Have you ever watched a metal lathe in action? It’s amazing how it shapes metal into precise parts. But did you know that one of the most important safety features is the metal lathe foot brake?

This tool can make a big difference in your workspace. Imagine you’ve just finished a project. The machine is still spinning, and suddenly, you need to stop it quickly. Without a foot brake, stopping safely can be tricky.

Essential tools like the metal lathe foot brake keep us safe. They give us control, making our work easier and more efficient. What if you could learn to use this brake to avoid accidents? Knowing how and when to use it is key.

Curious about how a simple foot brake can improve your metalworking? Let’s explore why this essential tool is a must-have for every metal lathe user. You might be surprised by the difference it can make!

Essential Tools For Metal Lathe: Foot Brake Importance

Essential Tools: Metal Lathe Foot Brake

The metal lathe foot brake is a crucial safety feature. It allows quick stops during operation, preventing accidents. Have you ever thought about how fast machines move? With a foot brake, users can feel much safer. It gives them control during heavy cutting tasks. A well-installed brake improves efficiency too. Discovering how this simple tool enhances safety may surprise you! Knowing about the foot brake can boost your confidence when using a metal lathe.Key Components of a Metal Lathe Foot Brake

Explanation of the mechanical parts involved. Discussion of the materials used for durability and effectiveness.A metal lathe foot brake has several key parts that work together to keep things safe and sound. The main parts include the pedal, linkage, and the brake assembly. The pedal is like a superhero; it helps stop the machine quickly! It is usually made from strong materials like steel or aluminum that won’t bend under pressure. The linkage connects the pedal to the brakes, allowing for smooth movement. Many manufacturers also choose high-quality rubber for grips, providing comfort and preventing foot slips during use. Who knew safety could be so… “foot-tastic”?

| Component | Material | Function |

|---|---|---|

| Pedal | Steel | Stops the machine |

| Linkage | Aluminum | Connects pedal to brakes |

| Grip | Rubber | Prevents slippage |

Benefits of Using a Foot Brake in Metal Lathes

Enhanced safety measures for operators. Improved precision and control during machining.A foot brake on a metal lathe provides key benefits. First, it greatly enhances safety for operators. It allows quick stopping, preventing accidents and injuries. Second, it improves precision during machining. Operators gain better control over the machine, leading to cleaner cuts. This combination makes working with lathes safer and more efficient.

Why is a foot brake important in metal lathes?

The importance lies in its ability to boost safety and increase control over the machinery. Quick stopping can save lives.

Benefits:

- Enhanced Safety: Rapid stopping reduces risks.

- Improved Control: Better precision in cuts and actions.

Installation Process of a Foot Brake

Stepbystep installation guide. Common mistakes to avoid during installation.Installing a foot brake for your metal lathe is a key step. Follow these simple steps for a successful setup:

- Gather your tools and safety gear.

- Read the instruction manual carefully.

- Position the foot brake under the lathe.

- Connect wires to the motor, following the color code.

- Secure all parts tightly.

- Test the foot brake before using the lathe.

Common mistakes to avoid:

- Not reading the manual thoroughly.

- Skipping safety checks.

- Loose connections that can cause failure.

Taking your time helps ensure safety and success!

How do I install the foot brake?

Start by gathering tools, following the manual, and ensuring proper connections. Always double-check your work before using the machine.

Maintenance Tips for Metal Lathe Foot Brakes

Regular checks and necessary adjustments. Recommended cleaning and lubrication practices.Keeping foot brakes in good shape is key for safety and performance. Regular checks help spot issues early. Here are some tips:

- Inspect for wear or damage often.

- Adjust the brake if it feels loose.

- Clean the brake area with a damp cloth.

- Use the right lubricant for smooth operation.

By following these simple steps, you can keep your metal lathe foot brake working well.

What are the signs of brake issues?

You might notice strange noises, reduced stopping power, or a wobbly pedal. If you see any of these signs, check the brake immediately.

