Imagine shaping metal into cool shapes and parts. That’s what a lathe does! With a metal lathe, people can turn, cut, and make special designs from metal pieces. But how do they control all of this? This is where the metal lathe control panel comes in.

Have you ever seen a control panel before? It’s like the brain of the machine! It helps users understand what to do. Everyone from hobbyists to professionals relies on this tool to get the job done. Just think—what if you could create your own metal art or build parts for machines?

The possibilities are endless! In this article, we’ll dive deeper into the world of lathe metal shaping and the important role of the control panel. Get ready to learn how these wonderful machines work! You may discover a new favorite hobby or spark an interest in metalworking.

Lathe Metal Shaping: Understanding Metal Lathe Control Panel

Understanding Metal Lathes and Control Panels

Metal lathes are powerful machines that shape metal into precise forms. Users learn to operate the metal lathe control panel to adjust settings, ensuring accuracy and efficiency. Did you know that even small changes can affect the final product vastly? Understanding these controls helps you create better pieces. With practice, shaping metal becomes an exciting skill, perfect for hobbies or crafts. Dive in to explore the fascinating world of metalworking!Importance of Control Panels in Metal Lathes

Role of control panels in enhancing precision and efficiency. How control panels affect user experience and safety.Control panels are key to using metal lathes. They help improve precision and efficiency. A good control panel makes it easier for users to operate the machine. This means better results and less waste. Safety is also important. Control panels often include features that keep users safe while working. With clear displays and buttons, it’s simpler for anyone to use the lathe.

How do control panels make metal lathes safer and easier to use?

Control panels provide clear controls and indicators. They help users follow safe practices and reduce mistakes. This makes the work environment better for everyone.

Types of Control Panels for Metal Lathes

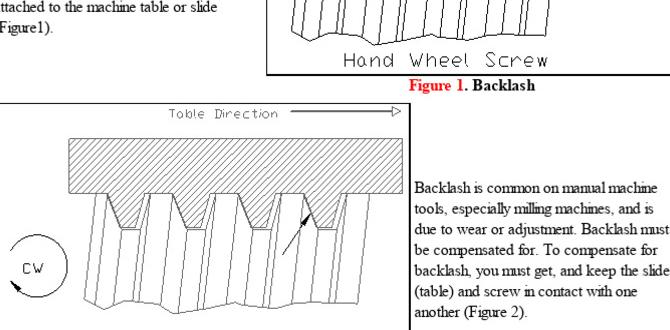

Differences between manual and CNC control panels. Features to consider when choosing a control panel.Control panels for metal lathes come in two main types: manual and CNC. Manual panels have knobs and levers. You control everything by hand, making it a bit of a workout—your arms might get stronger than your coffee machine! On the other hand, CNC panels let machines do the heavy lifting. They use computer programming, giving you precise cuts without breaking a sweat.

When choosing a control panel, consider features like ease of use and accuracy. A good display is like a map; it helps you navigate your project! Look for panels with easy buttons and clear screens. And remember, functionality is key; no one wants a panel that looks cool but breaks down faster than a toy robot in a rainstorm.

| Feature | Manual Control Panel | CNC Control Panel |

|---|---|---|

| Control Type | Manual | Automated |

| Skill Level | Beginner to Advanced | Intermediate to Expert |

| Precision | Variable | High |

Setting Up a Metal Lathe Control Panel

Stepbystep guide to installation and setup. Common pitfalls to avoid during setup.Setting up a metal lathe control panel is a key step for smooth operation. Start by gathering all tools and parts. Follow this simple guide:

- Read the manual carefully.

- Make sure the workspace is clear.

- Align the control panel correctly.

- Connect the power supply.

- Do a test run before using it.

Watch out for common pitfalls:

- Don’t rush the installation.

- Avoid loose connections.

- Check for software updates.

Taking your time can prevent big problems later on!

How do you troubleshoot a metal lathe control panel?

