Have you ever seen a piece of metal shaped into something useful? It’s amazing how a metal lathe can transform a simple block into a perfect cylinder. One of the coolest things you can do on a lathe is taper turning. But what does that mean?

Taper turning is when the end of a metal piece becomes thinner, making it pointy or sharp. You might wonder why someone would want to do that. Imagine building a toy rocket or a sleek pencil. Taper turning gives you those special shapes!

Using a lathe for metal shaping might seem tricky. However, with some practice, anyone can learn! Just picture the satisfaction of creating something from scratch. It feels like magic when you watch the metal spin and change right before your eyes!

Did you know that lathes have been around for thousands of years? They’ve helped people create tools, art, and even parts for machines. So, the next time you think about shaping metal, remember the power of a lathe and the fun of taper turning!

Lathe Metal Shaping Techniques: Mastering Metal Lathe Taper Turning Lathe Metal Shaping Is A Vital Process In Manufacturing And Precision Engineering, Specifically When It Comes To Taper Turning On A Metal Lathe. This Technique Allows For The Creation Of Conical Shapes With Accuracy And Efficiency. Whether You Are A Seasoned Machinist Or A Beginner Just Starting, Understanding The Intricacies Of Taper Turning Can Greatly Enhance Your Lathe Work. Understanding Lathe Metal Shaping Lathe Metal Shaping Involves Using A Lathe Machine To Remove Material From A Workpiece, Resulting In Various Shapes And Forms. The Metal Lathe Is One Of The Most Versatile Tools In A Machinist’S Arsenal, Capable Of Performing A Multitude Of Tasks. Taper Turning Is One Such Task That Specifically Refers To Producing A Tapered Shape, Which Is Crucial For Parts That Must Fit Together Seamlessly, Like Shafts Or Fittings. The Importance Of Taper Turning Taper Turning On A Metal Lathe Is Essential For Creating Components That Require A Gradual Reduction In Diameter. This Process Is Characterized By Its Precision, Allowing For Tight Tolerances That Are Crucial In Many Engineering Applications. Tapered Components Are Often Used In Applications Such As: – **Automotive Parts:** Many Engine Components Require Precision Tapers For Proper Assembly. – **Machinery Components:** Tapered Shafts Can Improve Stability And Fit In Machinery. – **Aerospace Engineering:** Components Must Fit Flawlessly Under Various Conditions, Where Taper Turning Becomes Critical. Methods For Taper Turning There Are Several Methods To Achieve Taper Turning On A Metal Lathe, Including: 1. **Compound Rest Method:** Adjusting The Compound Rest Allows For A Quick And Effective Way To Create Tapers. This Method Is Suitable For Small Projects And Involves Setting The Angle Of The Tool To Match The Desired Taper. 2. **Tailstock Offset Method:** By Moving The Tailstock Away From The Centerline Of The Lathe, A Taper Can Be Created With Straightforward Tool Movement. This Method Is Precise But Requires Careful Measurements To Ensure The Correct Taper Angle. 3. **Straight Turning Method:** Using A Taper Turning Attachment Or A Steady Rest, You Can Create Precise Tapers. This Is Often Used For Larger Parts Or More Complicated Shapes, Offering Versatility In Machining. Tips For Precision In Taper Turning – **Measure Carefully:** Accurate Measurements Are Crucial For Achieving The Desired Taper Angle. – **Use Sharp Tools:** Dull Tools Can Create Rough Finishes And Inaccuracies, So Always Ensure Tools Are Sharp. – **Take Test Cuts:** Before Finalizing Your Workpiece, Run A Test Cut To Verify Dimensions And Fit. Conclusion Mastering Lathe Metal Shaping, Particularly Taper Turning On A Metal Lathe, Is An Essential Skill For Any Machinist. By Understanding The Techniques And Methods Involved, As Well As The Applications Of Tapered Components, You Can Greatly Improve Your Machining Capabilities. Whether In A Professional Setting Or A Hobbyist’S Workshop, Honing These Skills Will Lead To More Precise And High-Quality Outcomes In Your Projects.

Lathe Metal Shaping: Mastering Taper Turning

Have you ever wondered how metal shapes are crafted with precision? The metal lathe plays a crucial role in this process. It’s a machine that spins metal pieces to shape them accurately. Taper turning is a specific skill, allowing craftsmen to create parts that gradually narrow. This technique finds use in everyday items, from tools to vehicle parts. Knowing how to use a lathe is an exciting step toward becoming a skilled metalworker. Isn’t it impressive what you can create with just a lathe?

