Choosing the right high-feed milling cutter can feel like a big puzzle. Have you ever wondered how experts pick the best tools for their jobs? A well-chosen milling cutter can save time and money. It can also make any project smoother.

Imagine you’re building a model airplane. If you have the right tools, you can create something amazing. The same goes for machining. High-feed milling cutters help machinists create precise parts quickly.

Did you know that selecting the right cutter can increase efficiency by up to 50%? That’s a huge boost! In this article, we will explore what makes a high-feed milling cutter special. You’ll learn tips on how to choose the best cutter for your needs.

So, whether you are a seasoned pro or just starting, understanding cutter selection is key. Let’s dive into the world of high-feed milling cutters and uncover the secrets to making the best choice!

High-Feed Milling Cutter Selection: Key Factors & Tips

High-Feed Milling Cutter Selection

Selecting the right high-feed milling cutter is crucial for efficiency. A good cutter can enhance speed and reduce costs. Look for a design that fits your specific material and task. Think about factors like cutting depth and width. Choosing high-quality materials improves durability. Did you know that a well-selected cutter can increase your machining productivity by up to 50%? Always consider each cutter’s unique features to find the best match for your project.Understanding High-Feed Milling

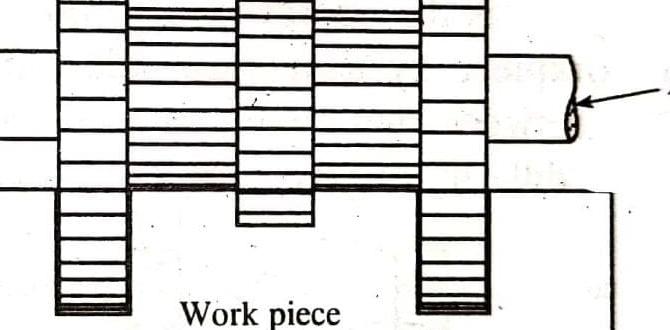

Definition and principles of highfeed milling. Advantages of highfeed milling over traditional methods.High-feed milling is a cutting process that removes material quickly. It uses tools with a high feed rate and shallow cuts. This way, it makes more parts in less time. Some benefits of high-feed milling include:

- Faster production: It works quickly, saving time.

- Less machine wear: The gentle cuts cause less stress on the tools.

- Better surface finish: It creates smoother surfaces and reduces finishing work.

In fact, using high-feed milling can increase efficiency by up to 75% compared to traditional methods! This makes it a smart choice for many manufacturers today.

What is high-feed milling?

High-feed milling is a method that cuts materials quickly and efficiently by using special tools. It allows for faster production with less wear on machines.

Key Advantages:

- Increased speed

- Less wear and tear

- Improved finish quality

Key Factors Influencing Selection

Material type and thickness considerations. Cutting speed and feed rate parameters.Several factors influence the choice of high-feed milling cutters. Material type is key. Different materials, like steel and aluminum, respond uniquely to cutting tools. Thickness also matters; thicker materials need stronger cutters. Cutting speed and feed rate are essential too. Higher speeds can lead to smoother finishes. However, if the feed rate is too fast, it can create rough edges. Choose wisely!

What materials should I consider when selecting a milling cutter?

Consider aluminum, steel, brass, and plastic. Each reacts differently, affecting your efforts.

Key Factors:

- Aluminum cuts easily.

- Steel is tough but needs slower speeds.

- Brass offers smoothness and beauty.

- Plastic is light and easy to shape.

Application Areas for High-Feed Milling Cutters

Industries that benefit from highfeed milling. Specific applications (aluminum, steel, etc.).Many industries love high-feed milling cutters. They can cut through materials like aluminum and steel faster than a cheetah on roller skates! In the automotive sector, these tools help shape parts quickly, making cars roll out of factories with speed.

| Industry | Application |

|---|---|

| Automotive | Machining car parts |

| Aerospace | Component shaping |

| Metalworking | High-volume production |

High-feed milling lets manufacturers save time and money. With these tools, they can produce parts more efficiently. This means more time for coffee breaks—because who doesn’t love coffee?

