Have you ever wondered how metal parts get such smooth surfaces? The secret often lies in a lathe. A lathe surface finish is crucial for many products we use daily. It helps parts fit together just right. Think about how annoying it is when things don’t fit well. That frustration can often be avoided with the right finish.

Picture this: you walk into a workshop and see a metal lathe machine spinning. It’s like watching an artist at work. With each turn, it carves away rough edges. This process creates a finish that shines.

But what exactly makes the difference between a good and a great finish? The answer lies in understanding how these machines work. The quality of the finish affects everything from the look of a product to its lifespan. Knowing this can save you time and money. Let’s dive deeper into the world of lathe surface finishes and see what we can discover!

Lathe Surface Finish: Enhancing Metal Lathe Machine Precision

Understanding Lathe Surface Finish in Metal Lathe Machines

Lathe surface finish is crucial for metal lathe machines. A shiny, smooth surface often means better quality parts. Did you know that a good finish can reduce friction? This helps in extending the tool’s life. You’ll learn that factors like cutting speed and tool material affect the finish. If you want precise results, mastering these elements is key. Imagine creating a perfectly polished metal piece; it’s easier than you think!Understanding Lathe Surface Finish

Definition of surface finish and its importance in machining. Common surface finish metrics: Ra, Rz, Rq.Surface finish means how smooth or rough a metal piece is after machining. It’s like giving your metal a nice haircut! Having a good finish is important. It can help parts fit better and last longer. Common ways to measure this are Ra, Rz, and Rq. Think of them as different ways to grade the smoothness. Ra is average roughness, Rz is the average of the highest peaks and deepest valleys, and Rq is like Ra’s stylish cousin. Here’s a little table to break it down:

| Metric | Description |

|---|---|

| Ra | Average roughness |

| Rz | Average peak-to-valley height |

| Rq | Root mean square roughness |

So, next time you see a shiny piece of metal, remember it’s not just a pretty face – it’s also got a great finish!

Factors Influencing Surface Finish in Lathe Operations

Material type and its impact on finish quality. Tool selection and characteristics, including cutting edge geometry.Many factors affect how smooth a metal surface becomes when using a lathe. One factor is the type of material. Softer materials like aluminum create a finer finish compared to harder ones like steel. Another key influence is the tools used. The geometry of the cutting edge shapes how well the tool cuts.

- Material Type: Soft metals yield better finishes.

- Tool Selection: Sharp tools cut smoother.

- Cutting Edge Geometry: Angles and shapes affect precision.

How does material type affect surface finish?

Materials like aluminum provide finer finishes than harder metals like steel. Softer materials are easier to cut, leading to improved surface quality.

What role does tool selection play in surface finish?

Sharp tools make smoother cuts. The right tool helps achieve better precision and finish quality, making your project look great.

Cutting Parameters and Surface Finish

The role of cutting speed, feed rate, and depth of cut. The significance of optimal parameter settings for achieving desired results.The cutting speed, feed rate, and depth of cut are key factors that affect how smooth the metal surface becomes. Each of these parameters has a unique role:

- Cutting Speed: This is how fast the tool moves. Faster speeds can give a smoother finish.

- Feed Rate: This is the amount of material removed per pass. A slower feed often improves the finish.

- Depth of Cut: This is how deep the tool cuts into the material. Shallower cuts usually lead to a better surface finish.

Finding the right settings is important. Optimal parameters can significantly improve results and bring out the best finish. It’s like making a cake—you need the right mix to get it just right!

What are the optimal settings for cutting parameters?

Optimal settings vary based on the material and the desired finish. Always experiment to find the perfect balance that works for your specific project!

Tooling for Optimal Surface Finish

Types of cutting tools suitable for achieving fine finishes. The impact of tool coatings and materials on performance.Choosing the right cutting tools is key for a great surface finish on metal. Here are some tool types commonly used:

- High-Speed Steel (HSS) tools are strong and last long.

- Carbide tools cut smoothly and handle heat well.

- Ceramic tools can cut very fast and are tough.

Tool coatings matter too! Special coatings can help your tools last longer and make cutting easier. For example, titanium nitride helps reduce friction. This means a better finish with less work!

What cutting tools are best for surface finish?

The best cutting tools are High-Speed Steel, Carbide, and Ceramic tools. Each type offers unique benefits for different tasks.

How do coatings affect tool performance?

Tool coatings improve durability and cutting performance. They lower friction and help achieve a smoother finish, making your work easier and better.

Lathe Setup and Maintenance for Best Results

Importance of proper machine alignment and calibration. Regular maintenance practices to ensure consistent surface quality.Setting up a metal lathe machine correctly is crucial for quality results. Proper alignment and calibration ensure that every cut is precise. Regular maintenance is key to maintaining consistent surface quality. Here are some important practices:

- Check alignment regularly.

- Calibrate tools before use.

- Lubricate moving parts often.

- Clean the machine after each session.

These steps help the lathe perform its best. Remember, a well-maintained machine leads to better surface finishes!

Why is proper setup important?

Proper setup improves accuracy and reduces mistakes. A small error can affect the entire project, making it crucial to align correctly.

