Have you ever wondered how metal lathes can work so smoothly? One key aspect is lathe lubrication. Proper lubrication helps machines run better and last longer. It keeps everything from getting too hot and helps parts move freely.

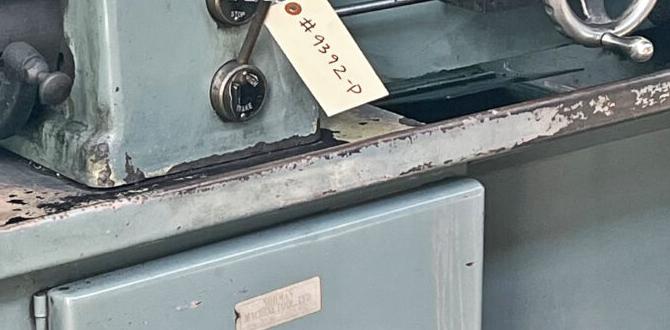

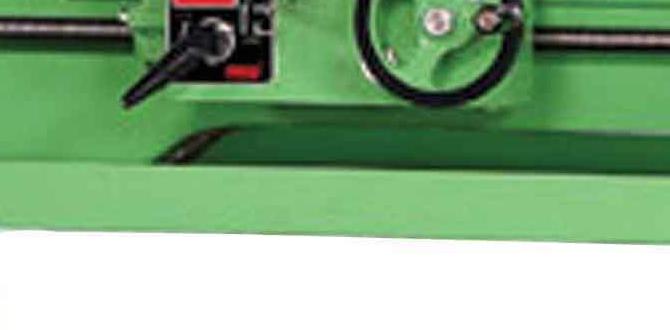

Imagine you’re at a workshop. You see a metal lathe and its control panel buzzing with activity. A skilled operator adjusts the settings while checking the lubrication. Why is lubrication so important? Without it, the lathe could easily overheat or break. That would mean delays and extra costs!

Here’s a fun fact: A well-lubricated lathe can be more precise. That means better results for all your metal projects! Understanding lathe lubrication and how to manage it through the control panel makes all the difference.

So, dive into the world of metal lathes. Discover how proper care can lead to amazing outcomes in your projects!

Lathe Lubrication For Metal Lathe Control Panel Efficiency

Lathe Lubrication and Control Panel Insights

Proper lathe lubrication is vital for smooth metalworking. A well-lubricated lathe reduces friction and wear, extending the machine’s life. The control panel is essential for monitoring functions, ensuring all parts work seamlessly. Did you know that regular lubrication can improve your project’s quality? Many beginners neglect this step, leading to poor outcomes. With the right techniques and tools, you can make your metal lathe perform like a pro!Understanding Lathe Lubrication

Importance of lubrication for lathe performance. Types of lubricants suitable for metal lathes.Lubrication is vital for metal lathes. It helps them run smoothly and last longer. Without proper lubrication, parts can wear out and damage may occur. There are different types of lubricants suitable for these machines. They include:

- Oil: Keeps parts sliding easily.

- Grease: Stays put and offers long-lasting protection.

- Cutting fluids: Cool and chip removal during cutting.

Using the right lubricant boosts performance and prevents costly repairs.

What is the role of lubrication in lathe performance?

Lubrication reduces friction and helps parts work smoothly. It also lowers heat, keeping your lathe in good shape.

Optimal Lubrication Points on a Metal Lathe

Key areas that require regular lubrication. Impact of neglecting lubrication on performance.On a metal lathe, some key spots need regular lubrication. These areas include the bearings, gears, and lead screws. By keeping these parts well-lubricated, the lathe runs smoothly. Neglecting lubrication can cause wear and tear. This may lead to serious damage. In fact, machines can lose efficiency and create poor-quality work without proper care. Always check and lubricate regularly to keep your metal lathe in great shape.

What are the key areas for lubrication on a metal lathe?

Key points for lubrication include:

- Bearings

- Gears

- Lead screws

- Bed rails.

