Have you ever wondered how metal parts come to life? The magic happens in a workshop with a lathe. A lathe is a tool that shapes metal into useful items. It’s quite fascinating to see how this machine works.

Today, many people use a lathe machining metal lathe controller to make things. But how do they manage the tools and machines to create precise shapes? That’s where the controller comes in. This device helps the lathe work smoothly. It can adjust speed and movement with just a few clicks.

Imagine creating a toy car wheel, a part for a bike, or even simple tools. The lathe allows you to craft these items easily when guided by the right controller. It’s like having a magic wand that shapes metal!

As we dive deeper into this topic, you’ll discover how lathe machining and its controllers can change the way we think about metalwork. Get ready to explore this exciting world where creativity and technology meet.

Lathe Machining: Exploring Metal Lathe Controller Technology

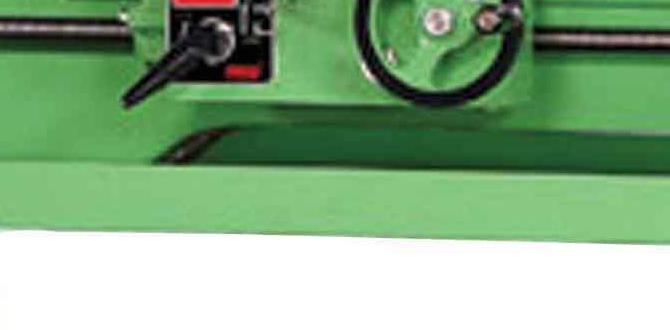

Lathe Machining Metal Lathe Controller

Lathe machining is a fascinating journey into shaping metal. A metal lathe controller plays a key role in this process. It helps users accurately control speed and movement. Have you ever watched a lathe work? It’s like watching a magician transform raw metal into beautiful shapes. This automatic tool creates precision parts for various industries. Learning about lathe controllers opens up opportunities in engineering and manufacturing. It’s amazing how technology transforms simple metal into complex creations!What is Lathe Machining?

Definition and basics of lathe machining. Different types of lathes in various industries.Lathe machining shapes materials by rotating them against a cutting tool. This process helps create cylindrical items, like pipes and rods. Many industries use lathe machines, including:

- Manufacturing: For creating parts in machines.

- Woodworking: For making furniture and art.

- Aerospace: For crafting precise engine parts.

Each type of lathe suits different tasks. Some common types are:

- Metal lathes: Used for shaping metal.

- Wood lathes: Crafted for shaping wood.

- CNC lathes: Computer-controlled for high precision.

This variety helps workers in different jobs create their designs more easily.

What is a lathe used for?

A lathe is used to shape materials, making items like gears, bolts, and even art pieces.

Components of a Metal Lathe

Key parts of a metal lathe and their functions. Importance of each component in the machining process.Every metal lathe has key parts that work together like a team of superheroes. The bed holds everything in place, while the headstock houses the motor and spindle, giving your projects some serious power. The tailstock helps with drilling and supporting long metal pieces, so they don’t feel lonely. Don’t forget the carriage—it moves the cutting tool along the metal. Each component has a special job that keeps the machining process running smoothly. Without them, it would be messy chaos, like a cat trying to ride a unicycle!

| Component | Function |

|---|---|

| Bed | Supports and aligns all parts |

| Headstock | Houses motor and spindle |

| Tailstock | Supports long pieces and aids in drilling |

| Carriage | Moves cutting tool along the material |

How to Choose the Right Metal Lathe Controller

Factors to consider when selecting a controller. Budget considerations and longterm investment.Choosing a metal lathe controller involves careful thought. Start with your budget. Is it a one-time purchase or a long-term investment? A well-made controller can last for years. Next, consider the features you need. Look for controls that are easy to use and fit your projects. Think about the brand too; they should be trusted and reliable. Compare different options to find the best fit.

What should I consider when choosing a controller?

Focus on quality, usability, and brand trust.Key Factors:

- Budget

- Features needed

- Brand reputation

Don’t rush your decision. A good controller pays off in the long run and makes your work easier. Look for reviews and ask others for advice. Make your choice wisely!

