Have you ever wondered how metal lathe works? It’s like a magic show for metal! With the right lathe gear ratio, you can shape, cut, and mold metal parts with ease. Understanding how these pieces fit together opens up a world of possibilities.

Imagine building something amazing, like your very own toy car. To do this, you need the right tools. The lathe gear ratio is crucial for getting the exact speed you want. It’s like adjusting the volume on your favorite song; you want it just right!

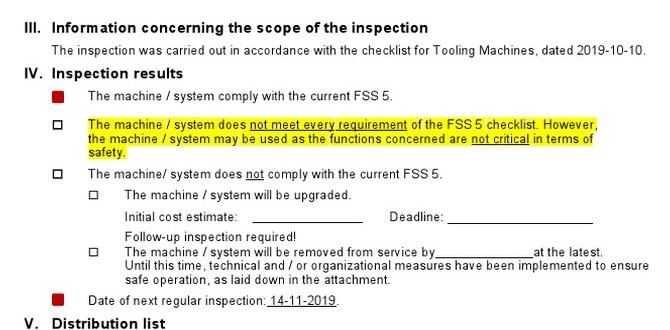

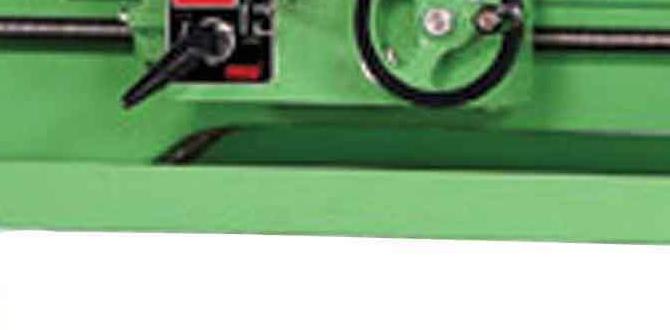

Did you know that the parts of a lathe can make all the difference? Each component plays a special role. From the motor to the gears, everything must work in harmony. This simple machine can turn a block of metal into a beautiful gear or even a stunning sculpture.

So, why should you care about lathe gear ratios and metal lathe parts? Because these concepts can change how you see metalworking. Join us as we explore the exciting world of lathes, one gear at a time!

Understanding Lathe Gear Ratio: Essential Metal Lathe Parts

Understanding Lathe Gear Ratio and Metal Lathe Parts

Lathe gear ratio is crucial for controlling speed and torque. It determines how fast the lathe turns the workpiece. Different metal lathe parts work together to achieve precise results. Did you know that changing the gear ratio can affect the finish of the metal? This flexibility allows for various tasks, from shaping to sanding. Understanding these components can help anyone improve their metalworking skills and achieve better results. Curious about which gear ratio suits your project? Explore more!What is a Lathe Gear Ratio?

Definition of gear ratio in the context of lathes. Importance of understanding gear ratios for machining efficiency.A gear ratio tells us how many times the main gear turns when we turn the handle. In lathes, this is key for making accurate parts. A better gear ratio means more control. This helps machinists work faster and with less waste.

- Higher gear ratio: More power for tough materials.

- Lower gear ratio: Better speed for fine detail work.

- Understanding ratios: Leads to smarter choices in machining.

Why is gear ratio important in lathes?

Knowing the gear ratio helps you pick the right speed and power. This means better results and less chance of mistakes. Understanding this ratio can improve your efficiency in machining.

How Gear Ratios Affect Lathe Performance

Impact on spindle speed and torque. Relationship between gear ratios and material processing.Gear ratios play a big role in how well a lathe works. They decide how fast the spindle spins and the force it generates. A higher gear ratio means the spindle spins slower, but it has more strength—perfect for cutting tough metals. On the other hand, a lower gear ratio makes it spin faster, ideal for softer materials. Imagine trying to eat a giant cake—sometimes you need to slow down and chew well! The right gear ratio can make all the difference in your metalworking game.

| Gear Ratio | Spindle Speed | Torque |

|---|---|---|

| High | Slow | High |

| Low | Fast | Low |

Types of Gear Ratios in Metal Lathes

Explanation of fixed vs. variable gear ratios. Pros and cons of different gear ratio types.In metal lathes, you can find two main types of gear ratios: fixed and variable. Fixed gear ratios are like that one song you can’t get out of your head — they stay the same no matter what. Meanwhile, variable gear ratios change based on need, so it’s like being a DJ, mixing your tracks for the perfect beat! Each type has its pros and cons. Fixed ratios offer simplicity, while variable ratios add flexibility. However, more choices might also lead to confusion. Here’s a quick glance:

| Type | Pros | Cons |

|---|---|---|

| Fixed | Simplicity and Stability | Limited options |

| Variable | Flexibility and Versatility | Can be confusing |

Choosing the right one depends on your needs, like picking the right ice cream flavor. Chocolate or vanilla? It’s all about personal taste!

Calculating Lathe Gear Ratios

Stepbystep method for calculation. Examples of common ratios used in metalworking.To find a lathe’s gear ratio, follow these simple steps. First, check the number of teeth on the driving gear. Next, count the teeth on the driven gear. Divide the driven gear’s teeth by the driving gear’s teeth. This gives you the gear ratio.

Common ratios in metalworking include:

- 1:1 – Standard speed

- 2:1 – Increased speed

- 3:1 – Fastest feed

Understanding these ratios helps in getting the right speed for your project!

What is the importance of lathe gear ratios?

Lathe gear ratios are crucial. They determine how fast the lathe turns. The right ratio helps you work smoothly. It affects the quality of your metal parts!

