If you love building things, you might have thought about using a lathe. A lathe is a tool that spins material to shape it. Imagine making your very own metal parts! But did you know you can convert other tools to work like a metal lathe? This is called a lathe conversion. It opens up new possibilities for projects.

Have you ever wondered what it feels like to create a unique design from scratch? With a lathe conversion, you can take an ordinary bench tool and turn it into a powerful metal lathe. Think about all the cool things you could make! From toys to practical gadgets, the sky is the limit.

Let’s dive deeper into how this works. You may be surprised by how simple it can be to transform your bench tool. By learning the right steps, you can unleash your creativity. Get ready to discover the amazing world of lathe conversions!

Lathe Conversion: Transforming A Metal Lathe Bench Efficiently

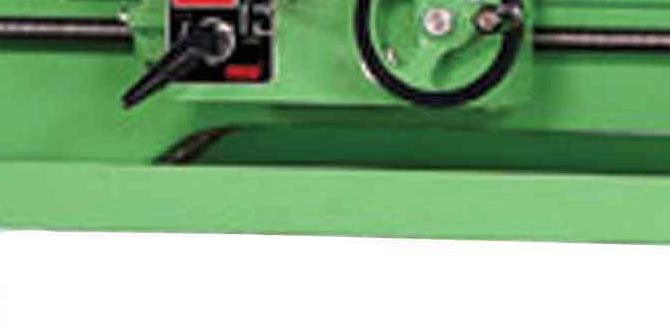

Lathe Conversion Metal Lathe Bench

Converting a regular bench into a metal lathe brings creativity to your workshop. Imagine transforming ordinary tools into precise machines. A lathe conversion saves money and space. DIY enthusiasts often share tips on selecting the right materials and ensuring stability. Did you know a sturdy bench can enhance your lathe’s performance? This conversion can empower you to create projects you never thought possible. With a little effort, you can craft beautiful pieces from metal, wood, and more!Understanding Lathe Conversion

Definition of lathe conversion. Importance of upgrading to a metal lathe bench.Lathe conversion means upgrading an older lathe into a better, more precise machine. This change makes your work smoother and faster. A metal lathe bench is solid and helps you create strong parts for projects. With this upgrade, you can:

- Make accurate cuts.

- Build bigger projects.

- Increase your efficiency.

Investing in a metal lathe bench is important for better results and long-lasting tools. It can truly transform your workshop experience!

Why Upgrade to a Metal Lathe Bench?

Upgrading to a metal lathe bench increases precision and effectiveness in all your tasks. A stable surface helps prevent movement while working. This leads to cleaner cuts and a safer workspace.

Benefits of Converting to a Metal Lathe Bench

Enhanced precision and accuracy. Increased durability and longevity.Switching to a metal lathe bench offers great perks. First, it boosts precision and accuracy. This means your projects turn out sharper than a freshly sharpened pencil! Plus, these benches are built to last. They have increased durability and longevity, so they won’t fall apart during your weekend hobby. A sturdy bench supports your work, allowing you to tackle tough jobs without breaking a sweat. Let’s dive into the numbers!

| Feature | Benefits |

|---|---|

| Precision | Improved accuracy leads to better-quality work. |

| Durability | Lasts longer, saving you money in the long run! |

Step-by-Step Process of Lathe Conversion

Preparation and planning for the conversion. Detailed instructions for each conversion phase.Before you start converting your lathe, a bit of planning helps. Gather all the tools and parts you’ll need; it’s like getting ready for a treasure hunt! Make a checklist, and stay organized, so you won’t suddenly need that missing wrench two hours in. Here’s a simple table to guide your preparation:

| Item | Description |

|---|---|

| Tools | Wrenches, screwdrivers, and a safety goggles |

| Parts | New motor, control box and belts |

| Space | A clean, flat workbench |

Now, let’s get down to the fun part! Follow these phases step-by-step, like following a recipe for cookies. It starts with disassembly – gently take apart parts like the motor and carriage. Next, clean everything up; dirt is not your friend! Afterward, install the new motor. Finally, connect the control box and test your masterpiece. With patience, you will have a great lathe that runs smoothly. Enjoy the process; it’s like making your old contraption feel young again!

Common Challenges and Solutions

Identification of typical obstacles during conversion. Practical tips for overcoming these challenges.Converting a machine can feel like solving a puzzle with missing pieces. Some common hiccups include choosing the right tools, understanding instructions, and not having enough space. But fear not! Keep your workspace tidy, and double-check your parts. A helpful tip: use labeled boxes for each tool, so you’re not searching like a squirrel in winter. It saves time and headaches.

| Challenge | Solution |

|---|---|

| Choosing the Right Tools | Read the manual and make a list! |

| Understanding Instructions | Take it step by step; maybe even grab a buddy! |

| Having Enough Space | Clear your bench; a shiny work area is a happy area! |

By tackling these challenges with simple strategies, you’ll be well on your way to becoming a lathe conversion pro. Remember, every expert was once a beginner who didn’t quit!

