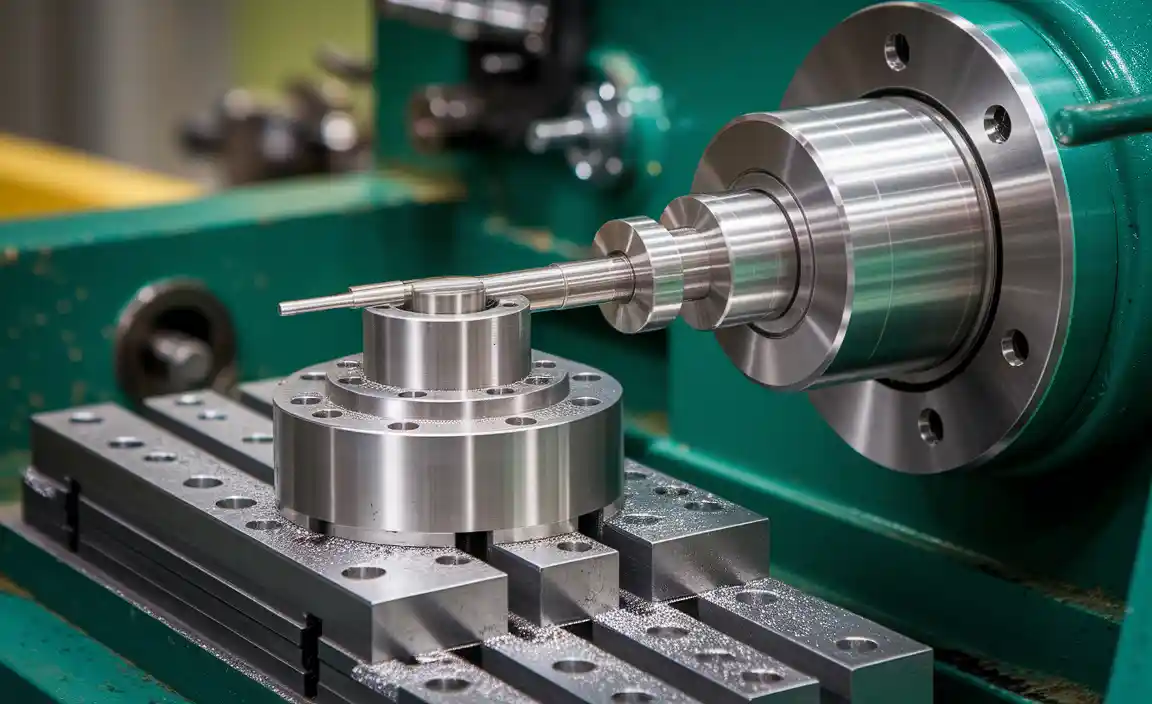

Have you ever watched a lathe in action? It’s almost like magic! A simple piece of wood or metal spins, and suddenly, it becomes something beautiful. But did you know that how you hold that material matters a lot?

One clever way to hold your workpiece is with a jam chuck. What makes it special? Foam padding! This simple addition helps keep your item safe while you shape it. Imagine working on a delicate piece and not worrying about it slipping. Pretty cool, right?

Learning about lathe turning jam chucks with foam padding can change your projects. It’s like having a superhero on your side. With the right tools and ideas, you can create amazing things without fear. Let’s dive deeper into this fun and useful method!

Lathe Turning Jam Chuck With Foam Padding: A Comprehensive Guide

What is a Jam Chuck?

Definition and purpose of a jam chuck in woodturning.. Benefits of using a jam chuck in various projects..

A jam chuck is a special tool used in woodturning. It holds your workpiece tightly while you shape it. This helps you work on the bottom or side without changing the piece. It makes crafting easier and improves your final product. Using a jam chuck has some great benefits:

- Stable Support: Keeps your project steady.

- Better Finish: Lets you reach all areas for a smooth look.

- Quick Setup: Easy to put on and take off.

Using foam padding with your jam chuck offers even more grip. This ensures your wood won’t slip and helps achieve perfect shapes. It’s a vital tool for both beginners and pros!

What are the advantages of using a jam chuck?

