Have you ever wondered how machinery turns raw metal into beautiful shapes? Entry-level metal lathes are a great place to start exploring this fascinating world. These machines use something called a gear train to help them work. But what exactly does that mean?

Imagine playing with a set of toy gears. Each gear turns and moves the others. This is how a gear train operates in a metal lathe! It helps control the speed and movement of the lathe. This makes sure every cut is just right.

Many people might think metalwork is only for experts. But anyone can learn it! Using an entry-level metal lathe is a fun way to start creating cool projects.

Did you know some famous inventors started with just a simple lathe? They turned their ideas into real tools and machines. You have that same potential! Now, let’s dive deeper into the world of entry-level metal lathes and discover how they work.

Entry-Level Metal Lathe Gear Train: Key Features Explained

Understanding Entry-Level Metal Lathe Gear Train

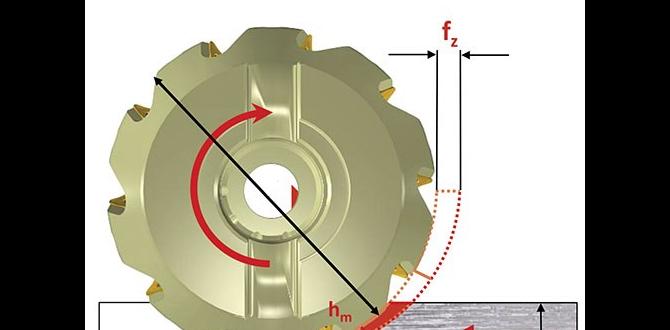

An entry-level metal lathe gear train is essential for beginners in machining. It helps control the lathe’s speed and torque, making it easier to work on different projects. Did you know that the right gear train can improve your work accuracy significantly? By learning proper gearing techniques, you can create precise parts and enhance your skills. Understanding how the gear train operates opens up a world of possibilities for hobbyists and future engineers alike.Components of an Entry-Level Metal Lathe Gear Train

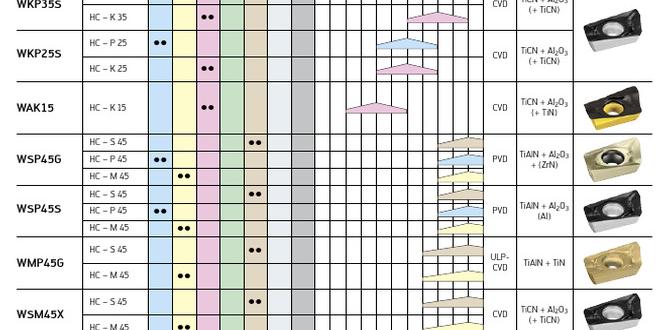

Breakdown of essential parts (gears, bearings, pulleys). Materials used in constructing gear trains.Every entry-level metal lathe gear train has essential parts. These include gears, bearings, and pulleys. Each component plays a special role, like a superhero team. The gears help turn movement, while bearings allow smooth spinning. Pulleys can change direction with the grace of a dancer!

As for materials, most gear trains use strong steel or aluminum. Steel is tough, while aluminum is light. Choosing the right material is like picking the right snack; it makes a big difference in performance!

| Component | Material |

|---|---|

| Gears | Steel or Aluminum |

| Bearings | Plastic or Metal |

| Pulleys | Rubber or Metal |

Fun fact: Did you know that a well-built gear train can last for years? It’s like having a reliable friend who never lets you down!

Advantages of Entry-Level Gear Trains

Benefits for hobbyists and small projects. Costeffectiveness compared to advanced models.Using an entry-level gear train can be a game changer for hobbyists. They are perfect for small projects like model making or DIY crafts. With these lathe machines, you get great precision without breaking the bank. They are often much cheaper than advanced models, leaving you with more cash for snacks—who doesn’t love snacks? Plus, they’re easy to handle, making them a favorite for beginners. In short, these gear trains offer a sweet blend of quality and affordability!

| Advantages | Description |

|---|---|

| Cost-Effective | Affordable compared to advanced models. |

| User-Friendly | Great for beginners and hobby projects. |

| Versatile | Perfect for various small tasks. |

Common Types of Gear Trains in Metal Lathes

Description of different gear train configurations. Comparison of standard versus variable speed gear trains.Many metal lathes use different gear trains, which help machines run smoothly. Standard gear trains have set speeds. They are simple and reliable. But variable speed gear trains allow you to change the speed as needed. This is helpful for different types of jobs. Here are some common types:

- Spur Gear Train

- Helical Gear Train

- Bevel Gear Train

Choosing the right gear train affects the lathe’s performance. It’s important for getting the job done right.

What is the difference between standard and variable speed gear trains?

Standard gear trains have fixed speeds, while variable speed gear trains can adjust speeds based on the task.

How to Choose the Right Gear Train for Your Entry-Level Lathe

Factors to consider (size, power requirements, machine compatibility). Recommendations for specific user needs (budget, project types).Choosing the right gear train for your lathe is important. Here are some factors to think about:

- Size: Make sure the gear train fits your lathe.

- Power Requirements: Check if your machine has enough power.

- Machine Compatibility: Ensure the gear works well with your model.

If you have a tight budget or special projects, look for these:

- Look for gear trains that offer good value.

- Choose one that suits the types of projects you like.

Smart choices can help you enjoy your projects more!

What should you look for when buying a gear train?

You should check size, power needs, and compatibility. These factors will help you find the best one for your lathe.

