Have you ever wondered how metal lathe projects come to life? The magic often starts with the lathe headstock bearing. This small but vital part keeps the machine running smoothly. It may seem simple, but without it, all your hard work can come to a halt. Imagine facing a big project and realizing your machine is stuck!

When you dive into the world of metal lathes, understanding these bearings can make a big difference. They ensure that your projects can spin and shape metals perfectly. But what exactly do they do? A lathe headstock bearing supports the weight and helps the spindle turn. This action is essential for achieving precision and accuracy.

Think about the last time you built something. You needed the right tools, right? The same goes for metal lathing. Knowing how to choose and maintain your lathe headstock bearing can enhance your skills. Plus, it can save you time and money!

Join us as we explore metal lathe projects and the importance of headstock bearings. You’ll discover tips, tricks, and helpful information. Who knows? You might just be inspired to start your next exciting project!

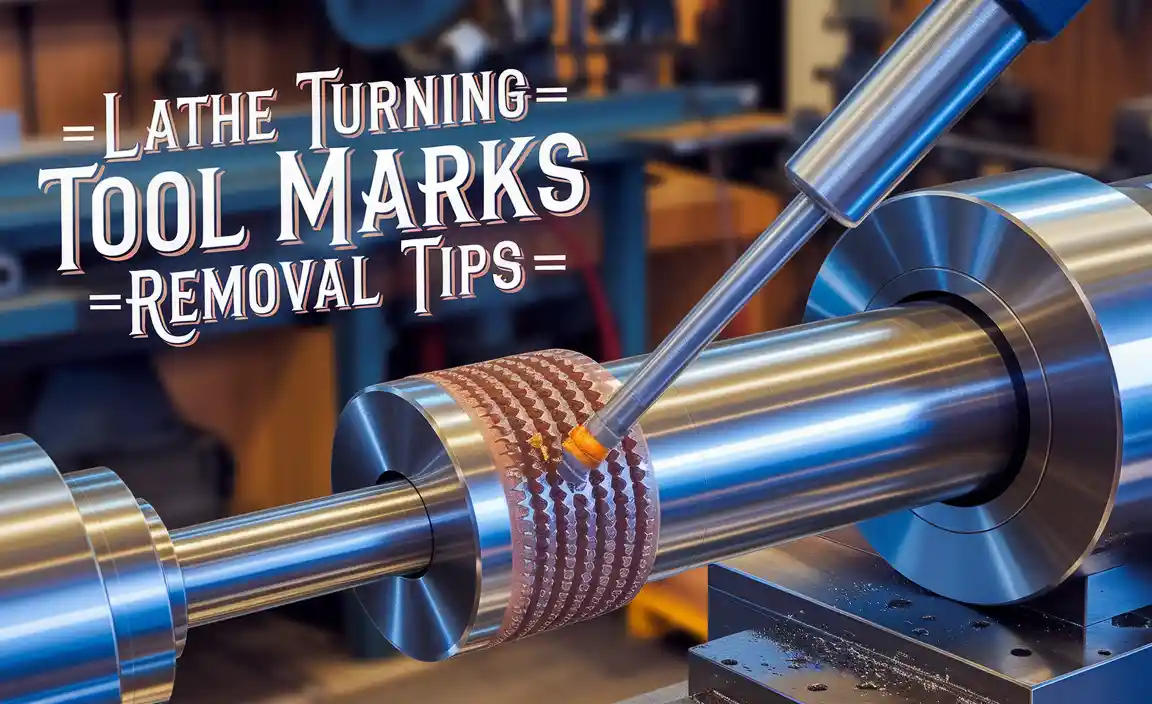

Lathe Headstock Bearing For Metal Lathe Projects: A Guide

Lathe Headstock Bearing Metal Lathe Projects

Lathe projects can be exciting and rewarding! The lathe headstock plays a crucial role in shaping materials. Did you know that a good headstock bearing can make a big difference in smooth operation? Strong bearings help reduce vibration and increase accuracy in your work. With a solid understanding of lathe mechanics, you can tackle fun projects like creating unique bowls or custom parts. Dive into the world of metal lathes, and unleash your creativity!Understanding Lathe Headstock Components

Description of headstock and its functions in a metal lathe. Importance of bearings in achieving precision and performance.The headstock is crucial in a metal lathe. It holds the spindle and gears, allowing the machine to spin materials securely. Smooth, efficient rotation is essential for accurate cutting and shaping. Bearings play a key role in this process. They reduce friction, helping the lathe work better. This leads to fine details in projects. Without good bearings, precision suffers. A well-functioning headstock makes a big difference in the final outcome of metal lathe work.

Why are bearings important in machining?

