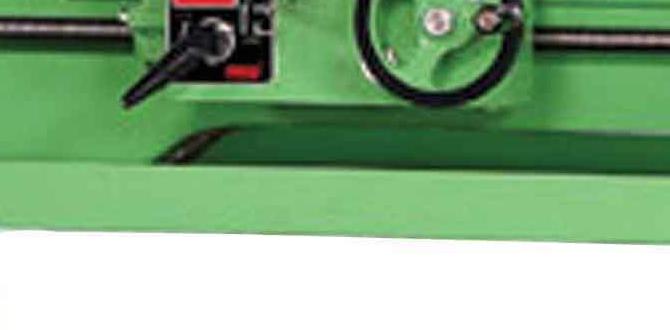

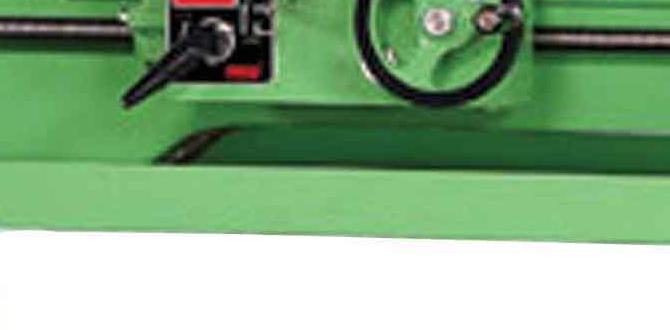

Have you ever wondered how metal parts get their shiny, smooth finishes? It’s like magic! But, it’s all about using a machine called a lathe. This incredible tool shapes metal into amazing designs. One key part of this machine is the tailstock. It helps hold the workpiece steady while you shape it.

Did you know that a good surface finish can make a huge difference? It can affect how a part looks and how well it works. Imagine if your toy car’s wheels were rough. It wouldn’t roll smoothly, right? That’s why understanding lathe surface finish is super important!

In this article, we will explore the world of metal lathes and their tailstocks. We’ll learn how to get the best surface finishes. Are you ready to dive into this exciting journey? Let’s get started!

Lathe Surface Finish: Optimizing Metal Lathe Tailstock Performance

Understanding Lathe Surface Finish and Tailstock Use

Lathe surface finish is vital for creating smooth, polished metal pieces. A metal lathe tailstock plays a key role in achieving this finish. It helps support long workpieces, preventing them from bending. Did you know that a smooth finish can improve a part’s performance? Choosing the right tools and settings makes a difference. With proper care, your lathe can deliver stunning results that meet high standards. Finding the right balance ensures your projects shine!Understanding Lathe Surface Finish

Definition and significance of surface finish in machining.. Common surface finish parameters and measurement techniques..Surface finish is the final texture of a material after machining. A good surface finish is essential because it affects how well parts fit and function together. It can improve the part’s strength and help prevent wear over time. There are different ways to measure surface finish quality, including:

- Roughness – how coarse or smooth the surface is.

- Waviness – the larger patterns on the surface.

- Lay – the direction of the surface pattern.

Measurement tools like micrometers and surface roughness testers help check these qualities. Remember, a better surface finish often leads to a better product!

What is the Importance of Surface Finish?

A smooth surface finish ensures parts work well together and last longer.

The Role of the Tailstock in Achieving Optimal Surface Finish

Explanation of the tailstock’s function and adjustments.. How tailstock setup affects surface finish quality..The tailstock is important for getting a smooth surface finish on metal. It holds the other end of the workpiece, providing stability. If set up properly, it helps keep everything centered. This support reduces vibrations and wobbling, which can spoil the finish.

Adjustments can influence quality. A wrongly set tailstock may lead to rough or uneven surfaces. Always check the alignment.

- Stable support: Helps keep parts steady.

- Proper alignment: Reduces vibration.

- Adjustable settings: Fine-tunes the fit.

How does tailstock setup affect surface finish quality?

