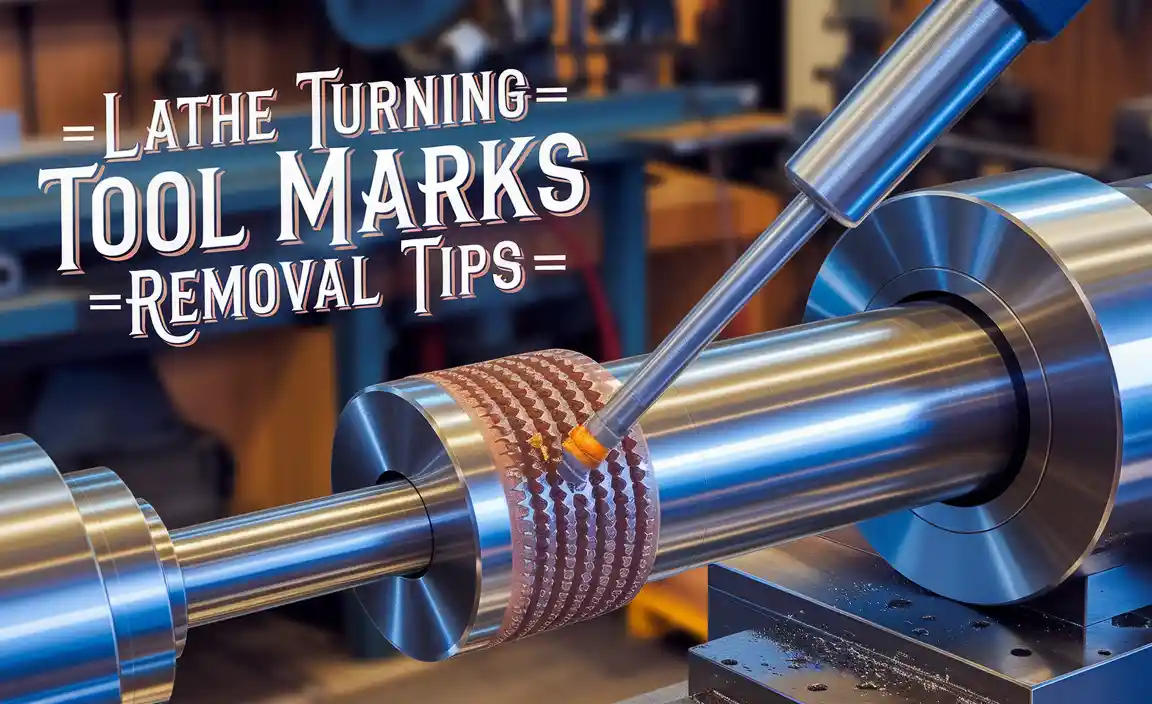

Have you ever wondered how machines cut metal with such precision? One key player in this process is the lathe. A lathe creates shapes and designs from metal and wood. But did you know the lathe gear ratio can change everything?

The gear ratio on a metal lathe is important. It helps control the speed and power of the lathe. This means you can create everything from small screws to big engine parts. Fascinating, isn’t it?

Imagine trying to carve a statue from a block of wood. If your tool moves too fast, you might mess up your design. But if it’s too slow, you’ll waste time. The lathe gear ratio helps you find that perfect balance.

In this article, we will explore the lathe gear ratio and its role in the metal lathe saddle. Discover how this simple adjustment can make a big difference in your crafting journey!

Understanding Lathe Gear Ratio For Metal Lathe Saddle Use

Lathe Gear Ratio and Metal Lathe Saddle

Understanding lathe gear ratios can elevate your metalworking skills. The gear ratio affects how fast your metal lathe spins. A higher ratio means quicker movements, while a lower one offers better control. Imagine shaping metal effortlessly! The saddle is crucial for holding your workpiece steady. Did you know that adjusting the gear ratio can make a huge difference in finishing your projects? Mastering this can turn you into a lathe expert!What is Lathe Gear Ratio?

Definition and significance of gear ratio in lathe operations. Explanation of how gear ratios affect spindle speed and torque.A gear ratio is a key part of how a lathe works. It helps control the speed and power of the machine. A higher gear ratio means the lathe spins faster but with less force. A lower ratio means more strength but lower speed. This balance is vital for getting the right finish on metal parts.

- Gear ratios affect spindle speed.

- They also determine torque, or twisting force.

How does gear ratio affect a lathe?

The gear ratio changes both speed and torque of the spindle. For example, using a high gear ratio allows for faster rotation, making it easier to cut soft metals. On the other hand, a low gear ratio provides more torque, which is better for hard metals.