Bearings ensure smooth rotation and reduce wear. This allows for cleaner cuts and better finishes in all projects. Quality bearings lead to longer-lasting performance, saving time and resources.

Key Functions of the Headstock

- Holds the spindle securely.

- Controls speed and direction.

- Supports various tools during operation.

How to Choose the Right Bearing for Your Lathe

Factors to consider (e.g., load capacity, speed ratings, lubrication). Common mistakes to avoid when selecting bearings.Choosing the right bearing can feel daunting, but it doesn’t have to be. Start by checking the load capacity; it’s like knowing how much a pizza can hold before it droops! Next, consider the speed ratings. You don’t want your lathe working harder than your pet goldfish during feeding time. Remember lubrication too; dry bearings are sad bearings. Avoid classic blunders like ignoring these key factors. Always ask for help if confused. It’s okay to say, “I need bearings!”

| Factor | What to Consider |

|---|---|

| Load Capacity | Choose for strength! |

| Speed Ratings | Don’t outrun your lathe! |

| Lubrication | Keep it smooth like butter! |

Maintenance and Care of Lathe Headstock Bearings

Best practices for maintaining bearings to extend lifespan. Signs of wear and how to diagnose bearing issues.To keep your lathe headstock bearings in good shape, follow some easy steps. First, always keep them clean and free from dirt. This helps them work better and last longer. Listen for unusual sounds while using the lathe. These sounds might mean the bearings are worn out. Check for any rough spots or stiffness when turning the spindle. Regular checks can save you trouble down the line!

What are the signs of worn-out bearings?

Look out for these clues:

- Strange noises: Knocking or grinding sounds can mean trouble.

- Increased vibration: Excessive shaking can indicate wear.

- Heat generation: If the bearings feel hot, they may be failing.

DIY Metal Lathe Projects Utilizing Headstock Bearings

Creative project ideas that leverage lathe headstock bearings. Stepbystep process for one standout project.Looking for a fun project? Try using lathe headstock bearings to make cool items. Here are some creative ideas:

- Custom drawer pulls

- Unique knobs for tools

- Stylish furniture accents

One standout project is a spinning top. Follow these steps:

- Gather materials: bearings, wood block, and a drill.

- Drill a hole in the center of the block.

- Insert the bearing into the hole.

- Shape the wood to create a beautiful design.

- Test the spin for balance and fun!

With some creativity and a lathe, you can make amazing things!

What are some simple DIY projects with a metal lathe?

Simple projects include making knobs, tool handles, and decorative items. These projects help build skills and can be very enjoyable.

Upgrading Your Lathe: When and Why to Replace Headstock Bearings

Indications that it’s time for a bearing replacement. Benefits of upgrading to highperformance bearings.Worn headstock bearings can slow down your metal lathe and affect your projects. If you notice unusual noises, vibrations, or harder metal cutting, it’s time for a change. Upgrading to high-performance bearings offers smoother operation, greater precision, and a longer lathe life. It can also help improve overall project quality.

When should you replace lathe bearings?

Look for these signs:

- Strange noises during operation

- Increased vibrations

- Difficulty in achieving smooth cuts

- Visible wear or damage

Replacing your bearings regularly can keep your lathe running like new.

Comparative Analysis: Popular Brands of Lathe Bearings

Review of top manufacturers and their offerings. Performance metrics and customer feedback on various brands.There are many brands that make lathe bearings, each with its own strengths. Some of the top manufacturers include Timken, known for their durability, and SKF, which adds a splash of innovation. Users rave about Timken’s long life and smooth operation. However, some find SKF’s features delightful, leading to smooth projects. Below is a quick comparison of popular choices:

| Brand | Performance | Customer Feedback |

|---|---|---|

| Timken | Durable & Smooth | “Lasts forever!” |

| SKF | Innovative Features | “Smooth like butter!” |

| FAG | Reliable & Strong | “Never lets me down!” |

Choosing the right bearing can make your projects easier. It helps to know what others say before diving in. Remember, even the best lathe needs the best gifts!

Conclusion

In summary, understanding lathe headstock bearings is crucial for successful metal lathe projects. Good bearings improve precision and extend the life of your lathe. You can enhance your skills by practicing with different projects. Explore more resources to deepen your knowledge and try new techniques. Get started today, and enjoy creating amazing metal works!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Projects:Sure! Here are answers to the questions about lathe headstock bearings and metal lathe projects. 1. A lathe headstock is the part of a lathe that holds the motor and spindle. It helps spin the material you’re working on. 2. Bearings are like little wheels inside the headstock. They help the spindle turn smoothly and easily. 3. You can use a lathe for many fun projects. You can make things like wooden bowls, toys, or even metal parts! 4. To make something on a lathe, you need to plan first. Sketch your design and gather your materials before starting. 5. Always be careful when using a lathe. Wear safety gear and keep your hands away from moving parts to stay safe.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!

