Have you ever wondered how metal objects are shaped so perfectly? One of the secrets lies in lathe machining. This process is like magic for creating round and smooth parts. With a metal lathe, skilled workers can turn raw metal into amazing products.

Picture this: a block of metal that transforms into a shiny, precise cylinder. Isn’t that fascinating? Lathe operations can make everyday items, like screws and gears. These items play a big role in our machines and tools.

Did you know that lathe machining dates back thousands of years? Ancient craftsmen used simple tools and techniques to carve metal. Today, we have advanced machines that make the job easier and faster. This blend of old and new can spark your imagination!

In this article, we will explore the world of lathe machining and metal lathe operations. You will learn how these machines work and why they are essential. Let’s dive into this exciting journey of craftsmanship!

Lathe Machining: Essential Metal Lathe Operations Explained

Lathe Machining: Mastering Metal Lathe Operations

Lathe machining involves shaping metal into desired forms. Imagine creating a perfect cylinder from a block of metal. This process is essential for many industries, from automotive to aerospace. Metal lathe operations utilize various tools for cutting, sanding, and drilling. Each task requires precision and skill to achieve the best results. Did you know that even small errors can lead to big problems in the final product? Learning these operations opens up a world of possibilities in metalworking.What is Lathe Machining?

Definition and purpose of lathe machining. Brief history and evolution of lathe machines.Lathe machining is like a magic trick for shaping metal. This process spins a piece of metal at high speed while tools carve it into a desired shape. Why use a lathe? Simple! It helps create everything from table legs to rocket parts. The lathe has ancient roots dating back to Egypt, evolving from simple hand-powered tools into today’s advanced machines. It’s a bit like going from a flip phone to a smartphone—huge upgrades!

| Year | Milestone |

|---|---|

| 1300 BC | First known lathe used in Egypt |

| 18th Century | Introduction of the metal lathe |

| 20th Century | Advancements with CNC technology |

In a nutshell, lathe machining turns raw metal into wonderful creations. So next time you see something made of metal, remember it might have had a spin with a lathe!

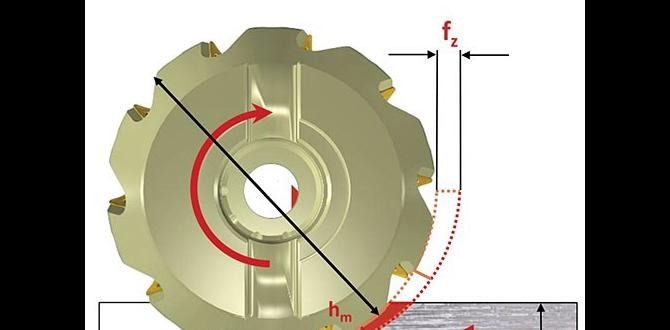

Essential Lathe Machining Operations

Common operations such as turning, facing, and drilling. Explanation of more advanced operations like taper turning and threading.Lathe machining includes several important operations. The most common ones are:

- Turning: Shaping a piece of metal by rotating it against a cutting tool.

- Facing: Smoothing the ends of the metal to make it flat.

- Drilling: Creating holes in the metal.

More advanced operations take your skills to the next level. Taper turning shapes metal into a cone. Threading makes grooves for screws or bolts. These skills help in making precise and useful parts.

What are the uses of lathe machining?

Lathe machining is widely used in various fields. It helps in creating parts for machinery, vehicles, and even furniture. Many industries rely on these operations for efficiency and accuracy.

Lathe Setup and Preparation

Steps for setting up a lathe machine. Importance of tool selection and workpiece alignment.Setting up a lathe machine is an important task. Follow these steps to do it right:

- Clear the workspace.

- Check the machine’s condition.

- Secure the tool holders and select the right tools for your project.

- Align the workpiece properly with the machine center.

Choosing the right tools and aligning the workpiece helps in making accurate cuts. A well-set lathe can make all the difference in your project.

Why is Lathe Setup Important?

A proper setup ensures safety and precision in machining tasks. When the lathe is set up correctly, it runs smoothly and reduces the chances of mistakes.

Key Steps for Setup:

- Verify tool sharpness and condition.

- Ensure the workpiece is stable.

This careful preparation boosts productivity and leads to better results!

Safety Precautions in Lathe Operations

Key safety practices for operating a lathe. Common hazards and how to prevent them.Using a lathe can be fun, but safety comes first! Always wear **safety goggles** to protect your eyes. Don’t forget ear protection too—machines can be loud! Keep your workspace tidy; trip hazards are no joke. Maintain a safe distance from rotating parts, and never reach into the lathe while it’s running. Your fingers will thank you! Check all tools before starting. Remember, accidents may happen, but with care, we can prevent them!

| Common Hazards | Prevention Tips |

|---|---|

| Loose clothing | Wear fitted clothes |

| Long hair | Tie it back |

| Inattention | Stay focused |

| Faulty equipment | Regular maintenance |

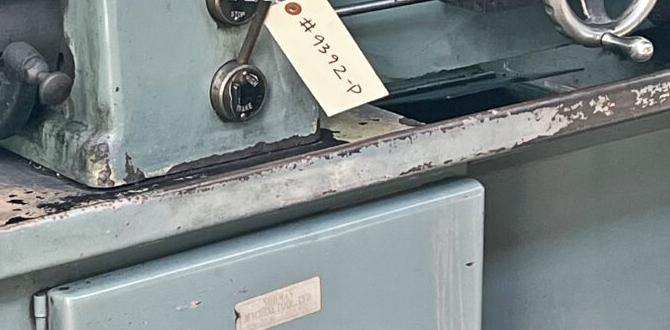

Maintenance and Troubleshooting of Lathes

Regular maintenance practices for optimal performance. Troubleshooting common issues in lathe operations.Keeping a lathe in good shape is important for smooth work. Here are some simple maintenance tips:

- Clean the machine regularly.

