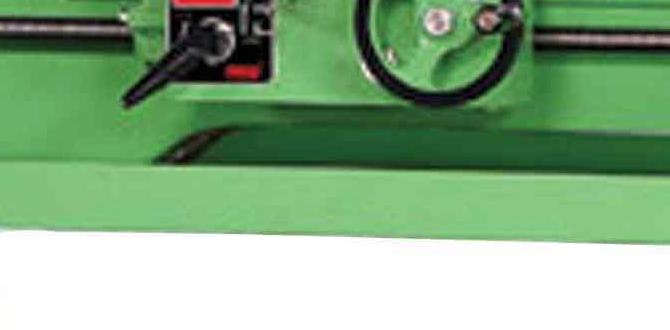

Have you ever wondered how amazing metal objects are made? From tiny screws to big machine parts, lathe machining plays a key role. If you are looking to dive into this fascinating world, finding the best metal lathe is very important.

Imagine transforming a dull piece of metal into a shiny, precise part. It sounds exciting, right? A good metal lathe can help you do just that!

Did you know that the lathe has been used for thousands of years? Early craftsmen shaped wood and stone with simple tools. Today, this skill is taken to a whole new level with advanced lathes. Knowing what to look for in the best metal lathe can make a huge difference in your projects.

Are you ready to explore the best options out there? Join us as we uncover tips and tricks to find the perfect lathe for all your metalworking needs!

Lathe Machining: Discover The Best Metal Lathe Options

Lathe Machining: Best Metal Lathe

Are you looking for the best metal lathe for your projects? A good lathe makes complex tasks easy and fun! Key features to consider include speed, size, and durability. You might find a mini lathe perfect for small jobs or a full-size model for heavy-duty tasks. Did you know skilled machinists can create amazing parts just from metal rods? Choosing the right lathe helps unlock your creativity and boost your skills in machining.Types of Metal Lathes

Description of various types of lathes: manual, CNC, and combo lathes. Pros and cons of each type for different applications.There are three main types of metal lathes, each with its own unique features and quirks. First up, we have the manual lathe. It’s like the classic car of machining, giving you full control but requiring more elbow grease. Next is the CNC lathe, which is the tech wizard of the group. It runs on computers and does the hard work for you! Finally, we have combo lathes. Think of these as the Swiss Army knife of lathes, combining various features for versatility.

| Type | Pros | Cons |

|---|---|---|

| Manual Lathe | Great control, hands-on experience | Labor-intensive, learning curve |

| CNC Lathe | High precision, saves time | Higher cost, takes tech skills |

| Combo Lathe | Multiple functions, space saver | Compromise on some features |

Choose wisely based on your project needs! Whether you want to be the master of your craft or let computers do the job, there’s a lathe for you.

Key Features to Consider When Choosing a Metal Lathe

Importance of swing over bed and distance between centers. Spindle speed range and its impact on machining capabilities. Drive systems: belt vs. direct drive.Choosing the right metal lathe can feel like a science experiment gone wrong. First off, think about the swing over bed and distance between centers. This affects your workpiece size. A larger swing means you can machine bigger items, like that gigantic trophy you promised to make for your pet goldfish. Next, check the spindle speed range. Higher speeds mean faster cutting, which is great unless you’re cutting your own fingers off! Finally, consider the drive system. Do you want a belt that might slip like a banana peel or a direct drive that goes *vroom* without much fuss? It’s like choosing between a bike and a rocket! Here’s a quick comparison for you:

| Feature | Belt Drive | Direct Drive |

|---|---|---|

| Speed | Variable | Constant high torque |

| Maintenance | More | Less |

| Noise | Louder | Quieter |

Take note of these features, and you’ll be whittling away like a pro in no time!

Best Metal Lathes in 2023

Top recommendations based on customer reviews and expert opinions. Comparison of specifications, features, and price points.Searching for the perfect metal lathe in 2023? Here’s a short list of top picks loved by users and pros alike. Each one offers unique features and specifications to fit your needs. Check out the comparison below to see which one suits your budget!

| Model | Specifications | Price |

|---|---|---|

| Lathe A | Variable speed, 12-20 inches swing | $500 |

| Lathe B | Digital readout, 14-30 inches swing | $800 |

| Lathe C | Heavy-duty, 16-24 inches swing | $1,200 |

With such choices, you’ll feel like a kid in a candy store! Remember, the best lathe will make your machining tasks easier and more fun.

