Have you ever watched a metal lathe in action? It can be fascinating to see how these machines shape metal into precise parts. But what if you could make this process even easier and more accurate? That’s where a lathe digital readout comes in.

A digital readout shows the exact position of your lathe tool. It gives you numbers instead of guesswork. Imagine cutting your metal piece perfectly every time. Wouldn’t that save you time and make your work more enjoyable?

Now, combine this with a power feed. A power feed moves the tool automatically. No more manual cranking! This means more focus on your project and less fatigue. It’s like having an extra set of hands.

Many hobbyists and professionals swear by these tools. They can transform the way you work with a metal lathe. So, if you want to boost your machining skills, keep reading. You might just discover how a lathe digital readout and power feed can change your projects for the better!

Lathe Digital Readout: Enhancing Metal Lathe Power Feed Efficiency

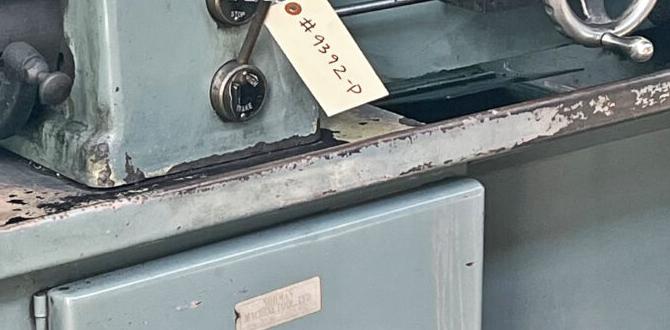

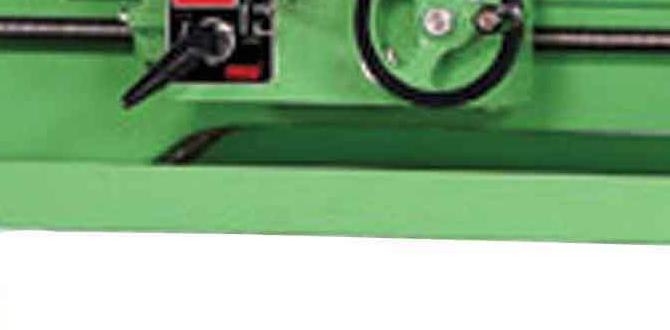

Lathe Digital Readout and Power Feed

Discover how a lathe digital readout enhances precision in metal lathing. Imagine crafting a perfect piece of metal with ease! A digital readout provides clear measurements for accuracy. It helps you avoid mistakes that can waste time and materials. The power feed aids in automatic movement, making your work smoother. With these tools, you can achieve professional results right at home. It’s like having a skilled guide by your side! Why not upgrade your lathe experience today?Understanding Lathe Digital Readouts

Explanation of digital readout technology in metal lathes. Importance of accuracy and ease of use in machining processes.Digital readouts (DROs) help people using metal lathes measure size accurately. They replace old measuring tools, making it simple to see numbers on a screen. This way, users get precise measurements quickly. Accuracy is key in machining, as even tiny mistakes can lead to big problems. Having easy-to-use displays not only saves time but also boosts confidence while working. Enhanced technology makes every cut smoother and smarter.

Why are digital readouts important?

Digital readouts are important because they improve accuracy and efficiency in machining tasks. They help users avoid mistakes and save time during projects.

Key Benefits of Digital Readouts:

- Precision: Ensure every measurement is exact.

- Speed: Check measurements quickly without hassle.

- Ease of use: Simple displays make it easy for beginners.

Benefits of Using a Digital Readout System

Improved measurement accuracy and reduced human error. Increased productivity and efficiency in machining operations.Using a digital readout system can change the way we work. This tool makes measurements more accurate. It helps to reduce human error. When mistakes happen less often, projects finish faster. With improved accuracy, we can trust our results more. This means increased productivity in machining operations. As a result, workers have more time to focus on other tasks. Everyone wins!

What are the key benefits of a digital readout system?

Key benefits include better accuracy in measurements, less mistakes, and faster work.Some advantages are:

- Improved measurement accuracy

- Reduced chance of human error

- Increased productivity

- Greater efficiency

Power Feed Systems: What You Need to Know

Definition and functioning of power feed systems in metal lathes. Benefits of integrating power feed with digital readouts.Power feed systems help metal lathes move automatically. This makes cutting easier and faster. Instead of turning a hand crank, the machine moves for you. This allows for more focus on the work. Digital readouts can work with power feeds. Together, they show exact measurements. This helps you avoid mistakes. Using both can improve speed and accuracy. Here are some key benefits:

- Increased precision in measurements

- Less physical effort needed

- Consistent cutting speed

What are the benefits of power feed systems?

