Lathe Alignment Tips: Ensuring Metal Lathe Tailstock Alignment

Lathe Alignment Tips: Metal Lathe Tailstock Alignment

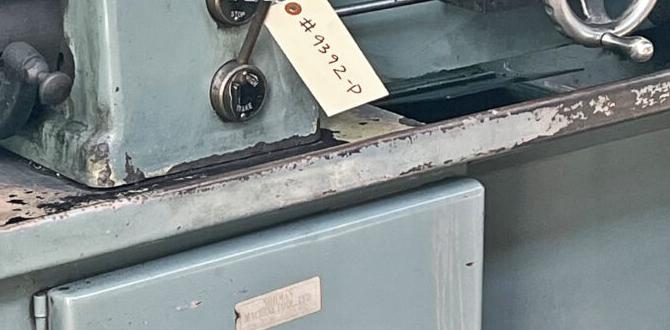

Aligning the tailstock on a metal lathe is crucial for accurate machining. Proper alignment ensures that your workpiece remains straight and steady. Did you know that misalignment can cause uneven wear on tools and affect the quality of your project? Start by checking the tailstock’s alignment with the spindle. Use a dial indicator for precision adjustments. Regular checks can save you time and frustration later. Remember, a small tweak now can lead to a successful project!Common Alignment Issues with Tailstocks

Identification of common misalignments in tailstock. Effects of misalignment on machining accuracy.Misalignments in tailstocks can be sneaky little gremlins in your machining process. You might notice uneven cuts or changed sizes in your workpiece. These issues often happen due to the tailstock being too high or low. Alignment matters! A misaligned tailstock can throw off the accuracy of your project dramatically. In fact, some experts say it can even ruin a perfectly good chunk of metal and turn it into scrap! Check out the table below for common problems:

| Alignment Issue | Effect on Machining |

|---|---|

| Too high | Creates tapered cuts |

| Too low | Leads to binding |

| Out of square | Causes uneven pressure |

Fixing these misalignments can save you time and materials. So, keep an eye on your tailstock, or it might just take you for a wild ride!

Tools Required for Tailstock Alignment

Essential tools for accurate tailstock alignment. Recommended measuring instruments for precision alignment.For precise tailstock alignment, certain tools can make a big difference. Here are some essentials:

- Calipers: They help measure small distances accurately.

- Dial Indicators: Great for checking if things are level.

- Ruler or Straightedge: Useful for straight measurements.

- Tape Measure: Handy for longer distances.

Having these tools ready will help ensure your metal lathe works perfectly. Each tool plays a role in making sure everything lines up just right.

What tools are best for tailstock alignment?

Calipers, dial indicators, rulers, and tape measures are the best tools for tailstock alignment.Step-by-Step Guide to Tailstock Alignment

Detailed procedures for checking tailstock alignment. Techniques for adjusting tailstock correctly.First, check if your tailstock is aligned with the lathe’s bed. Use a dial indicator to find any gaps. Next, loosen the tailstock’s locking screws. Carefully shift it until it’s aligned. Tighten the screws gently. You don’t want it to slip like a banana peel! To double-check, run a test piece and see if it stays straight. If it swerves, repeat the process until it’s perfect.

| Step | Action |

|---|---|

| 1 | Check alignment with a dial indicator |

| 2 | Loosen locking screws |

| 3 | Adjust until aligned |

| 4 | Tighten screws |

| 5 | Run a test piece |

Remember, precision matters. A small misalignment can cause big problems. Keep practicing, and soon, you’ll be a tailstock alignment pro!

Advanced Techniques for Enhanced Tailstock Performance

Tips for improving tailstock accuracy beyond basic alignment. Techniques to maintain tailstock alignment over time.To enhance tailstock performance, start by checking the lock-down bolts. Ensure they are tight but not overly so, which can lead to misalignment. Regularly clean the ways and tailstock to remove any debris. This can prevent wear and improve accuracy. Calibrate the tailstock frequently to maintain alignment as you use it. Over time, minor adjustments may be needed to keep things running smoothly.

How can you improve tailstock accuracy?