Components of a Metal Lathe Saddle

Description of the saddle’s role in the lathe system. Key components and their functions related to gear ratio.The saddle in a metal lathe is like a trusty sidekick. It holds the cutting tool and moves it back and forth. This helps shape the metal into the desired form. The saddle’s role connects to the gear ratio as it affects movement speed and precision. Key parts include the carriage, which slides smoothly, and the cross-slide that moves left and right. Together, they ensure the lathe works like a well-oiled machine, or at least we like to think so!

| Component | Function |

|---|---|

| Carriage | Slides to hold and guide the cutting tool. |

| Cross-slide | Moves the tool horizontally for accurate cuts. |

Importance of Gear Ratio in Metal Lathes

How gear ratios influence cutting speed and precision. Impact on the types of materials that can be machined.Understanding gear ratios in metal lathes is key for efficient work. Gear ratios affect two main areas: cutting speed and precision. A lower ratio means slower speeds but better control. A higher ratio can speed things up but might reduce precision. The type of material you can cut also depends on gear ratios. Softer materials can use faster settings, while harder materials need slower, more careful adjustments.

- Gear ratios affect cutting speed.

- Higher ratios = faster cuts, but less control.

- Hard materials need lower ratios for precision.

- Soft materials can afford higher speeds.

How do gear ratios impact metal lathe performance?

Gear ratios greatly influence how well and quickly a lathe works. The settings you choose can either enhance or limit the tasks you can perform.

Calculating Gear Ratios for Metal Lathes

Stepbystep guide to calculate gear ratios in different setups. Examples of common gear ratios used in metal lathes.Calculating gear ratios for metal lathes can be simple. First, find the number of teeth on the driving gear. Next, count the teeth on the driven gear. Then, use this formula: Gear Ratio = Teeth on Driven Gear / Teeth on Driving Gear. For example:

- Driving gear has 12 teeth.

- Driven gear has 36 teeth.

The gear ratio is 36 / 12 = 3. Common gear ratios for lathes often include:

- 1:1 for straightforward cutting

- 1:2 for smooth finish

- 1:3 for high-speed tasks

With these steps, you can adjust your metal lathe for different needs!

What is a common gear ratio for metal lathes?

The most common gear ratios for metal lathes are 1:1, 1:2, and 1:3. These ratios help achieve smooth cutting and better speed control.

Adjusting Gear Ratios on a Metal Lathe Saddle

Techniques for modifying gear ratios for specific tasks. Tips for maintaining optimal performance during adjustments.Modifying gear ratios on a metal lathe saddle can enhance your machining tasks. Here are some easy techniques:

- Examine the current gear setup.

- Calculate the desired RPM for your specific project.

- Adjust gears smoothly to avoid damage.

To maintain optimal performance:

- Lubricate moving parts regularly.

- Check for wear and tear on gears.

- Ensure all adjustments are tight and secure.

These steps can help you achieve better results while using your lathe.

What should I know about gear ratios for specific tasks?

Understanding gear ratios helps you adjust speed and torque for different materials.

Common Challenges with Gear Ratios in Metal Lathes

Analysis of frequent issues faced with incorrect gear ratios. Solutions and troubleshooting strategies for gear ratio problems.When using a metal lathe, wrong gear ratios can cause issues. You may notice poor cutting quality or uneven speeds. These problems affect your projects. Here are some tips to fix gear ratio challenges:

- Regularly check gear settings.

- Refer to the lathe manual for correct ratios.

- Adjust the saddle position for better alignment.

- Seek help from experienced users or forums.

Identifying these issues early can save you time and material!

What are some common problems with gear ratios?

Common problems include noisy operation, inconsistent speed, and poor finish on the material.

How can I solve these gear ratio issues?

To solve gear issues, check settings, realign the saddle, and consult the manual.

Best Practices for Lathe Gear Ratio Management

Maintenance tips for ensuring accurate gear ratios. Recommendations for selecting the right gear ratios for various applications.Keeping your lathe gear ratios accurate is key to smooth operations. Regular maintenance checks help spot issues before they become big problems. Looseness or dirt can cause misalignments. Always clean the components and check for wear. For selecting the perfect gear ratio, consider your project’s needs. Higher ratios can be useful for finer finishes, while lower ones might speed up production. Here’s a quick guide:

| Application | Recommended Gear Ratio |

|---|---|

| Fine Finishing | 10:1 |

| Heavy Cutting | 5:1 |

| General Work | 7:1 |

Remember, choosing the right ratio can save you time and effort, helping you avoid the dreaded ‘lathe regrets’!

Future Trends in Gear Ratios for Metal Lathes

Innovations and advancements in gear ratio technology. Potential future impact on metal lathe performance and efficiency.New ideas in gear ratios for metal lathes are making things better. Smart designs and improved materials can help machines run more smoothly. This means metal lathes can produce parts faster and with more precision. Smaller gear ratios could increase speed, while larger ones improve torque. For future users, these changes may lead to:

- Better performance with less energy

- Longer machine life and lower maintenance

- Higher quality finished products

The future looks bright for metal lathe technology!

