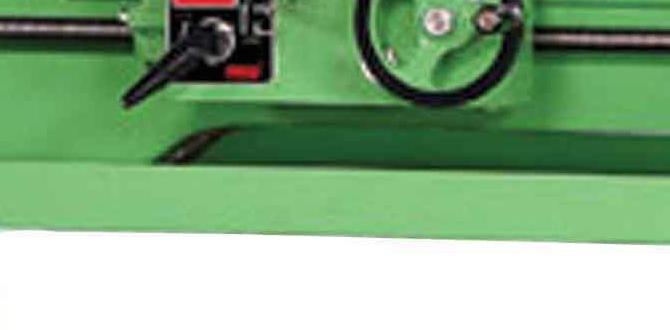

Have you ever watched a metal lathe at work? It’s amazing how this machine can shape metal with precision. But, to do this well, you need to know some important things.

One key aspect is the lathe power requirements. If you don’t have enough power, the lathe won’t perform right. Do you think a simple tool like a chuck key can make a difference? It really can! The chuck key helps hold the metal tightly. Without it, you could end up with a mess.

Imagine trying to fix your bike with a loose part. It just won’t work properly. The same happens with a metal lathe. Proper power and a good chuck key make all the difference. Stick with us, and you’ll learn how to achieve the best results with your lathe!

Lathe Power Requirements: Understanding Metal Lathe Chuck Key Needs

Lathe Power Requirements for Metal Lathe Chuck Key

Understanding lathe power requirements is essential for safe and effective machining. A metal lathe chuck key is a small but crucial tool that helps secure workpieces tightly. When choosing a lathe, consider its horsepower and torque. These factors affect the lathe’s ability to handle different materials. Did you know that an underpowered lathe can lead to poor results or even damage? Proper power ensures precision and quality, making your metalworking tasks easier and more efficient.Importance of Lathe Power Requirements

Definition and significance of power requirements in metal lathes. How power impacts performance and efficiency of machining processes.Power requirements in metal lathes are crucial for how they work. They define the energy needed to perform tasks. Proper power affects how fast and efficiently a lathe runs. Without the right power, machining can become slower and less precise, wasting time and materials.

- Efficiency: More power means quicker work.

- Performance: The right power leads to better results.

- Precision: Adequate power ensures accurate cuts.

Why Are Power Requirements Important?

Power requirements affect the speed and quality of metal lathes. If power levels are low, machines can struggle to perform tasks properly. This can lead to mistakes in projects and wasted materials.

Determining Power Requirements for Metal Lathes

Factors influencing power needs (material, operation type, etc.). Calculating the necessary power based on lathe specifications.Power needs for a metal lathe depend on several factors. First, consider the material you are working with; harder materials need more power. Next, think about the type of operation; cutting, drilling, and turning all require different energy levels. It’s like a hamster on a wheel – the more demanding the task, the faster that little guy has to run!

Calculating necessary power is simple. Check your lathe specifications, as they give important details. For instance, a lathe with a higher RPM often needs more horsepower. Here’s a quick table to help:

| Operation Type | Power Required (HP) |

|---|---|

| Cutting Soft Metals | 1-2 |

| Cutting Hard Metals | 2-5 |

| Drilling | 1-3 |

In summary, knowing your material and operation type is key to picking the right power. That way, your lathe won’t throw a tantrum when you start working!

The Role of the Chuck Key in Lathe Operations

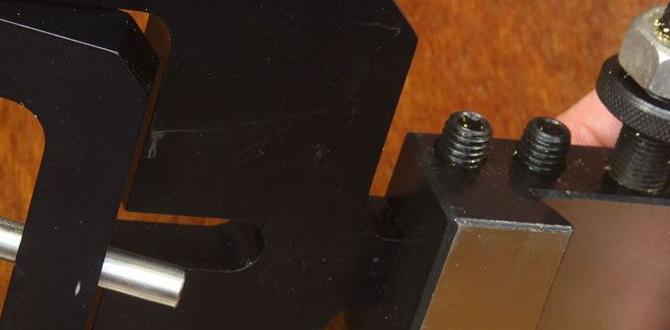

What is a chuck key and its function. Types of chuck keys and their impact on power efficiency.A chuck key is a small tool used with a lathe. Its job is to tighten or loosen the chuck, which holds the metal piece in place. This tool makes sure the metal stays put during cutting. There are different types of chuck keys, including:

- Standard: This key fits most chucks.

