Have you ever wondered how a lathe works? It’s like magic when metal turns into something useful. But what if that magic isn’t happening? One common problem is with the tailstock alignment of your metal lathe.

Imagine you’re ready to create the perfect cylinder. But your tailstock is off just a little bit! Your project can end up ruined. It’s frustrating, right? Luckily, you can fix this issue. Tailstock alignment is essential for accuracy in your work.

In this article, we will explore lathe restoration. We’ll focus on how to align the tailstock properly. You’ll learn simple steps to make your lathe work like new. Join us on this journey to restore your tools and improve your skills!

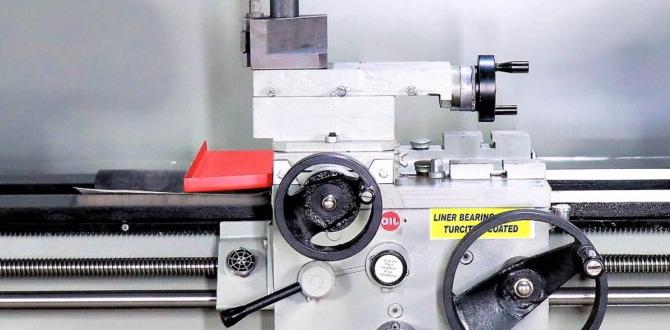

Lathe Restoration: Metal Lathe Tailstock Alignment Techniques

Lathe Restoration: Metal Lathe Tailstock Alignment

Getting your metal lathe tailstock aligned can be a game changer. It helps you make precise cuts and ensures your projects turn out great. Did you know that many people struggle with tailstock alignment? It’s often a simple adjustment that can boost your lathe’s performance. By checking for wear and maintaining a level support, you can restore your lathe’s accuracy. Proper alignment makes all the difference, bringing your projects to life with ease and efficiency!Understanding Tailstock Alignment

Definition and significance of tailstock alignment in metal lathes. Common issues resulting from poor tailstock alignment.Tailstock alignment is key for metal lathes. It ensures your workpiece stays straight and secure during machining. Proper alignment boosts accuracy and extends the life of your lathe. Without it, you may face common problems like:

- Uneven cuts: This can lead to poor quality work.

- Vibration: Misalignment causes excess movement, creating noise.

- Increased wear: Poor alignment speeds up damage to machine parts.

In summary, always check your tailstock alignment. It saves time and helps you produce better pieces.

What are the signs of poor tailstock alignment?

Signs include uneven cuts, vibration during operation, and excessive tool wear. These issues can cause frustration and reduce your work’s quality.

Signs Your Tailstock Needs Realignment

Identifying symptoms of misalignment. Impact on machining accuracy and quality.When your tailstock is off, it can cause problems. You may see signs like uneven cuts or wobbly pieces. This can create poor machining quality. Watch for these symptoms:

- Parts aren’t square or straight.

- Readings on your measuring tools are off.

- Strange sounds while machining.

Misalignment can lower your work’s accuracy. Poor quality can lead to wasted materials. No one wants that!

What are the signs of tailstock misalignment?

The main signs include uneven cuts, wobbly workpieces, or inaccurate measurements during machining. Identifying these early helps maintain your lathe.

Essential Tools for Tailstock Alignment

List of tools required for effective tailstock alignment. How to choose the right tools for your metal lathe.To align a tailstock properly, you need the right tools. Here’s a handy list:

- Tailstock alignment gauge

- Dial indicator

- Feeler gauge

- Torque wrench

- Calipers

Choosing tools is key. Make sure they are durable and precise. Quality tools help you get accurate results. Check prices and reviews to find the best options.

What tools are essential for tailstock alignment?

Essential tools include a tailstock alignment gauge, dial indicator, and feeler gauge. These help ensure your metal lathe operates smoothly and correctly.

Aligning a tailstock is crucial for precision work. Did you know that proper alignment can improve the accuracy of your cuts? This simple step can boost your project’s success. Remember, quality matters!

