Have you ever wondered how metal parts are made with such precision? One secret is lathe machining. This technique is essential in many industries. But what makes it so special? The answer lies in the metal lathe lead screw. This simple part plays a huge role in shaping metal accurately.

Imagine building your own robot or making a unique tool. You might use a lathe to carve your creations. The metal lathe lead screw helps move the cutting tool smoothly. This means better designs and fewer mistakes.

Fun fact: Did you know that the lead screw is often called the heart of the lathe? Without it, the machine wouldn’t work as well. As you read on, you’ll discover more about how this handy device helps metalworkers create amazing items. Let’s dive deeper!

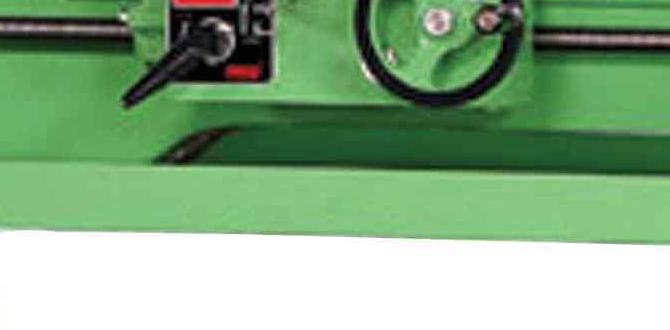

Lathe Machining: Understanding Metal Lathe Lead Screw Dynamics

Exploring Lathe Machining: The Lead Screw

Lathe machining is a key process in metalworking. One important part of this is the lead screw. This component helps control the cutting tool’s movement. Imagine shaping metal like clay! The lead screw ensures precision in creating parts. Without it, accuracy is lost. Fun fact: some lead screws can move as fast as you can turn a dial! Understanding the lead screw can make anyone fascinated with metal lathe machining.What is Lathe Machining?

Definition and basic principles of lathe machining.. Different types of lathes used in metalworking..Lathe machining is like magic for metal! It shapes pieces by spinning them and using tools to cut them down. Think of it as a spinning top getting a cool haircut. There are different types of lathes for metalworking, each with its special tricks. Some are great for straight cuts, while others can make fancy curves. Let’s take a quick look at the common types:

| Type of Lathe | Use |

|---|---|

| Engine Lathe | General purpose work |

| CNC Lathe | Precise, automated cuts |

| Turret Lathe | Fast production of multiple parts |

No matter the type, lathe machining makes metal feel like playdough in a kid’s hands. Now, who wouldn’t want to spin some metal and create cool shapes?

The Importance of Lead Screws in Metal Lathes

Function of lead screws in precision machining.. Comparison between lead screws and other motion systems..Lead screws play a big role in metal lathes, helping machines shape metal precisely. They turn rotation into movement, moving parts smoothly along a path, making accurate cuts every time. Imagine trying to slice a cake with a dull knife; that’s what it feels like without a good lead screw! In comparison to other systems, like ball screws, lead screws are often simpler and less expensive. However, they might not be as speedy. Here’s a fun comparison:

| Feature | Lead Screws | Ball Screws |

|---|---|---|

| Cost | Less | More |

| Speed | Slower | Faster |

| Precision | High | Very High |

So, while lead screws may not win a sprint, they sure know how to get the job done right!

How to Maintain Lead Screws for Optimal Performance

Key maintenance practices for extending lead screw life.. Common issues and troubleshooting tips..To keep lead screws working well, proper maintenance is key. Regularly clean the screws to remove dust and debris. Lubrication is also important; apply lubricant every few months. Check for wear and tear, as this can lead to problems. If you notice unusual noises, it may signal a problem. Always tackle issues quickly to avoid further damage.

What are common issues with lead screws?

Common issues include wear from friction, misalignment, and dirt buildup.

Key maintenance practices:

- Clean regularly

- Apply lubricant

- Inspect for wear

- Tackle noises right away

Lead Screw Replacement: When and How

Signs that indicate a need for lead screw replacement.. Stepbystep guide to replacing a lead screw in a metal lathe..Have you noticed your metal lathe acting a bit wonky? It’s time to check the lead screw! Signs like grinding noises, uneven movements, or rust could mean it’s time for a replacement. Don’t panic; replacing a lead screw is simpler than teaching a cat to fetch! Here’s a quick guide to help you out:

| Step | Action |

|---|---|

| 1 | Power off the lathe. Safety first! |

| 2 | Remove any covers and access the lead screw. |

| 3 | Carefully detach the old lead screw. |

| 4 | Replace it with the new lead screw. |

| 5 | Reassemble everything and power it back up. |

Now you’re good to go! Remember, a happy lead screw means a happy lathe. Keep an eye on those signs, and you’ll dodge any drama.

Real-World Applications of Metal Lathes and Lead Screws

Examples of industries relying on lathe machining.. Case studies showcasing successful applications of metal lathes..Many industries depend on metal lathes and lead screws for their work. These machines shape metal parts with great precision. For example, the automotive and aerospace industries use them to create parts for cars and airplanes. Additionally, medical equipment manufacturers rely on lathes for parts in devices like MRI machines. Case studies show how a local factory improved its production speed by 30% by using advanced metal lathes. This boosts efficiency and lowers costs.

What are some industries that use lathe machining?

Industries such as automotive, aerospace, and healthcare rely on lathe machining. They create vital components that make machines work better and safer.

