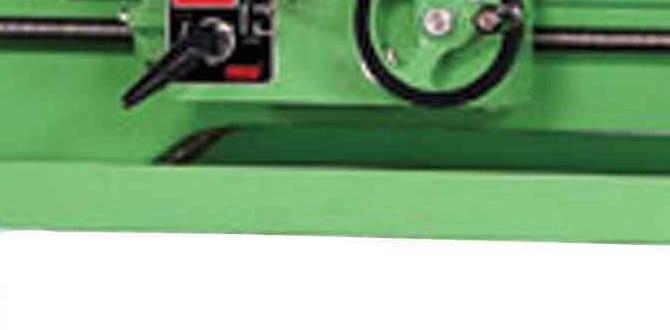

Have you ever wished for a magic tool that makes metal work easier? Imagine a metal lathe that runs like a well-oiled machine. With a lathe digital readout, you get just that! This incredible device shows you exactly how far the tool moves. It’s like having extra eyes to see your work.

Automation in metal lathes is changing the game. It helps make tasks quicker and more precise. Think about it: no more guessing. You can focus on your creative ideas instead of counting. Isn’t that exciting?

Take a moment to picture your workshop. What if every cut you make was perfect every time? With lathe digital readouts and automation, this dream can be a reality. Join us as we dive deeper into this fascinating world of metal lathe automation.

Lathe Digital Readout: Enhancing Metal Lathe Automation

Lathe Digital Readout Metal Lathe Automation

Do you know how a digital readout can change metal lathes? It makes setting measurements easier and faster. With this cool tech, you can see exact numbers on a screen instead of guessing. This helps create precise parts, which is super important in metalwork. Imagine cutting metal with perfect accuracy every time! Automation not only speeds up processes but also reduces errors. This means better quality and more productivity in workshops everywhere.What is a Digital Readout (DRO)?

Definition and functionality of DRO systems in machining.. Types of digital readouts used in metal lathes..A digital readout (DRO) is a smart gadget that helps machinists know exactly where their tools are. It tells you the precise position of the tool on a metal lathe. Using a DRO means fewer mistakes and more time to sip coffee instead of making adjustments. There are different types of DROs for metal lathes, including portable, fixed, and those with fancy features like touchscreens.

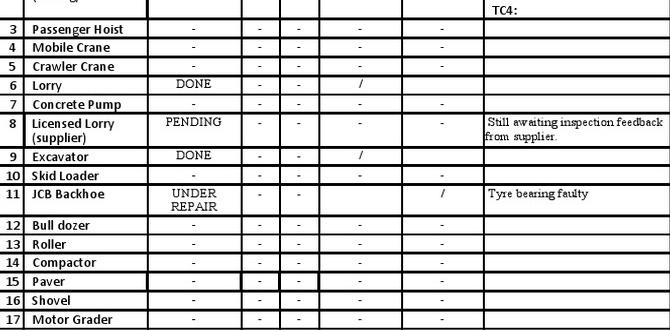

| Type of DRO | Features |

|---|---|

| Portable DRO | Easy to move, good for various machines |

| Fixed DRO | Stable, often more durable |

| Advanced DRO | Touchscreen, programmable options for experts |

In the world of machining, using a DRO is like having a GPS for your lathe – no more getting lost in the land of measurements!

Benefits of Using Digital Readouts on Metal Lathes

Improved accuracy in measurements and settings.. Timesaving advantages and increased productivity..Using digital readouts on metal lathes brings many benefits. First, they help you measure and set things with great accuracy. This means fewer mistakes. Next, they save time. You don’t have to guess or double-check. Instead, you can work faster. This leads to more work done in less time, boosting your productivity.

- Improved accuracy leads to better results.

- Time-saving features help you finish jobs quicker.

- Increased productivity allows for more projects completed.

How do digital readouts improve accuracy?

Digital readouts show exact measurements clearly. This reduces chances of error compared to manual methods.Integration of Digital Readouts with Automation

How DROs enhance the functionality of automated lathes.. Case studies of successful integration..Digital Readouts (DROs) are game-changers in automated lathes. They help machines work more accurately, saving time and reducing mistakes. With DROs, operators can see measurements in real time. This feature boosts efficiency. Case studies show that companies using DROs saw a 30% increase in production speed. Another company improved part accuracy, leading to less waste. These advancements make DROs essential for modern metal lathe automation.

How do DROs improve automated lathes?

DROs make automated lathes easier to use by displaying precise measurements. This means fewer errors and better products. Companies have reported smoother operations and faster production times.

Successful Case Studies

- One company cut production time by 30%.

- Another reduced waste by 25% using DROs.

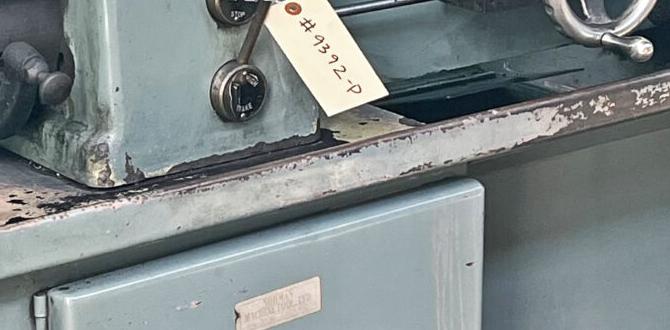

Installation Process of Digital Readouts on Metal Lathes

Stepbystep guide to installing a DRO system.. Common challenges faced during installation and solutions..Installing a digital readout (DRO) on a metal lathe can seem tough, but it’s easier if you follow steps. Here’s a simple guide:

- First, gather all the tools you need.

