Have you ever wondered how metal shapes are made? One important tool in metalworking is the lathe. It spins metal so workers can cut and shape it. A crucial part of this tool is called the metal lathe chuck key.

Imagine you’re at a workshop, watching a craftsman work magic with metal. The lathe whirs, and bits of metal come off like snowflakes. The craftsman uses the chuck key to secure the metal in place. Without it, things could get messy!

Did you know that using the right chuck key can make the job easier and safer? Learning about metal lathes and their parts can open a world of creativity. Next time you see a lathe, think about that little key that holds everything together!

Lathe Metal Shaping: Understanding Metal Lathe Chuck Key Usage

Lathe Metal Shaping: The Role of a Metal Lathe Chuck Key

Using a metal lathe can be exciting! A metal lathe helps shape metal into amazing designs. But did you know a metal lathe chuck key is essential? This small tool tightens or loosens the chuck, holding the metal firmly in place. Without it, your projects can go wrong. Imagine trying to create a perfect part, only to have the metal slip! Remember, this key is crucial for a successful lathe experience. It’s a small tool with big importance!What is a Metal Lathe?

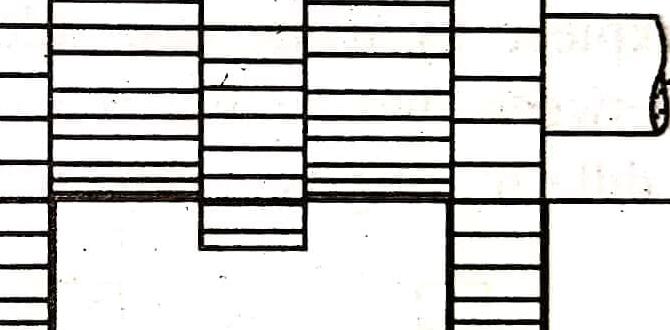

Definition and purpose of a metal lathe. Basic components and their functions.A metal lathe is a machine that shapes metal by spinning it around. Imagine using a pencil sharpener, but for metal! Its main job is to create precise shapes and parts. The main parts of a metal lathe include the bed, where everything rests, and the headstock, which holds the spinning metal. There’s also the tailstock, which helps support the metal while you work. And let’s not forget the chuck that holds the metal tight and the chuck key, used to tighten it. Without these pieces, you’d have a really fancy paperweight!

| Component | Function |

|---|---|

| Bed | Supports all parts |

| Headstock | Holds and spins the metal |

| Tailstock | Supports the metal |

| Chuck | Holds the metal in place |

| Chuck Key | Tightens the chuck |

Understanding Metal Shaping

Explanation of metal shaping processes in lathe work. Key techniques used in metal shaping.Metal shaping is important in lathe work. It involves changing a metal’s shape with a machine called a lathe. This process uses special tools and techniques to create different shapes and features. Here are key techniques found in metal shaping:

- Turning: Removing metal by rotating the workpiece.

- Drilling: Creating holes by using a drill bit.

- Facing: Making a flat end on the workpiece.

These methods help make parts for machines, tools, and more. Understanding these techniques is essential for anyone interested in metalworking.

What are the most common metal shaping processes?

The most common processes include turning, drilling, and facing. Each technique has a specific purpose and helps create different shapes.

Importance of Chuck Keys in Metal Lathes

Definition and function of a chuck key. How chuck keys secure the workpiece.A chuck key is a special tool for metal lathes. It helps to tighten or loosen the grip on the workpiece. This is very important for making sure everything stays in place while the lathe works. A secure workpiece means less chance of mistakes or accidents. Without a chuck key, the piece can move around, leading to bad cuts. Here are some key points about chuck keys:

- Locks the workpiece securely.

- Prevents slips or injuries.

- Makes work faster and easier.

A chuck key is small but mighty in the world of metal shaping!

Why is a chuck key crucial for metal lathes?

