Heavy Duty Metal Lathe Gear Train: Understanding Its Importance

Heavy Duty Metal Lathe Gear Train

The heavy duty metal lathe gear train is vital for precise machining. It transfers motion from the motor to the lathe, allowing it to cut and shape metal accurately. Did you know that a robust gear train enhances the machine’s lifespan? With fewer breakdowns, you save time and money. Proper maintenance, like lubrication and inspection, keeps the gears in top shape. Understanding this gear train can boost your craftsmanship and help you tackle bigger projects!What is a Heavy Duty Metal Lathe?

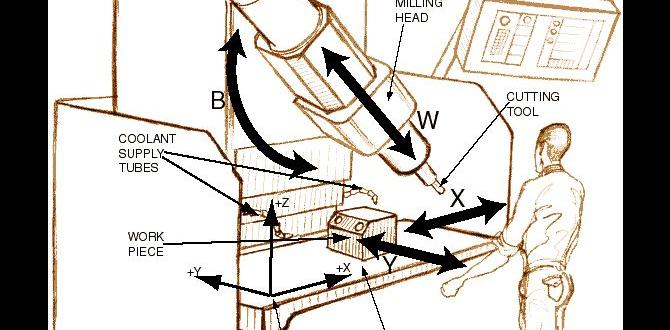

Definition and purpose of heavy duty metal lathes. Key features distinguishing heavy duty models from standard lathes.A heavy duty metal lathe is a powerful machine used for shaping metal. It turns raw metal into useful parts. These lathes are special because they can handle larger materials and tougher jobs than standard lathes. Key features include:

- Robust Construction: Built with sturdy materials for durability.

- Higher Weight Capacity: Can support heavier workpieces.

- Precision Controls: Allows for detailed adjustments during operation.

- Advanced Gear Train: Offers better torque for tough cutting.

Using a heavy duty lathe means greater efficiency and better results in metalworking.

What is the role of the gear train?

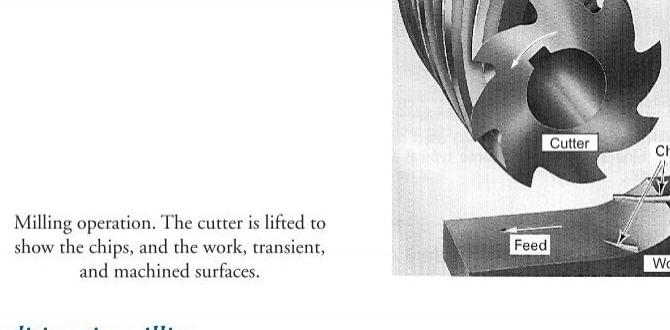

The gear train is crucial. It transfers power to the cutting tool. It helps in maintaining speed and precision.

The Importance of Gear Trains in Metal Lathes

Explanation of gear train functionality in lathes. Benefits of a welldesigned gear train in heavy duty operations.Gear trains play a vital role in metal lathes. They help transfer power from the motor to the cutting tool. This ensures the tool moves smoothly and does its job well. A well-designed gear train can bring many benefits:

- Increased torque for heavy tasks.

- Better control for precise cuts.

- Improved durability for long-term use.

Using quality gear trains is important, especially in heavy-duty operations. They help machines run efficiently and last longer. Overall, good gear trains support better performance and high-quality work.

What is the main role of gear trains in metal lathes?

The main role of gear trains in metal lathes is to transfer power effectively. They connect the motor to the cutting tool, allowing smooth and accurate movement during operation.

Types of Gear Trains Used in Heavy Duty Lathes

Comparison of different gear train configurations (e.g., simple, compound). Advantages and disadvantages of each type for various applications.There are different types of gear trains in heavy-duty lathes. Two common types are simple and compound gear trains. A simple gear train has fewer parts and is easier to manage. It offers a straightforward design but can have limited speeds. A compound gear train, with its multiple gears, allows for higher speeds and versatile operations but can be more complex. Here’s how they compare:

- Simple Gear Train:

- Advantages: Easy to use, fewer repairs needed.

- Disadvantages: Limited speed options.

- Compound Gear Train:

- Advantages: Greater speed and flexibility.

- Disadvantages: More maintenance required, harder to operate.

What is the best type of gear train for heavy-duty lathes?

The best type depends on the task. For simple jobs, a simple gear train works well. For complex jobs needing speed, a compound gear train is better.

How to Choose the Right Gear Train for Your Heavy Duty Metal Lathe

Factors to consider (torque requirements, machining precision). Guidelines for selecting the appropriate gear ratio.Choosing the right gear train can feel like finding a needle in a haystack. First, consider torque requirements. Torque speaks to the power your machine needs to cut through tough materials. Next up is machining precision. A high precision level ensures your work is smooth and accurate, like a well-trained squirrel on a tightrope. Finally, the gear ratio is crucial. A higher ratio gives you more torque, but less speed. Balance is key! Check out the table below for quick tips on selecting your gear train:

| Factor | Consideration |

|---|---|

| Torque Requirements | Determine the material type and thickness |

| Machining Precision | Higher precision needs may require lower gear ratios |

| Gear Ratio | Decide between speed and power based on your projects |

Common Issues and Solutions with Gear Trains in Lathes

Identifying typical problems (wear and tear, misalignment). Recommended maintenance practices and troubleshooting tips.Gear trains in lathes can sometimes feel like an old pair of shoes—worn out and a bit squeaky. Common issues include wear and tear and misalignment. These problems can lead to poor performance. Regular maintenance is key! Check for loose parts and clean them often to keep everything running smoothly. If you hear funny noises, don’t ignore them! A little troubleshooting goes a long way in making your lathe happy.