What are the benefits of improved gear ratios?

Improved gear ratios can lead to faster speeds and better control.

Conclusion

In summary, the lathe gear ratio influences how your metal lathe operates. Understanding this ratio helps you make better cuts and achieve precise results. The saddle also plays a key role in stability. You can explore more about gear ratios and their effects on your projects. Keep learning and experimenting with your lathe for even better skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Saddle:A lathe is a machine that helps us shape metal. The gear ratio changes how fast the lathe spins. If you want to spin it faster, you adjust the gear ratio. The metal lathe saddle holds the metal piece while it spins. This keeps everything steady and helps us make better shapes.

Sure! Please provide the question you would like me to answer.

What Is The Significance Of Gear Ratio In The Operation Of A Metal Lathe?The gear ratio in a metal lathe helps control how fast the machine works. When we change the gear ratio, we can make the lathe spin faster or slower. This lets us cut metal in different ways. A good gear ratio helps us do our work better and make nice shapes. It’s like choosing the right speed for riding your bike!

How Can Adjusting The Gear Ratio Affect The Cutting Speed And Torque In A Lathe?Adjusting the gear ratio on a lathe changes how fast the cutting tool spins. When you make the gear ratio higher, the tool spins faster, which increases cutting speed. If you make the gear ratio lower, the tool spins slower but gets more torque, meaning it can handle tougher materials better. So, changing the gear ratio helps you pick between speed and power!

What Components Of The Metal Lathe Saddle Are Influenced By The Gear Ratio Setting?The gear ratio setting on a metal lathe saddle affects parts like the lead screw and the spindle. The lead screw moves the cutting tool. The spindle controls how fast the lathe spins. When you change the gear ratio, you change how fast these parts work together. This helps us make different shapes and sizes in our projects.

How Do Different Gear Ratio Configurations Impact The Precision Of Machining Operations On A Lathe?Different gear ratios can change how fast or slow the lathe spins. When you use the right gear ratio, you make smoother cuts. This helps you create better shapes and sizes in your work. If the lathe spins too fast or too slow, it can make mistakes. So, choosing the right gear ratio helps you work more accurately.

What Factors Should Be Considered When Selecting A Gear Ratio For A Specific Turning Operation On A Metal Lathe?When choosing a gear ratio for a turning job on a metal lathe, think about several things. First, consider the material you are using. Harder materials need slower speeds. Next, think about how deep you want to cut. Deeper cuts need lower speeds too. Also, look at the size of your tool; larger tools may need different speeds. Finally, remember to follow safe speeds to keep everything working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe is a machine that helps us shape metal. The gear ratio changes how fast the lathe spins. If you want to spin it faster, you adjust the gear ratio. The metal lathe saddle holds the metal piece while it spins. This keeps everything steady and helps us make better shapes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratio In The Operation Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in a metal lathe helps control how fast the machine works. When we change the gear ratio, we can make the lathe spin faster or slower. This lets us cut metal in different ways. A good gear ratio helps us do our work better and make nice shapes. It’s like choosing the right speed for riding your bike!”}},{“@type”: “Question”,”name”: “How Can Adjusting The Gear Ratio Affect The Cutting Speed And Torque In A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting the gear ratio on a lathe changes how fast the cutting tool spins. When you make the gear ratio higher, the tool spins faster, which increases cutting speed. If you make the gear ratio lower, the tool spins slower but gets more torque, meaning it can handle tougher materials better. So, changing the gear ratio helps you pick between speed and power!”}},{“@type”: “Question”,”name”: “What Components Of The Metal Lathe Saddle Are Influenced By The Gear Ratio Setting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio setting on a metal lathe saddle affects parts like the lead screw and the spindle. The lead screw moves the cutting tool. The spindle controls how fast the lathe spins. When you change the gear ratio, you change how fast these parts work together. This helps us make different shapes and sizes in our projects.”}},{“@type”: “Question”,”name”: “How Do Different Gear Ratio Configurations Impact The Precision Of Machining Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different gear ratios can change how fast or slow the lathe spins. When you use the right gear ratio, you make smoother cuts. This helps you create better shapes and sizes in your work. If the lathe spins too fast or too slow, it can make mistakes. So, choosing the right gear ratio helps you work more accurately.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Gear Ratio For A Specific Turning Operation On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a gear ratio for a turning job on a metal lathe, think about several things. First, consider the material you are using. Harder materials need slower speeds. Next, think about how deep you want to cut. Deeper cuts need lower speeds too. Also, look at the size of your tool; larger tools may need different speeds. Finally, remember to follow safe speeds to keep everything working well.”}}]}