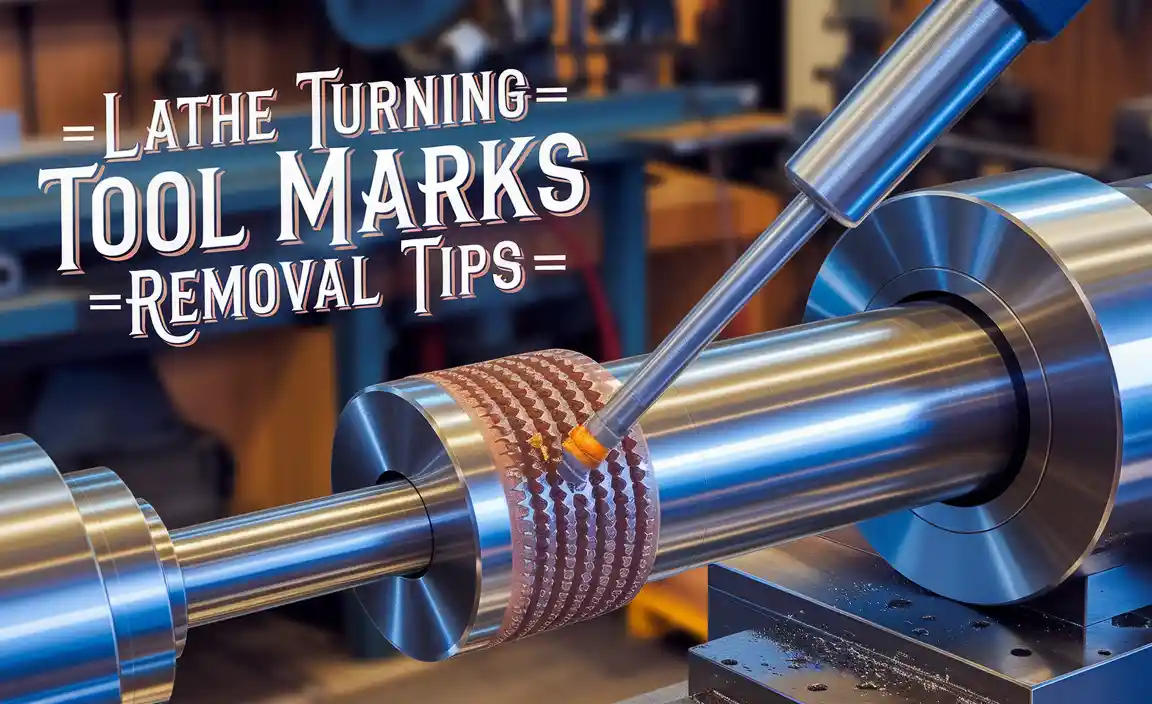

Have you ever heard the sound of a lathe at work? It’s like music in a workshop. A floor mount metal lathe is a powerful tool that turns metal into amazing shapes. Imagine creating parts for a model car or crafting unique gifts!

These lathes can cut, shape, and finish metal pieces. But how do you choose the right cutting tools for your lathe? It’s easier than it sounds! The right tools can make a big difference.

Did you know that the first lathes were made over 3,000 years ago? They were simple and hand-driven. Today, modern floor mount metal lathes use electricity and advanced technology, making tasks quicker and more accurate.

So, are you ready to learn more about lathe floor mount metal lathe cutting tools? Let’s dive in and explore the fascinating world of metalworking!

Lathe Floor Mount Metal Lathe Cutting Tools Explained

Understanding Lathe Floor Mount Metal Lathes and Cutting Tools

A lathe is a powerful tool for shaping metal. The floor mount design lets it stand sturdy, making it a popular choice. Key cutting tools include high-speed steel and carbide inserts. These tools provide precision and durability. Imagine creating intricate shapes from solid metal—it’s possible with the right lathe and tools! For anyone interested in metalwork, knowing about lathe cutting tools is essential for success. Wouldn’t you like to learn how to craft something unique?Understanding Lathe Floor Mount Metal Lathes

Definition and features of floor mount metal lathes. Advantages of using lathe floor mounts over other types.A lathe is a machine used to shape metal. A floor mount metal lathe is sturdy and sits on the floor. This makes it strong and stable. It can handle heavy materials without moving. Here are some features you might like:

- Powerful motors for efficient cutting

- Easy-to-use controls

- Flexible settings for different projects

Using a floor mount has benefits:

- It produces more precise cuts.