The role of a chuck key cannot be overstated. It ensures proper grip and control. With a strong hold, the risk of accidents decreases. This makes working with metal a safer experience.

Choosing the Right Chuck Key for Your Lathe

Factors to consider (size, compatibility, material). Common sizes and types of chuck keys.Picking a chuck key for your lathe is important. You need to think about three main things. First, the size should match your lathe. Next, compatibility with the chuck is key. Lastly, the material affects durability. Common sizes include 1/4″, 3/8″, or 1/2″. Here are some types of chuck keys:

- Standard chuck keys

- Ball-end chuck keys

- Quick-release chuck keys

Choosing wisely will make your work easier and safer.

What are common sizes for chuck keys?

Common sizes for chuck keys include 1/4″, 3/8″, and 1/2″. Knowing your lathe’s requirements helps you select the right one.

Maintenance Tips for Chuck Keys

Best practices for maintenance and care. Signs of wear and when to replace a chuck key.Keeping your chuck key in top shape is easy and fun! Check it often for any signs of wear, like cracks or bends. If it seems off, it might be time for a new one. A good chuck key makes work smoother, like butter on toast! Here are some quick tips:

| Maintenance Tips | Signs to Replace |

|---|---|

| Clean regularly with a cloth | Visible cracks or bends |

| Store in a dry place | Cuts or broken teeth |

| Lubricate moving parts | Worn-out grips |

Following these tips can help your chuck key last longer. Remember, a little care goes a long way, just like watering a plant—it blooms better!

Common Problems and Troubleshooting

Typical issues with lathe chucks and keys. Solutions for common problems encountered during metal shaping.Using a lathe can be a smooth ride, but sometimes bumps appear, like problems with chucks and keys. A common issue is a key that doesn’t fit properly. It can slip and make you feel like a clown trying to juggle! Another problem is the chuck becoming too loose, which could lead to your workpiece flying off like a rocket. Check the fittings regularly and tighten them to avoid these mishaps.

| Problem | Solution |

|---|---|

| Slipping key | Tighten or replace the key |

| Loose chuck | Re-tighten it or replace jaws |

| Worn parts | Regular maintenance can help |

Remember, there’s no need to feel stressed! Just keep an eye out for these issues, and you’ll be shaping metal like a pro in no time!

Safety Practices when Using a Metal Lathe

Essential safety gear to use. Key safety practices to follow during operation.Using a metal lathe can be fun, but safety is super important! First, put on safety goggles to protect those precious peepers. Don your ear protection too, as lathes can roar like a bear sometimes. Always check the machine before starting it. Your fingers deserve to stay intact! Keep your workspace tidy; you don’t want to trip over tools while spinning metal like a magician. Before working, make sure the lathe chuck key is removed—it’s a funny tool, but definitely no friend to spinning parts.

| Essential Safety Gear | Key Safety Practices |

|---|---|

| Safety goggles | Check the machine before use |

| Ear protection | Keep the area tidy |

| Gloves | Remove the lathe chuck key |

Conclusion

In conclusion, understanding the lathe, metal shaping, and chuck key is essential for metalworking. A lathe helps shape metal into desired forms. The chuck key securely holds the workpiece in place. You can improve your skills by practicing these techniques. Explore more resources or tutorials to learn about metal lathes and create amazing projects. Start shaping today!FAQs

Here Are Five Related Questions On The Topic Of Metal Shaping, Specifically Focusing On Metal Lathe Chuck Keys:A metal lathe chuck key helps us lock or unlock the chuck. The chuck holds the metal we want to shape. To use it, you insert the key into a hole and turn it. This tightens or loosens the grip on the metal. Be careful not to lose the chuck key, or it will be hard to work!

Sure! Please provide the question you want me to answer.

What Is The Primary Function Of A Chuck Key In A Metal Lathe, And How Does It Contribute To The Machining Process?The primary function of a chuck key is to tighten and loosen the chuck. The chuck holds the metal piece we want to shape. When you use the key, you can easily secure or remove the metal piece. This helps us work safely and makes sure the metal stays in place while we machine it. Without the chuck key, it would be harder to change pieces.

