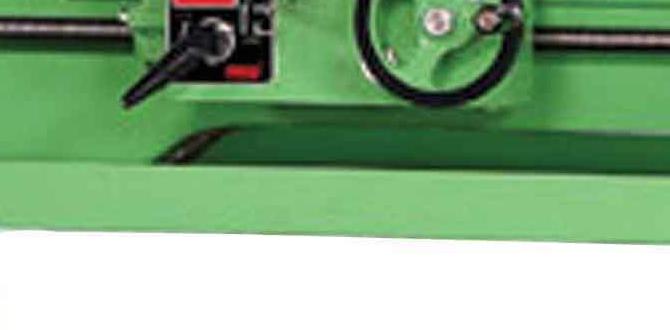

Have you ever wondered how metal lathes work so smoothly? The secret often lies in proper lathe lubrication. It’s amazing how a little oil can make a big difference. Imagine a robot that helps you with your projects. That’s what lathe automation can do! It takes the hard work out of running a metal lathe.

Many people don’t know that the right lubrication keeps the machine running longer and safer. Without it, parts can wear out quickly. You might even face accidents that could have been avoided. Wouldn’t it be great if you could focus on creating, instead of worrying about maintenance?

In our article, we will explore the importance of lathe lubrication and how automation can change your experience. Get ready to discover tips and tricks that will help you keep your machine running smoothly!

Essential Guide To Lathe Lubrication For Metal Lathe Automation

Lathe Lubrication and Metal Lathe Automation

Proper lathe lubrication is crucial for maintaining metal lathe performance. Without it, machines can wear out quickly. Lubrication reduces friction and heat, making lathe operations smoother. Did you know automation in lathe work can boost productivity? Automated systems provide precise lubrication, ensuring consistency. This helps prevent mishaps while saving time. Regular maintenance paired with automated lubrication systems can greatly extend the life of your equipment. Why not explore how these advancements can improve your work?Importance of Lathe Lubrication

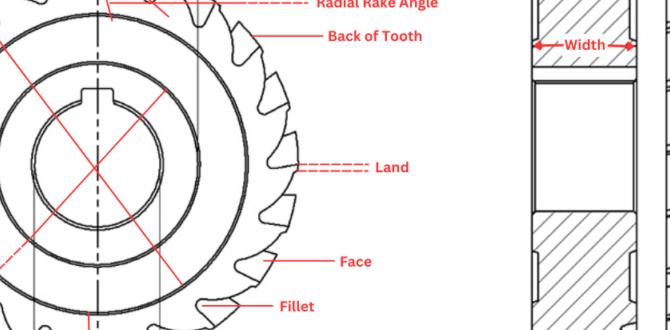

Discuss the role of lubrication in metal lathe operation.. Explain the consequences of inadequate lubrication..Lubrication keeps a metal lathe running smoothly. It reduces friction between moving parts. This helps prevent wear and tear, making the machine last longer. Without proper lubrication, machines can overheat and break down. Here are some effects of poor lubrication:

- Increased friction can lead to damage.

- Overheating can cause parts to melt or warp.

- Lower precision in cuts and shapes.

- Higher maintenance costs for repairs.

Regular lubrication is essential for efficient metal lathe automation. A well-lubricated lathe means safer and better quality work.

Why is lubrication needed for metal lathe operation?

Lubrication prevents damage and keeps the lathe functioning smoothly. It allows the highest level of performance and accuracy.