| Common Problem | Solution |

|---|---|

| Wear and Tear | Regularly inspect and replace worn parts. |

| Misalignment | Adjust the gear train for proper alignment. |

| Noisy Operation | Lubricate moving parts and check for loose fittings. |

Upgrades and Modifications for Enhanced Gear Train Performance

Popular upgrades for improving lathe efficiency. How modifications can impact overall performance and longevity.Upgrading your lathe can make a big difference. Many people choose to enhance their gear train for better results. Popular upgrades include:

- New gears for smoother operation

- Bearing replacements for reduced friction

- Motor enhancements for increased power

These modifications can boost efficiency and extend the life of your machine. Making these changes helps your lathe work faster and last longer. More efficiency means more work done in less time!

How do upgrades affect lathe performance?

Upgrades can dramatically improve lathe performance and extend its lifespan.What are some common upgrades?

- Replacing gears

- Adding better bearings

- Installing a more powerful motor

Case Studies: Successful Implementations of Heavy Duty Metal Lathe Gear Trains

Examples of businesses benefiting from customized gear trains. Lessons learned and best practices shared from the field.Many businesses have struck gold with customized gear trains. For example, a small shop increased their productivity by 40% after upgrading to a heavy-duty metal lathe gear train. That’s not just a fancy upgrade; it means less time spent waiting and more time creating! Lessons learned? Make sure to tailor gear trains to specific needs. Oddly enough, one company discovered that sometimes, simpler is better. They saved costs and improved efficiency by sticking to the basics.

| Business Type | Improvement |

|---|---|

| Small Machining Shop | 40% increase in productivity |

| Large Manufacturing Firm | 20% cost savings |

Future Trends in Heavy Duty Metal Lathe Gear Train Technology

Innovations on the horizon (smart technology, automation). Predictions for gear train advancements in metalworking industries.Exciting changes are coming for heavy duty metal lathe gear trains. Smart technology will help machines work better. Automation will make processes faster. These innovations will improve how we make parts in factories.

- Improved precision and efficiency

- Enhanced safety features

- Reduction in human error

Experts think gear trains will evolve quickly. They will become more powerful and adaptable. This will help workers create high-quality products with less effort.

What are the future advancements in gear train technology?

Expect smarter machines, faster operations, and better safety in gear train technology, which will benefit many industries.

Conclusion

In summary, a heavy-duty metal lathe gear train is essential for strong and precise machining. It helps you create accurate parts and handle tough materials. Understanding how gear trains work lets you improve your projects and skills. If you’re interested, explore more about lathe types and gear design. With practice and knowledge, you can master this important tool!FAQs

Sure! Here Are Five Related Questions On The Topic Of Heavy Duty Metal Lathe Gear Trains:Of course! A heavy-duty metal lathe is a machine that helps us shape metal. Gear trains in a lathe are like a team of gears working together to change how fast the machine turns. This helps us make different shapes and sizes of metal pieces. By using the right gear train, you can make your lathe stronger and more efficient. It’s important to understand how they work to use the machine well!

Sure! Please provide the question you would like me to answer.

What Are The Key Components Of A Heavy Duty Metal Lathe Gear Train, And How Do They Function Together To Transmit Power?A heavy-duty metal lathe gear train has several important parts. First, there are gears that are round wheels with teeth. These gears connect to each other to make movement easier. When one gear turns, it makes the next gear turn too. This helps power move through the machine so it can cut metal smoothly.

How Does The Gear Ratio In A Metal Lathe Gear Train Affect The Cutting Speed And Torque During Machining Operations?The gear ratio in a metal lathe controls how fast the cutting tool spins. A higher gear ratio means the tool spins faster, giving you a quicker cutting speed. But, this can reduce the strength, or torque, of the tool. If you want more power for tough jobs, a lower gear ratio is better. We need to find a balance for each type of work we do.

What Are The Common Materials Used For Manufacturing Gears In A Heavy Duty Metal Lathe, And Why Are These Materials Preferred?Common materials for making gears on a heavy-duty metal lathe include steel, aluminum, and plastic. We prefer steel because it is strong and lasts a long time. Aluminum is lightweight, which helps when we need to move things easily. Plastic is good for quieter machines and is cheaper. These materials help gears work well and last longer.

How Can Gear Wear And Backlash In A Metal Lathe Gear Train Impact Precision And Accuracy During Machining?When gears in a metal lathe wear out or get loose, they don’t fit together well. This can cause something called backlash, which is like a delay when you turn the machine. When this happens, the cutting tool might not go to the correct spot. So, the pieces you make can be a little off, making them less precise and accurate. To make good parts, we need gears that fit tightly and work smoothly.

What Maintenance Practices Are Recommended To Ensure Optimal Performance And Longevity Of A Heavy Duty Metal Lathe Gear Train?To keep your heavy-duty metal lathe gear train working well, you should clean it regularly. Dust can make it dirty and slow. Check the gears for signs of wear and tear and fix them if needed. Add oil to keep everything moving smoothly and reduce noise. Lastly, always read the manual for specific instructions.