but oil-based ones might offer better lubrication. Did you know that some coolants even help prevent rust? It’s important to compare different types to find one that fits your needs. Consider how much you’ll be using it and the materials you’ll work with.Understanding Metal Lathe Coolants

Definition and purpose of metal lathe coolants. Importance in machining processes and tool longevity.Coolants are liquids used in metal lathes to help during machining. They cool down the tools and the metal. This keeps everything from getting too hot. Using coolants is very important for a few reasons:

- They help make cuts smoother and easier.

- Coolants can help tools last longer by reducing wear.

- They prevent rust and other damage to parts.

Overall, metal lathe coolants are essential for the best machining results.

Why are coolants important in metal lathing?

Coolants keep tools cool and help them work better, ensuring longer tool life and improved performance.

Types of Metal Lathe Coolants

Waterbased coolants: properties and advantages. Oilbased coolants: characteristics and common uses. Semisynthetic coolants: a hybrid approach.There are three main types of metal lathe coolants: water-based, oil-based, and semi-synthetic. Each type has its own unique properties and benefits.

Water-based coolants are mostly made of water and special additives. They cool well and help keep parts clean. They are great for many metalworking jobs.

Oil-based coolants have a thicker consistency. They provide good lubrication and protect against rust. These are commonly used for heavy cutting tasks.

Semi-synthetic coolants mix both water and oil. They aim to combine the best of both worlds. This hybrid option offers cooling, lubrication, and less mess.

- Water-based: Excellent cooling properties.

- Oil-based: Great for lubrication.

- Semi-synthetic: Balanced features.

What makes water-based coolants special?

Water-based coolants are efficient and cost-effective. They provide excellent cooling without leaving a sticky residue. This keeps machines working smoothly and reduces wear.

Key Factors to Consider When Choosing Coolants

Viscosity and flow characteristics. Lubrication properties and cooling capabilities. Compatibility with various metals and materials.Choosing the right coolant for a metal lathe is important. Here are some key factors to think about:

- Viscosity and flow: The thickness of the coolant matters. Thin coolants flow better, while thick ones stick.

- Lubrication properties: Good lubricants reduce friction. This helps save energy and prevent wear and tear.

- Cooling capabilities: Effective coolants keep temperatures low. This protects the metal and tools from damage.

- Compatibility: Make sure the coolant works with the metals you use. Some coolants might react badly with certain materials.

Choosing wisely means ensuring a long life for your tools and smoother work.

What should you look for in metal lathe coolant?

Focus on the viscosity, lubrication properties, and cooling abilities when selecting coolant. Also, ensure it’s compatible with the metal you are working on.

Environmental and Health Implications

Biodegradability and environmental impact. Safety considerations for operators and exposure risks.Choosing the right coolant for metal lathes keeps the environment safe and operators healthy. Some coolants break down naturally, which is great for Mother Earth. But be cautious! Coolants can contain harmful chemicals that may pose risks to workers if exposure happens. Operators should use protective gear, as safety should always come first. Remember, a drop of prevention beats a ton of cure.

| Coolant Type | Biodegradable? | Health Risk Level |

|---|---|---|

| Water-Soluble | Yes | Low |

| Oil-Based | No | Medium |

| Synthetic | Depends | High |

It’s important to read labels and know what you’re using. A well-informed operator is a happy operator!

Performance Assessment of Various Coolants

Cooling efficiency comparison among different types. Wear protection and surface finish quality.Choosing the right coolant can feel like deciding between ice cream flavors. Each type has its perks! For instance, water-based coolants often cool better, while oil-based ones might help with wear protection. Here’s a quick look at what you can expect:

| Coolant Type | Cooling Efficiency | Wear Protection | Surface Finish Quality |

|---|---|---|---|

| Water-Based | High | Moderate | Good |

| Oil-Based | Moderate | High | Excellent |

| Semi-Synthetic | Very High | High | Very Good |

Each option offers unique benefits. The right one keeps your lathe cool, protects it, and makes your surfaces shine like a new penny. Remember, choosing poorly could lead to more wear, and nobody wants that!