Types of Lubricants for Metal Lathes

Describe various lubricant types (oil, grease, etc.).. Compare their effectiveness in different machining conditions..Choosing the right lubricant for a metal lathe is like picking the perfect ice cream flavor—it really matters! You can find oils, greases, and even specialty lubricants. Oils are great for high-speed operations, while greases stick around for a long time and reduce wear. Some say grease is lazy, but it’s just taking its sweet time! Each has its place depending on how fast or slow the lathe runs. They keep parts moving smoothly and make machining easier.

| Lubricant Type | Best For | Effectiveness |

|---|---|---|

| Oil | High-speed operations | Excellent |

| Grease | Slow-moving machines | Good |

| Specialty Lubricants | Harsh conditions | Outstanding |

Best Practices for Lathe Lubrication

Outline a stepbystep lubrication schedule.. Highlight common mistakes to avoid during lubrication..To keep your lathe running smoothly, follow a simple lubrication schedule. Lubricate your lathe daily before use. After every 10 hours of work, check the oil levels. Monthly, clean and refill lubrication systems. Avoid common mistakes, like forgetting to clean old oil or using the wrong type. These errors can lead to damage.

- Check for wear and tear on the oiling system.

- Don’t over-lubricate; it can cause mess and problems.

- Use the right lubricant for your specific lathe model.

What are the benefits of proper lathe lubrication?

Proper lubrication reduces friction, extends tool life, and enhances machine precision. This means smoother operation and better results in your projects. Regular maintenance can save time and money in the long run.

Automating the Lubrication Process

Explore available automation technologies for lubrication.. Discuss benefits of integrating automation in lathe operations..Modern technologies can make lube systems smarter. Automating lubrication means machines apply oil automatically. This keeps operations smooth and prevents wear. How does automation help? Here are some benefits:

- Saves time and effort

- Reduces waste of oil

- Keeps machines running longer

- Improves safety for workers

With automation, lathe operations become quicker. This leads to higher productivity. Happy machinists mean better results. Isn’t it cool how machines can help each other?

Why automate lubrication?

Automation helps machines stay in top shape. It cuts down on the need for manual checks. This means less chance of mistakes and better performance!

Maintenance Tips for Lathe Lubrication Systems

Provide maintenance guidelines for lubrication systems.. Suggest tools or devices that enhance lubrication efficiency..Keeping lathe lubrication systems in good shape helps machines run smoothly. Follow these tips for better maintenance:

- Check oil levels regularly to avoid dryness.

- Clean filters often to prevent blockages.

- Replace worn-out parts immediately.

- Use a lubrication chart for precise timing.

Tools like automatic oilers and grease guns can improve lubrication efficiency. These devices make sure that the right amount of lubrication goes to every part, which helps the lathe last longer. Regular maintenance and the right tools can help your lathe work better!

What tools improve lathe lubrication?

Devices like automatic oilers and grease guns enhance lubrication efficiency. They provide consistent lubrication, which reduces wear on moving parts and boosts the machine’s lifespan.

Case Studies: Successful Implementations

Present realworld examples of automated lubrication in metal lathes.. Analyze the outcomes and improvements from these implementations..Think of Bob’s Machine Shop. They installed an automated lubrication system on their metal lathe. This was a game-changer! Their machines now run smoother than a buttered banana on a slip ‘n slide. With the new system, machine wear fell by 30%, and production speed jumped by 25%. They even noticed fewer messy oil spills, which made Bob’s janitor very happy! This is just one of many success stories showing how automated lubrication can transform a shop.

| Company | Improvement in Wear | Increase in Speed</th |

|---|---|---|

| Bob’s Machine Shop | 30% | 25% |

Future Trends in Lathe Lubrication and Automation

Investigate emerging technologies in lubrication methods.. Discuss potential industry shifts related to automation in lathe services..New technologies are changing how we think about lathe lubrication and automation. For example, advanced lubrication methods can keep lathes running smoothly and safely. These new techniques promise to cut down on time and waste. Automation is also growing. It can make lathe services faster and more efficient. Many companies will likely focus on these improvements. Here are a few exciting trends to watch:

- Smart lubrication systems

- Robots in machining

- Real-time monitoring tools

Conclusion

In conclusion, proper lathe lubrication is essential for smooth operation and longer tool life. Automation can boost your efficiency and productivity, making tasks easier. By understanding these key points, you can improve your metalworking skills. I encourage you to explore more about lathe maintenance and automation techniques. Take the next step and start experimenting in your workshop!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Automation:Sure! Here are five important things about lathe lubrication and automation. Lubrication makes the lathe work smoothly and helps it last longer. You can use oil or grease to keep the parts sliding easily. Automation means using machines to do some tasks by themselves, so we don’t have to do everything by hand. This makes work faster and easier for everyone!

