Have you ever seen a beautiful wooden bowl that makes you wonder how it was made? The magic often comes from the lathe turning deep hollow vessel method. This technique allows craftsmen to create stunning shapes and designs.

Imagine spinning a piece of wood on a machine called a lathe. As it turns, you can carve out its center. The result is a hollow vessel that is not just useful but also a work of art. It’s like turning a simple log into something extraordinary!

Did you know that lathe turning has been around for thousands of years? Ancient craftsmen used this method to create everything from bowls to intricate sculptures. Today, artists still use it to express their creativity.

Why is this technique so special? It combines skill, precision, and imagination. Each piece is unique, telling its own story. As you read this article, you’ll discover tips and tricks for mastering the lathe turning deep hollow vessel method. Ready to explore the world of woodturning? Let’s dive in!

Lathe Turning Deep Hollow Vessel Method: A Comprehensive Guide

Understanding Lathe Turning

Definition and basics of lathe turning. Importance of lathe turning in woodworking and craftsmanship.

Lathe turning is a woodworking technique. It shapes materials like wood or metal into beautiful designs. This method involves spinning the material on a machine called a lathe. As the material spins, sharp tools carve out shapes. Lathe turning is important because it allows craftsmen to create items like bowls and vases. These pieces show skill and creativity. Many people use lathe turning for both fun and work, making it a key skill for woodworkers.

What is the importance of lathe turning in woodworking?

Lathe turning is vital in woodworking as it helps create smooth, round shapes. Craftsmen can design unique pieces while improving their skills. It also adds value to wooden items, making them special.

Benefits of Lathe Turning:

- Creates beautiful designs.

- Improves craftsmanship skills.

- Adds uniqueness to projects.

Tools and Equipment Needed

Essential tools for deep hollow vessel turning. Recommended lathes and accessories.

Creating a deep hollow vessel is a fun adventure! To start, you need a few key tools. First, grab a reliable lathe. Look for one with a sturdy bed and good power. Don’t forget a set of hollowing tools. These help reach those tricky spots inside your vessel. A bowl gouge is your trusty sidekick here.

Also, consider adding a laser or camera for better visibility. It’s like having superhero x-ray vision! Here’s a handy list of recommended tools:

| Tool | Description |

|---|---|

| Lathe | Powerful and stable for deep hollowing |

| Hollowing Tools | Perfect for reaching the depths |

| Bowl Gouge | Essential for shaping |

| Laser/Camera | Helps see inside the vessel |

With these tools, you’ll be turning vessels like a pro in no time! Ready to turn some magic?

Safety Precautions

Key safety practices while using a lathe. Personal protective equipment (PPE) and workspace safety.

Using a lathe is fun, but safety comes first! Always wear your personal protective equipment (PPE) like goggles, ear protection, and gloves. These can keep your eyes, ears, and hands safe from flying debris. A clean workspace is crucial too. No wandering tools or misplaced coffee cups! Clear your area of clutter. Remember, a happy lathe is a clean lathe!

| Safety Gear | Why It Matters |

|---|---|

| Goggles | Protects your eyes from chips. |

| Ear protection | Keeps your hearing safe. |

| Gloves | Protects your hands while working. |

Let’s not forget to check your lathe’s parts before working. This can save you from unexpected surprises, like that time Carl’s lathe sneezed and sent wood chips everywhere—yikes!

Step-by-Step Guide to Deep Hollow Vessel Turning

Preparation of the wood blank. Setting up the lathe for deep hollow turning. Detailed turning process: from rough shaping to finishing.

Start with a sturdy wood blank. Cut it to the right size and shape. Make sure it is dry to prevent cracking. Next, set up your lathe. Secure the wood firmly in place and check the speed settings. Now, it’s time to turn! Begin by rough shaping the vessel. Gradually refine the shape using sharp tools. Finish by sanding and polishing it for a smooth look. Enjoy your beautiful deep hollow vessel!

What tools do I need for deep hollow turning?

To turn a deep hollow vessel, you’ll need lathe tools, safety gear, and sandpaper for finishing. These tools help create a beautiful, smooth finished piece.

Common Challenges and Solutions

Typical problems faced during deep hollow vessel turning. Tips and techniques to overcome these challenges.

Deep hollow vessel turning can be tricky. Wood can crack, and tools may snag. Here are some challenges you might face:

- Tool Clogging: Shavings can build up.

- Wood Movement: Natural wood may warp.

- Chatter: The lathe might shake during turning.

To solve these, try these tips:

- Keep tools sharp.

- Work slowly and steadily.

- Use proper support for the wood piece.

These methods can help you turn beautiful vessels with ease!

What are the common problems in deep hollow vessel turning?

In deep hollow vessel turning, typical issues include tool clogging, wood movement, and chatter that disrupts your work.

How to overcome challenges in lathe turning?

To overcome challenges, sharpen tools, work slowly, and support your wood piece properly.

Finishing Techniques for Deep Hollow Vessels

Different finishing options available. How to enhance the aesthetic appeal of finished vessels.

To make your deep hollow vessels look their best, use various finishing techniques. These can include sanding, oiling, or using varnish. Each method adds a unique flair to your project. The right finish can showcase the wood’s natural beauty and grain. Consider these methods to enhance your work:

- Sanding for a smooth surface.

- Oiling to enrich colors.

- Varnish for shine and protection.

These finishing touches grab attention and bring your artistic vision to life!

What are common finishing techniques for deep hollow vessels?

Common techniques include sanding, applying oil, and using varnish. Each method can enhance your vessel’s look in different ways, making it truly unique.

Showcase of Deep Hollow Vessels

Inspiring examples of completed vessels. Discussion on design and creativity in deep hollow turning.

