Lathe for Resin: Your Essential Guide

Yes, you can use a lathe to shape and finish resin! This guide helps beginners choose, set up, and safely use a lathe specifically for resin projects, transforming your creative ideas into polished, professional-looking pieces. Get ready to spin and shape your resin creations!

Creating stunning resin art often involves shaping and refining the final piece. While many techniques exist, using a lathe can elevate your work to a new level of precision and polish. It might sound intimidating if you’re new to lathes, but don’t worry! Many wood lathes are perfectly suited for resin work with a little knowledge and care. This guide is designed to walk you through everything you need to know, from picking the right lathe to mastering the techniques, all in simple, easy-to-understand steps. Forget the jargon and complex manuals; we’re going to break it down so you can confidently start turning your amazing resin projects.

—

Why Use a Lathe for Resin?

You might be wondering why you’d even put resin on a lathe. That’s a great question! Traditionally, lathes are used for wood or metal. However, when resin is cast into a mold, especially cylindrical or irregular shapes that can be mounted, a lathe offers a fantastic way to achieve smooth, symmetrical, and perfectly finished surfaces. It’s especially useful for projects like:

- Pens and pencils

- Candlestick holders

- Vases and bowls

- Custom knobs and handles

- Geode coasters (shaped into rounds)

The precision of a lathe allows you to:

- Achieve perfect roundness and symmetry.

- Sand and polish surfaces to a glass-like finish.

- Carefully remove excess material from cast pieces.

- Create intricate details and shapes not possible with other methods.

It’s a way to take your resin projects from “handmade” to “professionally crafted” with incredible accuracy.

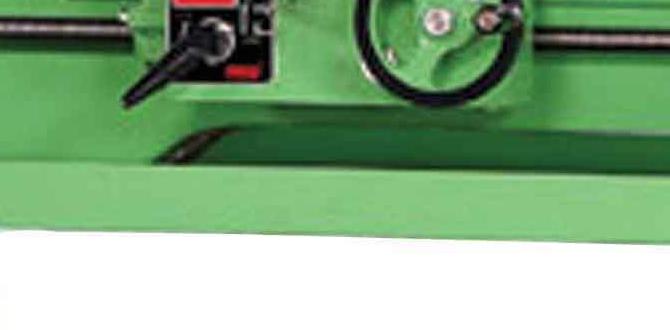

Choosing the Right Lathe for Resin

Not all lathes are created equal, and when it comes to resin, we’re generally looking at wood lathes. Metal lathes are much more powerful and designed for much harder materials, often overkill and potentially dangerous for resin. Here’s what to look for in a wood lathe suitable for resin work:

Key Features to Consider:

- Motor Power: For resin, you don’t need a powerhouse. A motor between 1/2 HP and 1 HP is usually sufficient. This range provides enough torque to shape resin without bogging down, but isn’t so powerful that it becomes uncontrollable.

- Spindle Speed: A variable speed lathe is ideal. This allows you to slow down the rotation for initial shaping and sanding, and then you can increase speed for finer finishing. Look for a lathe with speeds ranging from around 400 RPM up to 2000 RPM or more. Higher speeds can be great for polishing, but be cautious!

- Bed Length and Swing: The bed length determines the maximum length of your workpiece, while the swing (the diameter of the workpiece the lathe can handle) determines the maximum diameter. Consider the typical size of projects you plan to make. For pens and small items, a smaller lathe is fine. For larger bowls or vases, you’ll need a lathe with a longer bed and wider swing.

- Tool Rest: A sturdy and adjustable tool rest is crucial for control and safety. You’ll be holding turning tools against this rest as the resin spins.

- Construction: A heavier, more robust lathe will vibrate less, leading to smoother turning and a safer experience. Cast iron construction is generally preferred.

Small vs. Large Lathes for Resin

The size of the lathe you need really depends on your project scope:

- Mini Lathes: Perfect for beginners and those focused on small items like pens, bottle stoppers, or small intricate pieces. They are affordable, take up less space, and are less intimidating to start with.

- Midi Lathes: A step up, offering more power and capacity for slightly larger projects like small bowls or more substantial decorative items.

- Full-Size Lathes: For serious hobbyists or those creating large bowls, vases, or anything requiring significant material removal or a large swing. These can be expensive and require more space.

For most beginners diving into resin turning, a mini or midi lathe is the sweet spot. They offer enough capability without being overwhelming.

Essential Tools and Accessories for Resin Turning

Once you have your lathe, you’ll need the right tools and accessories to work with resin. Here’s a rundown:

Turning Tools:

While specialized resin turning tools exist, you can often adapt woodworking tools. The key is sharpness and proper technique.

- Gouges: Scalloped or standard bowl gouges (various sizes) are great for roughing out and shaping.