Jam chucks provide security and precision when turning wood. They save time and reduce mistakes. Plus, they work well on projects big and small!

Understanding Foam Padding

Importance of padding in jam chucks for improved grip.. Types of foam suitable for lathe turning..

Foam padding in jam chucks is like a cozy blanket for your projects. It helps grip pieces better, preventing them from slipping around. With improved grip, you can work faster and with more confidence. Choosing the right foam is key! Some popular types are polyethylene and neoprene, which are durable and provide great cushioning. Here’s a quick table to show different types of foam that work well:

| Type of Foam | Features |

|---|---|

| Polyethylene | Lightweight, durable |

| Neoprene | Flexible, water-resistant |

| Memory Foam | Soft, moldable |

With the right foam, your lathe turning can feel smooth, like butter on toast. Remember, a happy project is a grippy project!

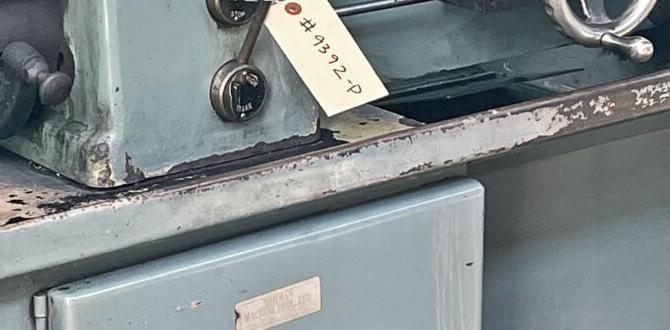

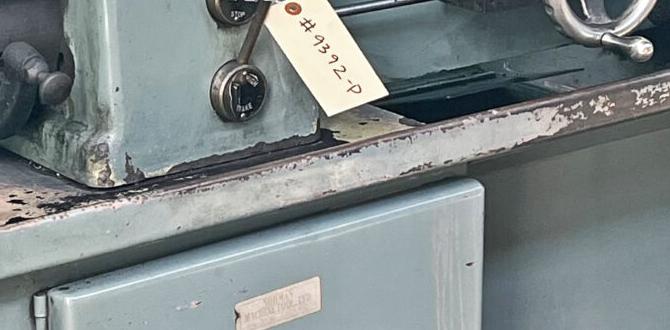

Materials Needed for Creating a Jam Chuck

List of essential tools and equipment for making a jam chuck.. Recommended types of wood and foam materials..

To make a jam chuck, you need some key items. First, grab your lathe, of course! Then, collect your favorite wood types like maple or pine. These are strong and easy to work with. Next, don’t forget the foam padding—this helps keep your pieces snug and safe. Got a measuring tape? That’s a must for accurate cutting. Finally, you might want some sanding paper to smooth those edges. Let’s not forget the fun part—sawdust! It adds a unique flair to any workshop. Here’s a quick look at essential materials:

| Materials | Purpose |

|---|---|

| Wood (Maple, Pine) | Structure of the jam chuck |

| Foam Padding | Protection and grip |

| Measuring Tape | For precise measurements |

| Sanding Paper | To smooth the surface |

Step-by-Step Guide to Making a Jam Chuck

Detailed instructions on designing and shaping the jam chuck.. Tips for ensuring a secure fit on the lathe..

First, gather materials for your jam chuck. Use a block of wood and foam padding. Start by shaping the wood to fit your project. Make it slightly larger than the item you want to hold. This will help grip securely. Smooth the edges for safety. Next, measure carefully. Cut the foam to match the wood. Attach it with glue for a snug fit. This helps ensure a soft touch when clamping.

When you’re ready to use it, test the fit on your lathe. A proper connection is key. If it feels loose, adjust the foam or wood. Keep trying until it feels right.

How can I ensure a good fit for my jam chuck?

Test the fit multiple times. Adjust the foam padding as needed. A snug fit will help avoid slipping during use.

Tips for fitting:

- Use clamps to hold everything tight.

- Check for gaps between the wood and foam.

- Mark adjustments clearly before cutting.

Techniques for Effective Lathe Turning with Jam Chucks

Strategies for achieving precision and stability while turning.. Best practices for using foam padding to avoid damage to workpieces..

