Have you ever watched a lathe spin? It’s fascinating! But did you know that knowing the RPM can make a big difference in your projects? A lathe digital RPM sensor mount helps you keep track of how fast the lathe is spinning. This is important for both safety and accuracy.

Imagine trying to create a perfect piece of wood or metal. If your lathe isn’t spinning at the right speed, it can ruin everything. That’s where the lathe digital RPM sensor mount comes in handy. It ensures you always know what speed you’re working at.

In this article, we’ll explore how this sensor mount works and why it’s a must-have for anyone who enjoys using a lathe. Plus, you’ll learn some tips to make your projects even better. Ready to dive in? Let’s get started!

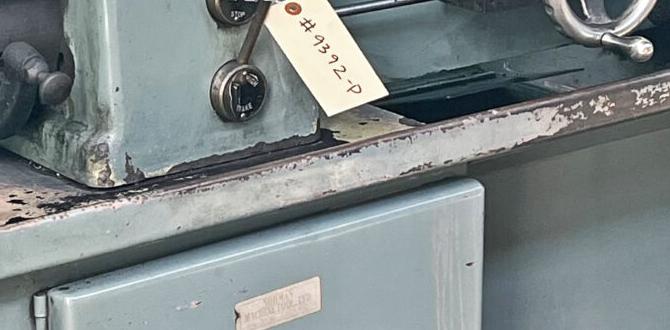

Effective Lathe Digital Rpm Sensor Mount Solutions

Lathe Digital RPM Sensor Mount: Key Insights

A lathe digital RPM sensor mount helps improve your machine’s performance. It accurately measures the rotation speed, making it easy to monitor while working. Imagine trying to cut wood without knowing if you’re going too fast or slow! This sensor adds precision and safety. It can boost your projects’ quality and save time. Whether you’re a beginner or a pro, this tool is a game changer for your workshop.What is a Lathe Digital RPM Sensor Mount?

Definition and purpose of a digital RPM sensor mount.. Key components and their functions in lathe operations..Imagine a high-tech gadget that helps a lathe work better and smarter. That’s where a digital RPM sensor mount comes in! This device measures how fast the lathe spins, using fancy sensors to keep everything in check. It makes sure the speed is just right, preventing mishaps that could turn your project into Swiss cheese—full of holes!

| Component | Function |

|---|---|

| Sensor | Tracks RPM and sends data to the display. |

| Mount | Holds the sensor in place, sturdy as a rock! |

| Display | Shows the RPM, so you can adjust speed easily. |

Each part plays a role, working together like a well-rehearsed dance troupe. So, with a digital RPM sensor mount, you get precise readings and great results—without the drama!

Importance of Accurate RPM Measurement in Lathes

Impact of precise RPM on machining quality and efficiency.. Common issues caused by inaccurate RPM readings..Having the correct RPM is vital for lathes. Accurate measurements help create better-quality parts. They improve how smooth and precise the cuts are. When RPM is off, mistakes can happen. You might see:

- Uneven surfaces on the workpiece

- Increased wear on tools

- Longer machining times

These issues can waste time and money. A reliable lathe digital RPM sensor mount can solve these problems. It ensures you get the best performance from your machine.

Why is accurate RPM reading important?

Accurate RPM readings help improve machining quality and efficiency. They ensure the tools work correctly, extending their life and saving resources.

Factors to Consider When Choosing an RPM Sensor Mount

Compatibility with different lathe models and configurations.. Sensitivity, range, and data feedback features..Choosing the right RPM sensor mount for your lathe can be tricky—like picking the right toppings for a pizza! First, check its compatibility with various lathe models. Some sensors fit only specific machines, leaving you in a pickle. Next, consider the sensitivity and range of the sensor. A good sensor should be responsive enough to catch even the slightest changes. Finally, what about data feedback? A digital sensor with quick data output can save you time and headaches! Here’s a handy table to help you remember:

| Factor | Details |

|---|---|

| Compatibility | Matches various lathe models |

| Sensitivity | Detects minor RPM changes |

| Data Feedback | Quick and accurate output |

Step-by-Step Guide to Installing a Digital RPM Sensor Mount

Tools and materials needed for installation.. Detailed installation process with visuals or diagrams..To install your digital RPM sensor mount, you’ll need a few handy tools and materials. Gather your:

- Drill

- Wrench

- Screwdriver

- Measuring tape

- Digital RPM sensor

- Mounting brackets

- Safety goggles

Start by marking where the mount goes. Use a measuring tape for accuracy. Then, drill holes for the brackets. Attach the sensor using the screws. Check that everything is tight. Finally, connect the sensor to your lathe. For visual help, you can find diagrams online. They show each step clearly.

