Have you ever wondered how a metal lathe works? Perhaps you’ve seen one in action and were amazed by the precision it offers. A lathe is a powerful tool in any workshop. It shapes metal with speed and accuracy.

Many hobbyists and professionals use a digital readout system on their metal lathe. This feature makes measurements clearer and tasks easier. Imagine getting exact measurements just by looking at a screen! It can turn a tricky job into a simple one.

Think about your own bench at home. What if you could enhance it with modern technology? A digital readout could bring a world of difference. As more people discover this tool, the demand grows. Almost every metalworker wants to try it out.

So, if you’re curious about how a lathe digital readout can change the way you work, keep reading! You’ll learn why this tool is becoming essential for many metal lathe users.

Lathe Digital Readout For Metal Lathe Bench Efficiency

Lathe Digital Readout for Metal Lathes

A lathe digital readout for a metal lathe bench is a tool that helps you measure with precision. It displays measurements digitally, reducing mistakes while machining. Imagine you’re cutting metal for a project; wouldn’t it be nice to get exact measurements easily? These readouts improve accuracy and save time. Plus, you can often install them on various lathe models. Using one can transform your metalworking experience into a hassle-free journey!What is a Digital Readout (DRO)?

Definition and purpose of a DRO. Benefits of using a DRO in metal lathes.A digital readout (DRO) is a smart tool that shows exact measurements on machines like metal lathes. It helps you see how far the tool moves, which is super handy! Instead of counting turns or guessing, you get precise numbers. This cuts mistakes in half! Using a DRO makes your work easier and faster. It’s like having a little librarian reminding you where all the good information is, but for your lathe! Plus, it brings a sprinkle of technology to your workshop—maybe it will even ask for a coffee break!

| Benefits of Using a DRO |

|---|

| Improved accuracy |

| Time-saving |

| Easy to read display |

| Less guessing games |

Key Features to Consider in a Digital Readout

Accuracy and precision. Display quality and usability. Input options and interface.Choosing the right digital readout for your bench lathe is crucial. First, accuracy and precision matter. A great readout shows measurements perfectly, so your projects turn out just right—no wobbly chairs allowed! Next, consider display quality and usability. You want something easy to read, even during a coffee spill!

Look for input options and an intuitive interface. A friendly design makes using the readout much easier—like having a buddy in the workshop. So, check for buttons that are easy to press, especially if you’re a fan of donuts over dumbbells!

| Feature | Importance |

|---|---|

| Accuracy | Essential for perfect cuts |

| Display Quality | Easy to read in all lighting |

| Input Options | Convenient to use |

Types of Digital Readouts for Metal Lathes

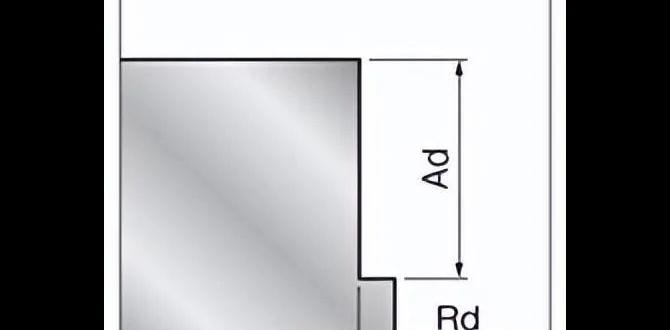

2axis versus 3axis DROs. Differences between magnetic and glass scale DROs.There are two main types of digital readouts (DROs) for metal lathes: 2-axis and 3-axis. A 2-axis DRO measures two directions, usually the X and Y axes. It’s simpler and often cheaper. A 3-axis DRO adds the Z-axis for depth measurement, making it more versatile for complex tasks.

Also, DROs can use magnetic or glass scales:

- Magnetic scales are durable and resistant to dirt.

- Glass scales provide high accuracy and clarity but can be fragile.

Each type has strengths. Choosing depends on your specific needs and work style.

What is a DRO for a lathe?

A DRO is a device that shows precise measurements on a lathe, making it easier to cut and shape materials accurately. It helps avoid mistakes and improves the quality of the final product.

Installation Tips for Your Digital Readout

Stepbystep installation process. Common challenges and solutions.Installing a digital readout is simpler than it seems. Start by turning off your metal lathe. Then, follow these steps:

- ***Mount the display unit*** onto the lathe arm.

- ***Attach the measuring scales*** to key points on the lathe.

- ***Connect the wires*** according to the manual.

Common challenges include misalignment and poor connectivity. To fix this, double-check all connections and align the scales properly. A good tip is to ask for help if you get stuck!

What are common issues during installation?

Some face difficulty aligning the scales or connecting the wires. Always ensure you follow the instructions closely. Double-check your work to avoid mistakes.

Calibration and Maintenance of Digital Readouts

Importance of regular calibration. Best practices for maintenance and care.Checking your digital readout is important. Regular calibration keeps it accurate. This helps you make better cuts and saves material. Without it, mistakes can happen, leading to waste. Maintenance is key, too. Take care of your machine to keep it running smoothly. Here are some best practices:

- Clean the display regularly.

- Check connections often.

- Store your lathe in a dry place.

- Update software as needed.

Follow these tips to ensure a long-lasting, reliable tool that gives precise readings every time.

Why is calibration important?

Calibration is important because it keeps the measurements accurate. This helps prevent errors and waste in metalworking.

Best maintenance tips:

- Inspect parts regularly.

- Check for wear and tear.