Understanding the Basics of Metal Lathes

Definition and components of a metal lathe. Types of metal lathes and their specific uses.

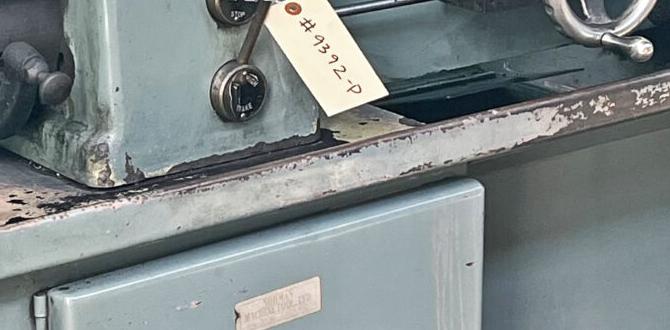

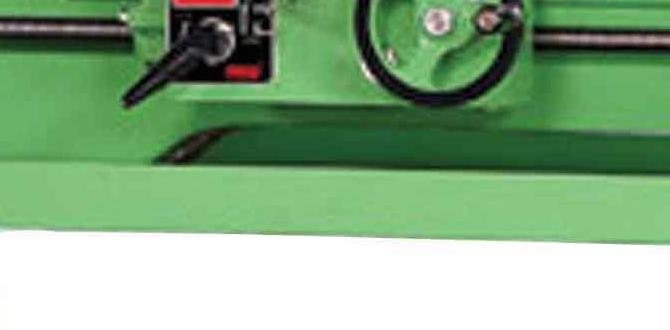

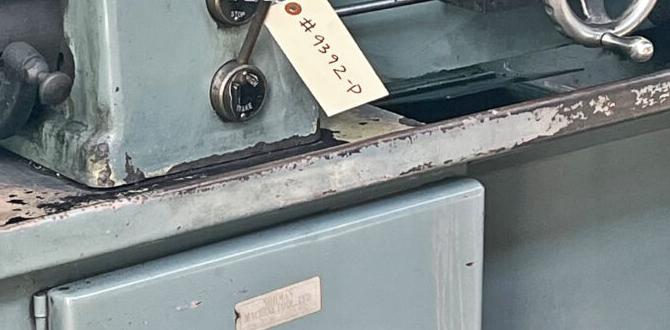

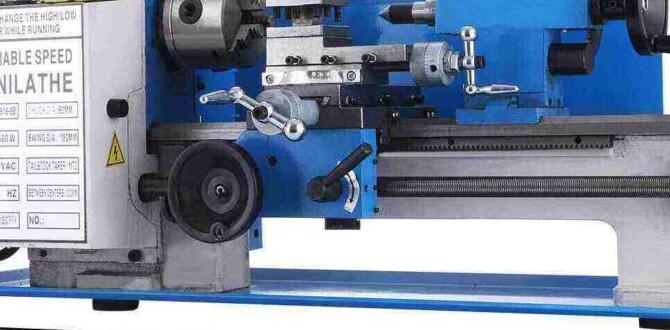

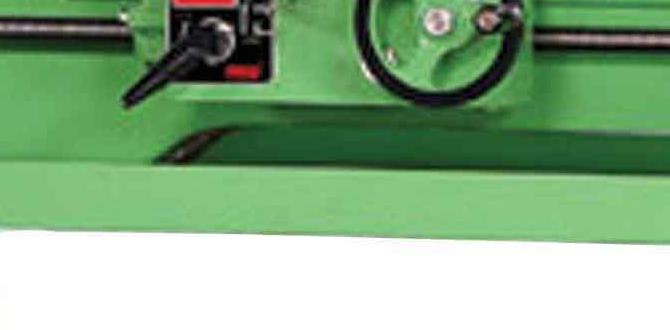

A metal lathe is a machine that shapes metal into different forms. It spins the metal while cutting tools remove material. Essential parts of a lathe include the bed, headstock, tailstock, and carriage. Metal lathes come in several types, each serving specific needs:

- Engine lathe: Great for various tasks like turning and tapering.

- CNC lathe: Computer-controlled for precise and complex designs.

- Turret lathe: Best for mass production with multiple tools.

Each type helps workers create parts like gears and rods efficiently.

What are the main types of metal lathes?

