Have you ever wondered how metal is shaped into the tools we use? Many people might not realize it starts with a machine called a lathe. This amazing tool can turn raw metal into precise shapes. But here’s the catch: to get the best results, you need the right plans. That’s where lathe CAD files come in.

Lathe CAD files contain detailed drawings that help you understand the design. They show you how to create parts like the lead screw for a metal lathe. The lead screw is crucial, as it moves the tool back and forth with great accuracy. Without it, nothing else works well!

Imagine building a model without instructions. It might look good, but wouldn’t function correctly. Similarly, having the right CAD files can make all the difference in your lathe projects. Even small errors can lead to big problems in metalworking.

Are you excited to learn about how lathe CAD files and lead screws work together? Let’s dive deeper into the world of precision machining and discover how these elements shape the metal we use every day!

Lathe Cad Files For Metal Lathe Lead Screw Designs

Understanding Lathe CAD Files for Metal Lathes

Lathe CAD files are crucial for designing metal lathes, particularly for components like lead screws. These files offer precise measurements, ensuring parts fit together perfectly. Have you ever wondered how engineers create seamless machinery? With CAD files, they visualize and plan every detail. A fun fact: even small errors can lead to big problems in metalworking! By learning about these files, you gain insight into the engineering world and the importance of accurate designs.Understanding Lathe CAD Files

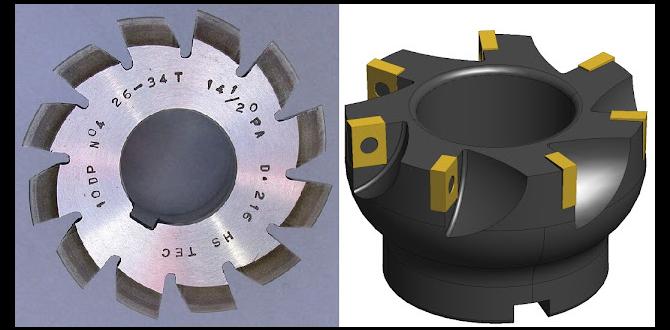

Definition of CAD files in the context of metal lathes. Importance of CAD files for lead screw design.CAD files are like blueprints for metal lathes. They tell machines how to create parts, including the all-important lead screw. This screw is key for making sure the lathe moves smoothly. Without proper CAD designs, you might end up with a lead screw that’s more crooked than a banana! Using CAD files helps engineers and hobbyists create accurate, detailed designs. They save time and make the process easier and fun!

| Feature | Importance |

|---|---|

| Accuracy | Ensures precise measurements for better fit. |

| Efficiency | Saves time compared to manual design methods. |

| Customization | Allows for tailored designs to meet specific needs. |

Benefits of Using CAD Files for Metal Lathes

Increased precision in manufacturing processes. Enhanced collaboration among engineers and designers.Using CAD files for metal lathes has some fantastic benefits! First, it helps in achieving increased precision in manufacturing. Every part can be made just right, like that perfect pancake flip! Second, these files boost teamwork among engineers and designers. They can share ideas quickly, making it easier to create awesome products together. Sharing is caring, right?

| Benefit | Description |

|---|---|

| Precision | Ensures parts are made accurately, reducing mistakes. |

| Collaboration | Makes it easier for teams to work together and share ideas. |

How to Create Effective Lead Screw CAD Files

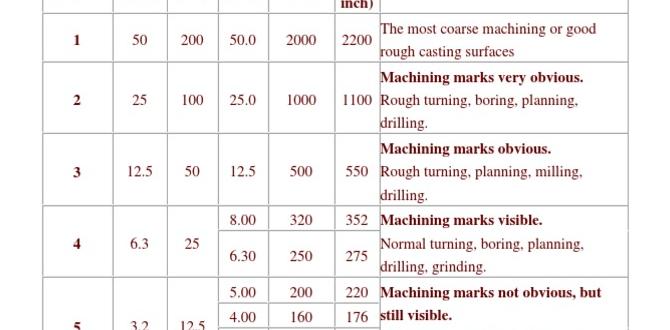

Stepbystep process for designing lead screws using CAD software. Best practices for dimensioning and tolerances.Designing lead screws with CAD software is a simple process. First, open your CAD tool. Then, choose the right units like inches or millimeters. Next, sketch the screw shape. Remember, it should have the correct pitch and diameter. Follow these best practices:

- Use clear dimensions.

- Set proper tolerances for fitting.

- Include detailed annotations.

Check your design frequently. This helps avoid mistakes. With patience and attention, you will create effective lead screw CAD files.

What are the best practices for lead screw CAD design?

The best practices include using clear dimensions, setting accurate tolerances, and adding helpful annotations.

Accessing Existing Lathe CAD Files

Resources for downloadable CAD files specific to lead screws. Review of online communities and forums for sharing design files.Finding lathe CAD files can be easier than you may think! Check out websites like GrabCAD and Thingiverse for free downloadable files. These sites often have great resources specifically for lead screws. Online communities, like Reddit or Facebook groups, are also buzzing with enthusiasts sharing their designs. Who knows, you might stumble across a file that makes your lathe dance! So dive in, and let those gears turn!

| Resource | Description |

|---|---|

| GrabCAD | A treasure trove of engineering CAD files. |

| Thingiverse | A popular spot for 3D models and designs. |

| Communities sharing tips and files. | |

| Facebook Groups | Connect with other lathe lovers! |

Common Mistakes to Avoid When Designing Lathe CAD Files

Discussion of frequent errors in lead screw design. Tips for avoiding pitfalls in CAD file creation.Designing lathe CAD files can be tricky. Most errors happen with the lead screw design. Common mistakes include wrong measurements, ignoring material properties, and not considering tolerances. To create better designs, follow these tips:

- Check your measurements twice.