What Types Of Bearings Are Commonly Used In The Headstock Assembly Of A Metal Lathe, And What Are Their Advantages And Disadvantages?In a metal lathe’s headstock, we often find two types of bearings: ball bearings and plain bearings. Ball bearings are round and help things move smoothly. They are great because they reduce friction and last a long time. However, they can be tricky to install and may cost more. Plain bearings are simpler and easier to put in, but they often wear out faster.

How Can Improper Bearing Maintenance Affect The Performance And Accuracy Of A Metal Lathe During Machining Projects?Improper bearing maintenance can cause problems in a metal lathe. When bearings aren’t cared for, they can get dirty or worn out. This makes the machine hard to move and can create vibrations. These issues can lead to mistakes in cutting, so your projects might not look or fit right. Taking care of the bearings helps the lathe work smoothly and accurately.

What Are Some Common Signs Indicating That The Headstock Bearings Of A Lathe May Need To Be Replaced Or Serviced?If your lathe is making strange noises, that’s a sign the headstock bearings might be worn out. You might also notice the lathe shaking while it works. If it’s hard to turn the handle smoothly, that’s another clue. Finally, if it seems to run slower than before, the bearings may need help. It’s a good idea to check them if you see these problems!

What Techniques Can Be Employed To Customize Or Improve The Bearing Configuration In A Metal Lathe For Enhanced Precision In Projects?To improve the bearing setup in a metal lathe, you can try a few simple steps. First, make sure the bearings are clean and free from dirt. You can also add lubrication to help them move smoothly. Another idea is to check if the bearings are securely fitted and not loose. Finally, if your lathe allows it, you can use better quality bearings for better precision in your work.

How Do Different Bearing Materials Influence The Overall Lifespan And Performance Of A Lathe During Heavy-Duty Machining Tasks?Different materials can change how long a lathe lasts and how well it works. If you use strong materials like steel, the lathe can handle heavy work better. Softer materials might wear out faster and cause problems. Choosing the right material helps you prevent breakdowns, so your lathe keeps running smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Projects:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are answers to the questions about lathe headstock bearings and metal lathe projects. 1. A lathe headstock is the part of a lathe that holds the motor and spindle. It helps spin the material you’re working on. 2. Bearings are like little wheels inside the headstock. They help the spindle turn smoothly and easily. 3. You can use a lathe for many fun projects. You can make things like wooden bowls, toys, or even metal parts! 4. To make something on a lathe, you need to plan first. Sketch your design and gather your materials before starting. 5. Always be careful when using a lathe. Wear safety gear and keep your hands away from moving parts to stay safe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In The Headstock Assembly Of A Metal Lathe, And What Are Their Advantages And Disadvantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe’s headstock, we often find two types of bearings: ball bearings and plain bearings. Ball bearings are round and help things move smoothly. They are great because they reduce friction and last a long time. However, they can be tricky to install and may cost more. Plain bearings are simpler and easier to put in, but they often wear out faster.”}},{“@type”: “Question”,”name”: “How Can Improper Bearing Maintenance Affect The Performance And Accuracy Of A Metal Lathe During Machining Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper bearing maintenance can cause problems in a metal lathe. When bearings aren’t cared for, they can get dirty or worn out. This makes the machine hard to move and can create vibrations. These issues can lead to mistakes in cutting, so your projects might not look or fit right. Taking care of the bearings helps the lathe work smoothly and accurately.”}},{“@type”: “Question”,”name”: “What Are Some Common Signs Indicating That The Headstock Bearings Of A Lathe May Need To Be Replaced Or Serviced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe is making strange noises, that’s a sign the headstock bearings might be worn out. You might also notice the lathe shaking while it works. If it’s hard to turn the handle smoothly, that’s another clue. Finally, if it seems to run slower than before, the bearings may need help. It’s a good idea to check them if you see these problems!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Customize Or Improve The Bearing Configuration In A Metal Lathe For Enhanced Precision In Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To improve the bearing setup in a metal lathe, you can try a few simple steps. First, make sure the bearings are clean and free from dirt. You can also add lubrication to help them move smoothly. Another idea is to check if the bearings are securely fitted and not loose. Finally, if your lathe allows it, you can use better quality bearings for better precision in your work.”}},{“@type”: “Question”,”name”: “How Do Different Bearing Materials Influence The Overall Lifespan And Performance Of A Lathe During Heavy-Duty Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials can change how long a lathe lasts and how well it works. If you use strong materials like steel, the lathe can handle heavy work better. Softer materials might wear out faster and cause problems. Choosing the right material helps you prevent breakdowns, so your lathe keeps running smoothly.”}}]}