Have you ever wondered how woodworkers get such smooth finishes on their projects? The secret often lies in their tools, especially lathe tools. One key factor in using lathe tools is the clearance angle. This angle can make a big difference in how well the tool cuts and how easy it is to use.

Imagine trying to chop vegetables with a dull knife. It’s messy, right? The same goes for lathe tools without the right clearance angle. A good angle helps the tool glide through the material instead of dragging. It reduces friction and lets you create beautiful shapes effortlessly.

This article will guide you through the importance of lathe tool clearance angles. You’ll learn what they are, why they matter, and how to measure them. Understanding these angles can make your projects not only easier but also more enjoyable. Are you ready to sharpen your skills and discover the magic behind clearance angles?

Lathe Tool Clearance Angle Guide: Essential Tips For Precision

Lathe Tool Clearance Angle Guide

Understanding the lathe tool clearance angle is crucial for any aspiring machinist. This angle affects how the tool interacts with the material. A proper clearance angle helps prevent friction and wear, ensuring a smoother cut. Did you know that too little clearance can lead to tool breakage? Learning about this can save time and money. By mastering the clearance angle, you enhance your turning skills and achieve better results in your projects.Understanding Lathe Tool Clearance Angles

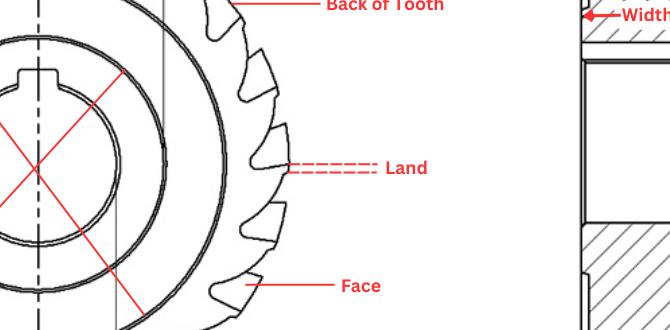

Definition and importance of clearance angles in lathe tooling.. Explanation of how clearance angles affect cutting performance..Cutting with a lathe is like baking a cake; you need the right angles for a perfect slice! Clearance angles are the space between the cutting tool and the workpiece. These angles matter because they affect how smoothly your tool cuts and how long it lasts. Think of it as giving your tool a little wiggle room to shimmy through the material without getting stuck. Too tight, and it’s a recipe for disaster!

| Clearance Angle | Effect on Cutting |

|---|---|

| Small Angle | More rubbing, less cutting. |

| Large Angle | Better clearance, smoother cuts. |

In summary, understanding clearance angles helps tools work better and last longer. Just like you wouldn’t wear shoes two sizes too small, your lathe tools need the right angles to perform their best!

How to Determine the Right Clearance Angle

Factors that influence the selection of clearance angles.. Guidelines for selecting clearance angles based on material types..Choosing the right clearance angle for lathe tools isn’t just a guessing game; it’s a science! Factors like material type and tool shape play a big role. For example, harder materials may need a larger angle to prevent chipping. This can feel like a puzzle, but worry not! Here’s a simple guide to help you out:

| Material Type | Suggested Clearance Angle |

|---|---|

| Soft Metals | 5-10 degrees |

| Hard Metals | 10-15 degrees |

| Plastics | 5-8 degrees |

And remember, too little angle might make your tool feel like it’s doing the cha-cha instead of cutting smoothly! So, adjust wisely, and happy turning!

Impact of Incorrect Clearance Angles

Common issues arising from inappropriate clearance angles, such as tool wear and poor surface finish.. Case studies or examples illustrating the consequences of incorrect angles..Incorrect clearance angles can lead to big problems in machining. For example, tool wear increases, making the tool dull faster. This can cause less precise cuts. The result? A poor surface finish that looks rough and unpolished. Consider a case where a factory used wrong angles. They faced complaints from customers about product quality. Missed deadlines also occurred due to needing extra repairs. Keeping the right angles is key for success.

What are the common issues from incorrect clearance angles?

Common issues include increased tool wear and a poor surface finish.Consequences of Incorrect Angles:

- Faster tool damage

- Rough surface textures

- Higher production costs

- Unhappy customers

Adjusting Clearance Angles on Lathe Tools

Techniques for adjusting clearance angles on various types of lathe tools.. Tools and equipment required for making adjustments..Adjusting the clearance angle on lathe tools is important for smooth cutting. Each tool might need a different angle to work best. Here are helpful techniques:

- Use an angle gauge to set accurate angles.

- Check the tool’s position with a caliper for precision.

- Loosen screws gently, then tilt the tool to find the right angle.

To adjust these angles, you need a few tools:

- Wrenches for loosening and tightening.

- Files to shape the angles as needed.

- Measuring tools for checking angles again.

With the right techniques and tools, you can improve your cutting performance!

What tools are needed for adjusting clearance angles?

To adjust clearance angles, you need a wrench, angle gauge, and measuring tools to ensure the correct adjustments.