- Scrapers: Round or flat nose scrapers are very useful for smoothing resin surfaces, especially after rough shaping with gouges. They are less aggressive and help prevent tear-out.

- Parting Tools: For cutting off your finished piece from the potentially messy resin blank.

- Detailer: Small tools for adding fine touches.

Important Note on Tool Material: Many carbide-tipped turning tools are excellent for resin. Their inserts are often easily replaceable and can handle the hardness of cured resin very well. Traditional high-speed steel (HSS) tools can also work, but may require more frequent sharpening.

Workholding:

This is how you attach your resin “blank” (the cast resin piece you want to turn) to the lathe.

- Faceplates: A flat disc that screws onto the lathe spindle. You then securely attach your resin blank to the faceplate using strong epoxy or screws (if the design allows). This is common for flat blanks like coaster sets or platters.

- Chucks: These are versatile gripping devices that mount on the spindle. They have jaws that can expand or contract to grip the inside or outside of a workpiece. For resin, a chuck is often used to hold a drilled hole or a pre-formed base. Look for a scroll chuck designed for woodturning; many can handle resin well.

- Screws/Drill Bits: Sometimes, you might drill a hole into your resin blank and attach it directly to the lathe spindle using mounting screws or a specialized screw chuck. Ensure the resin is thick enough to handle this.

Safety Gear:

Absolutely non-negotiable! Resin dust, even though it’s not as fine as wood dust, can be an irritant. And flying bits of resin are dangerous.

- Safety Glasses or Face Shield: Protect your eyes from flying debris. A full face shield is highly recommended.

- Dust Mask or Respirator: While resin dust might seem inert, it’s best to avoid inhaling it. A good quality dust mask (N95 or better) or a respirator is essential.

- Hearing Protection: Lathes can be noisy.

- Apron: To protect your clothes.

Other Useful Items:

- Epoxy or Strong Adhesive: For attaching blanks to faceplates or for repairs.

- Sandpaper: Various grits, from coarse to very fine (400, 600, 800, 1000, 2000 grit and higher for polishing).

- Polishing Compounds: For achieving a mirror shine.

- Transfer Punch Set: For marking drill points.

- Drill and Drill Bits: For creating mounting holes.

- Woodturning Tool Rest Extension: If your standard tool rest isn’t long enough for your projects.

Having these items ready will make your resin turning sessions much smoother and safer.

Preparing Your Resin for the Lathe

Casting resin is just the first step. Preparing your cast piece for the lathe is crucial for success and safety.

1. Casting the Blank

You’ll need to cast your resin in a way that allows you to mount it. Common methods include:

- Casting into a Mold: Pouring resin into a cylindrical or appropriately shaped mold. If you plan to turn a bowl, you might cast a thicker, irregular disc that can later be chocked or mounted.

- Casting onto a Core/Insert: For items like pens, you’ll typically cast resin around a metal tube insert. This tube will become your mounting point.

- Casting for Faceplate Mounting: For flat items like coasters or thin decorative discs, you might cast a roughly circular blank that you can later drill and attach to a faceplate.

2. Ensuring Full Cure

This is critical. Resin must be fully cured before you attempt to turn it. Most casting resins take 24-72 hours to reach full hardness, sometimes longer depending on ambient temperature and humidity. Attempting to turn uncured or under-cured resin can lead to:

- Gooey, sticky material sticking to your tools and the lathe.

- Poorly shaped or crumbling pieces.

- Unpredictable material behavior.

- Potentially dangerous tool catches.

Always follow the manufacturer’s curing instructions. It’s better to wait a little longer than to risk ruining your project and potentially damaging your tools or lathe.

3. Creating a Mounting Point

How you mount your piece depends on its shape and how you plan to work it. You need a stable, centered attachment to the lathe.

- Drilling for Chuck Jaws: If you’ve cast a solid blank (like a simple cylinder awaiting shaping into a vase), you might drill a centered hole that your chuck jaws can grip.

- Using a Metal Tube (for pens): If you cast around a metal tube, this tube can often be held in the chuck jaws or have a screw chuck attached to it.

- Drilling for Faceplate Mounting: For flat items, you’ll drill pilot holes at strategic points on the blank. These holes should match the mounting holes on a faceplate. Use a transfer punch to ensure accurate placement.

- Using a Screw Chuck: Some turners use a specialized screw chuck that screws into a pre-drilled hole in the resin blank. The chuck itself then mounts to the lathe.

Centering is Key: Whatever method you use, ensure your resin blank is as accurately centered as possible. An off-center blank will vibrate excessively, making it very difficult to turn and dangerous. Use a digital or mechanical indicator to check runout after mounting.