- It occupies less space than other types.

- It’s easier to use for larger projects.

What is the benefit of floor mount metal lathes?

Floor mount lathes offer stability and greater precision. Their strong base helps produce cleaner cuts and manage heavier materials easily.

Key Components of Floor Mount Metal Lathes

Breakdown of essential components (bed, carriage, tailstock). Importance of material quality in construction.Floor mount metal lathes are made up of key parts. The bed holds everything steady. The carriage moves back and forth with the cutting tool. The tailstock supports the end of a workpiece. Strong materials make lathes last longer and work better. Choosing top-quality materials is important for both safety and performance.

- Bed: A solid base for stability.

- Carriage: Enables precise movement.

- Tailstock: Supports projects from the end.

Why Is Material Quality Important?

Good materials ensure the lathe is durable and reliable. Cheap materials can break easily. This can lead to accidents and project failures. It’s best to invest in high-quality parts for safety and effectiveness.

Choosing the Right Cutting Tools for Your Lathe

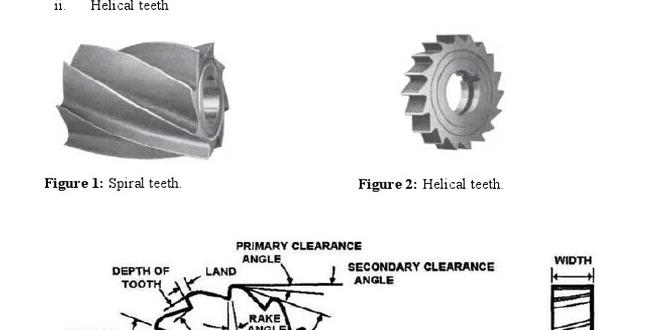

Types of cutting tools: highspeed steel vs. carbide. Factors to consider when selecting cutting tools (material, application).Selecting cutting tools for your lathe is important. Two main types are high-speed steel and carbide. High-speed steel is cheaper and good for beginners. Carbide lasts longer but costs more. Here are factors to consider:

- Material: Choose based on the metal you work with.

- Application: Think about the job you want to do.

- Durability: Carbide tools are more durable but harder to sharpen.

Always match the tool type to your project needs for the best results.

What is better, high-speed steel or carbide for cutting tools?

Carbide is better for long-lasting use and harder materials, while high-speed steel is great for beginners.

Maintenance Tips for Longevity of Lathe Cutting Tools

Regular cleaning and lubrication advice. How to sharpen and replace cutting tools effectively.Keeping your lathe cutting tools in top shape doesn’t need to be a chore. First, remember to clean them regularly. Dust and grime can dull their shine faster than a kid loses interest in homework! Use a soft cloth and some mild soap for a good scrub. Next, lubrication is key—like oiling a squeaky hinge. A little goes a long way in keeping the tools running smoothly.

Sharpening your cutting tools is another important step. Think of it like giving your tools a fresh haircut! Use a sharpening stone or file, and be careful not to take off too much; we don’t want bald tools! If they get too worn, it’s time to replace them. Keeping a new set on hand means being ready whenever inspiration strikes.

| Maintenance Task | How Often |

|---|---|

| Clean Tools | Every use |

| Lubricate | Weekly |

| Sharpen Tools | As needed |

| Replace Tools | When dull |

With these tips, your lathe cutting tools will last longer than your favorite pair of sneakers. So, give them some love, and they’ll keep you cutting like a pro!

Safety Practices While Using Lathe Cutting Tools

Essential safety gear and precautions. Common mistakes to avoid during operation.Using lathe cutting tools can be fun, but safety comes first. Always wear safety goggles to protect your eyes. Use ear protection if it’s noisy. Wear gloves to keep your hands safe, but remove them while operating the machine. Avoid reaching over the running lathe and keep your workspace tidy. Make sure to plan your cuts and double-check settings. Watch your fingers; it’s easy to make mistakes. Stay focused and don’t rush!

