If you’ve ever used a metal lathe, you know how important each part is. One key piece that can make a big difference is the lathe headstock bearing. Upgrading this part might sound like a small change, but it can really enhance your machine’s performance.

Imagine trying to cut a perfect piece of wood, but your machine just isn’t working right. It can be frustrating, right? That’s where a better bearing comes in. A new, smoother lathe headstock bearing can reduce vibrations and improve accuracy. Suddenly, your projects come out cleaner and faster!

Here’s a fun fact: even tiny changes to your lathe can lead to exciting outcomes. Upgrading your lathe headstock bearing is one of those changes. It’s like giving your machine a turbo boost!

Ready to learn more about this upgrade? Discover how the right bearing can transform your metal lathe experience. Let’s dive in!

Enhance Your Metal Lathe: Lathe Headstock Bearing Upgrade

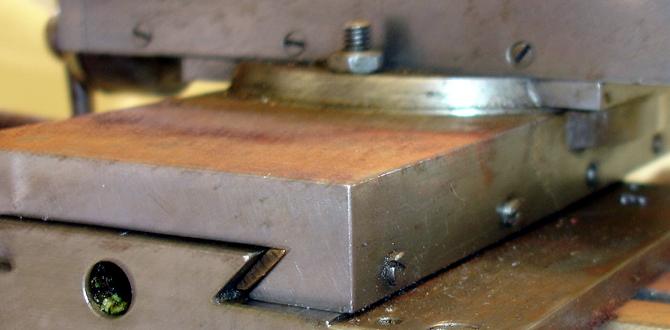

Lathe Headstock Bearing Metal Lathe Upgrade

Upgrading the lathe headstock bearing can greatly improve a metal lathe’s performance. Good bearings reduce vibrations and increase precision. Imagine making smoother cuts and creating better finishes on your projects. Did you know that a simple switch can extend your lathe’s lifespan? Choosing higher-quality bearings is key. They provide stability and support, making machining easier. This upgrade is a smart choice for any metalworker, enhancing both the quality of work and enjoyment in creating.Understanding Lathe Headstock Bearings

Definition and function of headstock bearings in metal lathes. Importance of bearing material and design on lathe performance.Headstock bearings play a key role in metal lathes. They help the spindle rotate smoothly. Without them, the lathe would shake and vibrate. This would make it hard to create precise shapes. The material and design of these bearings are very important. High-quality bearings improve performance and last longer. Good bearings help with better finishes on projects. Everyone wants a lathe that works well, right?

What materials are best for lathe headstock bearings?

Steel and bronze are often used for lathe headstock bearings. These materials are strong and can handle heavy work. They help the lathe run smooth and quiet.

Important Points:

- Headstock bearings support the spindle.

- They impact how well the lathe operates.

- Better materials lead to better results.

Signs You Need a Headstock Bearing Upgrade

Common issues indicating worn or inadequate bearings. Effects of worn bearings on machining accuracy and surface finish.Have you noticed a grumpy sound coming from your lathe? That might mean it needs a little TLC! Common signs of worn bearings include strange noises, excess vibration, and poor cutting. These issues can lead to bad machining accuracy and an uneven surface finish. Think of it as baking a cake without measuring—messy and disappointing! If you’re making more pancakes than precise parts, it might be time for an upgrade!

| Common Issues | Effects on Machining |

|---|---|

| Strange noise | Lower precision |

| Excessive vibration | Poor surface finish |

| Uneven cuts | Increased wear on tools |

Choosing the Right Bearing for Your Lathe Upgrade

Factors to consider: load capacity, lubrication type, and installation. Recommended bearing specifications for various lathe models.Choosing the right bearing for your lathe upgrade is important. Here are some key factors to keep in mind:

- Load capacity: Ensure that the bearing can handle the weight of your lathe.

- Lubrication type: Pick a bearing that matches your lubrication method, whether it’s grease or oil.

- Installation: Choose a bearing that is easy to install to avoid extra hassles.

For different lathe models, the specifications may vary. Check your machine’s manual for the right fit. A good choice can improve your lathe’s performance and longevity.

What should I consider when choosing a bearing?

Consider load capacity, lubrication type, and ease of installation to find the perfect bearing for your lathe.