Step-by-Step: Turning Your Resin Project

Once your blank is prepared and securely mounted, you’re ready to turn. Remember safety first!

Step 1: Set Up Your Lathe and Safety Gear

- Put on your safety glasses/face shield, dust mask, and hearing protection.

- Ensure your tool rest is positioned correctly and securely. For rough shaping, the rest should be close to the blank (about 1/8″ or 3mm gap) and slightly below the center line of the workpiece.

- Adjust your tool rest as you progress to stay close to the work.

Step 2: Mount Your Resin Blank

- Securely attach your prepared resin blank to the lathe using your chosen method (faceplate, chuck, screw chuck).

- Double-check that it’s tight and centered.

- Spin the lathe by hand to ensure there’s clearance for your tools and tool rest. Check for any parts that are hitting or might hit.

Step 3: Initial Shaping (Roughing)

- Start the lathe at a slow speed. For roughing out resin, speeds between 600-1200 RPM are usually a good starting point. Higher speeds can cause the resin to melt slightly, clog tools, and potentially lead to tears or catches.

- Use a gouge or scraper to begin removing material.

- Hold the tool firmly against the tool rest and engage the resin with a smooth, controlled motion.

- Take light cuts. Don’t try to remove too much material at once.

- Listen to the lathe and feel the tool. If there’s a lot of chatter or vibration, slow down, take lighter cuts, or ensure your blank is centered.

- Shape the blank to your desired basic form.

Step 4: Refining and Shaping

- Once the basic shape is achieved, you can refine it.

- You might slightly increase the speed, but still keep it moderate (e.g., 1000-1500 RPM).

- Use scrapers and sharper gouges to smooth out tool marks from the roughing stage.

- Pay attention to the surface. Resin can melt if too much friction is generated. Keep your tools sharp!

Step 5: Sanding

This is where you’ll start revealing the polished finish. This can be done either on the lathe or off.

- On the Lathe:

- Slow the lathe down significantly – often to speeds between 300-800 RPM.

- Start with a coarse grit sandpaper (e.g., 100-150 grit) and hold it against the spinning resin while applying gentle pressure. Move the sandpaper back and forth to avoid creating flat spots.

- Progress through finer grits (220, 320, 400, 600, 800, 1000, 1200, 1500, 2000+).

- With each grit, ensure you’ve removed the scratches from the previous one before moving to finer grits.

- Off the Lathe: You can also use random orbital sanders or sanding blocks off the lathe, especially for larger or flatter areas.

Step 6: Polishing

This is the final step to achieve that amazing shine. This is almost always done on the lathe.

- Use a polishing compound specifically designed for plastics or finishes. Some woodturners use a buffing wheel or a soft cloth with a polishing compound.

- Apply a small amount of compound to the resin or your buffing tool.

- With the lathe at a moderate to high speed (e.g., 1500-2000+ RPM), gently apply the buffing tool to the resin. The friction will generate heat, which helps the compound work.

- Work in sections and keep the polishing tool moving.

- You can then use a clean, soft cloth to buff off any residue and reveal a brilliant shine.

Step 7: Final Finishing

- After polishing, inspect your piece.

- You might apply a finishing wax or sealant for added protection and shine, especially if it will be handled frequently.

Speed Recommendations Summary Table:

Here’s a general guide for speeds. Always start slow and adjust based on how the resin behaves.

| Operation | Recommended Speed (RPM) | Notes |

|---|---|---|

| Mounting Check (Spinning by Hand) | 0 | Ensure no binding. |

| Roughing/Initial Shaping | 600 – 1200 | Take light cuts. Avoid melting. |

| Refining/Smoothing | 1000 – 1500 | Sharper tools help. |

| Sanding (Coarse to Medium) | 300 – 800 | Gentle pressure, keep moving. |

| Sanding (Fine) & Polishing | 1500 – 2000+ | Use polishing compounds. Heat helps. |

Tips for Turning Different Types of Resin

Different resin types can behave slightly differently on the lathe.

- Epoxy Resins (Casting Resins): These are the most common for DIY projects. They generally turn well once fully cured. Be aware that some epoxies can be quite hard. Pigments, glitter, or inclusions can affect the turning characteristics. For example, glitter can sometimes smear rather than sand cleanly.

- UV Resins: While often cured in layers, if you manage to cast a solid blank of UV resin, it tends to be very hard and can sometimes be brittle. It might be prone to chipping if tool pressure is too high.

- Polyurethane Resins: Can vary widely. Some are softer, some are very hard. Test a scrap piece if possible.

Dealing with Inclusions: Glitter, mica powders, and other inclusions can pose challenges. Glitter can melt or smear. Mica powders can load up sandpaper. The key is usually slower speeds, very sharp tools, and progressing through grits diligently.

<p