Best Practices for Maintaining Lathe Tool Clearance Angles

Routine checks and maintenance tips for sustaining optimal performance.. Recommended practices for tool storage and handling to preserve angles..Keeping lathe tool clearance angles tip-top is crucial for awesome performance. Start with routine checks; inspect your tools weekly to spot any wear. A little maintenance goes a long way! Clean tools gently and oil them for smooth motion. Store your tools in a dry place and use protective covers to keep angles safe. That way, they don’t end up getting dull, like your favorite joke after telling it too many times!

| Tip | Description |

|---|---|

| Routine Checks | Inspect tools weekly for wear and tear. |

| Cleaning | Use gentle cleaners and keep tools lubricated. |

| Storage | Store in a dry area with protective covers. |

Common Myths About Lathe Tool Clearance Angles

Debunking prevalent misconceptions surrounding clearance angles.. Clarifying the truths behind these myths with expert insights..Many people believe that a steeper clearance angle is always better. This myth can lead to confusion for beginners. In reality, the ideal angle can vary based on the material you’re working with. Sometimes, a lower angle is best for softer materials. Just like in cooking, not every recipe needs a full pinch of salt! It’s crucial to understand how these angles affect cutting and chip flow. Here’s a quick table to help clear things up:

| Material Type | Recommended Clearance Angle |

|---|---|

| Soft metals | 5-10 degrees |

| Hard metals | 10-15 degrees |

| Plastics | 3-8 degrees |

Understanding these angles helps you become a lathe tool master! Expert advice suggests experimenting with different angles to find what works best for you. Remember, tool knowledge is power!

Advanced Techniques for Experienced Users

Techniques for optimizing clearance angles for specialized machining tasks.. Innovations in tool design that impact clearance angles..For those who have a bit of experience under their tool belt, it’s time to level up your game! Adjusting your clearance angles can make a big difference in machining tasks. A sharp angle can enhance performance and lead to smoother finishes! Many modern tools now come with designs that help to optimize these angles. Let’s take a quick look:

| Tool Design Innovations | Impact on Clearance Angles |

|---|---|

| 5-Axis Machining | Allows for deeper cut angles and better surface contact. |

| Carbide Inserts | Improved durability means less frequent angle adjustments. |

| Specialized Rakes | Enhances chip removal and reduces friction. |

So, prepare to cut corners—efficiently, that is! Remember, with the right tools and angles, you’ll have your machining tasks running as smoothly as a buttered penguin on ice!

Conclusion

In summary, understanding lathe tool clearance angles is crucial for smooth machining. The right clearance helps prevent tool wear and ensures better performance. Remember to adjust angles based on your material. Practice using these tips on your projects. For more information, explore detailed guides or watch tutorial videos. Keep experimenting to improve your skills!FAQs

Here Are Five Related Questions On The Topic Of Lathe Tool Clearance Angle:The lathe tool clearance angle is important because it helps the tool cut smoothly. This angle keeps the tool from rubbing against the metal. When the angle is right, it makes cutting easier and helps the tool last longer. You always want to check this angle when using a lathe. It helps you make better and cleaner shapes in your work.

Sure! Please provide the question you would like me to answer.

What Is The Importance Of Clearance Angle In Lathe Tool Design And Performance?The clearance angle is important for lathe tools. It helps the tool cut smoothly without getting stuck. If the angle is right, the tool lasts longer and works better. This makes it easier for us to shape materials accurately. With a good clearance angle, we can do our jobs faster and with less effort.

How Does The Clearance Angle Affect The Surface Finish Of The Machined Workpiece?The clearance angle is the angle between the tool’s cutting edge and the workpiece. A good clearance angle helps the tool glide smoothly and cut better. If the angle is too small, it can leave rough spots on the surface. When the angle is just right, the workpiece looks shiny and smooth. So, the right clearance angle makes your workpiece nicer to touch and see.

What Are The Recommended Clearance Angles For Different Materials When Using A Lathe Tool?When using a lathe tool, the clearance angle is important for cutting. For soft metals like aluminum, you can use a clearance angle of about 8 to 10 degrees. For harder metals like steel, a larger angle of about 10 to 15 degrees works better. For plastic, a smaller angle of around 5 to 8 degrees is good. These angles help the tool cut smoothly and stay sharp.

How Can Improper Clearance Angles Lead To Tool Wear Or Failure During Machining Operations?Improper clearance angles can make it hard for the tool to slide smoothly over the material. This can cause extra friction, which makes the tool heat up. When a tool gets too hot, it can wear out faster or even break. You want the tool to stay sharp and work well, so proper angles are essential!

What Methods Can Be Employed To Accurately Measure And Adjust The Clearance Angle On Lathe Tools?To measure and adjust the clearance angle on lathe tools, you can use a protractor. Place the protractor against the tool to see the angle. You can also use a tool rest with markers to help guide you. If the angle isn’t right, you can grind the tool until it fits properly. Always double-check your work to make sure it’s correct!