A well-set tailstock improves surface finish by ensuring the workpiece remains steady during machining. This reduces chances of errors that can make the finish uneven.Essential Tools and Techniques for Improving Surface Finish

Recommended cutting tools for optimal surface finish.. Techniques for turning, facing, and finishing operations..To achieve a great surface finish on your lathe projects, choose the right cutting tools. High-speed steel (HSS) and carbide inserts work wonders! They are sharp and last long, making them perfect for smooth cuts. For turning, keep your tool at a 7-degree angle. This reduces chatter and helps finish nicely. While facing, take shallow cuts for a flawless surface. And don’t forget the finishing touches! A quick buff with a soft cloth can make your work shine like a star.

| Tool Type | Benefits |

|---|---|

| High-speed Steel (HSS) | Great sharpness and durability |

| Carbide Inserts | Long-lasting and perfect for smooth finish |

Maintaining Your Metal Lathe for Superior Surface Finishing

Importance of regular maintenance and calibration.. Tips for keeping the lathe clean and operational..Regular maintenance is key for a metal lathe. It helps in achieving a smooth surface finish and keeps your lathe running well. Calibration checks ensure everything is accurate. Here are some tips for maintenance:

- Clean chips and dust after each use.

- Check belts and gears for wear.

- Lubricate moving parts regularly.

- Inspect the tailstock for accuracy.

A well-maintained lathe works better and lasts longer. It can save you time and money.

Why is Regular Lathe Maintenance Important?

Regular maintenance is crucial because it prevents costly repairs and ensures safety during operations.

Common Issues and Troubleshooting Surface Finish Problems

Identification of common surface finish defects.. Solutions to rectify issues related to the tailstock and cutting tools..Surface finish problems can happen when using a metal lathe. Some common defects include rough spots and uneven surfaces. Identifying these issues early can save time and materials. Here are some problems to look for:

- Scratches on the surface

- Pitting or small holes

- Uneven thickness

To fix these issues, check the tailstock and cutting tools first:

- Make sure the tailstock is aligned properly.

- Inspect cutting tools for wear or damage.

- Use the right cutting speed and feed rate.

These steps can help improve your surface finish and make your work look better!

What are common defects in lathe surface finishes?

Common defects include scratches, pitting, and uneven thickness. These issues can affect the final quality of the product.

How to fix surface finish issues?

Check alignment, inspect tools, and adjust speeds for better results.

Best Practices for Precision Machining with Tailstock

Recommended practices for setup and operation.. Importance of testing and quality assurance in surface finishing..To get the best results with your tailstock, start with a solid setup. Make sure everything is tight, but don’t overdo it, or you might feel like a strongman at a carnival! Regularly check alignment for smooth operation. Testing your work is essential. Remember, if it doesn’t look good, it probably isn’t good! Quality assurance helps catch those sneaky mistakes before they ruin your finish. Think of it as a superhero cape for perfect surfaces!

| Best Practices | Importance |

|---|---|

| Check tailstock alignment | Prevents mistakes |

| Tighten components | Reduces wobble |

| Test surfaces | Ensures quality |

Conclusion

In summary, using a lathe can give you smooth metal surfaces. The tailstock helps securely hold your workpiece. Good surface finish improves your projects’ overall quality. Experimenting with different speeds and feeds can enhance your results. Keep learning about lathe techniques and consider practicing on scrap metal. You’ll soon create impressive, polished items that you can be proud of!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And The Metal Lathe Tailstock:Sure! Here are five questions about lathe surface finish and the tailstock: 1. What is a lathe? A lathe is a machine that helps us shape metal and wood. 2. Why is surface finish important? The surface finish makes the object smooth or rough, which affects how it looks and works. 3. What is a tailstock? The tailstock is a part of the lathe. It holds tools and helps push the material while we work. 4. How can we improve surface finish? We can improve it by using sharp tools and going slowly. 5. What do we use the tailstock for? We use the tailstock to support long pieces and to hold drill bits for making holes.

Sure! Just ask your question, and I’ll give you a clear and simple answer.

What Factors Influence The Surface Finish Quality When Using A Metal Lathe Tailstock During Machining Operations?When using a metal lathe tailstock, several things affect how smooth the surface of the metal will be. First, make sure the tailstock is lined up correctly. If it’s off, the tool can scratch the metal. Second, use the right speed for the lathe. If it’s too fast or too slow, it can create a rough finish. Finally, choose sharp tools because dull tools can make the surface look bumpy.