You can improve tailstock accuracy by regularly checking the alignment and calibrating it. Maintaining clean ways helps avoid wear, which can affect precision.

Additional Tips:

- Use a dial indicator for accurate measurements.

- Regularly inspect parts for wear and tear.

- Lubricate moving parts to ensure smooth operation.

Troubleshooting Tailstock Alignment Problems

Common signs of alignment issues and how to diagnose them. Quick fixes for frequent tailstock alignment problems.Alignment problems can be sneaky! You might notice some common signs, like your tailstock moving out of alignment or strange vibrations while turning. These issues can lead to uneven cuts, which is like slicing a cake with a wobbly knife. To diagnose the problem, check if your workpiece is tight against the tailstock. If not, you may need a quick fix like adjusting the tailstock position. Remember, even the best lathes can have an off day!

| Common Issues | Quick Fixes |

|---|---|

| Vibrations and wobbling | Check for loose bolts |

| Uneven cuts | Realign the tailstock |

| Difficulty in adjusting | Lubricate moving parts |

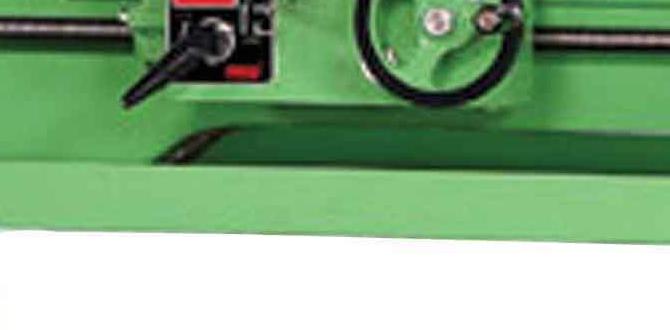

Regular Maintenance Practices for Lathe Alignment

Importance of routine checks and maintenance for lathe alignment. Recommended maintenance schedule for optimal performance.Keeping your lathe in top shape is essential for smooth operation. Regular checks help catch issues before they grow into big problems. Think of it as giving your lathe a wellness checkup! Following a maintenance schedule ensures everything runs smoothly, like a well-oiled machine—because nobody wants a grumpy lathe. Aim for quick inspections every week and a thorough check every month. Here’s a handy table to keep track of your lathe care:

| Maintenance Task | Frequency |

|---|---|

| Quick Inspection | Weekly |

| Thorough Check | Monthly |

Don’t let your lathe feel neglected! A little care goes a long way, ensuring your projects are as precise as a squirrel aiming for an acorn!

Frequently Asked Questions about Tailstock Alignment

Answers to common queries related to tailstock alignment. Expert tips on achieving consistent outcomes in alignment.Many people wonder about tailstock alignment and how to get it right. It’s key for a smooth operation. Here are some common questions:

| Question | Answer |

|---|---|

| How do I check my tailstock alignment? | Use a dial indicator on your lathe. It will show you if it’s off. |

| What happens if the tailstock is misaligned? | It can cause poor cuts and even damage your workpiece! |

| Any tips for fixing alignment? | Adjust the tailstock carefully, and always double-check! |

Following these tips helps you achieve better cuts. Think of it like getting your shoes tied just right before running—you want to avoid tripping, right?

Real-World Examples of Tailstock Alignment Challenges

Case studies highlighting tailstock alignment difficulties. Lessons learned from professional machinists on alignment practices.Many machinists face real challenges with tailstock alignment. For instance, one case study showed a spindle problem that caused parts to be uneven. This meant wasted material and time. Experts emphasize the need for accurate checks. They learned to use simple tools like a dial indicator to make adjustments. This small step can lead to big improvements. Here are key tips:

- Always check alignment before starting a project.

- Test regularly to avoid future issues.

- Keep tools in good condition for best results.

What are common tailstock alignment problems?

Common problems include misalignment of the tailstock and uneven cutting. These issues can cause poor-quality work and wastage.