Performance Metrics to Consider

Tool life and durability. Surface finish and dimensional accuracy.Selecting the right milling cutter can be like picking a pizza topping. Everyone wants their slice to be perfect! Consider tool life and durability. A good cutter should last long and handle tough materials. Next, think about surface finish and dimensional accuracy. Nobody enjoys a bumpy surface or a misshaped part. Aim for smooth cuts and exact dimensions, like a well-sliced cake!

| Metric | Importance |

|---|---|

| Tool Life | Longer life saves time and money. |

| Durability | Can withstand heavy use without failing. |

| Surface Finish | Ensures a polished final look. |

| Dimensional Accuracy | Makes parts fit together perfectly. |

Cost-Benefit Analysis of High-Feed Milling Cutters

Initial investment vs. longterm savings. Total cost of ownership and maintenance considerations.Choosing a high-feed milling cutter can feel like picking the right snack—do you want a quick treat or something that lasts? The initial investment might seem big, but long-term savings can sneak up on you like a friendly cat. Think of it as a wise investment rather than just a cost. Maintenance is key too! Keeping your cutter in shape can save you more than just pennies. Here’s a quick look:

| Cost Factors | Initial Cost | Maintenance | Long-Term Savings |

|---|---|---|---|

| High-Feed Milling Cutter | $$$ | Minimal | $$$$ |

| Standard Cutter | $$ | High | $$ |

In short, while you might pay more upfront for a high-feed cutter, you’ll save time, effort, and money down the road. Who wouldn’t want that?

Choosing the Right High-Feed Milling Cutter

Tips for selecting the best cutter for your needs. Common mistakes to avoid in the selection process.Selecting the right cutter can make a big difference. To find the best high-feed milling cutter, consider these tips:

- Know your material: Different materials need different cutters.

- Check the size: The cutter size should match your machine.

- Watch the speed: Faster isn’t always better; find the right balance.

- Look for quality: A good cutter lasts longer and cuts better.

Avoid these common mistakes:

- Choosing based on price alone: Don’t sacrifice quality for savings.

- Ignoring feed rates: Your speeds should match your cutter’s ability.

- Not asking for help: Seek advice from experts if you’re unsure.

What should I know before choosing a high-feed milling cutter?

Understanding your project and materials is key. Always consider the specific requirements of what you are cutting. This helps ensure you pick the most suitable cutter for the job!

Future Trends in High-Feed Milling Technology

Innovations in cutter design and materials. Predictions for the evolution of highfeed milling practices.The future of high-feed milling technology looks bright and exciting. Innovations in cutter design are changing the game! Companies are using new materials that are tougher and lighter. This means faster speeds and better precision. Imagine a milling cutter that does its job like a superhero! Predictions suggest that high-feed milling practices will evolve with smarter machines and better software. Soon, we might even have robots doing the heavy lifting. Who wouldn’t want to be friends with a robot that can mill a block of metal while sipping coffee?

| Innovation | Description |

|---|---|

| New Materials | Tougher and lighter for speed |

| Smart Machines | Automated and efficient milling |

| Advanced Software | Better design and operation |

Conclusion

In summary, selecting a high-feed milling cutter is crucial for efficient machining. Focus on material type, cutter geometry, and chip control. Always consider your specific project needs. By choosing wisely, you can improve speed and reduce costs. Explore more about cutter types and their advantages to make informed choices. Let’s keep learning to enhance your machining skills!FAQs

What Factors Should Be Considered When Selecting A High-Feed Milling Cutter For Specific Machining Applications?When choosing a high-feed milling cutter, you should think about the type of material you are cutting. Different materials need different tools. Also, consider the shape and size of the part you want to make. The speed of the machine and how deep you need to cut are important too. Lastly, think about how much you want to spend on the cutter.

How Does Cutter Geometry Influence The Performance And Efficiency Of High-Feed Milling Operations?Cutter geometry includes the shape and angles of the cutting tool. It affects how well the tool cuts the material. A good shape can help cut faster and smoother. This means we can finish jobs quickly and use less energy. When the cutter is designed well, we do better work!

What Materials Are Best Suited For High-Feed Milling Cutters, And How Do They Affect Tool Life And Wear Resistance?High-feed milling cutters work best with tough materials, like carbide or high-speed steel. These materials last longer and resist wear. When you use good materials, your tools stay sharp and last many cuts. This means you can work faster and spend less time replacing tools.

In What Scenarios Would A High-Feed Milling Cutter Provide A Significant Advantage Over Traditional Milling Tools?A high-feed milling cutter works better when you need to remove a lot of material quickly. It’s great for shaping big metal pieces or making items with lots of flat surfaces. This tool can also work faster on softer materials. You’ll finish your project sooner and save on machine wear and tear.

How Can One Optimize Cutting Parameters (Such As Feed Rate And Spindle Speed) When Using High-Feed Milling Cutters To Maximize Productivity And Part Quality?To optimize cutting parameters with high-feed milling cutters, you can adjust the feed rate and spindle speed. Start by testing different speeds to find what works best. Increase the feed rate to cut faster, but be careful not to hurt the part’s quality. Check the results and make small changes if needed. This way, you can make better parts quickly!