Have you ever wondered how a metal lathe works smoothly? A lot of it comes down to one essential thing: lubrication. Lathe lubrication is crucial for keeping your machine in top shape. Imagine trying to ride a bike with rusty wheels. It’s tough, right? The same applies to a lathe without proper oil.

Every bench lathe needs a little care to run well. When you lubricate it, you help the moving parts glide easily. This means better performance and a longer life for your tool. Did you know that regular maintenance can save you from costly repairs? It’s true!

If you’re a beginner or an experienced hobbyist, understanding lathe lubrication is key. You’ll not only improve your skills but also create better projects. So, let’s dive into the world of metal lathe bench maintenance and discover how to keep things running smoothly!

Essential Lathe Lubrication For Metal Lathe Bench Maintenance

Lathe Lubrication for Metal Lathes

Proper lubrication is essential for a metal lathe bench. It helps the lathe run smoothly and prevents wear. Did you know that using the right oil can extend the life of your lathe? Regular maintenance and lubrication keep the moving parts in great shape. Think about it—would you drive a car without oil? By ensuring your lathe is well-lubricated, you can improve performance and accuracy. Keep your metal lathe happy for better projects!Understanding Lathe Lubrication

Definition and importance of lathe lubrication. Common types of lubricants used in metal lathes.Lubrication keeps metal lathes running smoothly. It reduces friction and heat. This means less wear and a longer machine life. Proper lubrication also helps in getting the best results from your work.

Common types of lubricants for metal lathes include:

- Oil – Provides good lubrication and cooling.

- Grease – Stays in place and prevents dust.

- Cutting fluids – Helps in the cutting process by cooling.

What are the benefits of lathe lubrication?

Lathe lubrication improves efficiency, prolongs machine life, and ensures better finish quality.

Components of a Metal Lathe Needing Lubrication

Key parts of a metal lathe that require lubrication. Impact of proper lubrication on lathe performance.Keeping a metal lathe running smoothly is important. Certain parts need regular lubrication to function well. Here are key parts that require lube:

- Spindle bearings: These are crucial for spinning the workpiece.

- Carriage: This moves the cutting tool along the workpiece.

- Lead screw: It helps the lathe make precise cuts.

- Tailstock: It supports the end of the workpiece.

Proper lubrication ensures better performance and longer life for your lathe. It prevents wear and tear, making your work easier and more accurate.

Why is lubrication important for a metal lathe?

Good lubrication can boost your lathe’s performance. It reduces friction and heat which can damage parts. A well-lubricated lathe can last up to 50% longer and operate more efficiently.

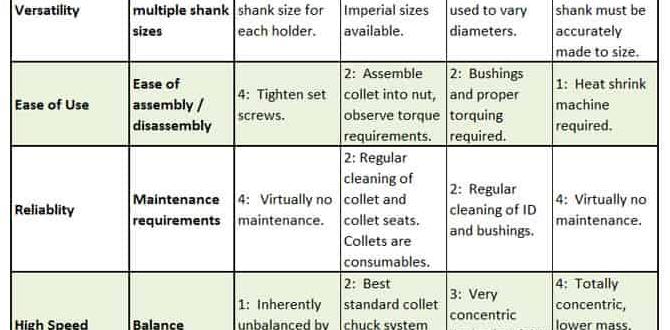

Choosing the Right Lubricant for Your Metal Lathe

Different types of lubricants and their specific applications. Factors to consider when selecting a lubricant.Choosing the right lubricant for your metal lathe is like picking the right snack for movie night—get it wrong, and things can get messy! There are three main types of lubricants: oils, greases, and waxes. Oils are great for high-speed operations, greases stick around for heavy loads, and waxes shine in low-speed tasks.

| Type of Lubricant | Best For |

|---|---|

| Oil | High-speed operations |

| Grease | Heavy loads |

| Wax | Low-speed tasks |

When selecting a lubricant, think about temperature, moisture, and pressure. Each factor can change how well the lubricant works. So, avoid using kitchen oil on your lathe—it won’t make your machine fry eggs, but it could cause a real mess!

