Have you ever watched a metal lathe in action? It spins and shapes metal with precision, bringing ideas to life. But how do you get started with a metal lathe setup? Many people find it tricky at first.

In this article, we’ll explore lathe CAD files and their role in setting up a metal lathe. Imagine having a blueprint that guides you every step of the way! These files can help both beginners and experienced users create amazing projects.

Did you know that CAD files can save you time? They provide details on everything from dimensions to material types. With the right setup, your metal lathe will become a powerful tool for creativity. Are you ready to learn how to make the most of it?

Lathe Cad Files: Essential For Metal Lathe Setup Skills

Lathe CAD Files: Metal Lathe Setup

Metal lathe setup can feel overwhelming at first. However, using lathe CAD files makes it easier. CAD files offer detailed designs that help you visualize your project. You can see every part and how they fit together. Imagine working on your project confidently, knowing you have accurate plans. Plus, you can save time by easily adjusting designs. Did you know that the right setup can enhance your lathe’s performance? Utilizing CAD files might just be the secret to your next great project!Understanding Metal Lathes

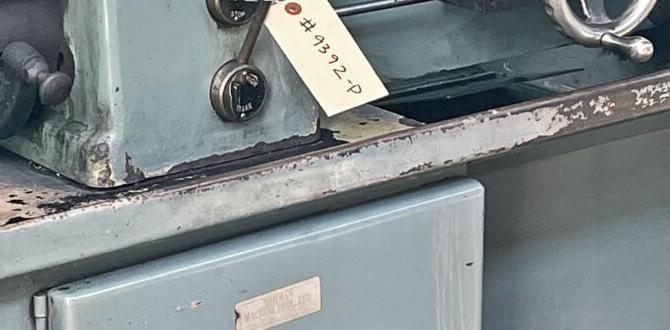

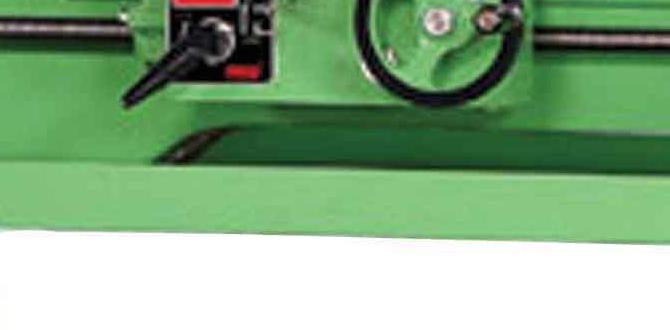

Definition and purpose of metal lathes. Types of metal lathes and their features.Metal lathes are powerful machines that shape metal into many forms. They spin the metal while tools cut it to size. Think of them as the magic wands of metalwork! There are various types, including engine lathes, bench lathes, and CNC lathes. Each has unique features that make them special. Want to look at some fun facts? Check out the table below!

| Type of Lathe | Features |

|---|---|

| Engine Lathe | Versatile and great for turning different shapes. |

| Bench Lathe | Small and perfect for home projects. |

| CNC Lathe | Computer-controlled for precise cuts. It’s like a robot doing the work! |

Each lathe type has its own benefits. Understanding them helps you choose the best one for your metal magic!

The Importance of CAD Files in Metal Lathe Setup

How CAD files streamline the design process. Benefits of using CAD files for precision and efficiency.Using CAD files can make setting up a metal lathe much easier. They help simplify the design process and save time. Imagine drawing a perfect circle without sweat! Precision is key in machining, and CAD files offer just that. They allow for exact measurements, ensuring your parts fit together like puzzle pieces. Plus, with improved efficiency, you’ll finish projects faster. Less fuss means more fun—what’s not to love about that?

| Benefits of CAD Files | Description |

|---|---|

| Streamlined Design | Quicker drawing and revisions. |

| Precision | Exact sizes and shapes every time. |

| Efficiency | Finish projects in less time. |

Preparing Your Workspace for Metal Lathe Operation

Necessary tools and safety equipment. Best practices for setting up a comfortable and organized workspace.Setting up your workspace for metal lathe operation is key! First, gather tools like wrenches and cutting bits. Don’t forget your safety gear, like goggles and gloves. They protect you from flying metal bits—ouch! Next, keep everything organized. A clear workspace helps you find your tools quickly. It’s like a treasure hunt, but with less pirates! Here’s a quick checklist:

| Essential Tools | Safety Equipment |

|---|---|

| Wrenches | Goggles |

| Cutting bits | Gloves |

| Measuring tools | Ear protection |

Remember to also keep a comfy chair nearby. You’ll want to sit down to celebrate your awesome projects!

Steps to Set Up a Metal Lathe Using CAD Files

Importing and interpreting CAD files for setup. Stepbystep instructions for initial lathe setup.To set up a metal lathe with CAD files, start by importing the files into your software. This shows you how to arrange parts. Next, take time to understand each component. Follow these steps accurately:

- Check the lathe’s power supply.

- Align the tool holder and cutting tools properly.

- Adjust the speed settings based on your material.

- Test the machine without any load.

Each step counts. Safety and precision help you to make great metal parts!

How do I import CAD files for lathe setup?

To import CAD files, open your CAD software and select ‘Import’. Choose the right file type for your lathe.

What should I do during initial lathe setup?

During setup, ensure all parts align correctly and check settings. Secure the tools to avoid accidents.

Common Troubleshooting Tips During Setup

Identifying and resolving common setup issues. Maintenance tips for ensuring optimal performance.Setting up your metal lathe can be tricky. It’s common to face a few problems. Here are some tips to help you fix them:

- Check the power supply; ensure it’s connected.

- Make sure all parts are secure and properly installed.

- Adjust the tool height to the correct level.