- Hex: This type has a hexagonal shape for better grip.

- Quick-release: This key allows for fast changes.

Using the correct chuck key improves power efficiency. A proper fit reduces wear and tear on the lathe, making work faster and smoother.

What is the function of a chuck key?

The function of a chuck key is to securely hold the workpiece in a lathe, ensuring safe and accurate cutting. It allows easy adjustments during operations.

Types of Chuck Keys

- Standard Chuck Key

- Hex Chuck Key

- Quick-release Chuck Key

Calculating Torque Requirements

The relationship between power, torque, and spindle speed. How to calculate required torque for different machining tasks.Power, torque, and spindle speed work together in a metal lathe. Higher speed often means less torque is needed. Torque is crucial for controlling cutting force. To calculate required torque for tasks, you can use the formula: Torque (T) = Power (P) / Spindle Speed (N). This helps you find the right setting for your project.

- More torque is needed for tougher materials.

- Soft materials require less torque.

- Use torque charts for quick reference.

How do you calculate power requirements?

To find power requirements, remember that Power = Torque x Spindle Speed. This can guide you to set your lathe correctly.

Common Power Issues and Solutions

Identifying powerrelated problems in lathe operations. Effective solutions to troubleshoot power deficiencies.Power problems in lathe operations can be sneaky. You might hear strange noises or see your lathe acting like it’s stuck in a mud puddle. First, check for loose wires or weak connections. If you see smoke, run—don’t walk! A fuse might blow like a birthday candle. Here’s a quick troubleshooting table:

| Issue | Possible Cause | Solution |

|---|---|---|

| Low Power | Weak Outlet | Try a different socket |

| Motor Overheating | Blocked Vents | Clear any obstructions |

| Strange Noises | Loose Parts | Tighten everything |

By keeping an eye out for these signs and solutions, you can keep your lathe spinning smoothly. Remember, a happy lathe is a productive lathe!

Maintenance Tips for Power Efficiency

Best practices for maintaining lathe motors and chuck keys. Importance of regular inspections and servicing.To keep your lathe running smoothly, regular maintenance is key. Start by checking the motor for dust and debris. A clean motor is a happy motor! Don’t forget the chuck key; it needs attention too. Make sure it turns easily and fits snugly. Regular inspections can save you time and money in the long run—after all, nobody likes surprises, especially when it comes to machinery!

| Maintenance Task | Frequency |

|---|---|

| Clean motor | Monthly |

| Inspect chuck key | Every use |

| Check lubrication | Every 3 months |

Following these tips will keep your lathe efficient and ready for action. Regular servicing is like giving your machine a little hug. It ensures everything runs smoothly, so you can enjoy your projects without worrying about hiccups! Remember, a well-maintained lathe is a happy lathe!

Future Trends in Lathe Power Technology

Innovations in lathe power systems and their benefits. Predictions for the evolution of lathe technology and power efficiency.New lathe power systems are changing the way we work. Exciting innovations are improving power efficiency. These advancements help machines run faster and safer. They also use less energy, which is great for the planet.

- Smart sensors monitor machine health.

- Advanced motors cut energy use.

- Lighter materials make machines easier to handle.

Experts predict that lathe technology will keep evolving. Future models may be even more efficient and user-friendly. Machines will likely become smarter, adapting to different tasks automatically.

What are some benefits of new lathe technology?

New lathe technology is safer, cheaper, and easier to use. Better energy use lowers costs. Smart features help users finish tasks quickly and accurately.