Lubrication Techniques and Best Practices

Recommended lubrication techniques for metal lathes. Frequency of lubrication for optimal performance.Keeping your metal lathe happy is all about the right lubrication. Use light oil for the spindle and heavy oil for the gears. It’s like giving your lathe a tasty snack! Aim to oil those parts every few hours while working. If you’re feeling lazy, don’t worry; every five project turns is also okay. Remember, a well-lubricated lathe is a happy lathe, and a happy lathe doesn’t make weird noises!

| Part | Recommended Lubrication | Frequency |

|---|---|---|

| Spindle | Light oil | Every few hours |

| Gears | Heavy oil | Every few hours |

| Overall | Both oils | Every five project turns |

Common Mistakes in Lathe Lubrication

Frequent errors made by metal lathe users. How to avoid these mistakes for improved machinery longevity.Many metal lathe users unknowingly make mistakes with lubrication. One big error is using too little oil. Think of it like trying to cook without enough butter—it just doesn’t pan out! Another common slip is using the wrong type of lubricant. This can lead to wear and tear, like wearing flip-flops in the snow. To keep your machine happy and running smoothly, always check the oil level and choose the right type. Regular maintenance is key!

| Common Mistakes | How to Avoid Them |

|---|---|

| Too little oil | Check levels often |

| Wrong lubricant type | Use the correct oil |

| Infrequent maintenance | Schedule regular checks |

Environmental Factors Affecting Lathe Lubrication

How temperature and humidity influence lubrication choice. Adjusting lubrication practices based on environmental conditions.Temperature and humidity play a big role in how well you can lubricate your lathe. If it’s super hot, grease can turn into slime. If it’s cold, it may get thick like a milkshake! Adjusting your lubrication practices is key. Use lighter oils on hot days and thicker greases when it’s chilly. This keeps your lathe running smooth, like a well-oiled machine—because nobody likes a grumpy lathe!

| Weather Condition | Best Lubrication |

|---|---|

| Hot | Light Oil |

| Cold | Thick Grease |

| Humid | Rust Preventive Oil |

By adjusting based on these factors, you ensure your lathe stays happy and productive! Remember, a happy lathe means less grumpy noises and more smooth operations!

Tools and Equipment for Lubricating Metal Lathes

Essential tools for applying lubricant to lathes. Maintenance kits and their importance.Using the right gear can make lathes feel like they have superpowers! Essential tools for lubricating metal lathes include oil cans, brushes, and rags. These little helpers ensure the machine runs smoothly. Don’t forget maintenance kits! They are like health check-ups for your lathe. Regular use of kits can extend your lathe’s life. Think of them as vitamin boosts for your machine. Here’s a fun tool checklist:

| Tool | Purpose |

|---|---|

| Oil Can | To apply lubricant smoothly |

| Brush | To spread lubricant evenly |

| Rags | To clean up excess grease |

With these tools, your lathe will be ready to spin its wheels—almost like a dance partner! Remember, a well-lubricated lathe is a happy lathe!

Signs Your Lathe Needs More Lubrication

Key indicators of insufficient lubrication. Listening to your machine: sounds to watch for.Taking care of your lathe is key for smooth operation. Watch for these signs that show it needs more lubrication:

- Unusual noises like grinding or squeaking may mean there’s not enough oil.

- Stiff movement indicates the parts aren’t sliding easily.

- Heat buildup shows that friction is high due to lack of lubrication.

Listening to your machine is important. If it sounds different than usual, check lubrication levels. Regular maintenance keeps it running well!

What are the signs of insufficient lubrication?

Key signs include unusual noises, stiff operation, and heat buildup. All these show that the lathe needs more oil to work well.

Innovations in Lathe Lubrication Technology

Recent advancements in lubrication systems for lathes. Benefits of automated lubrication systems.Recent technology has made lathe lubrication easier and smarter. Automatic lubrication systems now keep lathes running smoothly without human help. These systems save time and reduce the risk of over-lubricating. Think of it as your lathe getting a relaxing massage while you enjoy a snack! Here’s a quick look at the benefits of these new systems:

| Benefit | Description |

|---|---|

| Improved Efficiency | Less downtime means more time making cool stuff! |

| Consistent Lubrication | Say goodbye to squeaky noises and hello to silky smooth operations. |

| Longer Tool Life | Proper lubrication keeps your tools happy and working longer. |

With these advancements, lathes are not just machines; they’re pampered creations ready to tackle any project!

Case Studies: Successful Lathe Lubrication Practices

Examples of effective lubrication practices in various industries. Lessons learned from successful applications.Different industries show that good lathe lubrication is key for success. For instance, in automotive manufacturing, proper lubrication reduces wear and tear, keeping machines humming like a well-tuned car. A study found that effective oiling can cut downtime by 25%. In woodworking, lubricated lathes create smoother cuts, making craftsmen happier and their projects shine. The takeaway? Regular maintenance equals less hassle and more happy machines!

| Industry | Benefit of Lubrication | Success Rate |

|---|---|---|

| Automotive | Less wear and tear | 25% |

| Woodworking | Smoother cuts | High |

Conclusion

In conclusion, proper lathe lubrication is vital for your metal lathe bench to work smoothly. It reduces friction and prevents wear. You should regularly check and apply the right lubricant. This simple step can extend your lathe’s life and improve its performance. Keep learning about lathe maintenance to ensure your projects go smoothly and safely!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication For A Metal Lathe Bench:Sure! Here are five questions about lathe lubrication: 1. Why do we need to lubricate a lathe? Lubrication helps the lathe work smoothly. It keeps the parts from wearing out and helps them last longer. 2. What kind of oil should we use? You should use machine oil, which is made for tools like lathes. Always check the manual for the best type. 3. How often should we oil the lathe? You should oil the lathe every time you use it. This makes sure it runs well and stays in good shape. 4. Where do we put the oil? You should put oil on the moving parts. Look for spots that have oil holes or markings for oiling. 5. Can we use too much oil? Yes, using too much oil can make a mess. It can also attract dirt, which is not good for your lathe.