Conclusion

In conclusion, proper tailstock alignment on your metal lathe is crucial for accuracy. Always check the tailstock against the bed and adjust if necessary. Remember to use a dial indicator for precise results. You can improve your projects significantly by following these tips. We encourage you to practice and explore more resources to enhance your lathe skills further!FAQs

What Are The Key Indicators To Check For Proper Alignment Of A Lathe Tailstock With The Spindle Axis?To check if the tailstock of a lathe is aligned with the spindle, you can look for a few signs. First, use a center drill to make a small hole in a piece of wood. Then, measure the depth of that hole from the tailstock and the spindle. If both measurements are the same, your tailstock is aligned. If not, it needs to be adjusted. You can also check with a dial gauge for more precision.

How Can I Use A Dial Indicator To Ensure Accurate Alignment Of The Tailstock On My Metal Lathe?To align the tailstock on your metal lathe, place the dial indicator on the carriage. Then, move the tailstock close to the indicator. Turn the handle to slide the tailstock back and forth. Watch the dial. If it moves, adjust the tailstock until the dial stays steady. This way, your tailstock will be straight and ready to use!

What Common Problems Arise From Misalignment Of The Tailstock, And How Can They Affect Machining Quality?When the tailstock isn’t lined up right, it can cause problems. The tool might cut unevenly, making the piece look bad. You could also get extra wear on tools, which means they won’t last as long. This can lead to mistakes and waste time, making it harder to make quality pieces.

Are There Specific Steps Or Procedures To Follow When Adjusting The Tailstock For Alignment On A Metal Lathe?Yes, there are steps to follow when adjusting the tailstock on a metal lathe. First, make sure the lathe is off. Then, check if the tailstock is lined up with the spindle. You can do this by using a straight edge or a measuring tool. If it’s not aligned, loosen the screws on the tailstock and move it until it is straight. Finally, tighten the screws back to hold it in place.

How Does The Tailstock Alignment Impact Tool Wear And Workpiece Accuracy During Machining Operations?When the tailstock is not aligned correctly, it can cause problems. You may notice the tools wear out faster. This happens because the tool is not cutting evenly. If the tailstock is off, the workpiece might not be shaped correctly. Both tool wear and workpiece accuracy are important for good machining results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Indicators To Check For Proper Alignment Of A Lathe Tailstock With The Spindle Axis? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the tailstock of a lathe is aligned with the spindle, you can look for a few signs. First, use a center drill to make a small hole in a piece of wood. Then, measure the depth of that hole from the tailstock and the spindle. If both measurements are the same, your tailstock is aligned. If not, it needs to be adjusted. You can also check with a dial gauge for more precision.”}},{“@type”: “Question”,”name”: “How Can I Use A Dial Indicator To Ensure Accurate Alignment Of The Tailstock On My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on your metal lathe, place the dial indicator on the carriage. Then, move the tailstock close to the indicator. Turn the handle to slide the tailstock back and forth. Watch the dial. If it moves, adjust the tailstock until the dial stays steady. This way, your tailstock will be straight and ready to use!”}},{“@type”: “Question”,”name”: “What Common Problems Arise From Misalignment Of The Tailstock, And How Can They Affect Machining Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock isn’t lined up right, it can cause problems. The tool might cut unevenly, making the piece look bad. You could also get extra wear on tools, which means they won’t last as long. This can lead to mistakes and waste time, making it harder to make quality pieces.”}},{“@type”: “Question”,”name”: “Are There Specific Steps Or Procedures To Follow When Adjusting The Tailstock For Alignment On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are steps to follow when adjusting the tailstock on a metal lathe. First, make sure the lathe is off. Then, check if the tailstock is lined up with the spindle. You can do this by using a straight edge or a measuring tool. If it’s not aligned, loosen the screws on the tailstock and move it until it is straight. Finally, tighten the screws back to hold it in place.”}},{“@type”: “Question”,”name”: “How Does The Tailstock Alignment Impact Tool Wear And Workpiece Accuracy During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is not aligned correctly, it can cause problems. You may notice the tools wear out faster. This happens because the tool is not cutting evenly. If the tailstock is off, the workpiece might not be shaped correctly. Both tool wear and workpiece accuracy are important for good machining results.”}}]}