Have you ever wanted to turn your old metal lathe into a high-tech CNC machine? It’s easier than you think! With a metal lathe CNC retrofit, you can unlock new possibilities in your workshop. Just imagine transforming your simple lathe into a smart tool that can do amazing things.

But wait, you might wonder, what does “retrofit” even mean? Great question! Retrofit means adding new technology to something old. This process can breathe new life into your metal lathe and expand your skills.

In this article, we’ll explore how to use metal lathe CNC retrofit. You’ll learn step-by-step how to update your machine. You might even discover some surprising tips along the way. So, if you’re ready to take your metalworking to the next level, keep reading!

How To Use Metal Lathe Cnc Retrofit For Precision Machining

How to Use Metal Lathe CNC Retrofit

Retrofitting a metal lathe with CNC technology can boost your machining skills. This upgrade transforms a manual lathe into a powerful automated tool. Imagine turning complex designs into reality with precision! Learn to choose the right retrofit kit that fits your machine. You’ll discover how to install software and connect computer controls. With the right guidance, you can create detailed parts with ease. Get ready to revolutionize your metalworking projects!Understanding CNC Retrofitting

Definition of CNC retrofitting. Benefits of retrofitting a metal lathe.CNC retrofitting means upgrading old machines like metal lathes with new technology. It’s like giving a classic car a modern engine. Retrofitting brings several benefits:

- Increases accuracy

- Improves speed

- Reduces energy costs

- Extends machine life

Many manufacturers choose retrofitting because it’s cost-effective and boosts performance. This way, they stay competitive without buying new machines.

What are the benefits of CNC retrofitting?

The benefits include enhanced productivity, lower energy use, and better precision. Retrofitting can double a machine’s lifespan! It’s an excellent way to invest in older equipment.

Key Components of a CNC Retrofit Kit

Essential parts included in a retrofit kit. Importance of choosing the right kit for your lathe.A CNC retrofit kit includes various essential parts to upgrade your metal lathe. These parts make your machine smarter and more efficient. Key components often include:

- Control Unit: It operates and coordinates movements.

- Stepper Motors: These move the lathe precisely.

- Power Supply: It powers the entire system.

- Software: This helps with programming tasks.

Choosing the right kit is crucial for best performance. A good kit boosts speed and accuracy. Without it, your lathe may not work properly. Make sure to research before buying!

What are the essential parts of a CNC retrofit kit?

The essential parts include control units, stepper motors, power supplies, and software. Each part plays a vital role in enhancing the lathe’s performance.

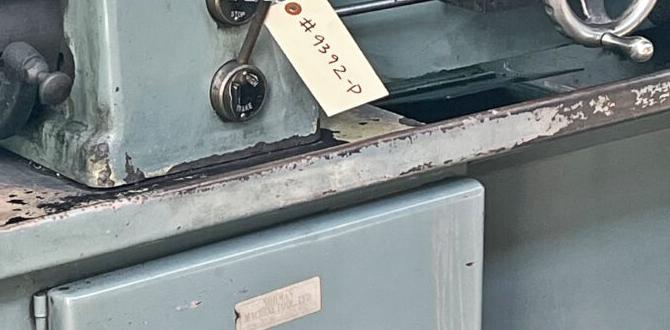

Preparing Your Metal Lathe for Retrofit

Assessing the current condition of your lathe. Necessary tools and workspace setup.Before diving into the world of CNC retrofitting, take a good look at your metal lathe. Is it rusting in the corner or still spinning like a champion? Assess its condition first. Once you know what you’re working with, gather your tools. Essential items include wrenches, screwdrivers, and maybe a magic wand—just kidding! Finally, set up a clean workspace. You don’t want to trip over tools while trying to make your lathe a CNC superstar!

| Tool | Use |

|---|---|

| Wrenches | For tightening parts |

| Screwdrivers | For assembling components |

| Safety Gear | To keep you safe from flying chips! |

Installation Process of CNC Retrofit

Stepbystep guide to installing the retrofit kit. Common pitfalls and how to avoid them.The first step in installing your CNC retrofit is to gather all parts. Check your kit twice, as missing pieces can turn into a scavenger hunt! Next, mount the new motor to your lathe. Use strong screws; your motor shouldn’t play hide and seek. After that, connect the wiring carefully. A tangled mess is like spaghetti on laundry day—never fun! Finally, test your setup before cutting. Remember, if it doesn’t run smoothly, it might be like that one friend who always shows up late—check those connections!