Features of Modern Lathe Controllers

Advanced functionalities and technology in contemporary controllers. Customization options and user interface design.Modern lathe controllers come packed with cool features. They use advanced technology for better performance. You can easily customize settings to suit your needs. The user interface is friendly, making it simple to operate. This helps users at every skill level. Here are some key features:

- High-tech software for precise cutting.

- Easy-to-read display screens.

- Flexible settings for different projects.

These features make machining smoother and fun!

What are the benefits of modern lathe controllers?

Modern lathe controllers improve precision, enhance efficiency, and allow user-friendly customization.

Common Issues and Troubleshooting Tips

Frequent problems encountered with lathe controllers. Stepbystep troubleshooting guide.Working with lathe controllers can have its challenges. Some common problems include software glitches, power interruptions, and incorrect settings. Here’s a simple troubleshooting guide:

- Check the power source. Ensure it is plugged in.

- Restart the lathe system to refresh software.

- Review settings for accuracy. Adjust if needed.

- Inspect cables for damage.

Regular maintenance can prevent many issues. Always refer to your manual for specific problems.

What are the common issues with lathe controllers?

Common issues include software bugs, power failures, and improper calibration. These problems can disrupt your work and lead to errors.

How can users troubleshoot these problems?

To troubleshoot, users can check connections, reboot systems, and adjust settings. Always keep an eye out for unusual noises or behaviors.

Best Practices for Operating Metal Lathes

Safety measures and operational protocols. Maintenance tips to prolong the lifespan of the lathe and controller.Working with metal lathes can be safe and efficient. Always wear protective gear, like goggles and gloves. Familiarize yourself with the lathe’s controls. Ensure the area is clean and free from clutter. Follow these maintenance tips:

- Check for loose parts regularly.

- Clean the machine after each use.

- Lubricate moving parts to reduce wear.

- Store the lathe in a dry place.

Proper care can extend the lifespan of both the lathe and its controller.

Why is safety important when using a lathe?

Safety prevents accidents and injuries. It ensures a smooth operation and protects you and those around you.

Future Trends in Lathe Machining Technology

Innovations in lathe machine tools and control systems. The role of automation and AI in metal machining.Big changes are brewing in lathe machining! New tools and control systems are popping up everywhere. These innovations make machining easier and more efficient. Thanks to automation and AI, machines can now do heavy lifting, leaving humans to sip coffee and supervise. Who wouldn’t want a robot buddy? And guess what? Machines can communicate and figure things out themselves! This means fewer errors and wasted materials—so you can save money and make your boss smile!

| Innovation | Impact |

|---|---|

| Smart Controllers | Boost efficiency and reduce setup time |

| AI Integration | Minimizes mistakes and improves safety |

| Automated Processes | Freed up manpower for creative tasks |

Case Studies: Successful Applications of Metal Lathes

Realworld examples of lathe machining in various industries. Lessons learned and best practices from these case studies.Many industries successfully use metal lathes. For instance, in the automotive sector, companies create reliable engine parts with high precision. This method reduces waste and improves safety. In aerospace, lathes help create lightweight components that withstand extreme conditions. Here are some lessons learned from these projects:

- Invest in quality machinery for better outcomes.

- Train workers regularly to enhance skills.

- Prioritize safety and maintenance for long-lasting equipment.

These examples show how effective metal lathes can be in various fields!

Why are metal lathes important?

Metal lathes provide accuracy and efficiency in making parts. They help businesses save time and money.

Conclusion

In conclusion, lathe machining is essential for shaping metal parts. A metal lathe controller helps you operate these machines easily. By learning more about these tools, you can improve your skills. Practice using a lathe to create your projects. We encourage you to explore resources or workshops to dive deeper into this fascinating craft!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Lathe Controllers:Sure! Here are five questions you can think about: 1. What is a lathe? A lathe is a machine that spins materials like wood or metal to shape them. 2. How does a lathe work? The lathe turns the material while cutting tools change its shape. 3. What is a lathe controller? A lathe controller helps you control how the lathe works. It makes things easier! 4. Why do we use lathes? We use lathes to make smooth and precise shapes for tools and toys. 5. Can a lathe work with different materials? Yes, lathes can work with wood, metal, and even plastic!