Sure! Please give me the question you’d like me to answer.

What Types Of Lubricants Are Best Suited For A Metal Lathe, And How Do They Differ In Application?For a metal lathe, you can use oil or grease. Oil is good for moving parts because it spreads easily. It helps keep things cool and stops rust. Grease stays in place better and is good for spots that don’t move much. You choose oil for parts that move fast and grease for parts that move slowly.

How Often Should A Metal Lathe Be Lubricated To Ensure Optimal Performance And Longevity?You should lubricate your metal lathe regularly, like every few hours of use. It helps the machine run smoothly and last longer. Always check the oil levels before you start working. If you hear strange sounds or see wear, it’s time to add more lubricant. Taking care of your lathe keeps it happy!

What Are The Signs That A Metal Lathe Is Under-Lubricated Or Over-Lubricated?If a metal lathe is under-lubricated, you might hear strange noises or see parts getting hot. The machine might also work slower than usual. On the other hand, if it’s over-lubricated, you might notice grease or oil dripping. The machine could become messy and harder to work with. Keeping the right amount of lubrication is very important for smooth operation!

How Do You Properly Apply Lubricant To Different Components Of A Metal Lathe?To apply lubricant to a metal lathe, first, turn off the machine. Use a clean cloth to wipe off any old grease. Then, put a small amount of lubricant on the moving parts like the slideways and the leadscrew. Be careful not to use too much. Finally, run the lathe for a few moments to help spread the lubricant around.

Are There Any Specific Maintenance Practices Related To Lubrication That Can Enhance The Precision And Efficiency Of Turning Operations?Yes, there are some simple ways to keep things running smoothly. First, you should keep the machines clean and dry. Next, use the right type of oil for your turning tool. This helps wheels and pieces move better. Finally, check and refill the oil often to keep everything working perfectly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication For A Metal Lathe Bench:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe lubrication: 1. Why do we need to lubricate a lathe? Lubrication helps the lathe work smoothly. It keeps the parts from wearing out and helps them last longer. 2. What kind of oil should we use? You should use machine oil, which is made for tools like lathes. Always check the manual for the best type. 3. How often should we oil the lathe? You should oil the lathe every time you use it. This makes sure it runs well and stays in good shape. 4. Where do we put the oil? You should put oil on the moving parts. Look for spots that have oil holes or markings for oiling. 5. Can we use too much oil? Yes, using too much oil can make a mess. It can also attract dirt, which is not good for your lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Lubricants Are Best Suited For A Metal Lathe, And How Do They Differ In Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you can use oil or grease. Oil is good for moving parts because it spreads easily. It helps keep things cool and stops rust. Grease stays in place better and is good for spots that don’t move much. You choose oil for parts that move fast and grease for parts that move slowly.”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Lubricated To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate your metal lathe regularly, like every few hours of use. It helps the machine run smoothly and last longer. Always check the oil levels before you start working. If you hear strange sounds or see wear, it’s time to add more lubricant. Taking care of your lathe keeps it happy!”}},{“@type”: “Question”,”name”: “What Are The Signs That A Metal Lathe Is Under-Lubricated Or Over-Lubricated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is under-lubricated, you might hear strange noises or see parts getting hot. The machine might also work slower than usual. On the other hand, if it’s over-lubricated, you might notice grease or oil dripping. The machine could become messy and harder to work with. Keeping the right amount of lubrication is very important for smooth operation!”}},{“@type”: “Question”,”name”: “How Do You Properly Apply Lubricant To Different Components Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To apply lubricant to a metal lathe, first, turn off the machine. Use a clean cloth to wipe off any old grease. Then, put a small amount of lubricant on the moving parts like the slideways and the leadscrew. Be careful not to use too much. Finally, run the lathe for a few moments to help spread the lubricant around.”}},{“@type”: “Question”,”name”: “Are There Any Specific Maintenance Practices Related To Lubrication That Can Enhance The Precision And Efficiency Of Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some simple ways to keep things running smoothly. First, you should keep the machines clean and dry. Next, use the right type of oil for your turning tool. This helps wheels and pieces move better. Finally, check and refill the oil often to keep everything working perfectly.”}}]}