- Understand the material you will use.

- Leave space for tolerances.

Avoiding these pitfalls will lead to better and easier projects.

What are mistakes to avoid in lead screw design?

Many people forget about proper alignment and gear ratios. These issues can cause the screw to jam or work poorly. Pay attention to details. This will make your project run smoother and more efficiently.

Future Trends in CAD Design for Metal Lathes

Innovations in CAD technology affecting metal lathe design. Predictions for the evolution of lead screw manufacturing practices.CAD technology is changing how we design metal lathes. Innovations like 3D modeling and simulation enhance precision and reduce errors. This makes the manufacturing process faster and easier. In the future, we may see new materials being used for lead screws. This could lead to stronger and lighter designs. Overall, these advancements will make metal lathes more efficient and user-friendly.

What is the future of lead screw manufacturing?

The future for lead screw manufacturing looks exciting. New techniques will allow for faster production. Automation will also play a big role in this change, making lathes more productive.

- Use of smart technology for better designs

- More eco-friendly materials

- Improved accuracy and efficiency

Conclusion

In summary, lathe CAD files help us design and understand metal lathes, especially lead screws. These designs make building or fixing lathes easier. If you’re interested, try finding some free CAD files online. You can learn a lot by experimenting with them. Keep exploring, and you’ll gain valuable skills in metalworking and design!FAQs

Here Are Five Related Questions On The Topic Of Lathe Cad Files For A Metal Lathe Lead Screw:What are CAD files? CAD stands for Computer-Aided Design. These files help people create blueprints for machines. You can use them to design parts for a metal lathe lead screw. This makes building and fixing things easier and more precise.

Sure! Just let me know what question you would like me to answer.

What Are The Key Dimensions And Specifications To Consider When Designing A Lead Screw For A Metal Lathe In Cad?When designing a lead screw for a metal lathe, you should think about its length, diameter, and thread type. The length tells you how far the screw can move. The diameter is how thick the screw is, which affects strength. The thread type determines how smoothly the screw turns. You also need to decide on the material, like steel, for durability.

Which Cad Software Is Most Commonly Used For Creating Detailed Models Of Lathe Components, Including Lead Screws?The most common CAD software for making detailed models of lathe parts is SolidWorks. It helps you design and visualize components clearly. Another popular choice is Autodesk Fusion 360, which is easy to use. Both programs are great for creating parts like lead screws. You can learn them with some practice!

How Can I Troubleshoot Issues That Arise When Importing Lead Screw Cad Files Into My Cnc Machine’S Software?To fix problems when you import lead screw CAD files into your CNC machine’s software, start by checking the file type. Make sure the software accepts the file you have. Next, look for any errors in the drawing. Sometimes, parts might be missing or not fit right. Finally, try restarting your software and importing the file again. That can fix many small issues!

Are There Any Standard File Formats For Lathe Cad Designs, And How Do They Affect The Compatibility With Different Machining Software?Yes, there are standard file formats for lathe CAD designs, like DXF and STL. These formats help different software understand the same design. If you save your design in a common format, it works better with other machining programs. This means you can easily share your design with friends or use it on different machines. Using the right file format keeps everything running smoothly!

What Are Some Common Design Features Or Design Best Practices To Ensure The Efficiency And Accuracy Of Lead Screws In A Metal Lathe Setup?To make lead screws work well on a metal lathe, we should keep them clean and well-lubricated. Using sturdy materials helps them last longer and stay accurate. You should also check the alignment often to avoid problems. Finally, using the right size for the job ensures everything fits and works smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Cad Files For A Metal Lathe Lead Screw:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “What are CAD files? CAD stands for Computer-Aided Design. These files help people create blueprints for machines. You can use them to design parts for a metal lathe lead screw. This makes building and fixing things easier and more precise.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Dimensions And Specifications To Consider When Designing A Lead Screw For A Metal Lathe In Cad?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a lead screw for a metal lathe, you should think about its length, diameter, and thread type. The length tells you how far the screw can move. The diameter is how thick the screw is, which affects strength. The thread type determines how smoothly the screw turns. You also need to decide on the material, like steel, for durability.”}},{“@type”: “Question”,”name”: “Which Cad Software Is Most Commonly Used For Creating Detailed Models Of Lathe Components, Including Lead Screws?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common CAD software for making detailed models of lathe parts is SolidWorks. It helps you design and visualize components clearly. Another popular choice is Autodesk Fusion 360, which is easy to use. Both programs are great for creating parts like lead screws. You can learn them with some practice!”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Issues That Arise When Importing Lead Screw Cad Files Into My Cnc Machine’S Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems when you import lead screw CAD files into your CNC machine’s software, start by checking the file type. Make sure the software accepts the file you have. Next, look for any errors in the drawing. Sometimes, parts might be missing or not fit right. Finally, try restarting your software and importing the file again. That can fix many small issues!”}},{“@type”: “Question”,”name”: “Are There Any Standard File Formats For Lathe Cad Designs, And How Do They Affect The Compatibility With Different Machining Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are standard file formats for lathe CAD designs, like DXF and STL. These formats help different software understand the same design. If you save your design in a common format, it works better with other machining programs. This means you can easily share your design with friends or use it on different machines. Using the right file format keeps everything running smoothly!”}},{“@type”: “Question”,”name”: “What Are Some Common Design Features Or Design Best Practices To Ensure The Efficiency And Accuracy Of Lead Screws In A Metal Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make lead screws work well on a metal lathe, we should keep them clean and well-lubricated. Using sturdy materials helps them last longer and stay accurate. You should also check the alignment often to avoid problems. Finally, using the right size for the job ensures everything fits and works smoothly.”}}]}