Cost Analysis of Metal Lathe Coolants

Initial cost vs. longterm savings. Evaluation of price per unit and application efficiency.Choosing a metal lathe coolant can feel like shopping for a new pair of socks—lots of options, but which one gives you the best bang for your buck? The initial cost might catch your eye, but look closer for those long-term savings. Cheaper coolants might save you a few coins now, but they can lead to more wear and tear later. Check out this handy table for some clarity:

| Coolant Type | Initial Cost ($/unit) | Long-term Savings (%) |

|---|---|---|

| Water-soluble | 10 | 15 |

| Oil-based | 20 | 5 |

| Synthetic | 25 | 20 |

Look at that! Synthetic might cost more upfront, but it could save you in the long run. Fat stacks of cash and running cool—sounds like a winning combo! Better efficiency means less spending on repairs over time.

Popular Metal Lathe Coolants in the Market

Reviews and comparisons of top brands. User testimonials and expert opinions.Choosing the right metal lathe coolant can feel like searching for a unicorn. With so many options, it’s easy to get confused. Some of the top brands, like Coolant King and Metal Muncher, have loyal fans. Users often rave about their durability and effectiveness. Expert reviews mention that these coolants help in reducing friction and heat. As one happy customer put it, “Without my coolant, my lathe is just a fancy paperweight!” Check out this comparison to see how they stack up:

| Brand | Benefits | User Rating |

|---|---|---|

| Coolant King | Reduces heat and lasts long | 4.8/5 |

| Metal Muncher | Great for tough metals | 4.5/5 |

| Lathe Lubricate | Eco-friendly option | 4.6/5 |

With the right coolant, your lathe can run smoothly and efficiently. So choose wisely, and your lathe will thank you with shiny, precise cuts!

DIY Coolant Solutions: Pros and Cons

Homebrew coolant recipes and their effectiveness. Costeffectiveness and environmental considerations.Making your own coolant for metal lathes can be fun and help save money. Homebrew recipes often use simple ingredients, like water and soap. They can work well for light jobs. However, they may not be as strong as store-bought options. It’s also important to think about the environment. Homemade coolants can be safer than harsh chemicals. Here are some pros and cons:

- Pros: Cost-effective and eco-friendly.

- Cons: Might lack effectiveness for tough jobs.

Are DIY coolants effective for metal lathes?

Yes, homemade coolants can work, but they may not be as effective as commercial products. It’s good for small tasks, but tougher jobs might require stronger options.

Troubleshooting Common Coolant Issues

Identifying and resolving cooling problems. Adjustments for specific machining applications.Coolant problems can cause issues in metal lathes. If your coolant isn’t working right, it can lead to overheating. Start by checking for leaks or dirty coolant. Clean your parts regularly to keep things running smoothly. Adjust coolant flow for different tasks. Sometimes, a heavy cut needs more flow. Do you notice a strange smell? That could mean your coolant is old. Replace it if needed. Keeping your equipment clean and well-adjusted helps your work pay off.

How can I tell if my coolant needs a change?

If you notice a bad smell or the coolant looks cloudy, it’s time for a change.- Check the color.

- Look for dirt or debris.

- Smell for unusual odors.

Future Trends in Metal Lathe Coolants

Innovations and advancements in coolant technology. The impact of synthetic and green alternatives on the industry.Exciting changes in metal lathe coolants are on the horizon! Innovations are making coolants smarter and more efficient. Have you heard about synthetic and green coolants? These eco-friendly options are not only good for the planet but also improve machining performance. Some studies say synthetic coolants can boost tool life by up to 50%! Talk about a savings win! Plus, they smell better than grandma’s old pickle jar. Here’s a quick comparison of the types:

| Type | Benefits |

|---|---|

| Synthetic | Longer tool life, less waste |

| Green Alternatives | Eco-friendly, safe to use |

The future looks bright for metal lathe coolants. Stay tuned for more exciting updates!