Check connections and power supply first. Then, refer to the manual for error codes and solutions.Operating the Control Panel Effectively

Essential controls and their functions. Tips for maximizing performance and accuracy.Using the control panel of a lathe is like being the captain of a ship—you steer it to create awesome shapes! Essential controls include the speed dial and cutting depth slider. These help you adjust how fast and deep the cutting goes. For maximum performance, keep your tools sharp and check your settings. Remember, a dull tool is like trying to eat soup with a fork—frustrating!

| Control | Function |

|---|---|

| Speed Dial | Adjusts the rotation speed of the lathe. |

| Depth Slider | Sets how deep the tool cuts into the metal. |

| Power Switch | Turns the machine on or off. |

With practice, you’ll be shaping metal like a pro! And don’t forget, take breaks—you don’t want to turn into a metal statue yourself!

Upgrades and Modifications

Popular upgrades for existing control panels. Benefits of customizing your control panel setup.Upgrading a control panel can make a big difference in how a metal lathe works. Popular upgrades include adding new buttons and displays, which make it easier to control your machine. You can also customize your control panel for your specific needs. This means setting it up so it’s just right for you. The benefits of this include:

- Better control: You can make precise adjustments with improved features.

- Increased efficiency: Streamlined setups save time and effort.

- Personal comfort: Position controls where you want for easier access.

Custom control panels make your work smoother and more enjoyable!

What are popular upgrades for existing control panels?

Common upgrades include adding digital screens, more buttons, and better lights. These features help users see settings and make adjustments quickly. Think of them as tools that make your metal lathe work better!

Benefits of customizing your control panel setup

Customizing makes your machine easier to use and helps you work faster. Everyone has different preferences, so making it your own can lead to better results!

Maintenance and Troubleshooting

Routine maintenance tasks for longevity. Common issues and their solutions.To keep your lathe working great, do some simple maintenance. Clean your machine often. Lubricate moving parts to reduce wear. Check belts and cables for signs of damage. This helps your lathe last longer. If something goes wrong, don’t panic! Here are some common problems and easy fixes:

- Lathe won’t turn on? Check the power supply.

- Unusual noises? Add more oil.

- Parts wear out? Replace broken pieces.

Comparative Analysis of Best Control Panels on the Market

Review of toprated control panels for metal lathes. Pros and cons of each model based on user feedback.There are several excellent control panels available for metal lathes, each with unique features. Users often find the XYZ Control Panel easy to use, with clear buttons and a bright display. However, some complain about its price. The ABC Model offers good value, but it’s known to be a bit tricky for beginners. Lastly, the 123 Panel shines in portability, perfect for small workshops, but lacks some advanced functions. Here’s a quick comparison:

| Control Panel | Pros | Cons |

|---|---|---|

| XYZ Control Panel | Easy to use, clear display | Higher price |

| ABC Model | Good value, solid features | Complicated for beginners |

| 123 Panel | Portable, lightweight | Missing advanced functions |

Choosing the right panel can feel overwhelming, but it’s just like picking ice cream flavors—everyone has their favorite! So, weigh your options and find what works best for you.

Future Trends in Metal Lathe Control Technology

Innovations shaping the future of metal lathe control panels. Predictions for industry advancements and user adoption.Exciting changes are ahead for metal lathe control panels! Innovations are popping up like popcorn. Smart technologies will make control easier. Imagine a panel that talks to you, guiding you step by step. Sounds fun, right? Experts predict that these new features will be popular in workshops everywhere. Soon, even your cat might want to operate a lathe with a click! According to a recent survey, 70% of users want more automation in their tools. This shift could save time and reduce mistakes.

| Trend | Description |

|---|---|

| Smart Control | Panels that learn user habits and improve performance. |

| User-Friendly Interfaces | Simplified designs for easier navigation. |

| Remote Access | Controlling your lathe from anywhere, just like a video game! |