- Lubricate moving parts for smooth function.

Regular maintenance keeps your lathe working well. Clean it often and check for wear. Remember, a well-cared lathe lasts longer and runs better!

What are common setup issues for a lathe?

Common issues include misaligned parts, loose connections, and incorrect tool height.How can I maintain my lathe?

Regular cleaning and lubrication are key.Advanced Techniques for Optimizing Lathe Performance

Tailoring CAD designs for specific lathe capabilities. Exploring automation and software integration for enhanced output.To boost your lathe setup, think about custom CAD designs. Each lathe has its own quirks, so a tailored design can work wonders. It’s like giving your lathe a special power-up! Pair this with automation and software tools, and you can crank out projects faster than a rabbit on caffeine.

| Technique | Benefit |

|---|---|

| Custom CAD Designs | Enhances precision for unique projects |

| Automation Integration | Increases speed and reduces manual work |

| Software Compatibility | Streamlines workflow and improves accuracy |

With these advanced techniques, you’ll be spinning out metal pieces that even a squirrel would envy!

Conclusion

In conclusion, having the right CAD files for metal lathe setup is crucial for success. You can design, modify, and improve your projects easily. Make sure to explore different resources online for quality CAD files. By practicing your setup skills, you will get better with each project. Keep learning and experimenting to master your metal lathe!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Setup:Sure! A CAD file is like a blueprint for machines. You use it to design parts for a lathe, which is a tool that shapes metal. To set up a metal lathe, you need to secure the metal piece and choose the right tools. Then, you follow the design in the CAD file to cut the metal into the right shape. Always remember to wear safety gear when using a lathe!

Sure! Please provide the question you would like me to answer.

What Are The Best Cad Software Options For Designing Components Specifically For Metal Lathe Machining?If you want to design parts for a metal lathe, some good software options are Fusion 360, SolidWorks, and TinkerCAD. Fusion 360 is great for beginners and has lots of tools. SolidWorks is a bit more advanced and good for detailed designs. TinkerCAD is easy to use and perfect if you’re just starting out. These programs help you create 3D models that you can turn into real parts.

How Can I Convert Cad Files Into A Format Compatible With Cnc Lathes?To convert CAD files into a format for CNC lathes, you need software. This software changes the CAD design into a code the CNC machine can understand. You can use programs like Fusion 360 or AutoCAD. Once you have the right software, open your CAD file and choose the option to export or save as a different format, like G-code. Then, you upload this new file to the CNC lathe.

What Considerations Should I Keep In Mind When Creating Cad Models For Complex Metal Lathe Setups?When creating CAD models for metal lathe setups, you should think about the shape and size of the parts. Make sure the details are clear and easy to see. You also need to think about how the machine will move and work with the models. Lastly, check your design for any problems before you use it. This helps everything fit together right.

How Do I Optimize My Lathe Setup For Efficiency And Precision Based On My Cad Designs?To make your lathe work better, start by checking your CAD designs. Make sure your measurements are correct. Next, set up your lathe tools for the cuts you need. Keep your work area clean and organized. Lastly, test your setup with a small piece before doing big projects. This way, you’ll save time and get better results!

What Are Some Common Mistakes To Avoid When Drafting Cad Files For Metal Lathe Projects?When making CAD files for metal lathes, don’t forget to check your measurements. Always use the right units, like inches or millimeters. Make sure shapes fit together well; they shouldn’t overlap. Also, remember to save your work often to avoid losing it. Lastly, avoid adding too many details that don’t help make the part.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Setup:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A CAD file is like a blueprint for machines. You use it to design parts for a lathe, which is a tool that shapes metal. To set up a metal lathe, you need to secure the metal piece and choose the right tools. Then, you follow the design in the CAD file to cut the metal into the right shape. Always remember to wear safety gear when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Cad Software Options For Designing Components Specifically For Metal Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you want to design parts for a metal lathe, some good software options are Fusion 360, SolidWorks, and TinkerCAD. Fusion 360 is great for beginners and has lots of tools. SolidWorks is a bit more advanced and good for detailed designs. TinkerCAD is easy to use and perfect if you’re just starting out. These programs help you create 3D models that you can turn into real parts.”}},{“@type”: “Question”,”name”: “How Can I Convert Cad Files Into A Format Compatible With Cnc Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To convert CAD files into a format for CNC lathes, you need software. This software changes the CAD design into a code the CNC machine can understand. You can use programs like Fusion 360 or AutoCAD. Once you have the right software, open your CAD file and choose the option to export or save as a different format, like G-code. Then, you upload this new file to the CNC lathe.”}},{“@type”: “Question”,”name”: “What Considerations Should I Keep In Mind When Creating Cad Models For Complex Metal Lathe Setups?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When creating CAD models for metal lathe setups, you should think about the shape and size of the parts. Make sure the details are clear and easy to see. You also need to think about how the machine will move and work with the models. Lastly, check your design for any problems before you use it. This helps everything fit together right.”}},{“@type”: “Question”,”name”: “How Do I Optimize My Lathe Setup For Efficiency And Precision Based On My Cad Designs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your lathe work better, start by checking your CAD designs. Make sure your measurements are correct. Next, set up your lathe tools for the cuts you need. Keep your work area clean and organized. Lastly, test your setup with a small piece before doing big projects. This way, you’ll save time and get better results!”}},{“@type”: “Question”,”name”: “What Are Some Common Mistakes To Avoid When Drafting Cad Files For Metal Lathe Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making CAD files for metal lathes, don’t forget to check your measurements. Always use the right units, like inches or millimeters. Make sure shapes fit together well; they shouldn’t overlap. Also, remember to save your work often to avoid losing it. Lastly, avoid adding too many details that don’t help make the part.”}}]}