Choosing the Right Lubricant for Your Lathe

Factors to consider when selecting lubricants. Comparison of different lubricant types (oil vs. grease).Choosing the right lubricant for your lathe can feel like picking the best candy at a store—there are so many options! First, think about the machine’s needs. Oils can flow easily and cool the machine, while greases stick around longer but can be thicker. Each has its perks, so choosing depends on your machine’s type and the tasks you do. Remember to check the label like it’s a secret recipe!

| Type | Pros | Cons |

|---|---|---|

| Oil | Good flow, cooling | Drains quickly |

| Grease | Long-lasting, sticks | Thicker, might trap dirt |

In general, let your lathe help you choose. It might not have a preference like humans do, but it sure knows what it likes! Always consult your manual—it’s like the wise old sage of your workshop.

How to Properly Lubricate Your Metal Lathe

Stepbystep lubrication process. Tips for maintaining correct lubrication levels.Lubricating your metal lathe is like giving it a nice oil bath—refreshing and necessary! Start by checking the lubrication points. Then, apply the right type of oil to each point—remember, too much lube is like overdoing a pizza party; it can be messy! Keep an eye on the levels regularly. Use an oil level gauge if you have one; it’s like checking your gas meter. Here’s a quick reference table:

| Lubrication Point | Recommended Oil | Frequency |

|---|---|---|

| Bed Ways | Vicolo Lube | Every day |

| Leadscrew | Light Oil | Every week |

| Gear Box | Heavy Oil | Monthly |

By following these steps, you’ll keep your lathe running smoothly—like a well-oiled machine! And remember, if it starts squeaking, it’s time for a refill!

Common Lubrication Mistakes to Avoid

Frequent errors users make with lathe lubrication. Consequences of improper lubrication practices.Many folks make silly mistakes when lubricating their lathes. A common blunder is using the wrong type of oil, which can lead to breakage or weird noises that sound like your lathe is singing. Not cleaning the lathe before applying oil is another big ‘no-no. Dust and debris can spoil the fun!

Improper lubrication can cause serious damage and shorten the lathe’s life. Here’s a quick breakdown:

| Common Mistake | Consequence |

|---|---|

| Wrong type of oil | Breakage and weird noises |

| Skipping clean-up | Increased wear and tear |

| Too much oil | Slippery mess and build-up |

Remember, a happy lathe means happy projects. Lubricate wisely and keep the metal magic flowing!

Maintaining Your Lathe Control Panel

Best practices for control panel maintenance. How lubrication affects control panel longevity.Taking good care of your lathe control panel is important. Proper maintenance helps it last longer. Cleaning regularly keeps dust away. Check the connections to ensure everything works well. Lubrication is key. It reduces friction and wears down parts. This keeps your machine running smoothly.

- Clean the panel weekly.

- Inspect for loose wires.

- Use the right lubricant often.

How does lubrication affect the control panel longevity?

Lubrication keeps parts moving easily and prevents damage. This increases the lifespan of the control panel. Without it, parts can stick or wear out quickly. Regularly oiling the machine can save time and money.

The Role of Lathe Maintenance in Productivity

Connection between lubrication, maintenance, and efficiency. Benefits of a welllubricated lathe on production quality.Keeping a lathe in tip-top shape makes a big difference in how it works. Regular maintenance and lubrication help keep everything running smoothly, so parts don’t get stuck. A well-lubricated lathe can boost production quality like adding sprinkles to a donut! Think of it this way: less friction means less wear and tear, which means your machine lasts longer. This can save time and money in the long run. So, let’s keep those lathes happy!

| Benefits of Lubrication | Impact on Production |

|---|---|

| Reduces friction | Increases efficiency |

| Prevents rust | Improves product quality |

| Extends machine life | Saves money |

FAQs About Lathe Lubrication and Control Panels

Commonly asked questions and expert answers. Troubleshooting lubricationrelated issues.Many users wonder about lathe lubrication and control panels. Here are some common questions and expert answers. First, how often should you lubricate your lathe? Experts say daily checks ensure smooth running. If you hear strange noises, it might mean your lathe is thirsty for oil. A quick look at the control panel can help you troubleshoot issues. The secret ingredient? A well-oiled lathe runs like a dream!