What safety gear do I need for using lathe cutting tools?

You should wear safety goggles, ear protection, and gloves without buttons. A dust mask may also help when working with wood or metal dust.

Common mistakes to avoid:

- Leaning over the lathe while it’s running.

- Using the wrong cutting tool.

- Not checking your work area first.

- Rushing through cuts.

- Ignoring safety procedures.

Tips for Maximizing Productivity with Lathe Tools

Workflow optimization strategies. Importance of setup and alignment.To get the most from your lathe tools, focus on your workflow. Organize your workspace efficiently. Keep tools close and label everything. This saves time and reduces mistakes. Proper setup and alignment are key. If your tools are aligned correctly, they work better and last longer.

- Check all settings before starting.

- Use clamps for stability to avoid any wobbling.

- Regularly inspect tools for wear and tear.

Following these tips can help boost your productivity and create better results.

How can I improve my lathe workflow?

Improving workflow involves keeping tools organized, maintaining a clean workspace, and ensuring all machines are set correctly. This setup can help you work faster and produce consistent results.

Comparison of Popular Floor Mount Metal Lathes in the Market

Review of leading models and their specifications. Pros and cons of each model and price considerations.Finding the right floor mount metal lathe is important for any aspiring craftsman. Here are some popular models that stand out in the market:

| Model | Specifications | Pros | Cons | Price |

|---|---|---|---|---|

| Model A | 12” swing, 36” bed | Great power, easy to use | Heavy build | $1,200 |

| Model B | 10” swing, 30” bed | Lightweight, portable | Less power | $800 |

| Model C | 14” swing, 40” bed | High precision, versatile | Pricey | $1,800 |

Each option has its charm, like a dog with a wiggly tail! Think about what you need before spending. Model A is powerful but heavy. Model B is great for moving around but less strong. Model C is precise but will cost you a bit more. Remember, picking a lathe isn’t like choosing a donut—you can’t always have both!

Conclusion

In summary, a lathe floor mount metal lathe is great for shaping metal. You can use various cutting tools to create precise designs. Remember to choose the right tool for your project. If you’re interested, explore more about lathe operations and techniques. Let’s get started on your metalworking journey!FAQs

What Are The Essential Cutting Tools Required For A Floor-Mounted Metal Lathe, And How Do They Differ In Application?To use a floor-mounted metal lathe, you need a few important cutting tools. First, there are high-speed steel (HSS) cutting tools. You use these for shaping and cutting metal. Then, you have carbide-tipped tools. These are stronger and last longer, so we use them for tough jobs. Lastly, we need boring bars to make holes in metal. Each tool helps us do different tasks in metalwork.

How Do You Properly Maintain And Sharpen Cutting Tools Used With A Lathe To Ensure Optimal Performance?To keep your cutting tools sharp and working well, you should clean them after each use. Use a cloth or brush to remove any dirt or metal shavings. You can sharpen the tools using a sharpening stone or a file. Always check the tool’s edge for sharpness before using it. If the tool is dull, take the time to sharpen it properly. This will help your lathe run smoothly.

What Are The Advantages Of Using Carbide Versus High-Speed Steel (Hss) Cutting Tools On A Floor-Mounted Metal Lathe?Carbide tools are stronger than high-speed steel (HSS) tools. They can cut through metal faster and last longer. This means you won’t need to change them as often. Using carbide tools can save you time and make your work easier. They also give a smoother finish on your metal pieces.

How Do You Select The Appropriate Cutting Speed And Feed Rate For Different Materials When Using A Lathe Cutting Tool?To choose the right cutting speed and feed rate for a lathe cutting tool, you need to think about the material. Harder materials, like steel, usually need a slower cutting speed. Softer materials, like aluminum, can go faster. You also want to adjust the feed rate based on the material; slower for hard materials and faster for soft ones. Always check the tool and material to get the best results!

What Safety Precautions Should Be Taken While Operating A Floor-Mounted Metal Lathe With Various Cutting Tools?When using a floor-mounted metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothes to avoid getting caught in the machine. Never reach into the machine while it’s running. Keep your hands away from the cutting tools. Lastly, make sure the area is clean and free of clutter.