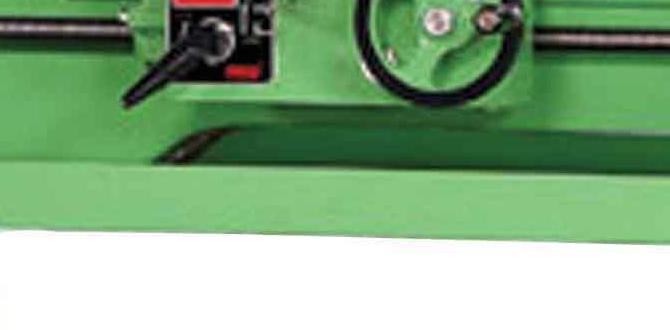

Have you ever watched a metal lathe in action? It’s like magic! But did you know that proper lathe alignment can make a huge difference in how it works? When a lathe is aligned well, it cuts metal smoothly and accurately. This helps in creating perfect parts every time.

Imagine trying to build a toy car with crooked wheels. It wouldn’t roll right, would it? The same idea applies to metal lathes. If the machine isn’t set up correctly, you might end up with mistakes. Is there anything more frustrating than wasted time and materials?

In this article, we will explore some great lathe alignment tips. You will also discover how to automate your metal lathe. Automation can make your work easier and save you time. Let’s dive into these tips that can help you become a pro at using your metal lathe!

Lathe Alignment Tips: Metal Lathe Automation Techniques

Lathe Alignment Tips for Metal Lathe Automation

Want to improve your metal lathe’s accuracy? Discover essential lathe alignment tips that can transform your crafting experience. Properly aligning your metal lathe not only enhances quality but also boosts efficiency. Did you know that a misaligned lathe can lead to costly mistakes? Regular checks and adjustments can save you time and materials. Explore easy techniques to automate this process, making your projects smoother than ever. Get ready to turn your ideas into perfectly machined realities!Understanding Lathe Alignment

Definition of lathe alignment in metalworking. Importance of proper alignment for efficiency and precision.Lathe alignment means making sure your lathe machine is set up perfectly. It’s like making sure your shoes are tied before a race. If the lathe isn’t aligned, your cuts can be off and your pieces might look like they took a tumble down the hill. Proper alignment is key for smooth operations and great results. It boosts both efficiency and precision. Remember, a straight cut makes everyone look skilled, while a wobbly one might make you the laugh of the workshop!

| Benefits of Proper Lathe Alignment | Consequences of Poor Alignment |

|---|---|

| Improves efficiency | Causes inaccurate cuts |

| Enhances precision | Wastes materials |

| Reduces wear on tools | Increases machine strain |

Common Misalignments in Metal Lathes

Types of misalignments: bed, tailstock, and centers. Effects of misalignment on machining accuracy and tool wear.Metal lathes can be a bit finicky. Common misalignments include issues with the bed, tailstock, and centers. If the bed isn’t straight, your work will wobble like a three-legged stool. A misaligned tailstock makes it hard to keep things in line, which can lead to uneven cuts. Lastly, centers that aren’t quite right can cause tool wear faster than a kid can wear out a pair of shoes.

| Type of Misalignment | Effects |

|---|---|

| Bed Misalignment | Wobbly work and poor finish |

| Tailstock Misalignment | Uneven cuts and inaccurate work |

| Centers Misalignment | Rapid tool wear and poor accuracy |

Better alignment means better cuts! Remember, a happy lathe makes for happy projects.

Tools and Equipment for Lathe Alignment

Essential tools for alignment checking: dial indicators, squares, etc.. Advanced equipment for automated alignment processes.Alignment is key to working with a lathe. The right tools make this task easier and more accurate. For checking alignment, consider using:

- Dial Indicators: These help you measure precise movements.

- Squares: They check if your setup is straight and level.

For automated processes, advanced tools can save time and improve accuracy. Systems now exist that use sensors and computers to ensure everything is perfectly aligned. These tools make work more efficient and reduce mistakes.

What tools are best for checking lathe alignment?

The best tools for checking lathe alignment are dial indicators and precision squares. These tools help you measure your setup accurately.

Step-by-Step Alignment Process

Preparing the lathe for alignment. Detailed steps for achieving precise alignment.To align your lathe, start by cleaning the machine. Remove dust and debris from the bed and tailstock. This is like brushing your teeth—nobody likes a dirty lathe! Next, check the levels. Use a bubble level to see if the lathe is perfectly horizontal. Adjust the feet until it’s just right. Remember, precise alignment prevents errors in your work. Here’s a quick view of the steps:

| Step | Action |

|---|---|

| 1 | Clean the lathe |

| 2 | Check the levels |

| 3 | Adjust the feet |

Check alignment using a dial indicator. It can pinpoint misalignments like a detective solving a crime! Achieving proper alignment helps avoid wobbly workpieces. So, every detail counts!

Regular Maintenance and Alignment Checks

Recommended maintenance schedule for lathes. Importance of routine alignment checks for longterm performance.Keeping your lathe in tip-top shape is as important as finding the right movie to watch on a Friday night! Regular maintenance helps your lathe run smoothly and makes it last longer. Everyone loves a machine that won’t throw a tantrum. Aim for a monthly check-up for belts and gears. Every few months, align the tailstock and headstock. If your lathe starts to seem grumpy, it’s time to check those alignments!

| Maintenance Task | Recommended Frequency |

|---|---|

| Inspect belts and gears | Monthly |

| Align headstock and tailstock | Every three months |

| Oil moving parts | Monthly |

Routines help keep your machine happy, which is important for long-term performance. A small effort today can prevent big headaches tomorrow. Remember, a well-maintained lathe is a happy lathe. And happy lathes make happy metalworkers!