How Does The Alignment And Adjustment Of The Tailstock Impact The Accuracy And Surface Finish Of The Workpiece?When the tailstock is lined up correctly, it helps keep the workpiece steady. This makes it easier to cut evenly. If the tailstock is off, the workpiece can wobble. A wobbly workpiece can end up with rough edges, which hurts how smooth it feels. So, adjusting the tailstock right gives you better results!

What Types Of Tooling And Techniques Can Be Used With A Lathe Tailstock To Achieve A Superior Surface Finish On Cylindrical Parts?To get a smooth surface on round parts, you can use special tools with the tailstock of a lathe. You might use a live center, which helps hold the part steady while it spins. We can also apply fine-grit sandpaper or polishing pads to smooth out rough spots. Keeping everything clean and well-lubricated, or using cutting oil, helps, too! Finally, adjusting the speed of the lathe can also improve the finish.

How Do Different Materials And Their Properties Affect The Surface Finish Achieved When Turning With A Metal Lathe Tailstock?Different materials can change how smooth a surface looks when we use a metal lathe tailstock. Harder materials, like steel, can make a shiny finish. Softer materials, like aluminum, might leave a rougher finish. The way the material feels also matters; rough materials can create bumps. So, the type of material we choose affects our finished piece.

What Maintenance Practices Should Be Observed For The Tailstock In Order To Ensure Consistent Surface Finish Results During Lathe Operations?To keep the tailstock working well, you should clean it regularly. Check for dirt and rust and wipe it down. Make sure it moves smoothly by adding some oil to the moving parts. Also, check the screws to ensure they are tight. This helps us get better surfaces when we use the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And The Metal Lathe Tailstock:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe surface finish and the tailstock: 1. What is a lathe? A lathe is a machine that helps us shape metal and wood. 2. Why is surface finish important? The surface finish makes the object smooth or rough, which affects how it looks and works. 3. What is a tailstock? The tailstock is a part of the lathe. It holds tools and helps push the material while we work. 4. How can we improve surface finish? We can improve it by using sharp tools and going slowly. 5. What do we use the tailstock for? We use the tailstock to support long pieces and to hold drill bits for making holes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Using A Metal Lathe Tailstock During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe tailstock, several things affect how smooth the surface of the metal will be. First, make sure the tailstock is lined up correctly. If it’s off, the tool can scratch the metal. Second, use the right speed for the lathe. If it’s too fast or too slow, it can create a rough finish. Finally, choose sharp tools because dull tools can make the surface look bumpy.”}},{“@type”: “Question”,”name”: “How Does The Alignment And Adjustment Of The Tailstock Impact The Accuracy And Surface Finish Of The Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is lined up correctly, it helps keep the workpiece steady. This makes it easier to cut evenly. If the tailstock is off, the workpiece can wobble. A wobbly workpiece can end up with rough edges, which hurts how smooth it feels. So, adjusting the tailstock right gives you better results!”}},{“@type”: “Question”,”name”: “What Types Of Tooling And Techniques Can Be Used With A Lathe Tailstock To Achieve A Superior Surface Finish On Cylindrical Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth surface on round parts, you can use special tools with the tailstock of a lathe. You might use a live center, which helps hold the part steady while it spins. We can also apply fine-grit sandpaper or polishing pads to smooth out rough spots. Keeping everything clean and well-lubricated, or using cutting oil, helps, too! Finally, adjusting the speed of the lathe can also improve the finish.”}},{“@type”: “Question”,”name”: “How Do Different Materials And Their Properties Affect The Surface Finish Achieved When Turning With A Metal Lathe Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials can change how smooth a surface looks when we use a metal lathe tailstock. Harder materials, like steel, can make a shiny finish. Softer materials, like aluminum, might leave a rougher finish. The way the material feels also matters; rough materials can create bumps. So, the type of material we choose affects our finished piece.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Observed For The Tailstock In Order To Ensure Consistent Surface Finish Results During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the tailstock working well, you should clean it regularly. Check for dirt and rust and wipe it down. Make sure it moves smoothly by adding some oil to the moving parts. Also, check the screws to ensure they are tight. This helps us get better surfaces when we use the lathe.”}}]}