Applications of Metal Lathes

Common industries and projects that utilize lathe machining. Specific tasks that can be completed with a metal lathe.Metal lathes are workhorses in many industries. They are crucial in places like factories and workshops where precision is key. You can create parts for machines, make tools, or even craft beautiful furniture. With a metal lathe, you can turn metal into shapes, thread screws, and drill holes. Let’s not forget, even custom trophies can get a quick makeover from a lathe! Here’s a peek at some of the main uses:

| Industry | Common Projects |

|---|---|

| Manufacturing | Auto parts, gear shafts |

| Construction | Building tools, fixtures |

| Crafts | Custom furniture pieces |

From auto parts to art, lathes do it all! Why settle for ordinary when you can make the extraordinary?

Tips for Maintaining Your Metal Lathe

Routine maintenance practices to extend the lifespan of your lathe. Common issues and troubleshooting tips for lathe operation.Taking care of your metal lathe is like brushing your teeth every day: it keeps it happy and healthy! Regular practices like cleaning the machine, checking for loose parts, and oiling moving parts can help it last longer. If it starts making funny noises, don’t panic! Check the belt and replace it if it looks worn. Here’s a simple table to help you remember:

| Maintenance Task | Frequency |

|---|---|

| Clean the lathe | After each use |

| Check belts and pulleys | Weekly |

| Oil moving parts | Monthly |

| Inspect for damage | Every 3 months |

Following these tips can help you avoid big problems. Remember, a happy lathe means better work and fewer repairs!

Safety Practices in Lathe Machining

Essential safety gear to wear while operating a metal lathe. Best practices to avoid accidents and injuries during machining.Working with a lathe is fun but also requires safety. Always wear protective gear to keep yourself safe. This includes:

- Safety goggles to protect your eyes from flying debris.

- Noise-canceling ear protection to avoid loud sounds.

- Gloves to keep your hands safe but remove them when the lathe is running.

- Steel-toed shoes to protect your feet from heavy tools.

To prevent accidents, follow these simple practices:

- Keep your workspace clean and organized.

- Do not wear loose clothing that could get caught in the machine.

- Always double-check the machine is off before making adjustments.

Remember, safety is the key to enjoying your lathe projects!

What gear do I need for lathe safety?

Essential gear includes safety goggles to shield your eyes, ear protection to block noise, and gloves (without loose cuffs). Always wear steel-toed shoes to protect your feet.

Upgrading Your Lathe: Accessories and Add-ons

Useful accessories for enhancing lathe capabilities (e.g., tool holders, chucks). Benefits of CNC retrofitting for improved precision and efficiency.Adding accessories to your lathe can make a huge difference. Think of tool holders and chucks as the sidekicks to your superhero lathe. They help you work faster and smarter! Did you know that CNC retrofitting can boost your lathe’s precision? It’s like giving your old lathe a magical upgrade. With better accuracy, you can create pieces that would impress even a picky robot. Upgrading can save you time, with up to 30% more efficiency!

| Accessory | Benefit |

|---|---|

| Tool Holders | Quick tool changes |

| Chucks | More stability |

| CNC Retrofitting | Enhanced precision |

Conclusion

In summary, the best metal lathes offer precision, durability, and versatility. When choosing one, consider size, power, and features. You can find great options for your projects. We encourage you to research and read reviews to make the best choice for your needs. Exploring different models will help you become more confident in your lathe machining skills.FAQs

Sure! Here Are Five Related Questions On The Topic Of “Best Metal Lathe Machining”:Sure! Here are five questions about the best metal lathe machining: 1. What is a metal lathe? A metal lathe is a machine that shapes metal into different forms. It spins the metal while cutting tools shape it. 2. Why do people use metal lathes? People use metal lathes to make parts for machines, tools, and other items. They help create precise shapes and sizes. 3. How do you choose the best metal lathe? To choose the best metal lathe, think about what you need it for. Check its size, features, and how much you want to spend. 4. What can you make with a metal lathe? You can make many things, like screws, bolts, and custom tools. The possibilities are nearly endless! 5. Is it hard to learn how to use a metal lathe? It can be tricky at first, but with practice, you can learn! Following instructions will help you become skilled.