Sure! Please provide the question you want me to answer.

What Are The Best Types Of Lubricants To Use For Different Components Of A Metal Lathe To Ensure Optimal Performance And Longevity?To keep a metal lathe running well, you need the right lubricants for its parts. For the moving parts, you can use light machine oil. It’s great because it helps everything move smoothly. For the spindle and gears, use grease, which stays on longer and protects them better. Always check the user manual to see what’s best for your specific lathe!

How Can Automation Systems Be Integrated Into A Metal Lathe To Improve The Efficiency Of The Lubrication Process?We can use automation systems to make lubrication easier on a metal lathe. First, we can add automatic oil dispensers that give the right amount of oil when needed. This means you don’t have to stop working to add oil. We can also use sensors to check if more oil is needed. This helps keep the machine running smoothly and saves time.

What Maintenance Practices Are Essential For Ensuring The Lubrication System Of A Metal Lathe Operates Effectively?To keep the lubrication system of a metal lathe working well, you should check the oil levels regularly. Make sure to fill up the oil if it gets low. You also need to clean any filters to remove dirt. Lastly, look for leaks and fix them right away. This keeps everything running smoothly!

How Does Inadequate Lubrication Affect The Machining Process And Final Product Quality In Automated Metal Lathes?Inadequate lubrication makes metal parts stick and rub against each other. This can cause extra heat, making the machine work harder. When that happens, the parts can get damaged or messy. You end up with a lower-quality product that might not fit or work well. So, keeping things well-lubricated is really important!

What Are The Latest Advancements In Lathe Lubrication Technology That Can Enhance Automation In Machining Operations?New lubrication systems help machines like lathes run smoother and longer. They use sensors to check when oil is needed. This means less stopping for workers. Smart machines can even add oil by themselves. These upgrades make machining faster and more efficient.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five important things about lathe lubrication and automation. Lubrication makes the lathe work smoothly and helps it last longer. You can use oil or grease to keep the parts sliding easily. Automation means using machines to do some tasks by themselves, so we don’t have to do everything by hand. This makes work faster and easier for everyone!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Types Of Lubricants To Use For Different Components Of A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe running well, you need the right lubricants for its parts. For the moving parts, you can use light machine oil. It’s great because it helps everything move smoothly. For the spindle and gears, use grease, which stays on longer and protects them better. Always check the user manual to see what’s best for your specific lathe!”}},{“@type”: “Question”,”name”: “How Can Automation Systems Be Integrated Into A Metal Lathe To Improve The Efficiency Of The Lubrication Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use automation systems to make lubrication easier on a metal lathe. First, we can add automatic oil dispensers that give the right amount of oil when needed. This means you don’t have to stop working to add oil. We can also use sensors to check if more oil is needed. This helps keep the machine running smoothly and saves time.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Lubrication System Of A Metal Lathe Operates Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lubrication system of a metal lathe working well, you should check the oil levels regularly. Make sure to fill up the oil if it gets low. You also need to clean any filters to remove dirt. Lastly, look for leaks and fix them right away. This keeps everything running smoothly!”}},{“@type”: “Question”,”name”: “How Does Inadequate Lubrication Affect The Machining Process And Final Product Quality In Automated Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Inadequate lubrication makes metal parts stick and rub against each other. This can cause extra heat, making the machine work harder. When that happens, the parts can get damaged or messy. You end up with a lower-quality product that might not fit or work well. So, keeping things well-lubricated is really important!”}},{“@type”: “Question”,”name”: “What Are The Latest Advancements In Lathe Lubrication Technology That Can Enhance Automation In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “New lubrication systems help machines like lathes run smoother and longer. They use sensors to check when oil is needed. This means less stopping for workers. Smart machines can even add oil by themselves. These upgrades make machining faster and more efficient.”}}]}