Have you ever wondered how metal shapes into precise parts? A heavy duty metal lathe plays a big part in that process. Imagine a machine that spins metal to create unique shapes. It’s like magic but with hard work and skill!

One of the most important parts of this machine is the compound rest. This piece helps workers adjust the tool’s position easily. With the right settings, it can make curved cuts or straight lines. Isn’t it cool how one part can change everything?

Many people use heavy duty metal lathes for different projects. From making tools to crafting art, these machines help bring ideas to life. Have you ever seen one in action? It’s fascinating to watch how metal transforms under the right conditions.

In this article, we will explore the magic behind the heavy duty metal lathe compound rest. We will learn how it works and why it is so important. Get ready to dive into the world of lathes!

Heavy Duty Metal Lathe Compound Rest: Essential Features And Benefits

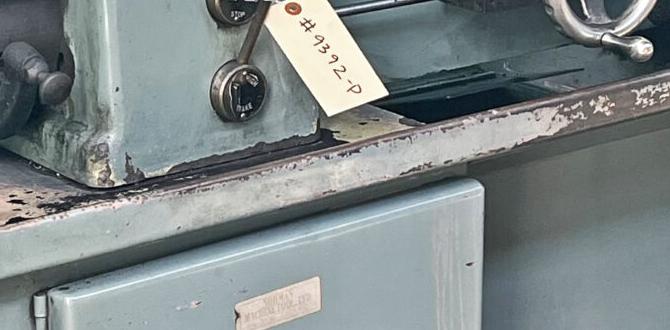

Heavy Duty Metal Lathe Compound Rest

The heavy duty metal lathe compound rest is essential for precise machining. It helps shape materials accurately, making tasks easier and more efficient. Think about how cool it is to create custom parts! This tool allows users to position the cutting tool accurately. Many say it improves their lathe’s performance significantly. With a robust compound rest, projects can go from just an idea to reality, making metalworking fun and satisfying. Who wouldn’t want to try that?What is a Heavy Duty Metal Lathe Compound Rest?

Definition and purpose of the compound rest. Importance in metalworking and machining process.A heavy duty metal lathe compound rest is a trusty tool in the world of machining. Think of it as a helper that holds the cutting tool steady as it spins and carves metal into shape. This part is crucial in metalworking because it allows for precise adjustments. Without it, turning metal would be like trying to cut cake with a wobbly knife—messy! The compound rest makes sure everything stays in line, keeping your projects neat and tidy. Just like a cat needs a sunny spot, a lathe needs a solid compound rest!

| Definition | Importance |

|---|---|

| Holds the cutting tool steady | Ensures precision in metalworking |

| Allows for angle adjustments | Makes projects neat and clean |

Key Features of Heavy Duty Metal Lathe Compound Rests

Construction materials and durability. Design aspects for precision and stability. Adjustable components and their functions.Heavy duty metal lathe compound rests are built for strength. They use tough materials that resist wear and tear, ensuring they last a long time. Their design promotes stability and precision, which is vital when shaping materials. Plus, many parts can be adjusted easily. This means you can tailor them to suit your projects perfectly. Think of it as having a best friend that always helps you get things just right! Check out the table below to see some of their key features.

| Feature | Description |

|---|---|

| Material | Durable steel for longevity |

| Design | Sturdy base for maximum stability |

| Adjustability | Easy adjustments for various functions |

Benefits of Using a Heavy Duty Metal Lathe Compound Rest

Enhanced accuracy and control in turning operations. Increased versatility for various machining tasks. Reduction of wear and tear on the lathe.Using a heavy duty metal lathe compound rest brings many advantages. First, it offers enhanced accuracy and control in your turning tasks. This means your projects come out looking sharp and precise—like they were made by a robot! Second, it boosts versatility. You can tackle a variety of machining tasks that make your workshop feel like a magic shop. Lastly, it helps to reduce wear and tear on the lathe itself, keeping it happy and healthy for longer. Think of it as giving your lathe a spa day!

| Benefit | Explanation |

|---|---|

| Accuracy | Improves precision in turning operations. |

| Versatility | Can handle many machining tasks with ease. |

| Durability | Reduces wear on the lathe, making it last longer. |

Factors to Consider When Choosing a Heavy Duty Metal Lathe Compound Rest

Weight and size compatibility with your lathe. Range of movement and degrees of freedom. Quality assurance and brand reputation.Choosing the right heavy duty metal lathe compound rest is important. First, check the weight and size compatibility with your lathe. The rest should fit well and support its weight. Next, consider the range of movement. A good rest allows you to move freely and easily. Lastly, look at the brand reputation. High-quality brands ensure reliability and safety. Trustworthy brands often provide better support and longer-lasting products.

What factors should I care about when selecting a metal lathe compound rest?

You should care about weight and size, range of movement, and brand quality.