Step-by-Step Tailstock Alignment Process

Instructions for initial setup before alignment. Detailed steps for achieving precise tailstock alignment.Before starting the tailstock alignment, make sure everything is set up properly. First, check the lathe bed for flatness. Use a level or a precision straightedge for this. Then, inspect the tailstock for any visible damage. Ensure it moves smoothly along the bed. Follow these steps for precise alignment:

- Loosen the tailstock screws slightly.

- Align the tailstock with the spindle.

- Tighten the screws gradually.

- Use a dial indicator to measure accuracy.

- Make small adjustments if necessary.

For best results, repeat the measuring until satisfied. Accurate alignment leads to better machining results!

How do you align a tailstock?

To align a tailstock, you need to lift and adjust it until it lines up with the spindle. Check it using a dial indicator and tighten it once it’s straight. Alignment ensures smoother cuts.

Techniques for Testing Tailstock Alignment

Methods to check alignment accuracy. Troubleshooting common alignment issues.To ensure your tailstock is aligned, you can use a few simple methods. First, check alignment by using a precision test bar. Place it in the spindle and measure the distance from the bar to the tailstock. Next, try the paper test. Slide a piece of paper between the tailstock and the bar. If it catches, the alignment might be off. For common issues, look for worn parts or loose screws. Tightening these might solve the problem.

What are some easy steps to test tailstock alignment?

You can use a test bar or a paper test to check if your tailstock is aligned correctly. Both are simple methods that give quick results.

Steps to follow:

- Use a precision test bar.

- Perform the paper test.

Maintenance Tips for Longevity of Tailstock Components

Best practices for regular maintenance. Tips for preserving the lifespan of the tailstock and its alignment.To keep your tailstock in top shape, regular maintenance is key. Check for wear and tear often. Clean all parts to remove dust and grime. Use a light oil for lubrication to avoid rust. Proper alignment is crucial. Here are some best practices:

- Inspect the tailstock regularly.

- Keep it clean and oiled.

- Ensure correct alignment every time you use it.

- Store it in a dry place to prevent moisture damage.

Following these steps will help extend the life of your tailstock, keeping it efficient and reliable.

How can I align my tailstock properly?

To align your tailstock correctly, adjust it with a dial indicator for accuracy. Ensure it matches the spindle axis. Regular checks will keep your lathe running smoothly!

Common Mistakes to Avoid During Tailstock Alignment

List of pitfalls that could lead to poor results. How to ensure a successful alignment process.Aligning your tailstock is like tuning a musical instrument. If you make mistakes, it can affect your work. Here are some common pitfalls:

- Not checking the bed for damage

- Skipping the pre-alignment check

- Using incorrect tools for alignment

- Ignoring the tailstock lock mechanism

To avoid these errors, it’s important to take your time and follow the steps carefully. Measure twice and adjust as needed, ensuring the tailstock lines up perfectly. A well-aligned tailstock leads to smoother cuts and better projects!

What are some tailstock alignment mistakes to watch out for?

Be mindful of checking the bed for damage and skipping pre-alignment checks. Using the right tools and securing the tailstock are key to neat results!

Resources for Further Learning

Recommended books, videos, and forums for metal lathe enthusiasts. Online communities for sharing knowledge and experiences related to tailstock alignment.If you want to dive deeper into the world of metal lathes, there are some great resources out there! For books, check out “The Metal Lathe” by David J. Gingery—it’s a must-read. YouTube has a treasure trove of videos; channels like NYC CNC explain everything, even if you think a tailstock is just a fancy hat! Online forums, like Practical Machinist, allow enthusiasts to share tips and tricks. Don’t be shy; ask questions and share your funny mishaps too!

| Resource Type | Name |

|---|---|

| Book | The Metal Lathe by David J. Gingery |

| Video | NYC CNC |

| Forum | Practical Machinist |

Conclusion

In conclusion, aligning the tailstock on a metal lathe is crucial for precise work. You should check for misalignment regularly. Simple adjustments can make a big difference in your projects. For a hands-on guide, consider reading more about specific alignment techniques. With practice, you’ll improve your skills and enjoy better results. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration And Tailstock Alignment:Sure! Here are five questions you might ask about fixing a lathe and keeping the tailstock straight. 1. How do I clean my lathe? 2. What tools do I need for restoration? 3. How can I tell if my tailstock is aligned? 4. Why is tailstock alignment important? 5. What if my tailstock is not straight? These questions will help you understand how to take care of your lathe!