To turn objects effectively on a lathe, focus on precision and stability. Start by securely mounting the workpiece. Use simple tools, maintaining control. To avoid damaging your work, add foam padding to the jam chuck. This cushion keeps everything safe. Here are some best practices:

- Check the foam for wear.

- Adjust padding thickness for different pieces.

- Keep your workspace clean.

- Use a slower speed for delicate materials.

With these tips, you can achieve great results while keeping your work intact.

How can foam padding improve lathe turning?

Foam padding protects your workpiece. It helps absorb shocks and prevents scratches. Using foam means less risk of damage, leading to smoother finishes.

Common Challenges and Solutions

Identifying issues that may arise during the turning process.. Practical solutions for common lathe turning problems with jam chucks..

Lathe turning can be tricky sometimes. One huge problem is the workpiece slipping off the chuck. This can make you feel like you’re trying to catch a runaway slice of pizza! An easy solution is using a jam chuck with foam padding. It keeps your project snug as a bug. Another common issue is chatter, that annoying vibration noise that feels like your lathe is trying to dance. To fix this, try adjusting the speed. Sometimes slower is better! Here’s a quick look at these challenges:

| Problem | Solution |

|---|---|

| Workpiece slips | Use jam chuck with foam padding |

| Chatter | Adjust the lathe speed |

Maintenance and Care for Your Jam Chuck

Tips on preserving the integrity of your jam chuck and foam padding.. Recommendations for regular inspection and replacement of materials..

Keeping your jam chuck in great shape is like maintaining a favorite toy. Regular checks are key. Look for any wear and tear on the foam padding. Replace worn materials to avoid slipping, just like you wouldn’t wear old shoes to gym class! A simple checklist can help. Check your equipment at least once a month. This way, your chuck stays snug, making those turns smooth. Here’s a quick guide:

| Task | Frequency |

|---|---|

| Inspect foam padding | Monthly |

| Replace worn padding | As needed |

| Clean surfaces | Weekly |

Stay on top of this, and your lathe will thank you with smooth operations. Remember, a happy chuck means happy turning!

Exploring Advanced Techniques and Variations

Innovative designs for jam chucks using different foam types.. How to adapt your techniques for various woodturning projects..

Explore new designs for jam chucks with foam padding! Different foam types can grip wood better. They help hold your projects steady. Soft foam is great for delicate pieces, while firm foam works well for heavy projects. Feel free to experiment! Adjusting your technique for various woodturning tasks can improve your results.

What are some effective foam types for jam chucks?

Soft foam, firm foam, and closed-cell foam are popular choices. Each type serves a different purpose based on the project at hand.

Tips for adapting techniques:

- Choose the right foam type for your project.

- Test various pressure settings for a better fit.

- Alter your woodturning speed for different materials.

Conclusion

In conclusion, a lathe turning jam chuck with foam padding is a great tool for your projects. It helps hold your work securely while protecting it from damage. Remember to choose the right foam for your material. Try making one for your next project! For more tips on using a lathe, check out additional resources online. Happy turning!

FAQs

Sure! Here Are Five Questions Related To Lathe Turning Jam Chucks With Foam Padding:

Sure! Here are five questions about using foam padding with jam chucks on a lathe. 1. What is a jam chuck? A jam chuck is a tool that holds wood tightly while you shape it on a lathe. 2. Why use foam padding? Foam padding keeps your wood from getting scratches or dents while it spins. 3. How do I make a jam chuck with foam? You can wrap foam around the jam chuck to fit your wood piece and clamp it securely. 4. Can I use any kind of foam? Yes, you can use soft foam that can squeeze and hold the shape of your wood. 5. How do I know if it’s working well? If your wood stays in place and looks smooth, then your jam chuck is working great!

Of course! Please provide the question you’d like me to answer.

What Are The Advantages Of Using Foam Padding In A Jam Chuck For Lathe Turning?

Using foam padding in a jam chuck for lathe turning has some great benefits. First, it helps hold your workpiece tightly without scratching it. Second, foam is soft, so it can protect the wood from damage. Lastly, it makes it easier to adjust the fit, keeping things steady while you work. This means you can create better shapes and designs!