Key Points:

- Weight and size fit your lathe

- Allow for easy movement

- Choose trusted brands

Common Applications for Heavy Duty Metal Lathe Compound Rests

Precision machining in industrial settings. Prototyping and custom fabrication projects. Hobbyist uses and DIY applications.Heavy duty metal lathe compound rests are true workhorses in many settings. They help with precision machining in factories and workshops, where every tiny detail matters. These tools aren’t just for pros; hobbyists love them too! Whether creating a custom part or trying a DIY project, they offer endless possibilities. In the world of prototyping, they make ideas come to life. Remember, without a good lathe, we’re just spinning our wheels—literally!

| Application | Description |

|---|---|

| Precision Machining | Used in industries for exact cuts. |

| Prototyping | Perfect for creating custom designs. |

| Hobbyist Projects | Great tool for DIY enthusiasts. |

Maintenance Tips for Heavy Duty Metal Lathe Compound Rests

Regular cleaning and lubrication practices. Inspection for wear and potential issues. Adjustments and alignments for optimal performance.Keeping your heavy duty metal lathe compound rest in great shape is a breeze! Start off with regular cleaning. Dust and grime can be sneaky, so a quick wipe down helps. Don’t forget the oil! A bit of lubrication keeps everything moving smoothly. Inspect for wear often. A little crack can turn into a big problem. And remember to check those adjustments and alignments. This ensures your lathe works its best, like a well-choreographed dance—no stepping on toes allowed!

| Maintenance Task | Frequency |

|---|---|

| Cleaning | After each use |

| Lubrication | Weekly |

| Inspection | Monthly |

| Adjustments | As needed |

Comparison with Other Types of Compound Rests

Advantages of heavy duty over standard models. Situations where different types might be preferred. Cost analysis and longterm value considerations.The heavy duty metal lathe compound rest is stronger than standard models. It can handle bigger jobs with ease. Here are some reasons why one might choose a heavy duty version:

- Better stability for tricky tasks.

- Longer lifespan, making it a good long-term investment.

- Higher precision, helping to create sharp cuts.

However, standard models are lighter and cheaper, good for smaller projects. Weighing the benefits can save money in the long run.

What are the benefits of heavy duty compound rests?

Heavy duty compound rests offer better stability, durability, and precision than standard models, making them ideal for larger projects and tough materials.

User Reviews and Experiences with Heavy Duty Metal Lathe Compound Rests

Feedback from professionals in the industry. Insights from hobbyists and DIY users. Case studies on operational success stories.User feedback on heavy-duty metal lathe compound rests reveals a mix of humorous yet insightful thoughts. Professionals often praise their robustness and precision. One expert amusingly noted, “It’s so sturdy, it could survive a bear hug!” Hobbyists appreciate its ease of use and versatility. They share stories of turning simple projects into masterpieces. Below is a summary of user experiences:

| User Type | Feedback |

|---|---|

| Professionals | Admire durability and accuracy. |

| Hobbyists | Enjoy simplicity and creativity boost. |

| DIY Users | Achieve impressive results with ease. |

Many report operational successes. One DIY user celebrated their new lathe by creating a wooden bowl that made a perfect fruit holder. These stories highlight the joy that heavy-duty metal lathe compound rests bring to users, whether they’re seasoned pros or enthusiastic beginners.

Conclusion

In summary, a heavy-duty metal lathe compound rest is essential for precision and stability in your projects. It helps you create accurate pieces with ease. By understanding its features, you can choose the right one for your needs. Explore more about lathes to improve your skills, and start crafting today!FAQs

Sure! Here Are Five Related Questions About Heavy Duty Metal Lathe Compound Rests:Sure! A heavy-duty metal lathe is a big machine used to make round shapes from metal. The compound rest is a part of the lathe that helps you move and position the cutting tool. It allows you to make precise cuts and shapes. You can adjust it for better control while working. This makes your projects easier and more accurate!

Sure! Please provide the question you’d like me to answer.

What Are The Key Components Of A Heavy Duty Metal Lathe Compound Rest And How Do They Function Together?A heavy-duty metal lathe compound rest has a few important parts. First, there’s the base, which holds everything steady. Then, we have the cross slide, which moves back and forth. The top slide allows for more tiny movements to shape metal. All these parts work together to help you carve and shape metal pieces smoothly and accurately.

How Can The Adjustment Of The Compound Rest Enhance Precision In Machining Operations On A Lathe?Adjusting the compound rest on a lathe helps you cut at different angles. This makes your work more accurate and neat. You can easily change the position, so your cuts are better shaped. By using it correctly, you can create smoother and more precise parts. This means your projects will turn out just how you want them!

What Materials Are Typically Used In The Construction Of Heavy Duty Metal Lathe Compound Rests, And How Do These Materials Affect Performance?Heavy-duty metal lathe compound rests are usually made from cast iron, steel, or aluminum. Cast iron is strong and helps reduce vibrations, making cutting smoother. Steel is tough and can handle heavy work without bending. Aluminum is lightweight, which makes it easier to move but might not be as strong. Each material helps your lathe work better in different ways!

How Do You Perform Maintenance And Calibration On The Compound Rest Of A Heavy Duty Metal Lathe To Ensure Optimal Accuracy?To keep the compound rest of a heavy-duty metal lathe working well, first, clean it with a soft cloth. Next, check for any loose screws and tighten them if needed. You can adjust the rest by using the dials to line it up correctly. Finally, test it by making some small cuts and see if everything is straight. If it’s not right, you might need to adjust it again.

What Common Challenges Or Issues Might Arise When Using A Compound Rest On A Heavy Duty Metal Lathe, And How Can They Be Addressed?When using a compound rest on a heavy-duty metal lathe, you might face a few problems. One issue is that it can get stuck, making it hard to adjust. You can fix this by keeping it clean and lubricated. Another problem is precision. If it’s not set correctly, your work might not turn out right. To solve this, double-check your measurements before you start cutting.