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Features Should I Look For When Selecting The Best Metal Lathe For Precision Machining?When picking a metal lathe for precision machining, you should look for a strong and sturdy frame. This helps keep everything steady while you work. Check if it has a good size and speed control, so you can cut metal easily. A reliable chuck is also important; it holds the metal tight while you shape it. Finally, easy-to-read dials and controls make your work simpler and more accurate.

How Does The Size And Weight Of A Metal Lathe Affect Its Performance And Suitability For Different Projects?The size and weight of a metal lathe matter a lot. Heavier lathes are more stable and won’t shake much when you work. This helps you make accurate pieces. Smaller lathes are easier to move and fit in tight spaces. They’re good for small projects but might not handle big jobs as well.

What Are The Top Brands Or Models Of Metal Lathes Recommended For Both Hobbyists And Professionals?Some top brands of metal lathes are Grizzly, Jet, and Shop Fox. For hobbyists, the Taig Mini Lathe is popular. If you’re a professional, the Haas TL series is a great choice. These lathes are easy to use and work well for all kinds of projects. You can trust these brands for good quality and performance.

How Do Cnc Lathes Compare To Traditional Manual Lathes In Terms Of Efficiency And Versatility In Machining?CNC lathes, which are computer-controlled machines, are usually faster than manual lathes. This means you can make more parts in less time. CNC lathes can also shape different types of materials easily, while manual lathes may need more skill. So, CNC machines are often better for quick and varied tasks.

What Maintenance Practices Are Essential To Ensure The Longevity And Optimal Performance Of A Metal Lathe?To keep a metal lathe working well, you need to clean it regularly. Dust and shavings can hurt the machine. You should also check and change the oil to keep moving parts slippery. Keep parts tight but not too tight, so everything moves smoothly. Finally, store it in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Best Metal Lathe Machining:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about the best metal lathe machining: 1. What is a metal lathe? A metal lathe is a machine that shapes metal into different forms. It spins the metal while cutting tools shape it. 2. Why do people use metal lathes? People use metal lathes to make parts for machines, tools, and other items. They help create precise shapes and sizes. 3. How do you choose the best metal lathe? To choose the best metal lathe, think about what you need it for. Check its size, features, and how much you want to spend. 4. What can you make with a metal lathe? You can make many things, like screws, bolts, and custom tools. The possibilities are nearly endless! 5. Is it hard to learn how to use a metal lathe? It can be tricky at first, but with practice, you can learn! Following instructions will help you become skilled.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Features Should I Look For When Selecting The Best Metal Lathe For Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a metal lathe for precision machining, you should look for a strong and sturdy frame. This helps keep everything steady while you work. Check if it has a good size and speed control, so you can cut metal easily. A reliable chuck is also important; it holds the metal tight while you shape it. Finally, easy-to-read dials and controls make your work simpler and more accurate.”}},{“@type”: “Question”,”name”: “How Does The Size And Weight Of A Metal Lathe Affect Its Performance And Suitability For Different Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and weight of a metal lathe matter a lot. Heavier lathes are more stable and won’t shake much when you work. This helps you make accurate pieces. Smaller lathes are easier to move and fit in tight spaces. They’re good for small projects but might not handle big jobs as well.”}},{“@type”: “Question”,”name”: “What Are The Top Brands Or Models Of Metal Lathes Recommended For Both Hobbyists And Professionals?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some top brands of metal lathes are Grizzly, Jet, and Shop Fox. For hobbyists, the Taig Mini Lathe is popular. If you’re a professional, the Haas TL series is a great choice. These lathes are easy to use and work well for all kinds of projects. You can trust these brands for good quality and performance.”}},{“@type”: “Question”,”name”: “How Do Cnc Lathes Compare To Traditional Manual Lathes In Terms Of Efficiency And Versatility In Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes, which are computer-controlled machines, are usually faster than manual lathes. This means you can make more parts in less time. CNC lathes can also shape different types of materials easily, while manual lathes may need more skill. So, CNC machines are often better for quick and varied tasks.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential To Ensure The Longevity And Optimal Performance Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you need to clean it regularly. Dust and shavings can hurt the machine. You should also check and change the oil to keep moving parts slippery. Keep parts tight but not too tight, so everything moves smoothly. Finally, store it in a dry place to prevent rust.”}}]}