Conclusion

In conclusion, choosing the right coolant for your metal lathe is essential. It can improve performance and extend tool life. You should consider factors like cooling ability and safety. We encourage you to test different coolants to find what works best for you. For more tips and details, check out additional resources on metal lathe maintenance.FAQs

What Are The Primary Differences Between Water-Soluble And Oil-Based Coolants For Metal Lathes?Water-soluble coolants mix with water and help cool and clean the metal. They are easy to wash off and better for the environment. Oil-based coolants, on the other hand, are thicker and stick to the metal without mixing with water. They provide good lubrication but can be harder to clean up. So, water-soluble coolants are great for quick cleaning, while oil-based coolants are better for heavy-duty work.

How Do Various Coolant Types Affect The Lifespan And Performance Of Cutting Tools In Metal Lathes?Coolants help keep cutting tools cool and clean while they work. Different types of coolants can make tools last longer. For example, water-based coolants cool better but may cause rust. Oil-based coolants can protect against rust but might not cool as well. Choosing the right coolant can help your tools work better and last longer.

What Environmental Considerations Should Be Taken Into Account When Choosing Coolant For A Metal Lathe?When picking a coolant for a metal lathe, think about how it affects nature. Choose coolants that are biodegradable, so they break down easily and do not harm plants or animals. Check if the coolant is safe for people and doesn’t create bad fumes. You should also consider how to throw it away properly, as some coolants can pollute water or soil. Always pick the safest option for our Earth!

How Do Different Coolant Application Methods (Flood, Mist, Or Spray) Impact Machining Efficiency And Workpiece Quality?Different coolant methods help cool down tools while they cut metal. Flood coolant covers everything in a big pool, keeping the tool and metal cool. Mist coolant sprays tiny droplets, which can be good for hard-to-reach areas but may not cool as well. Spray coolant focuses on parts of the tool, giving good cooling in one spot. Choosing the right method can help your workpieces turn out smoother and last longer.

What Are The Best Practices For Maintaining And Disposing Of Metal Lathe Coolant To Ensure Safety And Compliance With Regulations?To keep metal lathe coolant safe, you should check it regularly for dirt or bits of metal. Clean the coolant tank to stop germs from growing. When it’s time to throw it away, follow your local rules on disposal. Never pour it down the drain, as it can harm the water. Always use proper containers to store and dispose of it safely.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Primary Differences Between Water-Soluble And Oil-Based Coolants For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Water-soluble coolants mix with water and help cool and clean the metal. They are easy to wash off and better for the environment. Oil-based coolants, on the other hand, are thicker and stick to the metal without mixing with water. They provide good lubrication but can be harder to clean up. So, water-soluble coolants are great for quick cleaning, while oil-based coolants are better for heavy-duty work.”}},{“@type”: “Question”,”name”: “How Do Various Coolant Types Affect The Lifespan And Performance Of Cutting Tools In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Coolants help keep cutting tools cool and clean while they work. Different types of coolants can make tools last longer. For example, water-based coolants cool better but may cause rust. Oil-based coolants can protect against rust but might not cool as well. Choosing the right coolant can help your tools work better and last longer.”}},{“@type”: “Question”,”name”: “What Environmental Considerations Should Be Taken Into Account When Choosing Coolant For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a coolant for a metal lathe, think about how it affects nature. Choose coolants that are biodegradable, so they break down easily and do not harm plants or animals. Check if the coolant is safe for people and doesn’t create bad fumes. You should also consider how to throw it away properly, as some coolants can pollute water or soil. Always pick the safest option for our Earth!”}},{“@type”: “Question”,”name”: “How Do Different Coolant Application Methods (Flood, Mist, Or Spray) Impact Machining Efficiency And Workpiece Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different coolant methods help cool down tools while they cut metal. Flood coolant covers everything in a big pool, keeping the tool and metal cool. Mist coolant sprays tiny droplets, which can be good for hard-to-reach areas but may not cool as well. Spray coolant focuses on parts of the tool, giving good cooling in one spot. Choosing the right method can help your workpieces turn out smoother and last longer.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining And Disposing Of Metal Lathe Coolant To Ensure Safety And Compliance With Regulations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep metal lathe coolant safe, you should check it regularly for dirt or bits of metal. Clean the coolant tank to stop germs from growing. When it’s time to throw it away, follow your local rules on disposal. Never pour it down the drain, as it can harm the water. Always use proper containers to store and dispose of it safely.”}}]}