| Question | Answer |

|---|---|

| How often should I lubricate? | Every day for best performance! |

| What if it makes noises? | It might be out of oil. |

| Where’s the control panel? | Check the side near the motor! |

Conclusion

In summary, using proper lubrication on a metal lathe helps it run smoothly and lasts longer. The control panel makes it easy to adjust settings for better performance. By understanding these basics, you can maintain your lathe effectively. We encourage you to explore more about lathe maintenance to keep your tools in top shape. Happy machining!FAQs

What Types Of Lubricants Are Recommended For Use In Metal Lathe Lubrication Systems?For metal lathe lubrication, we can use oil and grease. Machine oil is great for keeping things moving smoothly. We should also choose high-quality grease for parts that need extra help. Always follow the machine’s instructions to pick the right type!

How Often Should The Lubrication System Of A Metal Lathe Be Serviced Or Checked?You should check the lubrication system of a metal lathe every day before you use it. If you notice any problems, fix them right away. It’s important to keep it clean and full of oil. This will help the lathe run smoothly and last longer.

What Are The Common Signs Of Inadequate Lubrication In A Metal Lathe During Operation?If your metal lathe isn’t getting enough oil, you might see some problems. The machine may make strange noises, like grinding or squeaking. You may also notice rough spots on the metal as you work. It could get really hot, too, which is not good. Check the oil levels if you see any of these signs!

How Does The Lubrication Control Panel Assist In Maintaining Optimal Performance And Longevity Of A Metal Lathe?The lubrication control panel helps keep the metal lathe running smoothly. It tells us when to add oil and grease. This oil reduces friction, so parts don’t wear out quickly. By using the panel, we can make the lathe last longer and work better. It helps us make sure everything is in good shape for our projects.

What Safety Precautions Should Be Taken When Handling Lubricants For Metal Lathe Maintenance?When you handle lubricants, always wear gloves to protect your hands. Use safety goggles to keep your eyes safe from spills. Make sure you’re in a well-ventilated area, so you don’t breathe in any harmful fumes. Always keep lubricants away from heat or open flames. Lastly, clean up any spills right away to avoid slips and falls.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Lubricants Are Recommended For Use In Metal Lathe Lubrication Systems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For metal lathe lubrication, we can use oil and grease. Machine oil is great for keeping things moving smoothly. We should also choose high-quality grease for parts that need extra help. Always follow the machine’s instructions to pick the right type!”}},{“@type”: “Question”,”name”: “How Often Should The Lubrication System Of A Metal Lathe Be Serviced Or Checked? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the lubrication system of a metal lathe every day before you use it. If you notice any problems, fix them right away. It’s important to keep it clean and full of oil. This will help the lathe run smoothly and last longer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Inadequate Lubrication In A Metal Lathe During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe isn’t getting enough oil, you might see some problems. The machine may make strange noises, like grinding or squeaking. You may also notice rough spots on the metal as you work. It could get really hot, too, which is not good. Check the oil levels if you see any of these signs!”}},{“@type”: “Question”,”name”: “How Does The Lubrication Control Panel Assist In Maintaining Optimal Performance And Longevity Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lubrication control panel helps keep the metal lathe running smoothly. It tells us when to add oil and grease. This oil reduces friction, so parts don’t wear out quickly. By using the panel, we can make the lathe last longer and work better. It helps us make sure everything is in good shape for our projects.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Handling Lubricants For Metal Lathe Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you handle lubricants, always wear gloves to protect your hands. Use safety goggles to keep your eyes safe from spills. Make sure you’re in a well-ventilated area, so you don’t breathe in any harmful fumes. Always keep lubricants away from heat or open flames. Lastly, clean up any spills right away to avoid slips and falls.”}}]}