| Steps | Common Pitfalls | How to Avoid |

|---|---|---|

| Gather parts | Missing pieces | Double-check the kit |

| Mount the motor | Loose screws | Tighten securely |

| Connect wiring | Tangled wires | Organize carefully |

| Test setup | Running issues | Check all connections |

Testing and Calibrating Your CNC Metal Lathe

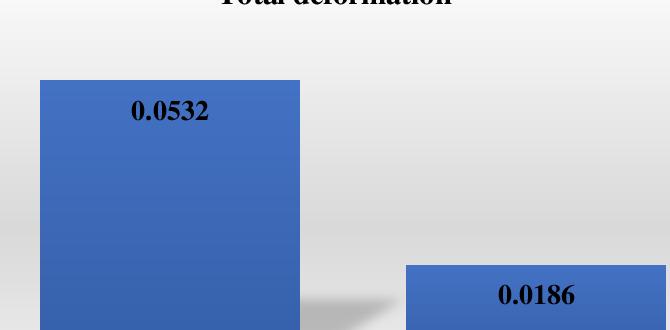

Importance of proper testing after installation. Calibration techniques for accurate machining.After installing your CNC metal lathe, proper testing is crucial. Think of it like tuning a guitar. You wouldn’t want to play a sour note, right? A well-calibrated machine ensures accurate cuts and smooth operation. Use techniques like measuring tool offsets and checking backlash for better precision.

| Calibration Technique | Description |

|---|---|

| Measuring Tool Offsets | Adjust the tool height and position for accuracy. |

| Checking Backlash | Ensure there’s no unnecessary movement in the system. |

With these steps, you’ll be on your way to creating amazing designs. Remember, a perfect piece starts with a perfect setup. Happy machining!

Maintenance Tips for CNC Retrofitted Lathes

Regular maintenance practices to follow. Troubleshooting common issues.Keeping your CNC retrofitted lathe in tip-top shape is essential. Regular checks are a must! Check the oil levels and clean the bed often. Dust and metal shavings love to party on your machine, so kick them out! If you notice strange noises or uneven cuts, don’t panic. Ask yourself, “Did I forget to tighten a bolt?” Tightening loose parts could save the day. Here’s a quick maintenance table:

| Practice | Frequency |

|---|---|

| Oil Check | Weekly |

| Cleaning | Daily |

| Bolt Tightening | Monthly |

Remember, a well-cared machine is a happy machine! Keep your lathe singing instead of squeaking.

Enhancing Productivity and Precision with CNC Retrofits

Tips for optimizing workflow and efficiency. Examples of improved processes after retrofitting.Upgrading a metal lathe with CNC retrofits can boost both productivity and precision. For example, using CNC control can significantly reduce setup time. You can automate repetitive tasks, allowing you to focus on more complex projects. Imagine finishing that tricky job before lunch! Studies show that productivity can increase by up to 30% with the right upgrades. Here are some tips to enhance your workflow:

| Tip | Description |

|---|---|

| Plan Your Cut | Map out your cuts to avoid mistakes. |

| Regular Maintenance | Keep your machine clean for smooth operation. |

| Avoid Distractions | Stay focused to boost output. |

After retrofitting, many users report smoother operations and fewer errors. With CNC, even the most complex designs become easier to handle. Instead of facing a mountain of tasks, you may find yourself breezing through projects. Who said machinery can’t be fun?

Conclusion

In conclusion, retrofitting a metal lathe with CNC can enhance your machining skills. You can improve accuracy and speed while working on projects. Start by researching suitable kits and learning about the installation process. We encourage you to try some hands-on practice and explore tutorials online. With patience and creativity, you’ll master CNC technology for your metalworking tasks!FAQs

Here Are Five Related Questions On The Topic Of Using A Metal Lathe For Cnc Retrofitting:CNC retrofitting means changing a metal lathe to use a computer for more precise work. You can take a regular metal lathe and add special parts, like motors and controls. This lets the machine work automatically. Using a CNC lathe makes it easier to create exact shapes and designs. It’s a fun project that helps you learn new skills!