Troubleshooting Common Alignment Issues

Identifying symptoms of alignment problems. Effective strategies for resolving alignment issues quickly.Alignment problems can fill you with dread, but spotting them is the first step! Look for signs like uneven cuts or strange vibrations. They are like your lathe’s way of yelling for help. To fix issues fast, check the bed for any warp and tighten all screws. Use a level and make sure everything is aligned. Here’s a handy table to help you troubleshoot:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Uneven cuts | Bad alignment | Realign the tailstock |

| Vibrations | Loose fittings | Tighten screws and bolts |

| Excessive wear | Improper setup | Recheck and adjust positions |

Remember, a happy lathe means smooth operations. And just like humans, they don’t like to be out of line!

Conclusion

In summary, aligning your metal lathe improves precision and quality. Start by checking levelness and adjusting as needed. Regular maintenance and automation tools can save you time and effort. You can experiment with different techniques to find what works best for you. For more tips, consider reading additional resources or joining a machining community. Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For Metal Lathe Automation:Sure! Here are some tips for keeping your metal lathe aligned. First, check if the lathe is level using a bubble level. Next, make sure the tailstock and headstock are straight. You can use a ruler or a dial indicator to help. Lastly, always tighten screws and bolts after adjusting them. Doing this helps the lathe work better and last longer!

Sure! Please provide the question you want me to answer.

What Are The Key Steps To Ensure Proper Alignment Of A Metal Lathe Before Automating Its Operations?To align a metal lathe, you first make sure the base is level. Next, check that the headstock and tailstock are straight. You can use a ruler or special tools to measure this. Then, tighten all the screws and bolts to keep everything in place. Finally, test the lathe by running it for a short time to see if it works well.

How Can Misalignment In A Metal Lathe Affect The Accuracy And Efficiency Of Automated Machining Processes?If a metal lathe is misaligned, it won’t cut metal properly. This can make parts too big or too small. If we keep making wrong parts, we waste time and materials. Misalignment slows down the machines and makes them less reliable. So, we need to make sure everything is lined up correctly!

What Tools And Techniques Are Recommended For Checking And Adjusting The Alignment Of A Metal Lathe?To check and adjust a metal lathe’s alignment, you can use some simple tools. A dial indicator helps you see if the lathe parts are straight. We also use a carpenter’s level to make sure everything is even. Sometimes, adjusting screws on the lathe will help fix any wrong angles. Always check your work after making changes!

How Does Regular Maintenance And Alignment Checks Contribute To The Longevity And Performance Of Automated Metal Lathes?Regular maintenance and alignment checks help keep automated metal lathes running well. This means they can work longer without breaking down. When we check and fix small problems early, it saves us time and money. A well-maintained lathe makes better parts, so everything stays smooth and safe. Taking care of the machine is like keeping your bike clean and tuned, which helps it ride better!

What Common Indicators Should Operators Look For To Identify Alignment Issues In A Metal Lathe During Automated Production?To spot alignment problems in a metal lathe, you should watch for a few signs. First, check if the parts are not shaped right or have weird bumps. Second, listen for strange noises that shouldn’t be there. You can also look for uneven wear on the cutting tools. Lastly, if the machine shakes or vibrates too much, that could mean something is off.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips For Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some tips for keeping your metal lathe aligned. First, check if the lathe is level using a bubble level. Next, make sure the tailstock and headstock are straight. You can use a ruler or a dial indicator to help. Lastly, always tighten screws and bolts after adjusting them. Doing this helps the lathe work better and last longer!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps To Ensure Proper Alignment Of A Metal Lathe Before Automating Its Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, you first make sure the base is level. Next, check that the headstock and tailstock are straight. You can use a ruler or special tools to measure this. Then, tighten all the screws and bolts to keep everything in place. Finally, test the lathe by running it for a short time to see if it works well.”}},{“@type”: “Question”,”name”: “How Can Misalignment In A Metal Lathe Affect The Accuracy And Efficiency Of Automated Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is misaligned, it won’t cut metal properly. This can make parts too big or too small. If we keep making wrong parts, we waste time and materials. Misalignment slows down the machines and makes them less reliable. So, we need to make sure everything is lined up correctly!”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Recommended For Checking And Adjusting The Alignment Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust a metal lathe’s alignment, you can use some simple tools. A dial indicator helps you see if the lathe parts are straight. We also use a carpenter’s level to make sure everything is even. Sometimes, adjusting screws on the lathe will help fix any wrong angles. Always check your work after making changes!”}},{“@type”: “Question”,”name”: “How Does Regular Maintenance And Alignment Checks Contribute To The Longevity And Performance Of Automated Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance and alignment checks help keep automated metal lathes running well. This means they can work longer without breaking down. When we check and fix small problems early, it saves us time and money. A well-maintained lathe makes better parts, so everything stays smooth and safe. Taking care of the machine is like keeping your bike clean and tuned, which helps it ride better!”}},{“@type”: “Question”,”name”: “What Common Indicators Should Operators Look For To Identify Alignment Issues In A Metal Lathe During Automated Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To spot alignment problems in a metal lathe, you should watch for a few signs. First, check if the parts are not shaped right or have weird bumps. Second, listen for strange noises that shouldn’t be there. You can also look for uneven wear on the cutting tools. Lastly, if the machine shakes or vibrates too much, that could mean something is off.”}}]}