Have you ever wondered how metal objects are shaped into precise forms? The answer often lies in a fascinating tool called a lathe. A lathe is a metal shaping machine that uses rotating pieces of metal to create amazing shapes. From simple knobs to complex parts, this machine plays a key role in manufacturing.

Imagine a sculptor, but instead of clay, they work with metal. The metal lathe machine spins the metal at high speeds, carving it into the desired shape. It’s like magic, turning raw metal into beautiful products.

Did you know that lathes have been used for thousands of years? Early versions of metal lathes date back to ancient Egypt. Today, they have evolved into powerful machines found in many workshops. By using a metal lathe, you can unlock endless possibilities in metalworking.

So, whether you want to build something new or understand how things are made, the lathe metal shaping process is a fantastic journey to explore.

Lathe Metal Shaping: Mastering The Metal Lathe Machine

Understanding Metal Lathes for Shaping Metal

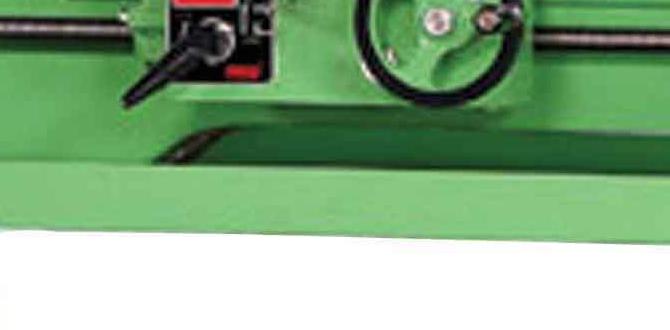

Metal lathes are amazing machines that transform raw metal into precise parts. They work by spinning metal while cutting tools shape it. This process can create everything from simple rods to complex gears. Did you know that lathes date back to ancient Egypt? They’ve evolved but still do the same essential job. Learning how these machines operate can open doors to exciting careers in engineering and manufacturing. Curious how they can turn a block into a masterpiece?

What is a Metal Lathe?

Definition and basic functionality. Types of metal lathes and their applications.

A metal lathe is a machine that shapes metal. It spins the metal on a rotating axis while a cutting tool removes excess material. This process creates smooth and precise shapes. Many industries use metal lathes, like automotive and aerospace. There are different types of metal lathes:

- Engine Lathe: A versatile machine for general work.

- CNC Lathe: Computer-controlled for high precision.

- Toolroom Lathe: Makes small, precise parts.

Each type serves different purposes, helping to create everything from car parts to intricate designs.

What tools do you use on a metal lathe?

Tools on a metal lathe include cutting tools, drills, and inserts. These help shape or drill holes in the metal.

Benefits of Using a Metal Lathe

Precision and accuracy in metal shaping. Versatility in manufacturing and machining.

Using a metal lathe is like having a superpower for shaping metal! This amazing machine makes precision and accuracy possible, so you can create parts that fit together perfectly. Imagine making cool shapes and designs with a twist! Plus, it’s versatile. You can use it for different tasks, from carving tiny details to crafting big pieces. It’s the Swiss Army knife of machines. No wonder even superheroes would take one if they could!

| Benefit | Description |

|---|---|

| Precision | Creates exact shapes and sizes. |

| Versatility | Useful for various manufacturing tasks. |

Different Types of Metal Lathes

Bench lathes vs. floor lathes. CNC lathes vs. manual lathes.

Metal lathes come in different types, each serving different needs. Bench lathes are smaller and fit on a table. They are great for light tasks. In contrast, floor lathes are much bigger. They handle heavy work and wider items.

CNC lathes use computers to control movement. They make precise cuts and shapes. Manual lathes rely on the worker’s hands. They allow for more creativity and control, but take more skill to operate.

What are the main differences between CNC and manual lathes?

CNC lathes are faster and more accurate. They work from a computer program. Manual lathes need skilled operators. They are more hands-on and flexible in creating unique designs.

Essential Features to Look for in a Metal Lathe

Chuck types and their significance. Motor power and speed variations.

Choosing the right metal lathe? Don’t forget about the chuck types! They hold your workpiece tight. Different chucks fit different projects, like a pen in your pocket! Motor power matters too. More power means better performance. Speed variations help you adjust as needed, like changing gears on a bike. If you’re shaping metal, check these features! You don’t want to end up with a lathe that’s slower than a tortoise on vacation!

| Chuck Types | Power Options |

|---|---|

| Three-Jaw Chuck | High Torque |

| Two-Jaw Chuck | Moderate Torque |

| Collet Chuck | Speed Variations |

Common Applications of Metal Lathes

Industries that benefit from lathe machines. Typical projects and products created using metal lathes.