Creating deep hollow vessels is like bringing a little magic into everyday life. You can see inspiring completed pieces, each unique in shape and flair. Some vessels twist and turn gracefully, capturing light like a ballerina on stage! Design is key here, with shapes that reflect both the maker’s heart and the materials used. Creativity flows like water, and each turn on the lathe reveals new possibilities. Let’s showcase some examples:

| Vessel Name | Designer | Unique Feature |

|---|---|---|

| Spiral Delight | Jane Doe | Swirling patterns |

| Nature’s Echo | John Smith | Wood grain art |

| Color Pop | Emily White | Vibrant colors |

Embracing design and creativity can ignite the magic of hollow turning. Each piece tells a story—there’s a fun twist waiting in every curve!

Resources for Learning More

Recommended books, websites, and video tutorials. Community groups and forums for turners.

If you’re eager to dive deeper into the world of lathe turning, there are plenty of resources at your fingertips. Grab some recommended books like “The Lathe Book” by Ernie Conover—it’s full of tips and tricks! Websites like Woodturners Association offer great articles. Also, check out video tutorials on YouTube; your lathe will thank you for it! Join community groups and forums where fellow turners share their adventures. Who knows, you might even get a few laughs!

| Type | Resource |

|---|---|

| Books | “The Lathe Book” by Ernie Conover |

| Websites | Woodturners Association |

| Video Tutorials | YouTube Channels on Woodturning |

| Forums | Woodturning Community Forums |

FAQs about Lathe Turning Deep Hollow Vessels

Answers to frequently asked questions. Expert tips for beginners in lathe turning.

Many people have questions about making deep hollow vessels on a lathe. Here are some answers and tips to help beginners.

What tools do I need for lathe turning?

You will need specific tools for this project. Essential tools include a lathe, chisels, and a bowl gouge. Safety gear like goggles is also important.

How do I start turning a vessel?

First, choose a good piece of wood. Make sure it is dry and has no cracks. Mount it securely on the lathe. Then, start shaping slowly.

Expert Tips:

- Practice on small pieces before moving to larger ones.

- Keep your tools sharp for cleaner cuts.

- Measure the thickness as you work for consistency.

Turning vessels can be fun! With practice, you can create amazing pieces. Enjoy the process and be patient as you learn.

Conclusion

In conclusion, the lathe turning deep hollow vessel method lets you create beautiful wooden pieces. You learn to control tools to shape wood. Remember to practice safety and patience. Each vessel shows your skill. Next, gather your tools and start experimenting with different designs. Explore books or online tutorials for more tips. Enjoy your creative journey with woodturning!

FAQs

Here Are Five Questions Related To The Lathe Turning Method For Creating Deep Hollow Vessels:

Sure! The lathe turning method helps us create deep hollow vessels by spinning wood. First, we attach a piece of wood to the lathe. As it turns, we use special tools to carve out the inside. This lets us make bowls and vases that are deep and smooth. In the end, we have beautiful things we can use or display!

Sure! Please provide the question you’d like me to answer, and I’ll do my best to help.

What Are The Essential Tools And Equipment Required For Turning Deep Hollow Vessels On A Lathe?

To turn deep hollow vessels on a lathe, you need a few important tools. First, you’ll need a lathe itself, which spins the wood. Then, use a hollowing tool to carve out the inside. A chuck holds the wood securely while you work. Finally, safety gear like goggles keeps your eyes safe.

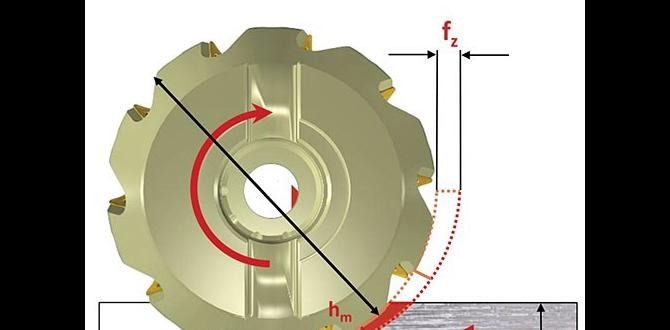

How Do You Determine The Appropriate Spindle Speed And Feed Rate For Turning A Deep Hollow Vessel To Prevent Chatter And Ensure A Smooth Finish?

To find the right spindle speed, you can start by checking your tool and material. Use a slower speed for deeper cuts to avoid chatter, which is noise and vibration. For feed rate, go slowly at first to see how it feels. You want a smooth finish, so make small adjustments as you work. Always listen and feel for any weird vibrations, and change your speed if needed.

What Specific Techniques Or Cutting Methods Are Recommended For Hollowing Out The Interior Of Deep Vessels While Maintaining Control And Stability?

To hollow out deep vessels, you can use a few simple techniques. First, a small drill can help make a hole in the center. Then, you can use a curved tool called a gouge to remove the inside material. It’s important to work slowly and carefully to keep the shape stable. Lastly, always hold the vessel firmly to avoid accidents.

What Safety Precautions Should Be Taken When Working With Deep Hollow Vessel Turning To Avoid Injuries And Ensure Proper Handling Of The Wood?

When working with deep hollow vessels, always wear safety glasses and a dust mask. Keep your hands and loose clothing away from the spinning wood. Use the right tools and follow instructions carefully. Make sure your workspace is clean and well-lit. Always check that the wood is secure before starting to turn.

How Can The Use Of Various Chisel Types And Hollowing Jigs Improve The Efficiency And Quality Of Deep Hollow Vessel Turning?

Using different chisel types helps you reach all parts of the wood. Some chisels are better for shaping, while others are great for finishing. Hollowing jigs hold your tools steady as you work, so you make smooth cuts. This makes your vessels look better and saves you time. Together, they help you create amazing deep hollow shapes more easily.