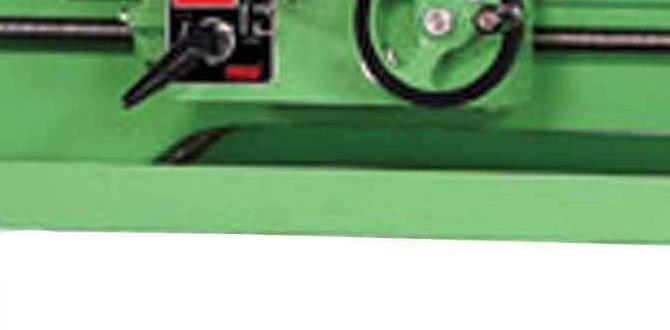

Have you ever wondered how metal parts are made with precision? One of the key tools in this process is the lathe parting tool. This special tool helps shape and cut metal lathe parts with great accuracy. Imagine watching a metal block transform into a beautiful piece of art right before your eyes!

Lathe parting tools are essential when working on a lathe. They help create clean cuts and smooth edges. But why is this important? Well, well-cut parts fit better and work more efficiently. This saves time and materials in projects!

Here’s a fun fact: Did you know that the oldest lathes date back to ancient Egypt? They used them to create intricate wooden sculptures. Today, we use modern metal lathes to craft everything from car parts to tiny screws.

In this article, we will dive deeper into lathe parting tools and their role in metalworking. Get ready to learn about different types of lathe parts and how they make creating metal pieces much easier!

Essential Lathe Parting Tool For Metal Lathe Parts

Lathe Parting Tool: Essential Metal Lathe Parts

Lathe parting tools are vital for metal lathe operations. They help cut off finished pieces smoothly, making them ideal for precision work. Have you ever wondered why these tools are so sharp? It’s because they need to slice through hard materials effortlessly. The design of lathe parts, like parting tools, enhances efficiency and accuracy. Understanding how they work can boost your metalworking skills. Exploring these tools can lead to better projects and a more enjoyable crafting experience!What is a Lathe Parting Tool?

Definition and purpose of a parting tool in lathe operations. Types of parting tools available: insert vs. solid.A lathe parting tool cuts through materials on a lathe. Its main job is to separate or “part” pieces. This tool is essential in making clean cuts and thin sections in metal and wood.

There are two main types of parting tools:

- Insert Tools: Replaceable tips make them easy to use.

- Solid Tools: Made from one piece, which can be stronger.

Choosing the right tool can help make your work smoother and more efficient. So, pick wisely!

What do parting tools do?

Parting tools make clean cuts and create pieces without damaging the main object. They help in dividing metal and wood effectively.

Importance of Parting Tools in Metalworking

Role of parting tools in enhancing machining accuracy. Applications of parting tools in various industries.Parting tools are like the secret agents of metalworking. They cut through metal to create precise shapes and sizes, boosting machining accuracy. With these tools, manufacturers can avoid mistakes and save materials. Think of it this way—without parting tools, you might end up with a metal blob instead of that shiny gear you wanted!

These tools find their homes in many industries, from automotive to aerospace. They help make everything from tiny screws to big machine parts. It’s like having a pizza cutter for metal—no one wants a messy slice! Remember, better tools mean better results.

| Industry | Application |

|---|---|

| Automotive | Parts cutting for engines |

| Aerospace | Precision components |

| Manufacturing | Custom shaped metal |

So, next time you spot a shiny machine part, thank the humble parting tool for its hard work!

Components of a Lathe Parting Tool

Description of the main parts of a parting tool: body, shank, cutting edge. Materials used in construction and their impact on performance.A lathe parting tool has three main parts: the body, shank, and cutting edge. The body is the large section that holds everything together. The shank fits into the lathe, while the cutting edge does the work of cutting metal. These tools are usually made from strong materials like high-speed steel or carbide, which help them last longer and cut more effectively.

What materials are used in lathe parting tools?