- Replace damaged components.

Taking care of your digital readout helps you work safely and efficiently.

Upgrading Your Metal Lathe with a DRO: Is It Worth It?

Costbenefit analysis. Impact on efficiency and accuracy.Installing a digital readout (DRO) on your metal lathe can make a big difference. It helps you measure accurately and work faster. Here are some reasons why it can be worth the cost:

- Boosts Efficiency: A DRO makes setup quicker and cuts time on each project.

- Increases Accuracy: You can measure in real-time, reducing errors in your work.

- Long-term Savings: A small investment leads to fewer mistakes and wasted materials.

Upgrading can pay off in the long run. Many people find it a smart choice!

Is upgrading worth it?

Yes, it can improve your work quality and speed! Many users notice these benefits right away, making it easier to justify the costs.

Common Issues and Troubleshooting Tips

Frequent problems encountered with DROs. Solutions for effective troubleshooting.Using a digital readout (DRO) on a metal lathe is great, but problems can happen. Common issues include miscalibration, flickering screens, or incorrect measurements. It’s like your DRO decided to take a vacation! To fix these, first, recalibrate your device; often, a quick adjustment can save your project. Check for loose wires, too; those sneaky connections can cause all sorts of trouble! Here’s a table for quick fixes:

| Problem | Solution |

|---|---|

| Miscalibration | Recalibrate the DRO settings. |

| Flickering Screen | Inspect and tighten connections. |

| Incorrect Measurements | Reset and double-check units. |

These tips should keep your lathe troubles to a minimum. Remember, even machines need some love!

Conclusion

In conclusion, a lathe digital readout enhances your metal lathe bench by improving accuracy and ease of use. This tool helps you measure quickly and precisely, making projects easier and more enjoyable. Consider exploring different models to find one that suits your needs. With a digital readout, you’ll see a big difference in your work. Let’s get turning!FAQs

What Are The Key Features To Look For In A Digital Readout System For A Metal Lathe Bench?When looking for a digital readout system for a metal lathe bench, you want some important features. First, it should be easy to read, with clear numbers. Next, it should have simple controls so you can use it easily. You’ll also want it to measure in both millimeters and inches. Lastly, a good system should be durable, so it can last a long time in your workshop.

How Does A Digital Readout Improve Precision And Efficiency When Operating A Metal Lathe?A digital readout shows you exact measurements on a screen. This helps you see how much you are cutting. You can adjust the tool very precisely, which makes your work better. It also saves time because you don’t have to measure with a ruler. This means you finish your projects faster and easier!

What Are Some Common Installation Practices For Integrating A Digital Readout Onto A Metal Lathe?To install a digital readout on a metal lathe, first, you need to clean the area where it will go. You can mount sensors on the lathe’s parts to measure movement. Make sure to connect all the wires carefully, following instructions. Finally, test the system to see if it works right. This helps you use your lathe better!

Can A Digital Readout Be Retrofitted To Older Metal Lathe Models, And What Considerations Should Be Taken Into Account?Yes, you can add a digital readout, or DRO, to older metal lathe models. First, check if your lathe has enough space for the new parts. You also need to consider the type of DRO that fits your lathe properly. Look at the installation instructions and ask for help if you’re unsure. Finally, make sure you understand how to use the DRO once it’s installed.

What Are The Maintenance Requirements For Ensuring The Longevity And Accuracy Of A Digital Readout System On A Metal Lathe?To keep your digital readout system on a metal lathe working well, you should clean it often. Dust and dirt can make it not work properly. You also need to check the cables for any damage. Finally, replace batteries when they run low to keep everything powered. Taking these steps helps your system last longer and stay accurate!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Digital Readout System For A Metal Lathe Bench? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking for a digital readout system for a metal lathe bench, you want some important features. First, it should be easy to read, with clear numbers. Next, it should have simple controls so you can use it easily. You’ll also want it to measure in both millimeters and inches. Lastly, a good system should be durable, so it can last a long time in your workshop.”}},{“@type”: “Question”,”name”: “How Does A Digital Readout Improve Precision And Efficiency When Operating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout shows you exact measurements on a screen. This helps you see how much you are cutting. You can adjust the tool very precisely, which makes your work better. It also saves time because you don’t have to measure with a ruler. This means you finish your projects faster and easier!”}},{“@type”: “Question”,”name”: “What Are Some Common Installation Practices For Integrating A Digital Readout Onto A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a digital readout on a metal lathe, first, you need to clean the area where it will go. You can mount sensors on the lathe’s parts to measure movement. Make sure to connect all the wires carefully, following instructions. Finally, test the system to see if it works right. This helps you use your lathe better!”}},{“@type”: “Question”,”name”: “Can A Digital Readout Be Retrofitted To Older Metal Lathe Models, And What Considerations Should Be Taken Into Account? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can add a digital readout, or DRO, to older metal lathe models. First, check if your lathe has enough space for the new parts. You also need to consider the type of DRO that fits your lathe properly. Look at the installation instructions and ask for help if you’re unsure. Finally, make sure you understand how to use the DRO once it’s installed.”}},{“@type”: “Question”,”name”: “What Are The Maintenance Requirements For Ensuring The Longevity And Accuracy Of A Digital Readout System On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your digital readout system on a metal lathe working well, you should clean it often. Dust and dirt can make it not work properly. You also need to check the cables for any damage. Finally, replace batteries when they run low to keep everything powered. Taking these steps helps your system last longer and stay accurate!”}}]}