How Can You Effectively Create A Jam Chuck Using Foam Padding To Secure Irregularly Shaped Workpieces?

To create a jam chuck, you can use a piece of foam padding. First, cut the foam into a shape that matches your workpiece. Then, wrap the foam around the workpiece so it fits snugly. Next, place the wrapped workpiece into the chuck. When you tighten the chuck, the foam holds it steady and secure!

What Types Of Foam Materials Are Most Suitable For Use In A Lathe Turning Jam Chuck, And Why?

For a lathe turning jam chuck, soft foams like polyurethane and memory foam work best. They are squishy, so they grip the object tightly. This helps hold the piece without scratching it. We want a foam that can shape itself around the object to keep it secure. This way, your work stays safe while you turn it.

Are There Any Specific Techniques Or Tips For Ensuring A Secure Grip When Using A Jam Chuck With Foam Padding?

To get a secure grip with a jam chuck and foam padding, start by putting the foam tightly around your piece. Make sure it’s even and covers all sides. Next, carefully tighten the jam chuck. You can gently press the foam to help hold your piece better. Always check if it’s tight before starting to work!

How Does The Use Of A Jam Chuck With Foam Padding Affect The Finish And Accuracy Of The Turned Piece?

Using a jam chuck with foam padding helps keep the piece steady while you work. This means you can turn it more accurately, making sure everything is even. The foam padding protects the finish, so it looks nicer when you’re done. It also helps prevent any scratches or dents. Overall, it makes your finished piece look better and helps you do a great job!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Turning Jam Chucks With Foam Padding:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about using foam padding with jam chucks on a lathe. 1. What is a jam chuck? A jam chuck is a tool that holds wood tightly while you shape it on a lathe. 2. Why use foam padding? Foam padding keeps your wood from getting scratches or dents while it spins. 3. How do I make a jam chuck with foam? You can wrap foam around the jam chuck to fit your wood piece and clamp it securely. 4. Can I use any kind of foam? Yes, you can use soft foam that can squeeze and hold the shape of your wood. 5. How do I know if it’s working well? If your wood stays in place and looks smooth, then your jam chuck is working great!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using Foam Padding In A Jam Chuck For Lathe Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using foam padding in a jam chuck for lathe turning has some great benefits. First, it helps hold your workpiece tightly without scratching it. Second, foam is soft, so it can protect the wood from damage. Lastly, it makes it easier to adjust the fit, keeping things steady while you work. This means you can create better shapes and designs!”}},{“@type”: “Question”,”name”: “How Can You Effectively Create A Jam Chuck Using Foam Padding To Secure Irregularly Shaped Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a jam chuck, you can use a piece of foam padding. First, cut the foam into a shape that matches your workpiece. Then, wrap the foam around the workpiece so it fits snugly. Next, place the wrapped workpiece into the chuck. When you tighten the chuck, the foam holds it steady and secure!”}},{“@type”: “Question”,”name”: “What Types Of Foam Materials Are Most Suitable For Use In A Lathe Turning Jam Chuck, And Why?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a lathe turning jam chuck, soft foams like polyurethane and memory foam work best. They are squishy, so they grip the object tightly. This helps hold the piece without scratching it. We want a foam that can shape itself around the object to keep it secure. This way, your work stays safe while you turn it.”}},{“@type”: “Question”,”name”: “Are There Any Specific Techniques Or Tips For Ensuring A Secure Grip When Using A Jam Chuck With Foam Padding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a secure grip with a jam chuck and foam padding, start by putting the foam tightly around your piece. Make sure it’s even and covers all sides. Next, carefully tighten the jam chuck. You can gently press the foam to help hold your piece better. Always check if it’s tight before starting to work!”}},{“@type”: “Question”,”name”: “How Does The Use Of A Jam Chuck With Foam Padding Affect The Finish And Accuracy Of The Turned Piece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a jam chuck with foam padding helps keep the piece steady while you work. This means you can turn it more accurately, making sure everything is even. The foam padding protects the finish, so it looks nicer when you’re done. It also helps prevent any scratches or dents. Overall, it makes your finished piece look better and helps you do a great job!”}}]}