The most common materials are:

- High-speed steel: Great for durability and heat resistance.

- Carbide: Excellent for long cuts without wear.

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: material compatibility, size, and cutting depth. Comparison of popular parting tool brands and models.Picking the right parting tool for your metal lathe can be tricky. First, think about material compatibility. Some tools work better with specific metals. Next, consider the size of the tool. It must fit your lathe perfectly. Cutting depth is also important. Make sure your tool can handle the depth you need.

Many brands offer a variety of parting tools. Some popular ones are:

- Brand A: Great for beginners.

- Brand B: Known for durability.

- Brand C: Offers precise cuts.

Do your research to find the best tool for your needs!

What should I consider when selecting a parting tool?

You should consider material compatibility, size, and cutting depth to choose the best tool for your needs.

Setting Up a Parting Tool on a Metal Lathe

Stepbystep guide to correctly install a parting tool. Tips for achieving optimal cutting depth and speed.Setting up a parting tool on your metal lathe can be easy and fun! Follow these steps for a clean cut:

- First, securely fasten the toolholder onto the tool post.

- Next, adjust the parting tool’s angle. It should be at about 90 degrees.

- Ensure the cutting edge is aligned with the workpiece center.

- Set your lathe speed. Start slow to avoid breakage.

- Finally, adjust the cutting depth gradually.

For best results:

- Use a thin parting tool for less resistance.

- Increase the speed if the cut is smooth.

- Monitor tool wear to maintain quality.

What is the best cutting depth for a parting tool?

The optimal cutting depth depends on your project. Generally, it should be around 0.020 to 0.050 inches. Deep cuts can stall the lathe. Always start shallow and increase as needed.

Common Issues and Troubleshooting

Identifying problems: chatter, tool breakage, and poor surface finish. Solutions and adjustments for effective parting operations.Knowing how to spot problems with lathe parting tools is key. You might hear chatter, or see a rough surface finish. Tool breakage can happen too. Don’t worry! Here are some fixes:

- Check tool speed and feed rate.

- Use the right tool type for your material.

- Make sure the tool is sharp.

Adjust these settings to improve your parting operations. Fixing these issues quickly can save time and materials!

What causes chatter in lathe operations?

The main cause of chatter is often too high a speed or low feed rate. Adjusting these can reduce vibrations.

How to fix poor surface finish?

A poor surface finish may be due to dull tools or incorrect settings. Try sharpening your tool and changing the feed rate.

Maintenance and Care for Lathe Parting Tools

Cleaning and storage recommendations to extend tool life. Guidelines for sharpening and replacing cutting edges.Taking care of your lathe parting tools is important for a long life. First, clean them after every use. This keeps dirt and metal shavings away. Store your tools in a dry place, so they don’t rust. For sharpening, use a fine file or sharpening stone. Always check cutting edges for wear. If they are past their prime, it’s time to replace them. Remember, dull tools might turn you into a ‘lathe snail’ working slower than necessary!

| Maintenance Tips | Details |

|---|---|

| Cleaning | Wipe tools with a soft cloth after each use. |

| Storage | Keep in a dry, cool place to prevent rust. |

| Sharpening | Use a file or stone for a fine edge. |

| Replacing Edges | Change them when they are dull or damaged. |

Comparing Parting Tools to Other Cutting Tools

Differences between parting tools and turning tools. Advantages of using parting tools in specific machining scenarios.Parting tools and turning tools are like apples and oranges. Both are great, but they serve different purposes. Parting tools are sharp and thin, designed to slice through metal like butter. They help separate parts of a workpiece neatly. Turning tools, on the other hand, shape metal by removing layers, much like sculpting a statue from marble.

| Parting Tools | Turning Tools |

|---|---|

| Ideal for cutting off pieces | Used for shaping and smoothing |

| Creates neat edges | Produces rounded surfaces |

| Fast and efficient | Slow and steady wins the race |

The advantage of using parting tools is clear in specific situations. They quickly cut through metal with minimal fuss, saving you time. Imagine trying to slice a cake with a butter knife—it’s messy! With parting tools, you can make the perfect slice without drama. So, choose wisely!