Power feed systems increase precision, reduce physical strain, and maintain a steady cutting pace.

Installation and Setup of Lathe Digital Readout Systems

Stepbystep guide to installing a digital readout. Tips for troubleshooting common setup issues.Installing a digital readout system can seem tricky, but it’s easy with a good plan. Follow these steps:

- Start by gathering all your tools and parts.

- Carefully attach the scales to your lathe. Make sure they are straight.

- Connect the wiring to the display unit.

- Adjust settings on your readout for accuracy.

- Test the system to ensure it works.

What if you run into problems? Check these common issues:

- Ensure all connections are tight.

- Calibrate the scales if the numbers are off.

- Look for software updates for your system.

These tips can help you set up your digital readout smoothly!

What are some common troubleshooting tips?

Common issues often arise during installation. Ensure all connections are secure, and check calibration for accurate readings. If problems persist, software updates may be necessary.

Maintaining Your Lathe Digital Readout and Power Feed

Routine maintenance tips to prolong lifespan. Common problems and solutions.Taking care of your lathe’s digital readout and power feed is like keeping your pet goldfish happy—regular attention makes it last longer! First, check the connections and cables. Dust them off and keep things tidy. Routine checks can spot small issues before they become big headaches. If your readout goes blank, don’t panic! A simple reset might do the trick. Below is a handy table for quick tips:

| Maintenance Focus | Tips |

|---|---|

| Connections | Ensure they are clean and secure. |

| Power Feed | Lubricate regularly for smooth movement. |

| Display Issues | Reset the system to fix blank screens. |

By following these tips, your lathe can run like a champ (or at least like a well-oiled machine) for many years!

Real-world Applications of Lathe Digital Readouts and Power Feed

Examples of industries and projects benefiting from these systems. Case studies showcasing beforeandafter efficiency improvements.Different businesses use lathe digital readouts and power feed to work better and faster. For example, machine shops, automotive industries, and furniture makers all benefit from these tools. They help in creating precise parts easily. Many companies have shared stories about their success:

- Before using digital readouts, a furniture company took hours to finish a single piece. After, they cut that time in half!

- A car repair shop saw a 30% increase in productivity after switching to power feeds.

These examples show how using technology can make a big difference in daily work.

What are some real-world uses of lathe digital readouts?

Companies in manufacturing, automotive, and woodworking often use these tools to improve accuracy and speed in their projects.

Expert Tips and Recommendations

Advice from professionals on choosing the right system for your needs. Key features to look for in highquality digital readouts and power feeds.Choosing the right system for your lathe can feel like picking ice cream flavors on a hot day—so many options! First, think about accuracy. You want a digital readout that shows you exactly what’s happening. Next, consider the ease of use. If it’s harder than your math homework, it’s not worth it! Lastly, check if the power feed is smooth. No one likes a rough ride! Here are some key features to look for:

| Feature | Description |

|---|---|

| Accuracy | Precision is key for great results. |

| Ease of Use | Straightforward controls make everything easier. |

| Smooth Operation | No jerky moves, please. Keep it smooth! |

Remember, the right choices can help your projects succeed while keeping frustration at bay. After all, you want to create, not create chaos!

Conclusion

In summary, a lathe digital readout improves precision for metal lathes. It helps you measure better and work more efficiently. Adding a power feed saves time and energy when cutting materials. If you’re eager to enhance your lathe skills, consider exploring different readout systems and power feed options. Dive deeper into these tools for hands-on experience and better projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readouts, Metal Lathes, And Power Feeds:Sure! Here are five questions you might have about lathes: 1. What is a lathe? A lathe is a machine that shapes metal and wood into round pieces. 2. How does a digital readout help? It shows you exact measurements while you work, so you can cut correctly. 3. What is a power feed? A power feed moves the tool automatically, so you don’t have to push it by hand. 4. Why use a metal lathe? A metal lathe helps you create precise shapes for tools and machines. 5. How do you keep a lathe safe? Always wear safety goggles and keep your hands away from moving parts.