Finishing Techniques for Enhanced Surface Quality

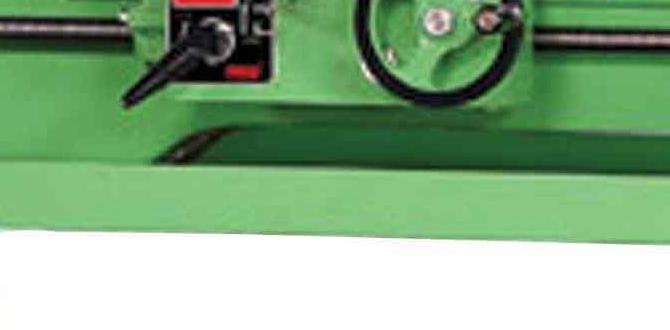

Various finishing processes: grinding, polishing, and buffing. When and how to apply finishing techniques postlathing.After using a metal lathe, finishing techniques can help enhance the surface quality. Popular methods include grinding, polishing, and buffing. Each technique is useful depending on the desired finish. For example, grinding creates a smoother surface, while polishing adds shine. Buffing helps achieve a high gloss finish. Apply these techniques after lathing to make your work look professional.

What are the different finishing processes?

Grinding, polishing, and buffing are the main finishing processes used after lathing.Some quick tips:

- Grinding: Use for removing material and achieving smoothness.

- Polishing: Best for adding a shiny finish.

- Buffing: Ideal for creating a high gloss effect.

Finishing not only improves appearance but also protects the metal. Remember, a tidy finish can make your project stand out more!

Common Problems and Solutions in Achieving the Desired Finish

Identifying issues like chatter and tool wear. Practical troubleshooting tips for resolving surface finish defects.Uneven surfaces can spoil your hard work with a lathe. Common issues include chatter and tool wear. Chatter creates vibrations that ruin smoothness. Tool wear can lead to rough cuts. Here are simple solutions:

- Check tool sharpness regularly.

- Reduce cutting speed to minimize chatter.

- Use proper feed rates to match the material type.

- Ensure the lathe is stable and firmly set.

Fixing these issues can lead to a better finish. Remember, practice helps improve your skills over time!

What can cause a poor surface finish on a lathe?

Common causes are tool wear, incorrect speeds, or poor machine alignment. Proper adjustments and regular maintenance can help avoid these problems.

Best Practices for Quality Control in Lathe Operations

Importance of inspection methods and equipment. Implementing quality management strategies in machining processes.Inspecting your work is important for lathe operations. Good inspection methods help find mistakes early. This saves time and money. Use tools like calipers, gauges, and micrometers to check sizes and shapes. Quality management strategies keep your process smooth. They help ensure every piece meets standards. Here are some tips:

- Check tools regularly for wear.

- Keep records of inspections.

- Train workers on quality checks.

- Review processes often to improve.

These steps lead to better parts and satisfied customers.

Why is quality control important in lathe operations?

Quality control ensures that parts are made correctly. It helps prevent costly errors and helps maintain customer trust.

Conclusion

In summary, the lathe surface finish is crucial for metal lathe machines. A smooth finish improves the look and function of your project. You can achieve this by selecting the right tools and techniques. Try experimenting with different settings on your lathe. For more tips, check out beginner guides or videos online. Happy machining!FAQs

What Factors Influence The Surface Finish Produced By A Metal Lathe Machine?The surface finish from a metal lathe machine depends on a few important factors. First, the type of tool we use affects how smooth the metal gets. Second, the speed of the machine can change the finish too; faster speeds can create lighter marks. Third, how hard we press the tool against the metal matters, as too much pressure can make the finish rough. Lastly, we need to choose the right types of metal, as some are smoother than others.

How Do Tool Geometry And Material Selection Affect The Quality Of The Surface Finish In Lathe Operations?Tool geometry is the shape and angles of the cutting tool. If the tool is sharp and shaped well, it cuts cleanly. This makes the surface of the material smooth. Material selection means picking the right kind of metal or wood for your project. Using the right materials helps get a better finish because they work well with the tool.

What Are The Different Methods For Measuring Surface Finish In Components Machined On A Lathe?We can measure surface finish in different ways. One method is using a tool called a roughness tester that feels the surface. You can also use a microscope to look closely for bumps and dips. Another easy way is to feel the surface with your fingers. Each method helps us know how smooth or rough a part is.

How Can Lathe Operators Improve Surface Finish Without Compromising Machining Speed?You can improve surface finish by using sharp tools. Sharp tools cut better and make smoother surfaces. You should also adjust the speed of the lathe. By finding the right speed, you can cut faster and still make a nice finish. Lastly, try using the right type of cutting oil. This helps keep things cool and smooth.

What Role Does Cutting Speed And Feed Rate Play In Achieving Optimal Surface Finish When Using A Metal Lathe?Cutting speed is how fast the tool moves through the metal. A faster speed can give a smoother surface. Feed rate is how much the tool moves sideways with each turn. If you set it just right, it helps make a nice finish too. So, finding the right speed and feed helps make your metal piece look great!