Conclusion

In summary, lathe parting tools are essential for shaping metal. They help cut and separate pieces accurately. Understanding their parts can boost your skills. You can explore different designs and uses to improve your work. Try using a parting tool on your next project to see how it enhances your crafting. Keep learning and practicing for the best results!FAQs

What Are The Key Features To Consider When Selecting A Lathe Parting Tool For Metalworking Applications?When you choose a lathe parting tool, look for a few important features. First, check the tool’s width. A thinner blade helps make clean cuts. Next, consider the material. High-speed steel (HSS) lasts longer. Finally, make sure the handle is easy to hold. This helps you control the tool better while you work.

How Do You Properly Set Up And Align A Parting Tool On A Metal Lathe To Ensure Optimal Cutting Performance?To set up a parting tool on a metal lathe, first, we need to turn off the machine. Next, you should attach the parting tool to the tool holder. Make sure the tool is straight and level with the workpiece. Then, set the tool’s height to match the center of the piece you’re cutting. Finally, double-check that everything is tight and secure before turning the lathe back on.

What Materials Are Commonly Used For Manufacturing Parting Tools, And How Do They Affect Tool Performance And Longevity?Parting tools are usually made from high-speed steel or carbide. High-speed steel is tough and stays sharp for a long time. Carbide is even harder, which helps it cut better and last longer. Using the right material helps the tool work well and stay useful for a long time.

Can You Explain The Difference Between Using A Parting Tool And A Cutting Tool In A Metal Lathe?A parting tool slices off a piece of metal from the main piece. It makes straight cuts to separate parts. A cutting tool shapes the metal by removing material from the surface. It helps us make the metal smooth or create different shapes. We use both tools for different tasks on a metal lathe.

What Common Issues Can Arise When Using A Lathe Parting Tool, And How Can They Be Resolved To Improve Machining Accuracy?When using a lathe parting tool, you might face issues like tool breakage, poor cuts, or chatter. To fix this, make sure the tool is sharp and set at the right angle. You can also slow down the machine speed for better control. Lastly, use enough cutting oil to keep everything running smoothly. These steps can help you make better, more accurate cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Lathe Parting Tool For Metalworking Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a lathe parting tool, look for a few important features. First, check the tool’s width. A thinner blade helps make clean cuts. Next, consider the material. High-speed steel (HSS) lasts longer. Finally, make sure the handle is easy to hold. This helps you control the tool better while you work.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Parting Tool On A Metal Lathe To Ensure Optimal Cutting Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a parting tool on a metal lathe, first, we need to turn off the machine. Next, you should attach the parting tool to the tool holder. Make sure the tool is straight and level with the workpiece. Then, set the tool’s height to match the center of the piece you’re cutting. Finally, double-check that everything is tight and secure before turning the lathe back on.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Manufacturing Parting Tools, And How Do They Affect Tool Performance And Longevity? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Parting tools are usually made from high-speed steel or carbide. High-speed steel is tough and stays sharp for a long time. Carbide is even harder, which helps it cut better and last longer. Using the right material helps the tool work well and stay useful for a long time.”}},{“@type”: “Question”,”name”: “Can You Explain The Difference Between Using A Parting Tool And A Cutting Tool In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A parting tool slices off a piece of metal from the main piece. It makes straight cuts to separate parts. A cutting tool shapes the metal by removing material from the surface. It helps us make the metal smooth or create different shapes. We use both tools for different tasks on a metal lathe.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise When Using A Lathe Parting Tool, And How Can They Be Resolved To Improve Machining Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe parting tool, you might face issues like tool breakage, poor cuts, or chatter. To fix this, make sure the tool is sharp and set at the right angle. You can also slow down the machine speed for better control. Lastly, use enough cutting oil to keep everything running smoothly. These steps can help you make better, more accurate cuts.”}}]}