Have you ever wondered how metal parts are shaped with precision? One important tool for this task is the lathe. A lathe helps make round or cylindrical items by removing material. But, there’s more to it than just a spinning piece. The lathe collet system makes changing tools quick and easy.

Imagine you are working on a project that needs different tools. You don’t want to waste time switching tools every few minutes. This is where the quick change tool post shines. It allows you to switch tools quickly and keeps your work flowing.

Did you know that using a lathe collet system can help make your work more accurate? It holds the tool tightly in place, reducing mistakes. So, whether you are a hobbyist or a professional, this tool system can be a game changer. Let’s dive deeper into the benefits of the lathe collet system and how it works with the quick change tool post.

Lathe Collet System: Metal Lathe Quick Change Tool Post Solutions Introduction In Metalworking And Machining, Efficiency Is Key. One Of The Prominent Solutions That Enhance Both Productivity And Precision In Metalworking Is The Lathe Collet System. This Article Delves Into The Lathe Collet System And Its Integration With The Metal Lathe Quick Change Tool Post, Exploring Their Benefits, Functionality, And How They Can Significantly Improve Your Machining Operations. Understanding Lathe Collet Systems A Lathe Collet System Is A Clamping Mechanism Specifically Designed To Securely Hold Round Or Hexagonal Workpieces In Place During Machining. Unlike Traditional Chucks, Collets Provide A More Uniform Grip, Which Is Crucial For Maintaining Precision. They Are Available In Various Sizes And Types, Making Them Versatile For Different Lathe Applications. The Importance Of Metal Lathe Quick Change Tool Posts Metal Lathe Quick Change Tool Posts Allow For Rapid Tool Transitions Without The Need For Extensive Setup Times. This Feature Is Vital For Shops That Deal With Frequent Workpiece Changes Or Have A Diverse Array Of Tasks. Quick Change Tool Posts Save Time, Reduce Operator Fatigue, And Ultimately Enhance The Overall Efficiency Of The Lathe Operations. Advantages Of Combining Collet Systems With Quick Change Tool Posts Integrating A Lathe Collet System With A Metal Lathe Quick Change Tool Post Presents Several Advantages: 1. **Enhanced Efficiency**: Tool Changes Become Faster And More Effortless, Allowing For Less Downtime. 2. **Consistent Precision**: Collets Minimize The Possibility Of Workpiece Slippage, Ensuring Consistent Cuts And Dimensions. 3. **Versatility**: Users Can Easily Switch Between Different Tools And Workpieces, Accommodating Various Machining Requirements. 4. **Improved Setup Times**: With A Simplified Clamping Mechanism, Setup Times Are Drastically Reduced. Conclusion The Combination Of A Lathe Collet System With A Metal Lathe Quick Change Tool Post Represents A Significant Advancement In Machining Technology. This Integration Not Only Boosts Efficiency And Precision But Also Allows Operators To Handle A Wider Range Of Tasks With Ease. Investing In These Systems Is A Step Towards Modernizing Your Machining Processes And Achieving Higher Quality Results.

Understanding Lathe Collet System for Metal Lathes

A lathe collet system is a clever way to grip tools securely on a metal lathe. Imagine quickly changing tools without wasting time! This system allows for fast swaps, enhancing productivity. The quick change tool post simplifies adjustments while working. Did you know that using collets can lead to a smoother finish on your workpieces? With these systems, even beginners can achieve professional results easily and efficiently. Explore how a collet system can transform your lathe experience!What is a Lathe Collet System?

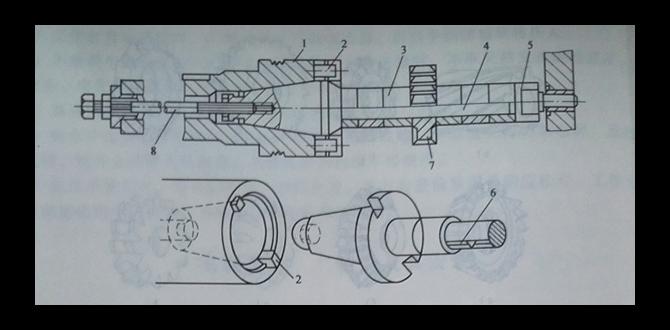

Definition and components of a lathe collet system.. Advantages of using collets in metalworking..A lathe collet system is a clever tool that holds parts securely while they spin. Think of it like a strong hug for metal! It uses special nuts and sleeves to grip workpieces tightly, making it easy to switch tasks. This system is popular because it saves time and offers precision.

| Component | Function |

|---|---|

| Collet | Grips the workpiece |

| Nut | Secures the collet in place |

| Adapter | Connects the collet to the lathe |

Using collets in metalworking has its perks! They provide better grip, reduce vibration, and allow for quick changes. This means less time fiddling with tools and more time creating. Who wouldn’t want that? So, if you want to boost your metalworking game, consider trying a lathe collet system!

Benefits of a Quick Change Tool Post

Efficiency improvements in operation time.. Enhanced versatility for varying machining tasks..A quick change tool post makes your work on a lathe faster and easier. It lets you switch tools in a snap, which means less waiting and more making! Imagine finishing tasks in half the time—less time watching the clock and more time crafting. Plus, you can tackle all sorts of projects without missing a beat. Variety is the spice of life, right? Here’s a quick look at its fantastic perks:

| Benefit | Description |

|---|---|

| Efficiency | Change tools quickly to save time. |

| Versatility | Handle many tasks with ease. |

With a quick change tool post, you can cut down operation time while enjoying the flexibility to switch between multiple machining tasks. It’s like having a Swiss Army knife for metalworking!