Of course! Please provide the question you’d like me to answer.

What Are The Advantages Of Using A Digital Readout System On A Metal Lathe Compared To Traditional Dial Indicators?Using a digital readout system on a metal lathe makes it easier to see measurements. You can read numbers clearly on a screen. It helps you make precise cuts without guessing. Digital systems can also show how much to move the tool, making your work faster. Overall, it’s like having a helpful guide while you work!

How Does A Power Feed Mechanism Improve The Efficiency And Precision Of Machining Operations On A Lathe?A power feed mechanism helps make machining on a lathe easier and more accurate. It moves the cutting tool automatically instead of us doing it by hand. This means you can work faster without getting tired. It also helps create smoother and more even shapes, so everything fits better. Overall, it makes the job go quicker and with less mistakes!

What Specific Features Should One Look For In A Digital Readout System For A Metal Lathe To Enhance Productivity?When choosing a digital readout (DRO) system for a metal lathe, look for easy-to-read displays. You want clear numbers that show measurements quickly. Check for simple buttons that are easy to use. A good DRO should allow you to save measurements, so you don’t have to write them down. Lastly, look for one that shows you both inches and millimeters, so it fits your needs.

Can A Digital Readout Be Retrofitted Onto An Older Metal Lathe, And If So, What Are The Considerations For Installation?Yes, you can add a digital readout to an older metal lathe. First, check if your lathe is compatible with the new parts. You will need to measure everything carefully so that it fits. Also, think about how to power the readout and where to place the screen. Finally, follow the instructions that come with the readout for proper installation.

How Do Power Feed Rates Impact The Surface Finish And Dimensional Accuracy Of Machined Parts On A Lathe?Power feed rates change how quickly the machine cuts. If you use a slow feed rate, the surface feels smoother and looks nicer. But if you go too fast, it can leave rough edges. Also, slower rates help make parts more accurate in size. So, it’s important to choose the right speed for the best results!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readouts, Metal Lathes, And Power Feeds:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might have about lathes: 1. What is a lathe? A lathe is a machine that shapes metal and wood into round pieces. 2. How does a digital readout help? It shows you exact measurements while you work, so you can cut correctly. 3. What is a power feed? A power feed moves the tool automatically, so you don’t have to push it by hand. 4. Why use a metal lathe? A metal lathe helps you create precise shapes for tools and machines. 5. How do you keep a lathe safe? Always wear safety goggles and keep your hands away from moving parts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Digital Readout System On A Metal Lathe Compared To Traditional Dial Indicators?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a digital readout system on a metal lathe makes it easier to see measurements. You can read numbers clearly on a screen. It helps you make precise cuts without guessing. Digital systems can also show how much to move the tool, making your work faster. Overall, it’s like having a helpful guide while you work!”}},{“@type”: “Question”,”name”: “How Does A Power Feed Mechanism Improve The Efficiency And Precision Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A power feed mechanism helps make machining on a lathe easier and more accurate. It moves the cutting tool automatically instead of us doing it by hand. This means you can work faster without getting tired. It also helps create smoother and more even shapes, so everything fits better. Overall, it makes the job go quicker and with less mistakes!”}},{“@type”: “Question”,”name”: “What Specific Features Should One Look For In A Digital Readout System For A Metal Lathe To Enhance Productivity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital readout (DRO) system for a metal lathe, look for easy-to-read displays. You want clear numbers that show measurements quickly. Check for simple buttons that are easy to use. A good DRO should allow you to save measurements, so you don’t have to write them down. Lastly, look for one that shows you both inches and millimeters, so it fits your needs.”}},{“@type”: “Question”,”name”: “Can A Digital Readout Be Retrofitted Onto An Older Metal Lathe, And If So, What Are The Considerations For Installation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can add a digital readout to an older metal lathe. First, check if your lathe is compatible with the new parts. You will need to measure everything carefully so that it fits. Also, think about how to power the readout and where to place the screen. Finally, follow the instructions that come with the readout for proper installation.”}},{“@type”: “Question”,”name”: “How Do Power Feed Rates Impact The Surface Finish And Dimensional Accuracy Of Machined Parts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Power feed rates change how quickly the machine cuts. If you use a slow feed rate, the surface feels smoother and looks nicer. But if you go too fast, it can leave rough edges. Also, slower rates help make parts more accurate in size. So, it’s important to choose the right speed for the best results!”}}]}