Examples of Lathe Applications:

- Automotive Parts

- Aerospace Components

- Medical Devices

- Tools and Machinery

Choosing the Right Metal Lathe for Your Needs

Factors to consider when selecting a metal lathe.. Recommended brands and models based on lead screw quality..Buying a metal lathe can be exciting yet challenging. First, think about size. Smaller lathes work well for home projects. Next, consider the lead screw quality. A good lead screw helps with accuracy. Check the motor power too. Strong motors handle tough jobs better. Lastly, look for trusted brands. Here are a few:

- Jet

- Taiwan

- Grizzly

- South Bend

These brands offer great features and durability.

What should you look for in a metal lathe?

Choose a lathe with a strong construction, easy operation, and good reviews. A high-quality lathe will last longer and perform better.

Key Features to Consider:

- Size and weight

- Lead screw accuracy

- Motor strength

- Brand reputation

With these tips, picking the right metal lathe will be easier and more fun!

Conclusion

In summary, a lathe is important for machining metal. The lead screw helps move the cutting tool smoothly. Understanding these parts improves your skills in metalworking. You can start practicing on a lathe or read more about different lathe types. Keep exploring and experimenting to become a better machinist. Your journey in metalworking can be exciting and rewarding!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On The Lead Screw Of A Metal Lathe:Sure! The lead screw on a metal lathe helps move the cutting tool. It works like a twisty road for the tool to follow. This helps make smooth cuts on metal. When you turn the handle, the lead screw moves the tool in a straight line. It makes it easier to create the shapes you want!

Sure! Just ask your question, and I will answer it!

What Is The Function Of The Lead Screw In A Metal Lathe, And How Does It Contribute To The Machining Process?The lead screw in a metal lathe helps move the cutting tool along the metal. We turn it to make the tool go side to side or in and out. This makes it easier to shape the metal correctly. Without the lead screw, it would be hard to control where the tool cuts. It really helps us make accurate parts!

How Can Wear And Tear On The Lead Screw Affect The Precision And Accuracy Of A Lathe Operation?Wear and tear on the lead screw can cause problems when using a lathe. A lead screw helps move the tool accurately. If it is worn out, the tool may not follow the correct path. This makes your work less precise and can create mistakes. Taking care of the lead screw helps keep your lathe working well!

What Are The Common Materials Used For Manufacturing Lead Screws In Metal Lathes, And What Properties Make Them Suitable?Lead screws in metal lathes are often made from steel and bronze. Steel is strong, so it helps the lead screw last longer. Bronze is good because it can reduce friction, allowing parts to move smoothly. Both materials are tough and can handle heavy work without getting damaged. This makes them great choices for making lead screws!

How Can One Properly Maintain And Lubricate The Lead Screw To Ensure Optimal Performance And Longevity?To keep the lead screw working well, you should clean it regularly. Use a soft cloth to wipe off dust and dirt. Then, apply a little bit of lubricant, like machine oil, evenly along the screw. This helps it move smoothly and last longer. Make sure to do this maintenance every few months!

What Are Some Troubleshooting Steps If A Lead Screw Is Causing Uneven Movement Or Play In The Lathe Carriage?If your lathe carriage isn’t moving smoothly, we can check a few things. First, make sure the lead screw is clean. Dust and dirt can get in the way. Then, check if the screws that hold the lead screw are tight. If they are loose, tighten them up. Finally, look for any worn-out parts that might need replacing.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On The Lead Screw Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The lead screw on a metal lathe helps move the cutting tool. It works like a twisty road for the tool to follow. This helps make smooth cuts on metal. When you turn the handle, the lead screw moves the tool in a straight line. It makes it easier to create the shapes you want!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I will answer it!”}},{“@type”: “Question”,”name”: “What Is The Function Of The Lead Screw In A Metal Lathe, And How Does It Contribute To The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw in a metal lathe helps move the cutting tool along the metal. We turn it to make the tool go side to side or in and out. This makes it easier to shape the metal correctly. Without the lead screw, it would be hard to control where the tool cuts. It really helps us make accurate parts!”}},{“@type”: “Question”,”name”: “How Can Wear And Tear On The Lead Screw Affect The Precision And Accuracy Of A Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Wear and tear on the lead screw can cause problems when using a lathe. A lead screw helps move the tool accurately. If it is worn out, the tool may not follow the correct path. This makes your work less precise and can create mistakes. Taking care of the lead screw helps keep your lathe working well!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Manufacturing Lead Screws In Metal Lathes, And What Properties Make Them Suitable?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screws in metal lathes are often made from steel and bronze. Steel is strong, so it helps the lead screw last longer. Bronze is good because it can reduce friction, allowing parts to move smoothly. Both materials are tough and can handle heavy work without getting damaged. This makes them great choices for making lead screws!”}},{“@type”: “Question”,”name”: “How Can One Properly Maintain And Lubricate The Lead Screw To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lead screw working well, you should clean it regularly. Use a soft cloth to wipe off dust and dirt. Then, apply a little bit of lubricant, like machine oil, evenly along the screw. This helps it move smoothly and last longer. Make sure to do this maintenance every few months!”}},{“@type”: “Question”,”name”: “What Are Some Troubleshooting Steps If A Lead Screw Is Causing Uneven Movement Or Play In The Lathe Carriage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe carriage isn’t moving smoothly, we can check a few things. First, make sure the lead screw is clean. Dust and dirt can get in the way. Then, check if the screws that hold the lead screw are tight. If they are loose, tighten them up. Finally, look for any worn-out parts that might need replacing.”}}]}