How Do You Properly Use A Chuck Key To Ensure That A Workpiece Is Securely Held In Place During Lathe Operations?To use a chuck key, first, make sure the lathe is off. Insert the chuck key into the holes of the chuck. Turn the key to tighten the jaws, which hold the workpiece. Make sure it’s tight enough so the workpiece won’t move. Always remove the chuck key before starting the lathe.

What Are The Common Types Of Chuck Keys Used With Metal Lathes, And How Do They Differ In Design And Functionality?Common types of chuck keys used with metal lathes are the T-handle, the pin type, and the ratchet type. The T-handle is shaped like a letter “T” and helps you turn it easily. The pin type has a round pin that fits into holes for gripping. The ratchet type lets you turn it without going back, making it faster and easier to use. Each one helps you tighten or loosen the chuck, which holds the metal in place while you work.

What Safety Precautions Should Be Taken When Using A Lathe Chuck Key To Prevent Accidents Or Damage To The Machine?When using a lathe chuck key, always keep your hands away from the moving parts. Make sure the machine is off before you start. Always check that the key is removed after tightening the chuck. Wear safety glasses to protect your eyes from flying debris. Finally, never rush; take your time to work safely.

How Can Improper Use Or Loss Of A Chuck Key Impact The Quality Of The Finished Workpiece And The Overall Efficiency Of The Lathe Operation?Using a chuck key wrong or losing it can cause problems. The chuck holds the tool or workpiece tight. If it’s loose, the workpiece can wobble during cutting. This makes the piece uneven and messy. Also, if you waste time looking for the chuck key, it slows down the work and makes everything less efficient.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Metal Shaping, Specifically Focusing On Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe chuck key helps us lock or unlock the chuck. The chuck holds the metal we want to shape. To use it, you insert the key into a hole and turn it. This tightens or loosens the grip on the metal. Be careful not to lose the chuck key, or it will be hard to work!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Chuck Key In A Metal Lathe, And How Does It Contribute To The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The primary function of a chuck key is to tighten and loosen the chuck. The chuck holds the metal piece we want to shape. When you use the key, you can easily secure or remove the metal piece. This helps us work safely and makes sure the metal stays in place while we machine it. Without the chuck key, it would be harder to change pieces.”}},{“@type”: “Question”,”name”: “How Do You Properly Use A Chuck Key To Ensure That A Workpiece Is Securely Held In Place During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a chuck key, first, make sure the lathe is off. Insert the chuck key into the holes of the chuck. Turn the key to tighten the jaws, which hold the workpiece. Make sure it’s tight enough so the workpiece won’t move. Always remove the chuck key before starting the lathe.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Chuck Keys Used With Metal Lathes, And How Do They Differ In Design And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of chuck keys used with metal lathes are the T-handle, the pin type, and the ratchet type. The T-handle is shaped like a letter T and helps you turn it easily. The pin type has a round pin that fits into holes for gripping. The ratchet type lets you turn it without going back, making it faster and easier to use. Each one helps you tighten or loosen the chuck, which holds the metal in place while you work.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Lathe Chuck Key To Prevent Accidents Or Damage To The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe chuck key, always keep your hands away from the moving parts. Make sure the machine is off before you start. Always check that the key is removed after tightening the chuck. Wear safety glasses to protect your eyes from flying debris. Finally, never rush; take your time to work safely.”}},{“@type”: “Question”,”name”: “How Can Improper Use Or Loss Of A Chuck Key Impact The Quality Of The Finished Workpiece And The Overall Efficiency Of The Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a chuck key wrong or losing it can cause problems. The chuck holds the tool or workpiece tight. If it’s loose, the workpiece can wobble during cutting. This makes the piece uneven and messy. Also, if you waste time looking for the chuck key, it slows down the work and makes everything less efficient.”}}]}