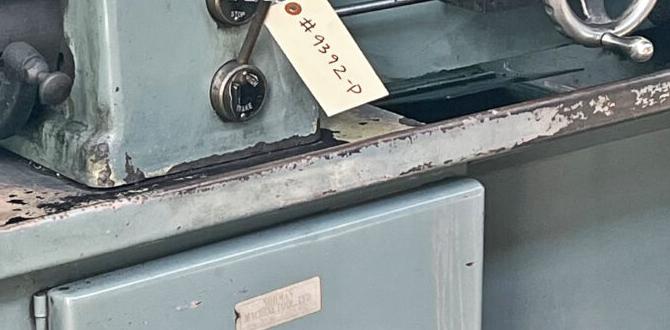

Popular Foot Brake Models for Metal Lathes

Comparison of toprated models on the market. Features and specifications that stand out.Different foot brake models suit various metal lathes. Let’s check out some popular ones!

- Model A: Known for quick response and firm grip.

- Model B: Features a safety latch and a larger pedal.

- Model C: Lightweight design, perfect for easy installation.

Each model has unique features. Model A focuses on speed, while Model B emphasizes safety. Model C is user-friendly for beginners. Choose wisely for the best metal lathe experience!

What are the top features to look for in a foot brake?

Key features include durability, responsiveness, and ease of use. A good foot brake should last a long time and work quickly.

Common Issues with Foot Brakes and Troubleshooting

List of frequent problems encountered. Effective troubleshooting methods and solutions.Foot brakes can sometimes act like a temperamental cat—unpredictable and a bit stubborn! Common issues include brakes sticking, strange noises, or not responding at all. These pesky problems make it tough to keep your metal lathe running smoothly. But don’t panic! Here are some troubleshooting tips to help you out:

| Problem | Solution |

|---|---|

| Brake sticks | Check for any dirt or debris. Clean it up! |

| Strange noises | Look for loose parts. Tighten them! |

| No response | Inspect wiring connections. Ensure they’re secure! |

Following these steps can save your day and keep your lathe in tip-top shape! Remember, a well-maintained foot brake is a happy foot brake!

Comparison: Foot Brake vs. Hand Brake in Metal Lathes

Pros and cons of each braking system. Situational preferences: when to use one over the other.Foot brakes and hand brakes serve the same purpose in metal lathes, but each has its quirks. The foot brake keeps your hands free for other tasks. You can stomp it like a bug when you need to stop quickly! However, it can be tricky to control sometimes. The hand brake is more precise, letting you stop gently. Still, you might need to stretch to reach it, like trying to grab the last cookie on the top shelf! Below is a quick comparison:

| Brake Type | Pros | Cons | Best Use Situation |

|---|---|---|---|

| Foot Brake | Hands-free operation | Less control | Quick stops |

| Hand Brake | Precise stopping | Requires hand reach | Delicate work |

So, next time you’re in the shop, pick your brake wisely. Your project might thank you—or at least not turn into a big mess!

Expert Tips for Optimizing Your Metal Lathe Foot Brake

Usage techniques for maximizing efficiency. Upgrades and accessories that complement foot brakes.To make your metal lathe foot brake work better, focus on two things: how you use it and what extras you can add. Proper foot placement helps control your movements. This ensures safety and skill. Adding upgrades like a stronger spring can improve response. Accessories, such as a foot pedal extension, can help reach the brake easily. Remember these tips to maximize your work efficiency.

What are the best usage techniques for a metal lathe foot brake?

Proper foot placement and steady pressure improve safety and control.Additional Accessories for Foot Brakes

- Foot pedal extension for better reach

- Upgraded springs for quicker response

- Non-slip mats for better grip

Conclusion

In summary, the foot brake is an essential tool for metal lathes. It ensures your safety while working and helps control the machine effectively. You should always check its condition before use. We encourage you to learn more about it and practice using it safely. This will help you become a better machinist and enjoy your projects even more!FAQs

Here Are Five Related Questions On The Topic Of Essential Tools For A Metal Lathe Foot Brake:A foot brake for a metal lathe helps you stop the machine quickly and safely. It’s important for protecting you and others nearby. Some essential tools you might need include a screwdriver, a wrench, and safety goggles. Always wear your goggles when working to keep your eyes safe. Make sure everything is tight and in working order before using the lathe.

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Primary Functions Of A Foot Brake On A Metal Lathe, And How Does It Enhance Safety During Operation?The foot brake on a metal lathe helps you stop the machine quickly. When you press it, the lathe slows down fast. This is important because it keeps you safe while you work. If something goes wrong, you can quickly stop and avoid accidents. So, using the foot brake makes it easier for you to stay safe.