- Next, read the manual carefully.

- Then, attach the display unit to your lathe.

- After that, connect the sensors to measure movements.

- Lastly, test the system before using it.

Sometimes, you might face issues like misalignment or poor readings. To fix this, double-check all connections and ensure sensors are installed correctly. These steps will help you get your DRO working smoothly!

What challenges can arise during installation?

Common challenges include misalignment of parts or confusing wiring. These usually happen during setup. Use the manual for guidance. Also, carefully measure distances to avoid errors.

Installing a DRO can make your metal lathe work faster and more accurately. Remember to take your time and check everything. It’s worth the effort!

Maintaining Digital Readouts for Longevity

Tips for proper care and maintenance of DRO systems.. Signs of wear and troubleshooting common issues..Taking care of your digital readout (DRO) is as important as taking care of your favorite toy! Regular checks ensure it stays in tip-top shape. First, wipe the screen gently with a soft cloth to keep it clear—like cleaning drool off a puppy’s face. Watch out for signs of wear, like a flickering display or unresponsive buttons. These could mean trouble. Below is a quick reference table for easy maintenance:

| Tip | Description |

|---|---|

| Clean Regularly | Use a soft cloth to avoid scratches. |

| Check Connections | Ensure wires are snug and not frayed. |

| Calibration | Calibrate often for accurate readings. |

Remember, a well-maintained DRO is a happy DRO! It helps you avoid *frustration* and keeps your metal lathe running smoothly. Always pay attention to the details, and your DRO will last a long time, just like your favorite pair of socks (or at least until they get a hole in them!).

Trends in Metal Lathe Technology and Future Innovations

Emerging technologies in lathe automation and readings.. Predictions for the future of metal lathe operations..New tools are changing how metal lathes work. Machines get smarter with technology. Automation helps lathes run more smoothly. They can operate without so much help from people. Digital readouts make it easy to see measurements. This means better accuracy and less waste. In the future, we can expect powerful features like:

- More automated controls

- Advanced software for easy programming

- Greater precision in finishes

Some think that 50% of lathe operations will use automation in the next decade. This change will make work faster and safer for everyone.

What are the predictions for metal lathe technology?

Experts believe that metal lathe technology will become more automated and precise. This will lead to safer and faster workflows. New machines will use smart features that need less human help over time.

Choosing the Right Digital Readout for Your Needs

Factors to consider based on your specific lathe applications.. Comparing costs and specifications of popular models..Finding the perfect digital readout for your lathe can be as tricky as threading a needle with a spaghetti noodle. First, think about your specific lathe applications. Do you need precision for tiny parts or heavy-duty work? Next, let’s talk numbers! Cost matters. Some models may look fancy, but be sure they fit your wallet. Check this handy comparison:

| Model | Price | Features |

|---|---|---|

| Model A | $200 | Basic functions, user-friendly |

| Model B | $400 | Advanced features, great for pros |

| Model C | $300 | Good balance of cost and features |

Choosing wisely can save you time and headaches. Remember, investing in the right tool can make your work smoother than butter!

Conclusion

In conclusion, a lathe digital readout makes metal lathe automation easier and more precise. You can see measurements clearly, helping you work faster. This technology saves time and reduces mistakes. If you’re ready to improve your lathe skills, consider exploring more about digital readouts. Start practicing today and see how it transforms your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout And Metal Lathe Automation:A lathe is a machine that shapes metal. A digital readout shows you exact measurements as you work. Automation helps the lathe work by itself or with less help from you. This makes it faster and more accurate. Using these tools can make your projects easier and more fun!

Sure, I can do that! Just give me the question you want me to answer, and I’ll keep it simple and clear.

What Are The Key Benefits Of Using A Digital Readout System On A Metal Lathe Compared To Traditional Measurement Methods?Using a digital readout system on a metal lathe is really helpful. First, it shows the measurements right on a screen, making it easy to see. You won’t have to guess or use extra tools. This means you can work faster and make fewer mistakes. Plus, it can help you measure tiny parts more easily!

How Does Automation In Metal Lathes Improve Precision And Efficiency In Machining Processes?Automation in metal lathes helps make parts faster and more accurately. Machines can work without taking breaks. This means we get more pieces done in less time. They also make fewer mistakes because computers control everything. So, you’ll have better quality parts, and we can work quickly!

What Are The Common Features To Look For When Selecting A Digital Readout System For A Metal Lathe?When choosing a digital readout system for a metal lathe, look for a clear display. You want to see numbers easily. Check for simple buttons; they should be easy to use. Also, ensure it has good accuracy, so your measurements are right. Finally, see if it can fit your lathe well.

How Can Integrating Cnc Technology With Traditional Metal Lathes Enhance Productivity And Accuracy In Machining?Using CNC, which stands for Computer Numerical Control, with traditional metal lathes improves work. You can create parts faster because the computer helps with the cutting. It also makes the cuts very precise, so the pieces fit together better. By using both, we can save time and get better results in our projects.

What Are Some Troubleshooting Tips For Common Issues Encountered With Digital Readout Systems On Metal Lathes?If your digital readout isn’t working on a metal lathe, check the power first. Make sure the machine is plugged in and turned on. Next, look for loose wires or connections. If the display is still blank, try resetting the system, often just by turning it off and back on. Finally, clean the screen and the sensors to remove any dirt or dust.