Many industries love using metal lathes. They help create cool stuff! For example, the automotive world uses them to make parts like gears and shafts. Similarly, in aviation, metal lathes shape delicate components for airplanes. Fun fact! Some folks even use them for crafting unique art pieces or fancy furniture. Check out the table below for more examples:

| Industry | Common Products |

|---|---|

| Automotive | Gears, Shafts |

| Aerospace | Engine Parts, Brackets |

| Manufacturing | Machinery Parts, Tools |

| Arts and Crafts | Decorative Items, Furniture |

Metal lathes are essential tools that make our lives easier and more interesting!

Safety Practices When Operating a Metal Lathe

Recommended safety gear and precautions. Common risks and how to mitigate them.

Using a metal lathe can be tons of fun, but safety comes first! Always wear safety goggles to protect your eyes from flying chips. Don’t forget ear protection; lathes can be as loud as a rock concert! Keep your hair tied back and wear snug clothes—no loose ties that could wave goodbye to your fingers! Here’s a quick look at common risks:

| Risk | Safety Precaution |

|---|---|

| Flying debris | Wear goggles |

| Noisy operation | Use earplugs |

| Mechanical injuries | Keep hands away from moving parts |

Staying alert while working is key—don’t daydream about lunch! If you follow these tips, you’ll be a safe lathe wizard!

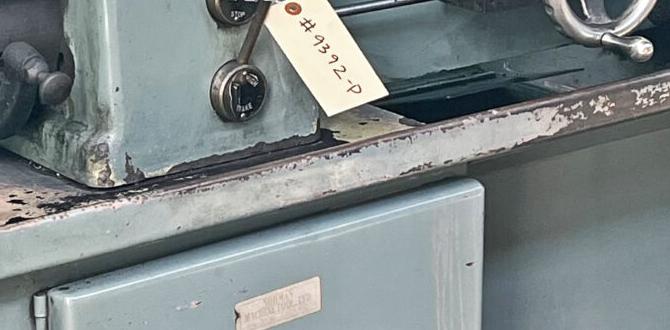

Maintenance Tips for Longevity

Regular maintenance tasks and schedules. Troubleshooting common issues with metal lathes.

Keeping your lathe in tip-top shape is easier than it seems! First, always check and clean the tools before and after use. A clean lathe is a happy lathe! Set a routine for oiling moving parts; it’s like giving your machine a spa day. Don’t forget to look for wear and tear. If things start to rattle or shake, it’s time for a little TLC. Here’s a handy schedule:

| Task | Frequency |

|---|---|

| Clean Tooling | After each use |

| Oil Moving Parts | Weekly |

| Check for Loose Screws | Monthly |

Remember, ignoring small issues can lead to big problems! If your lathe starts making funny noises, don’t panic. Tighten a few screws or check the belts. Sometimes it just wants a little attention!

Choosing the Right Metal Lathe for Your Needs

Factors to consider based on specific projects. Recommendations for beginners vs. experienced machinists.

Finding the right metal lathe makes a big difference in your work. Start by thinking about what you’ll make. Here are some things to consider:

- Project Size: Smaller projects need smaller lathes.

- Experience Level: Beginners may want simpler models.

- Precision Needs: Some jobs require high accuracy.

For beginners, a benchtop lathe can be great. They are easy to use and not too costly. Experienced machinists might prefer a heavy-duty model. These machines offer more options and power.

What should beginners look for in a lathe?

Beginners should focus on ease of use, cost, and durability. A simple design helps them learn quickly.

What should experienced users consider?

- More features for detailed work.

- Higher power for tough materials.

- Advanced controls for precision adjustments.

Choosing wisely can help you enjoy your projects even more!

Future Trends in Metal Lathe Technology

Innovations in lathe design and functionality. The impact of automation and smart technology on metal shaping.

New designs are transforming metal lathe machines. These innovations enhance performance and make shaping metal easier. Automation is also taking center stage. Smart technology helps lathe machines work faster and more accurately. Machines can now adjust settings on their own. This means better products are made quickly.

- Advanced sensor systems boost precision.

- User-friendly interfaces make operation simple.

- More efficient energy use lowers costs.

What are the benefits of automation in metal lathes?

Automation improves speed and precision, allowing machines to perform tasks without constant human help. It saves time and reduces mistakes.