Engine lathes, CNC lathes, and turret lathes are the three main types. Each serves different needs, from basic shaping to advanced automation.

The Importance of Taper Turning

Explanation of taper turning in metal shaping. Applications and advantages of taper turning in various industries.

Taper turning is a cool technique in metal shaping that makes pieces narrow at one end. It helps to create pointed or slanted shapes, perfect for many uses. For example, you can find tapered parts in tools, furniture, and even parts in cars. The main benefits of taper turning include:

- Improved fit in machinery

- Better aerodynamics for moving parts

- Increased strength in some designs

This method is important in industries like manufacturing and construction. It helps create strong, efficient, and useful products.

What is taper turning used for?

Taper turning is used to create pieces that fit well, improve performance, and are visually appealing.

Step-by-Step Guide to Taper Turning on a Metal Lathe

Setting up the lathe for taper turning. Detailed process of taper turning, including measurements and adjustments.

To start taper turning on a metal lathe, set it up correctly. First, adjust the lathe bed. Make sure it is level and securely mounted. Next, gather your tools: a cutting tool, calipers, and a measuring tape. Measure the desired taper angle. Adjust the tailstock accordingly. Don’t forget to check the alignment often. It’s crucial for a precise cut.

- Level the lathe bed.

- Gather the right tools.

- Measure the taper angle.

- Adjust the tailstock.

- Check alignment frequently.

How do you measure taper angles for metal lathes?

The best way to measure taper angles is by using calipers and a protractor. Start from the large end of your piece and take measurements at both ends. This helps ensure accuracy.

Common Techniques for Effective Taper Turning

Popular taper turning methods (e.g., compound rest, taper attachment). Tips for achieving precision and accuracy during taper turning.

Taper turning is vital for creating precise shapes on a metal lathe. Two popular methods for achieving this are compound rest and taper attachment. The compound rest allows for adjusting angles easily, while the taper attachment gives more direct control. To ensure your taper turning is accurate, remember these tips:

- Check your measurements often.

- Adjust your speed for smoother cuts.

- Use sharp tools for clean edges.

By following these steps, your taper turning will be more precise every time!

What is the best method for taper turning?

The best method for taper turning depends on your project needs. For small angles, the compound rest is ideal. For larger angles, a taper attachment works better.

Safety Considerations While Using a Metal Lathe

Important safety measures to follow while taper turning. Personal protective equipment required during metal lathe operations.

Using a metal lathe can be fun, but safety comes first! Always wear eye protection to avoid flying debris. Gloves may look cool, but they can get caught in a lathe. Instead, keep your hands safe and free. Wearing steel-toed boots protects your feet from heavy parts falling. Don’t forget a dust mask if you’re working with messy materials. Safety is key, and it doesn’t hurt to look like a superhero while doing it!

| Personal Protective Equipment | Purpose |

|---|---|

| Safety Goggles | Protect eyes from debris |

| Ear Protection | Reduce loud noises |

| Dust Mask | Filter harmful dust |

| Steel-Toed Boots | Protect feet from falling objects |

Maintaining Your Metal Lathe for Optimal Performance

Best practices for lathe maintenance and care. Importance of regular inspection and servicing.

Keeping your metal lathe in tip-top shape is key for smooth operations. Regular inspections help catch issues before they become big headaches. Make sure to clean the parts often. Dust and debris can really mess things up! Use this handy table for quick maintenance tips:

| Maintenance Task | Frequency |

|---|---|

| Clean the lathe | After every use |

| Check the oil | Weekly |

| Tighten bolts | Monthly |

| Inspect belts and gears | Every three months |

Staying on top of these tasks will keep your lathe running like a champ. Remember, an ounce of prevention is worth a pound of cure, especially when your tools are involved!

Case Studies: Successful Taper Turning Projects

Examples of notable projects featuring taper turning. Lessons learned and innovations from these projects.