How Do You Properly Install And Adjust A Foot Brake On A Metal Lathe To Ensure Optimal Performance?To install a foot brake on a metal lathe, first make sure the lathe is off. You attach the brake to the base of the lathe using screws. Next, connect the brake pedal to the brake mechanism. To adjust it, press the pedal to see if it stops the lathe quickly. If it doesn’t, loosen the adjustment screw and move it slightly, then try again. Keep adjusting until it works just right.

What Types Of Foot Brake Systems Are Available For Metal Lathes, And What Are The Advantages And Disadvantages Of Each?There are two main types of foot brake systems for metal lathes: mechanical and electrical brakes. Mechanical brakes work with levers and cables. They are simple and easy to fix if needed. However, they can wear out over time and may require more effort to use. Electrical brakes use motors to stop the lathe. They are quick and smooth, making it easier to stop. On the downside, they can be more costly and may need special upkeep.

How Can Regular Maintenance Of A Foot Brake Contribute To The Longevity And Safety Of A Metal Lathe?Regularly checking the foot brake on a metal lathe helps it work better and last longer. If we keep it in good shape, it stops the machine safely. This makes sure we won’t get hurt while using the lathe. Taking care of the brake also means it won’t break down as quickly. So, we stay safe, and the lathe stays in great condition!

What Are Some Common Issues Users Face With Metal Lathe Foot Brakes, And How Can These Be Effectively Resolved?Users often face problems with metal lathe foot brakes not stopping or being hard to press. This can happen if dirt gets in the brakes or if they are worn out. To fix this, you should clean the area and make sure everything is tight. If the brake still doesn’t work, you might need to replace it. Always check your manual for help!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Essential Tools For A Metal Lathe Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A foot brake for a metal lathe helps you stop the machine quickly and safely. It’s important for protecting you and others nearby. Some essential tools you might need include a screwdriver, a wrench, and safety goggles. Always wear your goggles when working to keep your eyes safe. Make sure everything is tight and in working order before using the lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of A Foot Brake On A Metal Lathe, And How Does It Enhance Safety During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foot brake on a metal lathe helps you stop the machine quickly. When you press it, the lathe slows down fast. This is important because it keeps you safe while you work. If something goes wrong, you can quickly stop and avoid accidents. So, using the foot brake makes it easier for you to stay safe.”}},{“@type”: “Question”,”name”: “How Do You Properly Install And Adjust A Foot Brake On A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a foot brake on a metal lathe, first make sure the lathe is off. You attach the brake to the base of the lathe using screws. Next, connect the brake pedal to the brake mechanism. To adjust it, press the pedal to see if it stops the lathe quickly. If it doesn’t, loosen the adjustment screw and move it slightly, then try again. Keep adjusting until it works just right.”}},{“@type”: “Question”,”name”: “What Types Of Foot Brake Systems Are Available For Metal Lathes, And What Are The Advantages And Disadvantages Of Each?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are two main types of foot brake systems for metal lathes: mechanical and electrical brakes. Mechanical brakes work with levers and cables. They are simple and easy to fix if needed. However, they can wear out over time and may require more effort to use. Electrical brakes use motors to stop the lathe. They are quick and smooth, making it easier to stop. On the downside, they can be more costly and may need special upkeep.”}},{“@type”: “Question”,”name”: “How Can Regular Maintenance Of A Foot Brake Contribute To The Longevity And Safety Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regularly checking the foot brake on a metal lathe helps it work better and last longer. If we keep it in good shape, it stops the machine safely. This makes sure we won’t get hurt while using the lathe. Taking care of the brake also means it won’t break down as quickly. So, we stay safe, and the lathe stays in great condition!”}},{“@type”: “Question”,”name”: “What Are Some Common Issues Users Face With Metal Lathe Foot Brakes, And How Can These Be Effectively Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Users often face problems with metal lathe foot brakes not stopping or being hard to press. This can happen if dirt gets in the brakes or if they are worn out. To fix this, you should clean the area and make sure everything is tight. If the brake still doesn’t work, you might need to replace it. Always check your manual for help!”}}]}