Maintenance Tips for Your Converted Metal Lathe Bench

Regular maintenance practices to extend lifespan. Troubleshooting common issues postconversion.To keep your converted metal lathe bench in top shape, regular maintenance is key. This not only helps it run better but also extends its lifespan. Here are some useful tips:

- Check and tighten bolts every month.

- Clean chips and dust after every use.

- Oil moving parts regularly.

- Inspect belts for wear and tear.

If you face issues like vibrations or strange noises, don’t worry. First, make sure everything is properly tightened. If vibrations continue, check for misaligned parts. A little care goes a long way in keeping your lathe bench working smoothly!

What are common problems after converting a metal lathe?

Common issues include vibration, noise, and misalignment. Proper adjustments and lubrication can often fix these problems.

Cost Analysis of Lathe Conversion

Breakdown of potential expenses involved. Costbenefit comparison of upgrading versus new purchase.Understanding costs is key in lathe conversions. First, consider potential expenses. This might include parts, tools, and labor. A breakdown is helpful:

- Parts: $300 – $800

- Tools: $100 – $300

- Labor: $200 – $500

Next, think about the cost-benefit. Upgrading can be cheaper than buying new. A new lathe might cost $2,000 or more. Upgrading saves money but needs careful planning.

Why Upgrade a Lathe?

Upgrading a lathe often costs less and can improve your current machine’s performance. It’s smart to analyze needs and expenses before making a decision.

Real-Life Case Studies of Successful Lathe Conversions

Examples of users who have converted their lathes. Lessons learned and outcomes achieved.Many people have taken on the challenge of converting their lathes, resulting in some fascinating successes. For example, one user transformed an old lathe into a high-speed masterpiece. They learned that patience is key. Another turned a simple model into a CNC machine, discovering that a little wiring magic works wonders. These cases show that with creativity and effort, big improvements are possible. Plus, you might just need a dancing monkey to cheer you on!

| User | Transformation | Lessons Learned |

|---|---|---|

| User A | High-speed lathe | Patience pays off. |

| User B | CNC machine | Wiring can be fun! |

These stories show how exciting lathe conversions can be. They prove that small changes can lead to big results and a few laughs along the way!

Resources for Further Learning

Recommended books, websites, and forums for lathe enthusiasts. Online courses and workshops for advanced techniques.If you’re curious about improving your lathe skills, you’re in luck! There are plenty of resources to help you zoom ahead. First, consider reading some fantastic books and check out popular websites about lathe techniques. Forums, like a digital gathering of lathe lovers, can give you tips and tricks only the pros know. Want to level up your game? Try online courses and workshops to master advanced methods. After all, every great woodworker needs a little help, right? Remember, even the best lathes started as just a couple of metal pieces!

| Type | Resource |

|---|---|

| Books | The Complete Guide to Lathes |

| Websites | LatheWorld.com |

| Forums | LatheTalk.com |

| Online Courses | Udemy’s Lathe Mastery Course |

Conclusion

In conclusion, a lathe conversion transforms a regular bench into a useful metal lathe. This upgrade improves your crafting and saves space. You get better precision and efficiency for your projects. If you’re interested in metalworking, consider trying a conversion yourself. Explore guides and videos for tips, and start creating amazing things today!FAQs

What Are The Essential Features To Consider When Converting A Bench For A Metal Lathe Setup?When converting a bench for a metal lathe, you need to think about a few key things. First, make sure the bench is sturdy. A strong bench keeps the lathe stable while you work. Next, check the height; it should feel comfortable when you stand or sit. Also, have enough space around the lathe so you can move easily and safely. Finally, consider good lighting to see your work clearly.

How Can I Determine The Appropriate Size And Weight Capacity For A Bench To Support A Metal Lathe?To find the right size and weight capacity for a bench to hold a metal lathe, start by checking the lathe’s manual. It will tell you how much weight it needs to be safe. Next, measure the space where you want to put the bench. Make sure the bench is big enough to fit the lathe and your working area. Finally, choose a sturdy bench that can hold at least the weight of the lathe plus some extra for safety.

What Types Of Materials Are Best Suited For Constructing A Sturdy Metal Lathe Bench?To build a strong metal lathe bench, you should use thick wood or heavy metal. Solid wood like oak is great because it’s tough and stable. Steel or welded metal can make the bench very strong, too. You want materials that won’t bend or break when you use the lathe. Choose something that can hold the weight of your tools!

What Are The Common Mistakes To Avoid When Converting An Existing Workbench Into A Metal Lathe Bench?When you convert a workbench into a metal lathe bench, avoid a few common mistakes. First, make sure the bench is strong enough. A weak bench can break when you use the lathe. Second, check that the lathe is level. If it’s not level, your work will be uneven. Lastly, remember to keep the area around the lathe clean and organized. A messy space can lead to accidents.

How Can I Optimize The Layout Of My Metal Lathe Bench For Efficiency And Ergonomics?To make your metal lathe bench better, start by placing tools you use often within easy reach. Keep your lathe in the center of the bench. Arrange your measuring tools and materials close by too. Make sure your chair or stool lets you sit comfortably while you work. Finally, keep the area tidy so you can find things quickly.