Recommended Specifications:

- Small lathes: ABEC-3 bearings, 25mm diameter

- Medium lathes: ABEC-5 bearings, 40mm diameter

- Large lathes: ABEC-7 bearings, 60mm diameter

Step-by-Step Guide to Upgrading Lathe Headstock Bearings

Necessary tools and materials for the upgrade process. Detailed instructions on how to replace headstock bearings safely and effectively.Upgrading your lathe headstock bearings is like giving your machine a new pair of sneakers—suddenly, it moves like a champ! First, gather some essential tools. You’ll need a wrench, screwdriver, and maybe a mallet (it helps with stubborn parts). Make sure to have your new bearings ready too!

Next, follow these simple steps:

| Step | Instructions |

|---|---|

| 1 | Turn off and unplug the lathe first. Safety first, folks! |

| 2 | Remove the headstock from the lathe body. |

| 3 | Carefully take out the old bearings. |

| 4 | Insert the new bearings snugly. |

| 5 | Reattach the headstock and plug the lathe back in. |

And voila! Your lathe is ready to spin with fresh energy. Remember, upgrading isn’t just about performance; it’s also about confidence. You can do this!

Benefits of Upgrading Your Lathe Headstock Bearings

Improved accuracy and surface finish in machined parts. Enhanced lathe durability and maintenance considerations.Upgrading your lathe headstock bearings brings many benefits. First, it improves accuracy in your machined parts. This means your projects will have a better surface finish. You’ll create smoother and cleaner items. Second, upgraded bearings boost the lathe’s durability. This helps your machine last longer with less maintenance. Less wear and tear means fewer repairs, saving you time and money.

- Better accuracy leads to high-quality products.

- Longer-lasting parts reduce replacement costs.

- Less maintenance means more time for projects.

What are the key benefits of upgrading lathe headstock bearings?

Improved accuracy, better surface finish, and increased durability are key benefits of upgrading lathe headstock bearings.Common Mistakes to Avoid During the Upgrade

Typical errors made during installation and how to prevent them. Importance of following manufacturer specifications and guidelines.Upgrading your lathe can be exciting, but mistakes are common. First, many forget to check manufacturer specifications. Always read the instructions carefully. Without this, you might choose the wrong parts. Second, not securing the bearings properly can lead to problems. Use the right tools and techniques to avoid trouble. Lastly, improve your workspace. A clean area helps prevent errors. Keep these points in mind for a smooth upgrade.

Common Errors During Installation

- Ignoring manufacturer specifications

- Improperly securing bearings

- Messy workspace leading to distractions

Importance of Following Guidelines

Following guidelines ensures safety and equipment longevity. It helps you avoid costly errors. Don’t skip crucial steps to finish faster.

Maintenance Tips for Longevity of Upgraded Bearings

Best practices for lubricating and maintaining bearings. Signs of wear to watch for postupgrade and when to act.Upgraded bearings need care for them to last. Lubricating them regularly is key. Use the right lubricant as recommended. Keep them clean to avoid dirt buildup. Check for any strange noises while running. A grinding sound might mean trouble. Watch for any unusual vibrations. These can show wear and tear. If you notice these signs, act quickly to prevent further damage.

What are the best practices for lubricating bearings?

To keep your bearings in great shape, always check their oil levels. If they are low, refill them. Use the lubricant suggested by the manufacturer. This ensures smooth operation. Keep the bearings clean from dust and particles. Regular maintenance can save you time and money.

Signs of wear to watch for:

- Strange noises

- Unusual vibrations

- Overheating

Cost Considerations and ROI for Upgrading Bearings

Breakdown of typical costs involved in the upgrade. Evaluating the longterm benefits versus initial investment.Upgrading your lathe bearings can feel like jumping into a pool of expenses, but it can save you from sinking later! Typical costs for this upgrade range from $100 to $500, depending on the quality and type of bearings. Think of it as an investment in your hobby or business. Over time, you could see better performance, less maintenance, and even longer tool life. Investing now can lead to savings later, and who wouldn’t want that? A well-maintained lathe can boost your productivity, making your early costs a wise decision!

| Cost Breakdown | Initial Investment | Long-term Benefits |

|---|---|---|

| Quality Bearings | $100 – $500 | Less Maintenance |

| Labor | $50 – $200 | Improved Performance |

| Total Estimate | $150 – $700 | Increased Productivity |

Conclusion

Upgrading the lathe headstock bearing can improve your metal lathe’s performance. Better bearings reduce friction and enhance accuracy. This upgrade makes your projects smoother and more enjoyable. If you’re ready to boost your lathe, consider your options. You can search for specific parts or read guides online. Let’s keep learning to make our machines work even better!FAQs

Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Upgrades For Metal Lathes:Upgrading the bearings in a lathe headstock can make the machine work better. Bearings help the parts move smoothly. When we change to stronger bearings, our lathe can spin faster and last longer. It’s like giving your toy a new battery for better playtime! Always check that the new parts fit your lathe before upgrading.