Conclusion

In summary, understanding lathe power requirements is crucial for using your metal lathe safely and effectively. Always use the correct chuck key to avoid accidents. Make sure your lathe has enough power for your projects. For more tips and advice, consider reading more about lathe maintenance and safety. This will help you become a confident machinist!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Chuck Keys:Sure! Here are some important things to know about lathe power and chuck keys. 1. A lathe needs enough power to spin the metal or wood. This power comes from its motor. 2. A chuck key helps you open and close the chuck, which holds the material you’re working on. 3. It is important to always use the right size of chuck key for your lathe. 4. When you finish using the lathe, always take out the chuck key. It keeps you safe. 5. Remember, safety is key when using a lathe! Always wear safety gear.

Sure! Please share the question you’d like me to answer.

What Factors Influence The Power Requirements Of A Metal Lathe When Machining Different Materials?The power needed for a metal lathe changes based on the material you’re using. Hard materials, like steel, need more power to cut than soft materials, like aluminum. The size of the part also matters—bigger parts need more power. Lastly, the speed of the lathe affects power use; faster cuts usually require more energy.

How Do You Determine The Appropriate Size And Type Of Chuck Key For A Specific Lathe Chuck?To find the right chuck key for your lathe chuck, first look at the chuck itself. Check its size; it should match the teeth inside. You can usually find the size on a sticker or label. If you’re not sure, ask someone for help. Finally, make sure the key type fits the tool you want to use.

What Are The Potential Consequences Of Using An Inadequate Or Incorrect Chuck Key On A Metal Lathe?Using the wrong chuck key on a metal lathe can be really dangerous. You might not be able to tighten the tool properly. This can cause it to slip or even fly off while the lathe is running. If that happens, you could get hurt, or the machine could break. Always use the right key to stay safe and keep things working well!

How Does The Power Consumption Of A Lathe Impact The Overall Efficiency Of A Machining Operation?The power consumption of a lathe affects how well it works. When a lathe uses a lot of power, it can slow down other machines. If it uses less power, we save energy and money. This helps everything run smoother. So, using power wisely makes the whole machining process better!

What Safety Precautions Should Be Taken When Using A Chuck Key With A Metal Lathe?When using a chuck key with a metal lathe, always keep your hands clear of the moving parts. Make sure the lathe is turned off before you attach or remove the chuck key. Always put the chuck key back in its place when you’re done. Wear safety goggles to protect your eyes from any flying metal. Lastly, never leave the chuck key in the chuck while the lathe is running.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some important things to know about lathe power and chuck keys. 1. A lathe needs enough power to spin the metal or wood. This power comes from its motor. 2. A chuck key helps you open and close the chuck, which holds the material you’re working on. 3. It is important to always use the right size of chuck key for your lathe. 4. When you finish using the lathe, always take out the chuck key. It keeps you safe. 5. Remember, safety is key when using a lathe! Always wear safety gear.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Power Requirements Of A Metal Lathe When Machining Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power needed for a metal lathe changes based on the material you’re using. Hard materials, like steel, need more power to cut than soft materials, like aluminum. The size of the part also matters—bigger parts need more power. Lastly, the speed of the lathe affects power use; faster cuts usually require more energy.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Size And Type Of Chuck Key For A Specific Lathe Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right chuck key for your lathe chuck, first look at the chuck itself. Check its size; it should match the teeth inside. You can usually find the size on a sticker or label. If you’re not sure, ask someone for help. Finally, make sure the key type fits the tool you want to use.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Using An Inadequate Or Incorrect Chuck Key On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the wrong chuck key on a metal lathe can be really dangerous. You might not be able to tighten the tool properly. This can cause it to slip or even fly off while the lathe is running. If that happens, you could get hurt, or the machine could break. Always use the right key to stay safe and keep things working well!”}},{“@type”: “Question”,”name”: “How Does The Power Consumption Of A Lathe Impact The Overall Efficiency Of A Machining Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power consumption of a lathe affects how well it works. When a lathe uses a lot of power, it can slow down other machines. If it uses less power, we save energy and money. This helps everything run smoother. So, using power wisely makes the whole machining process better!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Chuck Key With A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a chuck key with a metal lathe, always keep your hands clear of the moving parts. Make sure the lathe is turned off before you attach or remove the chuck key. Always put the chuck key back in its place when you’re done. Wear safety goggles to protect your eyes from any flying metal. Lastly, never leave the chuck key in the chuck while the lathe is running.”}}]}