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Key Features To Look For In A Digital Controller For A Metal Lathe?When choosing a digital controller for a metal lathe, look for a clear display. You want to see measurements easily. Good buttons are important too because they help you switch settings quickly. Check for easy setup; it should not be confusing. Finally, make sure it can control speed well, so you can work on different projects easily.

How Can Cnc (Computer Numerical Control) Technology Enhance The Precision And Efficiency Of Lathe Machining?CNC stands for Computer Numerical Control. It helps machines like lathes work better. With CNC, machines follow precise instructions from a computer. This means they can make parts very accurately and quickly. You get better results in less time, making things easier for everyone.

What Are The Common Troubleshooting Steps For A Lathe Controller That Is Not Responding Correctly?If your lathe controller isn’t working right, here’s what you can do. First, check the power supply to make sure it’s plugged in and turned on. Next, look for loose wires or connections. Then, reset the controller by turning it off and back on. Finally, consult the manual for any special settings. If it still doesn’t work, ask a helper for more ideas!

How Does The Programming Of A Lathe Controller Differ Between Manual And Automated Machining Processes?When you use a manual lathe, you control everything by hand. You decide how fast and where to move the tool. In automated machining, the lathe has a computer that does this for you. You program it once, and it repeats the tasks automatically. This means you don’t have to be there all the time when it’s working.

What Types Of Software Are Typically Used To Program A Lathe Controller For Complex Machining Tasks?To program a lathe controller, we often use Computer-Aided Design (CAD) software. This helps us create shapes and drawings. Then, we use Computer-Aided Manufacturing (CAM) software to turn those drawings into instructions for the machine. Sometimes, we also use G-code, which is a special language that tells the lathe what to do. These tools help us make complex parts easily and accurately.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Lathe Controllers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you can think about: 1. What is a lathe? A lathe is a machine that spins materials like wood or metal to shape them. 2. How does a lathe work? The lathe turns the material while cutting tools change its shape. 3. What is a lathe controller? A lathe controller helps you control how the lathe works. It makes things easier! 4. Why do we use lathes? We use lathes to make smooth and precise shapes for tools and toys. 5. Can a lathe work with different materials? Yes, lathes can work with wood, metal, and even plastic!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Digital Controller For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital controller for a metal lathe, look for a clear display. You want to see measurements easily. Good buttons are important too because they help you switch settings quickly. Check for easy setup; it should not be confusing. Finally, make sure it can control speed well, so you can work on different projects easily.”}},{“@type”: “Question”,”name”: “How Can Cnc (Computer Numerical Control) Technology Enhance The Precision And Efficiency Of Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC stands for Computer Numerical Control. It helps machines like lathes work better. With CNC, machines follow precise instructions from a computer. This means they can make parts very accurately and quickly. You get better results in less time, making things easier for everyone.”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps For A Lathe Controller That Is Not Responding Correctly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe controller isn’t working right, here’s what you can do. First, check the power supply to make sure it’s plugged in and turned on. Next, look for loose wires or connections. Then, reset the controller by turning it off and back on. Finally, consult the manual for any special settings. If it still doesn’t work, ask a helper for more ideas!”}},{“@type”: “Question”,”name”: “How Does The Programming Of A Lathe Controller Differ Between Manual And Automated Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a manual lathe, you control everything by hand. You decide how fast and where to move the tool. In automated machining, the lathe has a computer that does this for you. You program it once, and it repeats the tasks automatically. This means you don’t have to be there all the time when it’s working.”}},{“@type”: “Question”,”name”: “What Types Of Software Are Typically Used To Program A Lathe Controller For Complex Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To program a lathe controller, we often use Computer-Aided Design (CAD) software. This helps us create shapes and drawings. Then, we use Computer-Aided Manufacturing (CAM) software to turn those drawings into instructions for the machine. Sometimes, we also use G-code, which is a special language that tells the lathe what to do. These tools help us make complex parts easily and accurately.”}}]}