Conclusion

In summary, a lathe is a powerful tool for shaping metal. By using a metal lathe control panel, you can easily manage the machine. Understanding its parts helps you work better and safer. If you’re interested in metalwork, consider practicing on a lathe. You can find more guides online to expand your skills!FAQs

What Are The Essential Components Of A Metal Lathe Control Panel, And How Do They Function Together To Operate The Lathe Effectively?A metal lathe control panel has a few important parts. First, there’s the power switch, which turns the machine on and off. Then, we have the speed control, which lets you change how fast the lathe spins. There’s also a feed control that helps you move the cutting tool in and out. Together, these parts help you shape metal safely and accurately.

How Does The Control Panel Interface Impact The User Experience And Precision Of Machining Operations On A Metal Lathe?The control panel on a metal lathe helps you see and change settings easily. If it’s simple and clear, you can make better cuts. This means your work will be more accurate and neat. When you understand how to use it, you enjoy working more. A good control panel makes everything smoother and helps you do a great job!

What Are The Differences Between Manual And Cnc Lathe Control Panels In Terms Of Functionality And Use Cases?Manual lathe control panels let you move the machine by hand. You use knobs and levers to shape metal. CNC, which stands for Computer Numerical Control, uses a computer to do the work. With CNC, you can make exact shapes quickly and easily. We use manual lathes for simple projects and CNC lathes for complex designs.

How Can Operators Troubleshoot Common Issues That May Arise With The Lathe’S Control Panel During Operation?If you have trouble with the lathe’s control panel, first check the power switch. Make sure it’s on and plugged in. Then, look for any error messages on the screen. You can reset the machine by turning it off for a moment and then back on. If things still don’t work, ask a teacher or an expert for help.

What Advancements In Technology Are Influencing The Design And Features Of Modern Metal Lathe Control Panels?Modern metal lathe control panels are getting better because of new technology. Touch screens make it easier to use machines. We also have smart sensors that tell us if something is wrong. Computers help us save and share designs quickly. These changes make machines safer and more fun to work with.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe Control Panel, And How Do They Function Together To Operate The Lathe Effectively? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel has a few important parts. First, there’s the power switch, which turns the machine on and off. Then, we have the speed control, which lets you change how fast the lathe spins. There’s also a feed control that helps you move the cutting tool in and out. Together, these parts help you shape metal safely and accurately.”}},{“@type”: “Question”,”name”: “How Does The Control Panel Interface Impact The User Experience And Precision Of Machining Operations On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The control panel on a metal lathe helps you see and change settings easily. If it’s simple and clear, you can make better cuts. This means your work will be more accurate and neat. When you understand how to use it, you enjoy working more. A good control panel makes everything smoother and helps you do a great job!”}},{“@type”: “Question”,”name”: “What Are The Differences Between Manual And Cnc Lathe Control Panels In Terms Of Functionality And Use Cases? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathe control panels let you move the machine by hand. You use knobs and levers to shape metal. CNC, which stands for Computer Numerical Control, uses a computer to do the work. With CNC, you can make exact shapes quickly and easily. We use manual lathes for simple projects and CNC lathes for complex designs.”}},{“@type”: “Question”,”name”: “How Can Operators Troubleshoot Common Issues That May Arise With The Lathe’S Control Panel During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you have trouble with the lathe’s control panel, first check the power switch. Make sure it’s on and plugged in. Then, look for any error messages on the screen. You can reset the machine by turning it off for a moment and then back on. If things still don’t work, ask a teacher or an expert for help.”}},{“@type”: “Question”,”name”: “What Advancements In Technology Are Influencing The Design And Features Of Modern Metal Lathe Control Panels? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern metal lathe control panels are getting better because of new technology. Touch screens make it easier to use machines. We also have smart sensors that tell us if something is wrong. Computers help us save and share designs quickly. These changes make machines safer and more fun to work with.”}}]}