Sure! Please give me the question you want me to answer.

What Are The Key Components Required For A Successful Cnc Retrofit Of A Metal Lathe?To successfully retrofit a metal lathe with CNC, you need a few key parts. First, you need a good computer to control the machine. Then, install motors that move the lathe’s parts. You will also need special software to give instructions. Finally, make sure to have sensors for safety and accuracy. With these, your lathe will work like a modern CNC machine!

How Do I Select The Appropriate Cnc Control Software For My Lathe Retrofit Project?To choose the right CNC (Computer Numerical Control) software for your lathe, start by considering what you need. Think about the features you want, like easy controls and good support. Check if your software can work with your lathe’s hardware. Finally, read reviews from other users to see what they like or dislike. This way, you can find a software that fits your project best!

What Are The Common Challenges Faced During The Retrofitting Process Of A Metal Lathe, And How Can They Be Overcome?When we retrofit a metal lathe, we face a few challenges. First, old parts might not fit with new ones. To fix this, we can measure carefully and make adjustments. Second, we need to learn how to use new tools. We can overcome this by reading instructions or watching videos. Finally, finding the right replacement parts can be hard, but we can ask for help from experts.

How Do I Ensure The Accuracy And Precision Of My Metal Lathe After Completing The Cnc Retrofit?To ensure your metal lathe works well after the CNC retrofit, start by checking all parts are tight and properly aligned. You can use a simple ruler or special tools to measure the settings. Then, run a test piece of metal to see how it cuts. If it’s not perfect, adjust the settings until it is. Finally, keep your lathe clean and oil it regularly to help it stay accurate.

What Are The Benefits Of Retrofitting A Traditional Metal Lathe To Cnc Compared To Purchasing A New Cnc Machine?Retrofitting a traditional metal lathe to CNC means changing it to work with computers. This can be cheaper than buying a new CNC machine. You can keep using your old lathe, which saves money. It also lets you customize the machine to fit your needs better. Plus, you can learn more about how machines work while making upgrades.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Using A Metal Lathe For Cnc Retrofitting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC retrofitting means changing a metal lathe to use a computer for more precise work. You can take a regular metal lathe and add special parts, like motors and controls. This lets the machine work automatically. Using a CNC lathe makes it easier to create exact shapes and designs. It’s a fun project that helps you learn new skills!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Required For A Successful Cnc Retrofit Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To successfully retrofit a metal lathe with CNC, you need a few key parts. First, you need a good computer to control the machine. Then, install motors that move the lathe’s parts. You will also need special software to give instructions. Finally, make sure to have sensors for safety and accuracy. With these, your lathe will work like a modern CNC machine!”}},{“@type”: “Question”,”name”: “How Do I Select The Appropriate Cnc Control Software For My Lathe Retrofit Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right CNC (Computer Numerical Control) software for your lathe, start by considering what you need. Think about the features you want, like easy controls and good support. Check if your software can work with your lathe’s hardware. Finally, read reviews from other users to see what they like or dislike. This way, you can find a software that fits your project best!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Retrofitting Process Of A Metal Lathe, And How Can They Be Overcome?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we retrofit a metal lathe, we face a few challenges. First, old parts might not fit with new ones. To fix this, we can measure carefully and make adjustments. Second, we need to learn how to use new tools. We can overcome this by reading instructions or watching videos. Finally, finding the right replacement parts can be hard, but we can ask for help from experts.”}},{“@type”: “Question”,”name”: “How Do I Ensure The Accuracy And Precision Of My Metal Lathe After Completing The Cnc Retrofit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure your metal lathe works well after the CNC retrofit, start by checking all parts are tight and properly aligned. You can use a simple ruler or special tools to measure the settings. Then, run a test piece of metal to see how it cuts. If it’s not perfect, adjust the settings until it is. Finally, keep your lathe clean and oil it regularly to help it stay accurate.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Retrofitting A Traditional Metal Lathe To Cnc Compared To Purchasing A New Cnc Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting a traditional metal lathe to CNC means changing it to work with computers. This can be cheaper than buying a new CNC machine. You can keep using your old lathe, which saves money. It also lets you customize the machine to fit your needs better. Plus, you can learn more about how machines work while making upgrades.”}}]}