Conclusion

In summary, a metal lathe machine is a powerful tool for shaping metals. It helps create precise parts for many projects. You can use it for hobbies or professional work. Learning to operate a lathe can boost your skills. Try exploring tutorials online or in local workshops to start your journey. Let’s shape something amazing together!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Machines:

Sure! A metal lathe machine is a tool that shape metal pieces. It spins the metal as a sharp tool cuts into it. You can make things like rods, cones, and cylinders. It’s like using a pencil to draw shapes, but with metal! This machine helps in building many cool things, like parts for cars and toys.

Sure! Just ask your question, and I’ll be happy to help you with a short answer!

What Are The Primary Components Of A Metal Lathe, And How Do They Function Together To Shape Metal?

A metal lathe has a few main parts. First, there’s the bed, which is the strong base that holds everything together. Next, we have the headstock, which spins the metal. The tailstock can move and holds the other end of the metal piece. The cutting tool shapes the metal as it turns. All these parts work together to make cool shapes from metal.

What Types Of Materials Can Be Machined Using A Metal Lathe, And What Factors Influence Material Selection?

You can use a metal lathe to machine metals like aluminum, brass, steel, and copper. These materials are strong and easy to shape. When we choose a material, we think about how strong it needs to be and how it will be used. We also want materials that are easy to work with and won’t break easily.

How Do Different Cutting Tools And Techniques Affect The Precision And Quality Of The Finished Metal Workpiece In Lathe Operations?

Different cutting tools and techniques help us make metal pieces look nice and fit well. If you use sharp tools, they cut better and make smooth edges. When we change our cutting speed and angles, we can improve how neat the piece turns out. If we are careful and use the right tool, our finished workpieces will be high quality. So, choosing the right cutting tool really matters!

What Are The Safety Protocols That Operators Should Follow When Using A Metal Lathe To Prevent Accidents And Injuries?

When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothes to avoid getting caught in the machine. Before starting, check that all tools are in place and nothing is loose. Always use both hands when working, and never talk to others while the lathe is running. If something goes wrong, turn off the machine right away.

How Has Modern Technology, Such As Cnc (Computer Numerical Control), Transformed The Traditional Metal Lathe Machining Process?

Modern technology like CNC, which stands for Computer Numerical Control, has changed how we use metal lathes. With CNC, computers now control the lathes instead of just people. This makes the machines more accurate and faster. You can create complex shapes easily, and everything is more precise. Overall, it helps to make better products in less time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Machines:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe machine is a tool that shape metal pieces. It spins the metal as a sharp tool cuts into it. You can make things like rods, cones, and cylinders. It’s like using a pencil to draw shapes, but with metal! This machine helps in building many cool things, like parts for cars and toys.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer!”}},{“@type”: “Question”,”name”: “What Are The Primary Components Of A Metal Lathe, And How Do They Function Together To Shape Metal?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has a few main parts. First, there’s the bed, which is the strong base that holds everything together. Next, we have the headstock, which spins the metal. The tailstock can move and holds the other end of the metal piece. The cutting tool shapes the metal as it turns. All these parts work together to make cool shapes from metal.”}},{“@type”: “Question”,”name”: “What Types Of Materials Can Be Machined Using A Metal Lathe, And What Factors Influence Material Selection?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a metal lathe to machine metals like aluminum, brass, steel, and copper. These materials are strong and easy to shape. When we choose a material, we think about how strong it needs to be and how it will be used. We also want materials that are easy to work with and won’t break easily.”}},{“@type”: “Question”,”name”: “How Do Different Cutting Tools And Techniques Affect The Precision And Quality Of The Finished Metal Workpiece In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and techniques help us make metal pieces look nice and fit well. If you use sharp tools, they cut better and make smooth edges. When we change our cutting speed and angles, we can improve how neat the piece turns out. If we are careful and use the right tool, our finished workpieces will be high quality. So, choosing the right cutting tool really matters!”}},{“@type”: “Question”,”name”: “What Are The Safety Protocols That Operators Should Follow When Using A Metal Lathe To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothes to avoid getting caught in the machine. Before starting, check that all tools are in place and nothing is loose. Always use both hands when working, and never talk to others while the lathe is running. If something goes wrong, turn off the machine right away.”}},{“@type”: “Question”,”name”: “How Has Modern Technology, Such As Cnc (Computer Numerical Control), Transformed The Traditional Metal Lathe Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern technology like CNC, which stands for Computer Numerical Control, has changed how we use metal lathes. With CNC, computers now control the lathes instead of just people. This makes the machines more accurate and faster. You can create complex shapes easily, and everything is more precise. Overall, it helps to make better products in less time.”}}]}