Maintenance Tips for Metal Lathe Gear Trains

Routine maintenance practices to extend gear life. Troubleshooting common issues with gear trains.Keeping your metal lathe gear train happy is like giving it a spa day! Regular maintenance works wonders. Check for any strange noises—it’s like your lathe is trying to speak its mind. Clean the gears often; dust makes them grumpy! If your lathe acts up, check the alignment first; it’s the biggest troublemaker. Remember, a little grease can go a long way, just like chocolate on a bad day!

| Routine Maintenance | Troubleshooting Tips |

|---|---|

| Check gears for dirt. | Listen for unusual sounds. |

| Lubricate every few weeks. | Inspect alignment regularly. |

| Watch for wear and tear. | Replace damaged parts ASAP. |

Upgrades and Modifications for Entry-Level Lathe Gear Trains

Popular upgrades for performance improvement. DIY modification ideas for enhanced functionality.Upgrading a lathe gear train can really boost performance. Some popular upgrades include adding a better drive belt and using higher-quality bearings. These changes help the machine run smoother. DIY modifications can enhance its use too. For example, you can build a custom tool holder or make a simple speed control. This adds flexibility to your projects. Here are some common ideas:

- Install a stronger motor

- Add a tachometer for speed tracking

- Use a better lubrication system

These simple upgrades and modifications can greatly improve your lathe’s efficiency and functionality.

What are good upgrades for entry-level lathes?

Common upgrades include better drive belts, high-quality bearings, and stronger motors.

What DIY modifications can enhance functionality?

Building custom tool holders and adding speed controls are great DIY projects.

Safety Precautions When Using Metal Lathe Gear Trains

Essential safety measures during operation. Importance of proper training and understanding machining tools.Using a metal lathe can be fun, but safety is super important! Always wear protective gear, like goggles and gloves, to shield yourself from flying bits. Knowing how to use your tools is key. Proper training helps you avoid accidents. Remember, you don’t want to turn into a metal sculpture yourself! Here’s a quick safety tips table:

| Safety Measure | Description |

|---|---|

| Protective Gear | Wear safety goggles and gloves to protect yourself. |

| Proper Training | Understand how to use the lathe before starting. |

| Workspace Cleanliness | Keep the area tidy to avoid trips and falls. |

With these tips, you’re on the right path to safely enjoy your metalworking adventure! Remember, safety first—sculpting shouldn’t involve getting chiseled yourself!

Conclusion

In summary, an entry-level metal lathe gear train helps you create accurate parts. Understanding its components is important for smooth operation. You’ll learn about speed, torque, and efficiency while working with it. If you’re interested, explore more about gear mechanics and improve your skills. Your journey in metalworking can be exciting and rewarding! Keep practicing and learning!FAQs

Sure! Here Are Five Questions Related To Entry-Level Metal Lathe Gear Trains:Sure! Here are five questions related to entry-level metal lathe gear trains: 1. What is a metal lathe? A metal lathe is a machine that spins metal to shape it. You can use it to make different parts. 2. Why do we need gear trains? We need gear trains to change the speed and power of the lathe. They help us control how fast the metal spins. 3. How do we choose the right gear? We choose the right gear based on the project. You need to think about the size and speed needed. 4. What happens if the gears don’t match? If the gears don’t match, the lathe might not work well. It can be slower or even break. 5. How can I learn more about gears? You can learn more about gears by watching videos or reading books about lathes and machines.

Sure! Please provide me with the question you’d like me to answer.

What Is The Primary Function Of A Gear Train In An Entry-Level Metal Lathe?A gear train helps a metal lathe turn at different speeds. It uses gears to change how fast the machine spins. You can pick a speed that works best for your project. This makes it easier to cut metal shapes just right.

How Do Different Gear Ratios In The Gear Train Affect The Cutting Speed And Torque Of The Lathe?Different gear ratios change how fast the lathe spins and how much power it uses. A higher gear ratio makes the lathe turn faster but gives less power. This is good for lighter jobs. A lower gear ratio makes it turn slower but gives more power, perfect for tough jobs. So, you can pick the right gear ratio for what you’re making!

What Are Common Materials Used For Gears In Entry-Level Metal Lathes, And How Do They Impact Performance And Durability?Common materials for gears in entry-level metal lathes include plastic, aluminum, and steel. Plastic gears are light and quiet but can wear out quickly. Aluminum gears are stronger and last longer, making them a good choice for beginners. Steel gears are the toughest, giving the best performance and durability. The choice of material affects how long the gears will last and how well they work.

How Does One Calculate The Gear Ratio In A Metal Lathe’S Gear Train, And Why Is This Calculation Important For Machining Operations?To calculate the gear ratio in a metal lathe, you divide the number of teeth on one gear by the number of teeth on another gear. For example, if one gear has 20 teeth and another has 10 teeth, the ratio is 20 divided by 10, which equals 2. This means the first gear turns twice for every turn of the second gear. Knowing the gear ratio helps you understand how fast or slow the lathe will turn, which is important for making accurate cuts. It ensures you can create the right shapes and sizes in metal.

What Maintenance Practices Are Recommended For Ensuring The Longevity Of The Gear Train In An Entry-Level Metal Lathe?To keep the gear train in a metal lathe working well, you should oil it regularly. Make sure you clean off any dirt and dust. Check for any loose parts and tighten them if needed. Always follow the manufacturer’s instructions to know how and when to do these tasks. This will help your lathe last longer.