Sure! Please provide the question you want me to answer.

What Are The Common Signs That Indicate A Misalignment In The Tailstock Of A Metal Lathe?If the tailstock of your metal lathe is misaligned, you might notice some problems. First, your work pieces may not be straight. They might wobble or not fit right. Second, you could see uneven cuts on your material. Finally, it might be hard to keep your tools in the right place. These signs mean it’s time to check the tailstock.

What Tools Or Methods Can Be Used To Accurately Align The Tailstock On A Metal Lathe During Restoration?To align the tailstock on a metal lathe, you can use a few simple tools. A dial indicator helps measure tiny distances and check if it’s straight. You can also use a measuring tool called a caliper to check the distance from the tailstock to the spindle. Another method is to use a test rod, which is a straight piece that lets you see if everything lines up. Finally, adjusting the screws on the tailstock can help you get it just right.

How Does Tailstock Alignment Affect The Precision Of Machining Operations On A Metal Lathe?When we use a metal lathe, the tailstock helps hold the tool in place. If it’s not lined up right, the tool can wobble. This wobbling makes it hard to cut the metal evenly. So, careful alignment helps us make better shapes and sizes. That way, our work is neat and fits together well.

What Are The Step-By-Step Procedures To Check And Adjust The Tailstock Alignment After Restoring A Lathe?To check and adjust the tailstock on a lathe, follow these steps. First, use a long, straight rod called a test bar. Place it in the lathe and tighten it. Now, see if the test bar is straight by looking at the ends. If it isn’t, loosen the tailstock screws, then gently move it until the ends line up. Tighten the screws again and check with the test bar. Repeat if needed until it’s perfect!

Are There Specific Maintenance Practices That Can Help Maintain Proper Tailstock Alignment Over Time?Yes, you can keep the tailstock aligned by checking it regularly. First, clean it to remove dust and dirt. Then, make sure all screws are tight and not loose. You can also check its position with a ruler or special tool. If you notice anything off, fix it right away!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration And Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about fixing a lathe and keeping the tailstock straight. 1. How do I clean my lathe? 2. What tools do I need for restoration? 3. How can I tell if my tailstock is aligned? 4. Why is tailstock alignment important? 5. What if my tailstock is not straight? These questions will help you understand how to take care of your lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Misalignment In The Tailstock Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock of your metal lathe is misaligned, you might notice some problems. First, your work pieces may not be straight. They might wobble or not fit right. Second, you could see uneven cuts on your material. Finally, it might be hard to keep your tools in the right place. These signs mean it’s time to check the tailstock.”}},{“@type”: “Question”,”name”: “What Tools Or Methods Can Be Used To Accurately Align The Tailstock On A Metal Lathe During Restoration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, you can use a few simple tools. A dial indicator helps measure tiny distances and check if it’s straight. You can also use a measuring tool called a caliper to check the distance from the tailstock to the spindle. Another method is to use a test rod, which is a straight piece that lets you see if everything lines up. Finally, adjusting the screws on the tailstock can help you get it just right.”}},{“@type”: “Question”,”name”: “How Does Tailstock Alignment Affect The Precision Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a metal lathe, the tailstock helps hold the tool in place. If it’s not lined up right, the tool can wobble. This wobbling makes it hard to cut the metal evenly. So, careful alignment helps us make better shapes and sizes. That way, our work is neat and fits together well.”}},{“@type”: “Question”,”name”: “What Are The Step-By-Step Procedures To Check And Adjust The Tailstock Alignment After Restoring A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the tailstock on a lathe, follow these steps. First, use a long, straight rod called a test bar. Place it in the lathe and tighten it. Now, see if the test bar is straight by looking at the ends. If it isn’t, loosen the tailstock screws, then gently move it until the ends line up. Tighten the screws again and check with the test bar. Repeat if needed until it’s perfect!”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Practices That Can Help Maintain Proper Tailstock Alignment Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can keep the tailstock aligned by checking it regularly. First, clean it to remove dust and dirt. Then, make sure all screws are tight and not loose. You can also check its position with a ruler or special tool. If you notice anything off, fix it right away!”}}]}