How to Install and Set Up a Collet System on a Metal Lathe

Stepbystep guide to installation.. Common pitfalls to avoid during setup..Adding a collet system to your metal lathe can boost your work efficiency. First, take a moment to read the manual. A little reading can save you from big mistakes! Next, follow these steps:

| Step | Action |

|---|---|

| 1 | Clean the lathe’s spindle area. |

| 2 | Install the collet chuck securely. |

| 3 | Test the fit with different collets. |

Watch out for common issues! Many forget to align the collet properly. This can result in wobbly workpieces. Remember, poor alignment leads to poor performance! With these tips, you’ll set up your collet swiftly and start making magic on your lathe!

Maintaining Your Lathe Collet System

Recommended maintenance practices for longevity.. Signs that indicate need for maintenance or replacement..To keep your lathe collet system in great shape, follow these easy tips:

- Regularly clean the collet and spindle to avoid grime build-up.

- Check for wear and tear on the collet teeth.

- Lubricate moving parts to ensure smooth operation.

- Store collets in a dry place to prevent rust.

Watch for these signs to know when to maintain or replace:

- Difficulty tightening or loosening the collet.

- Unusual vibrations during use.

- Visible damage or cracks on the collet.

What are the signs that your lathe collet system needs maintenance?

Check for tightness issues, strange sounds, or visible damage. These signs mean it’s time to act!

Applications of Lathe Collet Systems in Metalworking

Common industries and projects utilizing collet systems.. Examples of specific machining tasks improved by collets..Many businesses use lathe collet systems in their metalwork. They help make the work faster and easier. Common industries include:

- Aerospace: for precise parts

- Automotive: for gears and shafts

- Manufacturing: for creating tools

Collets improve various tasks, such as:

- Holding small parts securely

- Changing tools quickly

- Finishing jobs with high accuracy

With lathe collet systems, workers save time and energy, making their projects more efficient.

What tasks can lathe collets improve?

Lathe collets can improve tasks like quick tool changes, precise part holding, and cutting accuracy. They help workers finish jobs faster and with better quality.Choosing the Right Collet System for Your Metal Lathe

Factors to consider when selecting a collet system.. Recommendations based on specific use cases or materials..Picking the right collet system for your metal lathe is important. Consider these factors:

- Material type

- Collet size

- Workpiece shape

- Precision needs

For soft materials, like aluminum, use expand collets. It’s easier to grip. For harder materials, like steel, consider using precision collets. They offer better stability. Always choose the collet that fits your specific project to get the best results.

What should I consider when choosing a collet system?

Think about the type of work you do and the materials you’ll use. Matching your collet to your project makes your work more efficient and precise.

Conclusion

In conclusion, a lathe collet system makes changing tools quick and easy. A quick change tool post saves you time and boosts your efficiency. With these tools, you can work on projects more smoothly. We encourage you to explore different models and find the best fit for your metal lathe. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Quick Change Tool Posts For Metal Lathes:Sure! A lathe is a machine that helps us shape metal. A collet system holds tools tightly so they don’t move around. Quick change tool posts let you switch tools fast, saving you time. This makes working with lathes easier and faster. Both are great for anyone who works with metal!

Sure! Please give me the question you’d like me to answer.

What Are The Advantages Of Using A Collet System Compared To Traditional Chuck Systems In Metal Lathes?Using a collet system on a metal lathe has some cool benefits. Collets hold the metal pieces tighter, which means they won’t move around when you work. This helps you make better and more accurate cuts. Collets are also easier to change, saving you time while you work. Overall, they make your project quicker and smoother!

How Do Quick Change Tool Posts Improve Efficiency And Productivity In Machining Operations On A Lathe?Quick change tool posts help you switch tools on a lathe very fast. Instead of taking a long time to change tools, you can do it in a few seconds. This means you spend less time waiting and more time making things. This quick change makes work easier and lets you finish more jobs in a day. That’s why they help with efficiency and productivity!

What Factors Should Be Considered When Selecting A Collet Size And Type For Specific Metalworking Applications?When choosing a collet size and type, think about the size of the tool you’ll use. You need a collet that matches your tool for a safe fit. The type of metal you’re working with matters too. Some metals need more grip to prevent slipping. Finally, consider the machine you have; it should work well with the collet you choose.

Can A Quick Change Tool Post Be Installed On Any Metal Lathe, Or Are There Compatibility Issues That Need To Be Addressed?A quick change tool post can’t be used on every metal lathe. Each lathe has different sizes and shapes. You need to check the size of your lathe and the tool post. Some tools may fit on certain lathes but not others. Always read the instructions to be sure!

What Maintenance Practices Are Recommended To Ensure Optimal Performance And Longevity Of Lathe Collet Systems And Quick Change Tool Posts?To keep lathe collet systems and quick change tool posts working well, you should clean them often. Use a soft cloth to wipe away dust and chips. Check for any signs of rust or damage. Make sure to lubricate moving parts with the right oil. Finally, store them safely when you’re not using them. This helps them last longer!