Taper turning is more than just a fancy term; it’s an art form! One standout project involved creating a sleek chair leg that not only looked great but was also sturdy. Inventive minds used a lathe for precise shaping, showing how metal lathe innovations can lead to beautiful outcomes. Another example is crafting bicycle parts for better aerodynamics. Lessons learned? Always double-check your measurements. Remember, a tiny mistake can result in a lopsided bike. And who wants that while speeding downhill?

| Project | Feature | Lesson Learned |

|---|---|---|

| Chair Leg | Sleek design | Measure twice, cut once! |

| Bicycle Parts | Improved aerodynamics | No lopsided bikes! |

Conclusion

In conclusion, metal lathes are essential tools for shaping metal accurately. Taper turning allows you to create pointed shapes, which are useful in many projects. You can apply these skills in various applications, from manufacturing to DIY tasks. Explore more about lathe techniques to improve your metalworking skills. Dive into books or online resources for hands-on learning!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Taper Turning:

Sure! A lathe is a machine that helps us shape metal. We can make things like pipes or small parts. Taper turning means making one end of the metal smaller than the other. It helps fit pieces together better. Using a lathe is like using a pencil to shape your art, but for metal!

Sure! Please provide the question you would like me to answer.

What Are The Key Steps Involved In Setting Up A Metal Lathe For Taper Turning?

To set up a metal lathe for taper turning, first, you need to measure the piece you want to cut. Next, adjust the lathe’s tailstock to the right angle for the taper. Then, you lock the tailstock in place so it doesn’t move. After that, you turn on the lathe and carefully feed the tool into the metal. Finally, check your work to make sure the taper looks right.

How Does The Use Of A Taper Turning Attachment Enhance The Accuracy Of Taper Cuts On A Lathe?

A taper turning attachment helps you make angled cuts on a lathe. It moves the tool in a precise way. With this attachment, you can get perfect angles every time. This means your shapes will fit together better, and your projects will look nicer. It makes your work easier and more accurate!

What Types Of Materials Are Commonly Used For Workpieces When Performing Taper Turning On A Metal Lathe?

When we use a metal lathe for taper turning, we often work with materials like steel, aluminum, and brass. Steel is strong and good for tough jobs. Aluminum is light and easy to shape. Brass looks nice and is great for decorations. These materials help us create different types of parts.

Can You Explain The Difference Between A Straight Taper And A Combination Taper, And How Each Is Achieved On A Lathe?

A straight taper is when one end of a piece is smaller than the other in a straight line. You can make it by moving your cutting tool in one direction. A combination taper has two parts: one end is straight, and the other part curves. To make this, you change how you move the tool as you cut, creating both a straight and a curvy shape.

What Safety Precautions Should Be Taken When Operating A Lathe For Taper Turning To Prevent Injuries?

When using a lathe for taper turning, you should always wear safety goggles to protect your eyes. Keep long hair tied back and remove loose clothing or jewelry to prevent them from getting caught. Always check that the machine is off before you adjust anything. Make sure your hands stay away from the moving parts. Lastly, stay focused and don’t rush your work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Taper Turning:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. We can make things like pipes or small parts. Taper turning means making one end of the metal smaller than the other. It helps fit pieces together better. Using a lathe is like using a pencil to shape your art, but for metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Setting Up A Metal Lathe For Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for taper turning, first, you need to measure the piece you want to cut. Next, adjust the lathe’s tailstock to the right angle for the taper. Then, you lock the tailstock in place so it doesn’t move. After that, you turn on the lathe and carefully feed the tool into the metal. Finally, check your work to make sure the taper looks right.”}},{“@type”: “Question”,”name”: “How Does The Use Of A Taper Turning Attachment Enhance The Accuracy Of Taper Cuts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A taper turning attachment helps you make angled cuts on a lathe. It moves the tool in a precise way. With this attachment, you can get perfect angles every time. This means your shapes will fit together better, and your projects will look nicer. It makes your work easier and more accurate!”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Commonly Used For Workpieces When Performing Taper Turning On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a metal lathe for taper turning, we often work with materials like steel, aluminum, and brass. Steel is strong and good for tough jobs. Aluminum is light and easy to shape. Brass looks nice and is great for decorations. These materials help us create different types of parts.”}},{“@type”: “Question”,”name”: “Can You Explain The Difference Between A Straight Taper And A Combination Taper, And How Each Is Achieved On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A straight taper is when one end of a piece is smaller than the other in a straight line. You can make it by moving your cutting tool in one direction. A combination taper has two parts: one end is straight, and the other part curves. To make this, you change how you move the tool as you cut, creating both a straight and a curvy shape.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Lathe For Taper Turning To Prevent Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe for taper turning, you should always wear safety goggles to protect your eyes. Keep long hair tied back and remove loose clothing or jewelry to prevent them from getting caught. Always check that the machine is off before you adjust anything. Make sure your hands stay away from the moving parts. Lastly, stay focused and don’t rush your work.”}}]}