Sure! Just ask your question, and I will answer it for you.

What Are The Benefits Of Upgrading To High-Quality Bearings In The Headstock Of A Metal Lathe?Upgrading to high-quality bearings in a metal lathe helps it work better. You’ll notice smoother movement, which makes cuts cleaner. It also lasts longer, saving you money on replacements. Plus, it reduces noise, making it nicer to use. Overall, high-quality bearings help your lathe do its job more easily and efficiently.

How Can One Determine Whether Their Metal Lathe’S Headstock Bearings Need Replacement Or Upgrade?To check if your metal lathe’s headstock bearings need replacing, listen for strange noises. If you hear grinding or rattling sounds, that’s a warning sign. You can also feel for movement; if the spindle wobbles, it’s bad. Lastly, check for unusual heat; if it’s too hot to touch, it’s time for a change.

What Types Of Bearings Are Available For Lathe Headstock Upgrades, And How Do They Compare In Performance And Cost?For lathe headstock upgrades, you can choose between plain bearings and ball bearings. Plain bearings are simple and often cheaper, but they can wear out faster. Ball bearings are stronger and help the lathe spin better, but they cost more. If you want better performance, ball bearings are usually the best choice, even if they cost extra.

What Is The Process For Installing Upgraded Bearings In A Lathe Headstock, And What Tools Are Required?To install upgraded bearings in a lathe headstock, you start by unplugging the machine. Then, you take off the headstock cover. Next, you remove the old bearings carefully. After that, you put in the new bearings and put everything back together. You will need tools like a screwdriver, a wrench, and sometimes a hammer. Remember to follow all safety rules while you work!

How Can Upgraded Headstock Bearings Affect The Precision And Longevity Of A Metal Lathe’S Performance?Upgraded headstock bearings help the metal lathe spin more smoothly. This means the cuts you make will be cleaner and more accurate. If the bearings are strong, the lathe lasts longer because they wear out less. So, using better bearings means better work and more years of use!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Upgrades For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading the bearings in a lathe headstock can make the machine work better. Bearings help the parts move smoothly. When we change to stronger bearings, our lathe can spin faster and last longer. It’s like giving your toy a new battery for better playtime! Always check that the new parts fit your lathe before upgrading.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I will answer it for you.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Upgrading To High-Quality Bearings In The Headstock Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading to high-quality bearings in a metal lathe helps it work better. You’ll notice smoother movement, which makes cuts cleaner. It also lasts longer, saving you money on replacements. Plus, it reduces noise, making it nicer to use. Overall, high-quality bearings help your lathe do its job more easily and efficiently.”}},{“@type”: “Question”,”name”: “How Can One Determine Whether Their Metal Lathe’S Headstock Bearings Need Replacement Or Upgrade?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your metal lathe’s headstock bearings need replacing, listen for strange noises. If you hear grinding or rattling sounds, that’s a warning sign. You can also feel for movement; if the spindle wobbles, it’s bad. Lastly, check for unusual heat; if it’s too hot to touch, it’s time for a change.”}},{“@type”: “Question”,”name”: “What Types Of Bearings Are Available For Lathe Headstock Upgrades, And How Do They Compare In Performance And Cost?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For lathe headstock upgrades, you can choose between plain bearings and ball bearings. Plain bearings are simple and often cheaper, but they can wear out faster. Ball bearings are stronger and help the lathe spin better, but they cost more. If you want better performance, ball bearings are usually the best choice, even if they cost extra.”}},{“@type”: “Question”,”name”: “What Is The Process For Installing Upgraded Bearings In A Lathe Headstock, And What Tools Are Required?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install upgraded bearings in a lathe headstock, you start by unplugging the machine. Then, you take off the headstock cover. Next, you remove the old bearings carefully. After that, you put in the new bearings and put everything back together. You will need tools like a screwdriver, a wrench, and sometimes a hammer. Remember to follow all safety rules while you work!”}},{“@type”: “Question”,”name”: “How Can Upgraded Headstock Bearings Affect The Precision And Longevity Of A Metal Lathe’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgraded headstock bearings help the metal lathe spin more smoothly. This means the cuts you make will be cleaner and more accurate. If the bearings are strong, the lathe lasts longer because they wear out less. So, using better bearings means better work and more years of use!”}}]}