Common Challenges with Gear Ratios

Issues with mismatched gear ratios. Solutions for optimizing gear performance.Many problems pop up with gear ratios, like mismatched sizes making your metal lathe act like a grumpy cat. This can slow down operations and cause poor cuts. To keep everything running smoothly, check your gear ratios regularly. Proper alignment can save your tools from an early retirement! Consider changing gears or adjusting the setup to optimize performance. Remember, a happy lathe means happy projects.

| Challenge | Solution |

|---|---|

| Mismatched gear ratio | Regular checks and adjustments |

| Slow operation | Upgrade gears for better fit |

| Poor cuts | Optimize alignment and settings |

Upgrading Metal Lathe Gear Ratios

Tips for selecting the right gear ratio for specific projects. Recommended part upgrades for improved performance.Choosing the right gear ratio can make a big difference in your metal lathe projects. Consider what you are making. Do you need high speed or more power? For delicate work, a lower ratio helps control the tool better. A higher ratio is great for heavy-duty jobs.

- Evaluate your project needs.

- Check if parts like the motor or drive belt need upgrades.

- Look for durable gear materials to extend life.

Upgrading parts can improve performance. For example, using precision gears can enhance accuracy. This small change can lead to bigger results!

What gear ratio should I choose for my project?

The right gear ratio depends on your project’s needs. Low ratios are best for accuracy, while high ratios work well for speed and power.

Future Trends in Lathe Machinery and Gear Technology

Innovations in gear design and materials. Predictions for the future of lathe gear ratios in metalworking.New ideas in gear design and materials are changing lathe machines. Engineers are using lighter and stronger materials. This makes the gears last longer. Innovations lead to newer gear shapes that improve efficiency.

- 3D printing for custom gear parts.

- Smart sensors for real-time feedback.

- Environmentally friendly materials.

What is the future of lathe gear technology?

Experts believe the future will focus on smarter gears and better materials. These changes will help metalworkers create accurate parts more easily.

Conclusion

In summary, understanding lathe gear ratios helps you control your metal lathe’s speed and torque. Knowing the parts of the lathe is essential for effective use. You can create precise shapes and improve your projects. Explore more about lathe gear ratios and parts to become a better metalworker. Let’s keep learning and making amazing things together!FAQs

What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe?Gear ratios on a metal lathe help control how fast the machine spins. When you change the gears, you can make the lathe turn faster or slower. This is important because different materials need different speeds to cut properly. By adjusting the gear ratio, you can get the best results for what you’re making. It helps us work better and safer!

How Do You Determine The Appropriate Gear Ratio For Different Turning Operations On A Lathe?To determine the right gear ratio for turning on a lathe, you first need to know the type of material you’re working with. Softer materials, like wood, need a slower speed, while harder materials, like metal, need a faster speed. Next, check the lathe’s manual. It often has suggestions for gear settings. Finally, test it out. Adjust the gears until the turning feels smooth and works well.

What Are The Common Types Of Gears Used In Metal Lathe Mechanisms?In metal lathes, we often see a few common types of gears. First, there are spur gears, which look like flat wheels with teeth. They help change the speed of the lathe. Next, we have bevel gears, which fit at an angle and help connect different parts. Lastly, there are worm gears that let us turn things with less effort. These gears work together to help us make cool shapes from metal!

How Can Changing The Gear Ratio Affect The Cutting Speed And Torque Of A Lathe?Changing the gear ratio changes how fast a lathe spins the tool. If you use a higher gear ratio, the lathe spins faster. This makes the cutting speed go up, but it gives you less torque. Torque is the power to push harder, which is important for cutting thicker materials. A lower gear ratio gives you more torque but slower cutting speed.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of Gear Assemblies In A Metal Lathe?To keep gear assemblies in a metal lathe working well, you should do a few things. First, always keep them clean. Use a soft cloth to wipe off dust and dirt. Next, add oil or grease to the gears. This helps them move smoothly. Finally, check for any broken parts or unusual sounds. Fixing these quickly can save you trouble later!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios on a metal lathe help control how fast the machine spins. When you change the gears, you can make the lathe turn faster or slower. This is important because different materials need different speeds to cut properly. By adjusting the gear ratio, you can get the best results for what you’re making. It helps us work better and safer!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Gear Ratio For Different Turning Operations On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To determine the right gear ratio for turning on a lathe, you first need to know the type of material you’re working with. Softer materials, like wood, need a slower speed, while harder materials, like metal, need a faster speed. Next, check the lathe’s manual. It often has suggestions for gear settings. Finally, test it out. Adjust the gears until the turning feels smooth and works well.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Gears Used In Metal Lathe Mechanisms? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, we often see a few common types of gears. First, there are spur gears, which look like flat wheels with teeth. They help change the speed of the lathe. Next, we have bevel gears, which fit at an angle and help connect different parts. Lastly, there are worm gears that let us turn things with less effort. These gears work together to help us make cool shapes from metal!”}},{“@type”: “Question”,”name”: “How Can Changing The Gear Ratio Affect The Cutting Speed And Torque Of A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the gear ratio changes how fast a lathe spins the tool. If you use a higher gear ratio, the lathe spins faster. This makes the cutting speed go up, but it gives you less torque. Torque is the power to push harder, which is important for cutting thicker materials. A lower gear ratio gives you more torque but slower cutting speed.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of Gear Assemblies In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep gear assemblies in a metal lathe working well, you should do a few things. First, always keep them clean. Use a soft cloth to wipe off dust and dirt. Next, add oil or grease to the gears. This helps them move smoothly. Finally, check for any broken parts or unusual sounds. Fixing these quickly can save you trouble later!”}}]}