- Check oil levels and add oil as needed.

- Inspect belts and gears for wear.

- Lubricate moving parts to prevent rust.

If problems arise, here’s how to troubleshoot:

- Check for strange noises to find loose parts.

- Adjust the speed if the lathe vibrates too much.

- Examine tools for dullness which can cause issues.

Regular care can save time and money, letting you focus on making great things.

What are common problems with lathe machines?

Common issues include vibration, tool chatter, and uneven cuts. These problems often stem from poor maintenance or damaged parts.

Future Trends in Lathe Machining Technology

Innovations in lathe technology (e.g., automation, smart lathes). Impact of Industry 4.0 on lathe machining operations.Lathe machining is changing fast, just like how you trade your old video games for new ones! New innovations are popping up every day. Smart lathes now adjust themselves, almost like magic! Automation whispers to machines, making them smarter and quicker. And with Industry 4.0 around, these lathes connect to the internet. They share info like best buddies, improving how we work. This makes operations super efficient, keeping everyone happy and smiling, even the machines!

| Innovation | Description |

|---|---|

| Smart Lathes | These machines can self-adjust and improve performance. |

| Automation | Machines work faster and can handle tasks with less human help. |

| Industry 4.0 | Machines connect online to share important data. |

Conclusion

In conclusion, lathe machining is a fundamental skill in metalworking. It helps shape and cut materials into precise parts. Understanding lathe operations can boost your hands-on abilities. We encourage you to try simple projects or read more about lathe techniques. Exploring this field can be fun and rewarding, so dive in and start creating!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Operations:Sure! A lathe is a special machine that helps us shape metals. We can use it to make round or smooth shapes. When we turn on the lathe, it spins the metal, and we use tools to cut it. This way, we can create parts for machines or toys. It’s a fun way to make things!

Sure! Please provide the question you’d like me to answer.

What Are The Fundamental Types Of Operations That Can Be Performed On A Metal Lathe?On a metal lathe, you can do three main operations. First, you can cut metal into shapes. This is called turning. Second, you can drill holes into the metal. Lastly, you can sand or polish the metal to make it smooth. These steps help us create different metal parts.

How Do You Select The Appropriate Cutting Tool Material For Different Metals During Lathe Machining?To choose the right cutting tool for different metals, first, consider the metal type. Softer metals like aluminum need softer tools, while hard metals like steel need tougher tools. You want a tool that can cut without breaking easily. We also look at how fast we are working. Faster speeds often need stronger materials.

What Safety Precautions Should Be Taken When Operating A Metal Lathe?When using a metal lathe, you should always wear safety glasses to protect your eyes. Keep long hair tied back and wear tight clothing to avoid getting caught. Never reach over the moving parts, and use tools correctly. Make sure the area is clean, so you don’t trip. Lastly, always follow your teacher’s or supervisor’s instructions.

How Can You Determine The Optimal Cutting Speed And Feed Rate For A Specific Metal Workpiece?To find the best cutting speed and feed rate for a metal piece, you can follow some simple steps. First, check the metal’s type and hardiness. Each metal works best with different speeds. Next, look up guidelines or charts that give you starting numbers. You can also try cutting at different speeds to see what works best. The goal is to make clean cuts without damaging the metal or the tool.

What Are Common Troubleshooting Techniques For Issues Encountered During Lathe Machining, Such As Chatter Or Tool Wear?If you hear chatter or see tool wear while using a lathe, you can try a few things. First, make sure the lathe is very tight and stable. Next, check if the cutting tool is sharp and replace it if it’s dull. You can also lower the cutting speed or feed rate to help solve these problems. Lastly, keep everything clean so there’s no build-up that can cause more issues.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Operations:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a special machine that helps us shape metals. We can use it to make round or smooth shapes. When we turn on the lathe, it spins the metal, and we use tools to cut it. This way, we can create parts for machines or toys. It’s a fun way to make things!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Fundamental Types Of Operations That Can Be Performed On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “On a metal lathe, you can do three main operations. First, you can cut metal into shapes. This is called turning. Second, you can drill holes into the metal. Lastly, you can sand or polish the metal to make it smooth. These steps help us create different metal parts.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Cutting Tool Material For Different Metals During Lathe Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right cutting tool for different metals, first, consider the metal type. Softer metals like aluminum need softer tools, while hard metals like steel need tougher tools. You want a tool that can cut without breaking easily. We also look at how fast we are working. Faster speeds often need stronger materials.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety glasses to protect your eyes. Keep long hair tied back and wear tight clothing to avoid getting caught. Never reach over the moving parts, and use tools correctly. Make sure the area is clean, so you don’t trip. Lastly, always follow your teacher’s or supervisor’s instructions.”}},{“@type”: “Question”,”name”: “How Can You Determine The Optimal Cutting Speed And Feed Rate For A Specific Metal Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best cutting speed and feed rate for a metal piece, you can follow some simple steps. First, check the metal’s type and hardiness. Each metal works best with different speeds. Next, look up guidelines or charts that give you starting numbers. You can also try cutting at different speeds to see what works best. The goal is to make clean cuts without damaging the metal or the tool.”}},{“@type”: “Question”,”name”: “What Are Common Troubleshooting Techniques For Issues Encountered During Lathe Machining, Such As Chatter Or Tool Wear?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you hear chatter or see tool wear while using a lathe, you can try a few things. First, make sure the lathe is very tight and stable. Next, check if the cutting tool is sharp and replace it if it’s dull. You can also lower the cutting speed or feed rate to help solve these problems. Lastly, keep everything clean so there’s no build-up that can cause more issues.”}}]}