What is essential for installing a digital RPM sensor mount?

You’ll need basic tools like a drill, a wrench, and a screwdriver, plus the RPM sensor itself. Make sure you have safety goggles on for protection.

Troubleshooting Common RPM Sensor Issues

Identification of frequent problems during operation.. Solutions and preventive measures for maintaining sensor accuracy..Troubleshooting an RPM sensor can be tricky, but don’t worry! Start by checking for common issues like loose connections and dirt. If your sensor is wobbling or giving strange readings, it might be time for a little cleaning. A consistent RPM reading matters, just like counting how many cookies you can eat in one sitting! Regular maintenance can keep your sensor happy and accurate. Remember, even sensors need their beauty sleep!

| Common Issues | Solutions |

|---|---|

| Loose connections | Check and tighten all wires |

| Dirt buildup | Gently clean the sensor |

| Incorrect readings | Re-calibrate the sensor |

Taking a few minutes each month for checks can prevent bigger problems later on. Think of it like brushing your teeth – a little effort goes a long way!

Future Trends in Lathe RPM Sensor Technology

Innovations to expect in sensor technology for lathes.. Benefits of adopting advanced RPM measurement systems..Exciting changes are coming for lathe RPM sensors! New sensors will be faster and smarter, making metalwork easier. Expect improvements like wireless connections and better accuracy. These advancements will help makers work quicker and with less fuss. Imagine having a tool that tells you exactly how fast your lathe is spinning, all while you sip your coffee!

| Innovation | Benefit |

|---|---|

| Wireless Sensors | More freedom to move! |

| High Accuracy | Less chance of errors! |

Upgrading to these new systems means smoother operations and safer setups. As they say, “A happy lathe is a productive lathe!” Waving goodbye to old tech is always a plus!

Conclusion

In summary, a lathe digital RPM sensor mount is important for precise measurements. It helps you track speed easily and improve your projects. Using this tool can enhance your work quality. We encourage you to explore different types of RPM sensors and how they fit your lathe. Dive into more resources to boost your skills and create amazing projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Rpm Sensor Mounts:Sure! A lathe is a tool that spins material to shape it. A digital RPM sensor tells us how fast it’s spinning. We can make mounts for these sensors to keep them in the right place. When we use good mounts, we get better readings. This helps us work more safely and accurately!

Sure! Please provide the question you’d like me to answer.

What Are The Different Types Of Digital Rpm Sensors Suitable For Lathe Applications, And How Do They Differ In Terms Of Accuracy And Installation?There are a few types of digital RPM sensors for lathes. One type is called a magnetic sensor. It is easy to install and works well for most uses. Another type is an optical sensor, which can be more accurate but is trickier to set up. Lastly, there are contact sensors, which need to touch the spinning part but are very accurate. So, your choice depends on how precise you want to be and how easy you want the installation to be.

How Can You Properly Mount A Digital Rpm Sensor On A Lathe To Ensure Optimal Performance And Measurement Accuracy?To properly mount a digital RPM (Revolutions Per Minute) sensor on a lathe, start by finding a stable spot on the machine. Make sure the sensor is close to the part that turns, like the spindle. You should use screws or clamps to hold it firmly. Check that the sensor faces the rotating part directly to get clear readings. Lastly, test it to ensure it measures correctly as the lathe runs.

What Are The Key Considerations When Designing A Custom Mount For A Digital Rpm Sensor On A Lathe, Including Factors Like Vibration And Alignment?When designing a mount for a digital RPM sensor on a lathe, you should think about a few important things. First, make sure the mount holds the sensor steady so it doesn’t shake. You also want to line up the sensor correctly with the lathe’s moving parts. Choosing strong materials helps prevent damage from vibrations. Lastly, test the setup to ensure it works properly while the lathe is running.

How Can You Integrate A Digital Rpm Sensor With Existing Lathe Control Systems For Real-Time Monitoring And Data Logging?To integrate a digital RPM (Revolutions Per Minute) sensor with your lathe, you first need to connect the sensor to the control system. You can use wires to link them together. Next, we need to set up software that reads data from the sensor. This will help you see the RPM in real-time on a screen. Finally, we can save this data for later use or review.

What Troubleshooting Steps Can Be Taken If A Digital Rpm Sensor Mounted On A Lathe Is Providing Inconsistent Or Inaccurate Readings?If your digital RPM sensor isn’t working right, first check the wires. Make sure they’re connected tightly and aren’t damaged. Next, clean the sensor to remove any dirt or oil. Also, try moving the sensor closer to the spinning part to help it read better. If it still doesn’t work, consider asking a grown-up for help.